UNIT#4, STG FLOOR

|

UNIT#4 FRONT SIDE

|

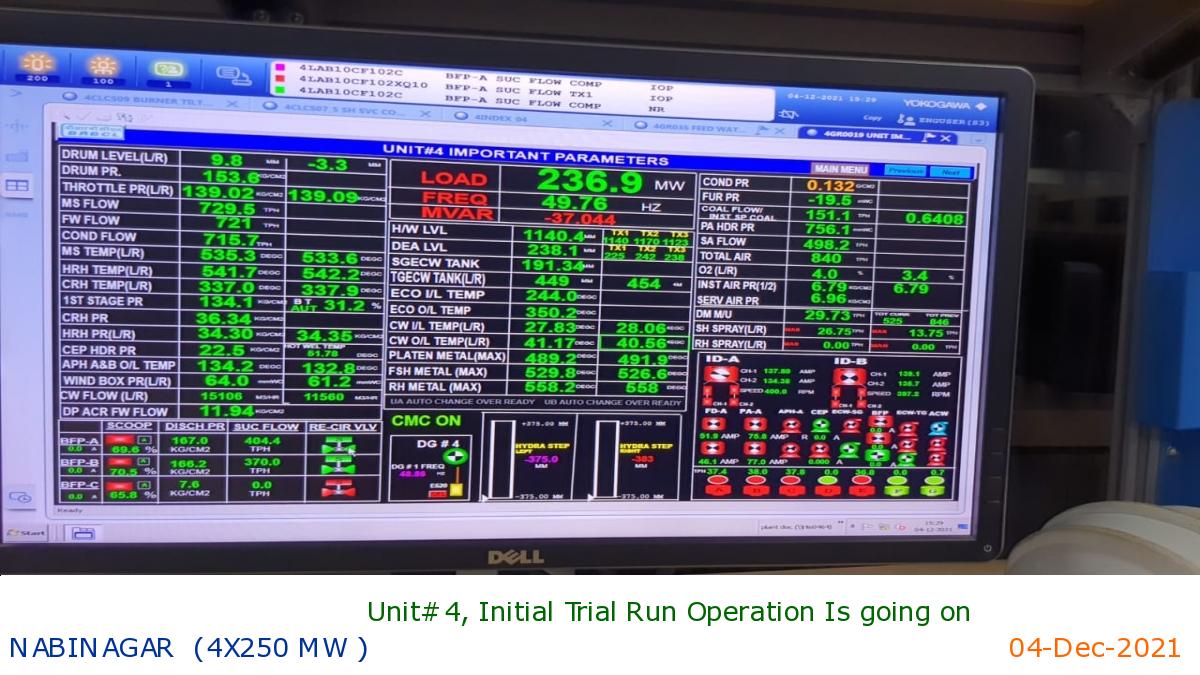

Unit#4, Initial Trial Run Operation Is going on

|

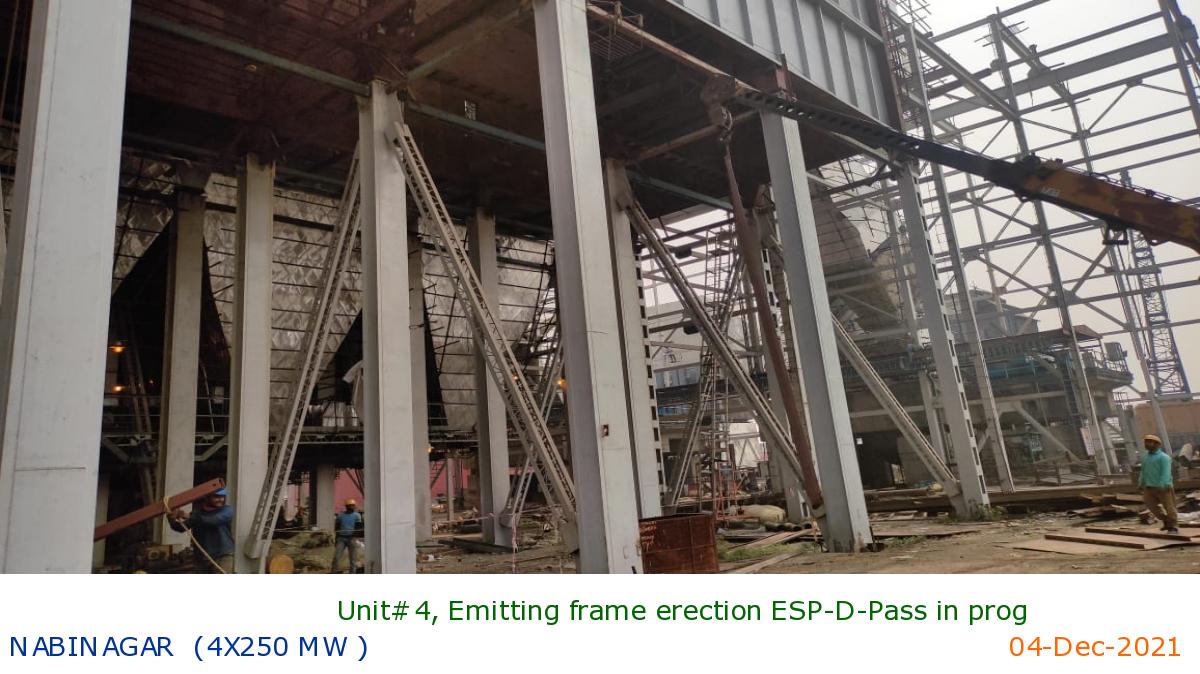

Unit#4, Emitting frame erection ESP-D-Pass in prog

|

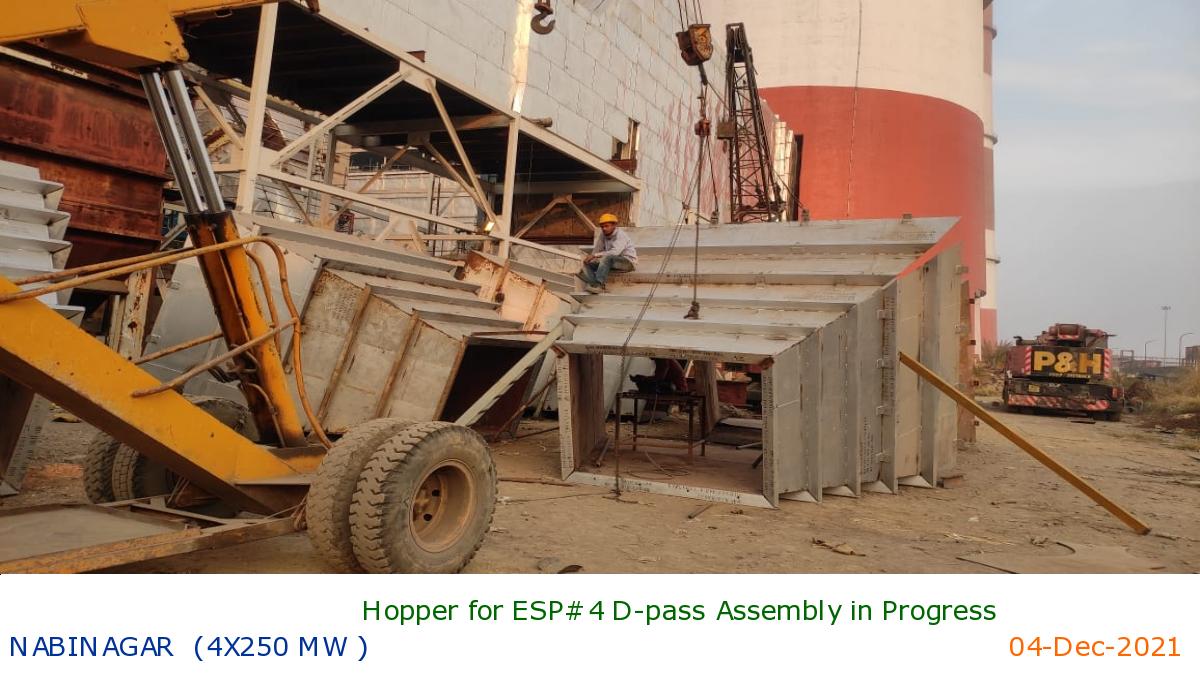

Hopper for ESP#4 D-pass Assembly in Progress

|

Boiler from Left Side, Unit-04

|

Feeder Str Status, Unit-04

|

ESP Pass-A & B I/L Ducting, Unit-4

|

FD fan- A, Unit-04

|

Mill Erection, Unit-04

|

Condenser Tube Insertion, Unit-04

|

Underground ACW Piping, Unit-04

|

ESP Pass-A & B Outlet side, Unit-4

|

ID O/L Duct to Chimney, Unit-04

|

Unit#04 Boiler from Right Side

|

ESP Pass-A & B Inlet Side, Unit-4

|

MILL BUNKER STR STATUS, UNIT#04

|

Boiler from Right Side, Unit-04

|

ID O/L Duct to Chimney, Unit-04

|

MILL BUNKER STR STATUS, UNIT#04

|

ESP Pass-A Inlet Side, Unit-4

|

TG Floor, Unit-04

|

Boiler from Left Side, Unit-04

|

MILL BUNKER STR STATUS, UNIT#04

|

ESP Pass-A & B & P&Q Row Str Ern. Unit-4

|

ECW PIPING & PUMPS UNIT-04

|

Condenser erection U#4

|

TG Building without roofsheeting, U#4

|

HRH & BFD line passing over PRDS floor, Unit-04

|

|

|

|

Condenser erection U#4

|

MILL BUNKER STR STATUS, UNIT#04

|

ESP Pass- A,B & C Erection, Unit#4

|

ID fan & Duct Erection Unit#4

|

MILL BUNKER STR STATUS, UNIT#04

|

IMPELLER SHAFT ASSY, ID FAN-4B.

|

ESP Pass-A & B, Unit-4

|

Unit#04 Condenser

|

Unit-4 Mill-D

|

ESP Pass-A & B, Unit-4

|

TG Building without roofsheeting, U#4

|

LP Heaters U#4

|

Incomplete PRDS floor, U#4

|

LP Heaters U#4

|

ESP, Unit-4

|

Condenser erection U#4

|

TG Bearing pedestal U#4

|

Unit-4 Mill-A Erection Started

|

ID-4B O/L Duct erection

|

ESP Pass-A Unit-4

|

Unit#04 Boiler

|

|

|

|

|

Unit 4 MIll Grouting work in progress

|

Unit 4 ESP pass A erection work

|

Unit 4 HP DFT positioned

|

Unit 4 Condenser Left wall erection work

|

Unit 4 ID Fan B erection work

|

Unit IV ESP Column Erection work in progress

|

Unit 4 TG ECW Canal piping work

|

Unit IV ESP Column Erection work in progress

|

Unit 4 Mill foundation

|

Unit IV ID Fan -Chimney Ducting

|

Unit IV ESP Column Erection work in progress

|

Unit 4 Generation Base Plate Gringing work

|

Unit 4 Seal Air Fan Foundation

|

Unit 4 ESP pass A erection work

|

Unit 4 ID Fan A Erection work

|

Unit 4 Generator Foundation Plate Blue Matching

|

Unit 4 Water Chamber Hole Cleaning

|

Unit 4 Padestal 4 Hole Blue matching work

|

Unit 4 CW (L) Piping work in progress

|

Unit 4 Condenser Bottom Plate Erection work

|

Unit IV ESP Column Erection work in progress

|

Unit 4 CW Line(L) Concreting work

|

Unit 4 ESP pass A erection work

|

Unit 4 Mill Column Erection work in progress

|

Unit 4 Boiler to APH Duct lifting work

|

Unit 4 Generator Foundation Plate Blue Matching

|

Unit 4 Condenser Side Wall pre-erection work

|

Unit 4 ESP pass A erection work

|

Unit 4 Water Box Tube Hole cleaning

|

Unit 4 CW (Right pass) erection work is in pro

|

Unit IV ESP Column Erection work in progress

|

Unit 4 CST lifting to 35m is in progress

|

Unit 4 CW (Right pass) pre erection work is in pro

|

Unit 4 Condenser Bottom Plate erection work

|

Unit 4 ID Fan A Rotor shaft erection

|

Unit 4 ESP Column lifting in progress

|

Unit 4 Condenser Bottom Plate positioned on deck

|

Unit 4 ESP pass A erection work

|

Unit 4 FD fan Foundation plate Blue matching work

|

Unit 4 Boiler Chute erection work

|

Unit 4 Boiler Burner erection work

|

Unit 4 Condenser Bottom Plate erection work

|

Unit 4 ID Fan A Rotor shaft erection

|

Unit 4 Condenser Hotwell assembly

|

Unit 4 FD Fan Motor erection

|

Unit 4 Hotwell pre-erection work in progress

|

Unit 4 Chimney ID fan Duct work

|

Unit 4 CW (L) Piping erection work

|

Unit 4 FD Fan Impeller Casing erection work in pro

|

Unit 4 Condenser bottom plate assembly

|

Unit 4 CW line Pipe erection work

|

Unit 4 ESP Ash Hopper work

|

Unit 4 CW line Piping work in progress

|

Unit 4 Condenser bottom plate assembly

|

Unit 4 Air Pre Heater Support structure lifting

|

Unit 4 CW line Piping work in progress

|

Unit 3 PA Fan Monorail erection work

|

U 4 Condenser Bottom Plate pre-erection work

|

U 3 Deareator Floor Scrap removal work

|

U 3 Bunker G drain Chute Erection Work

|

Unit 3 PG Test preparation work

|

Unit 4 Condenser bottom plate assembly Bad ern

|

Unit 4 TG ECW line Canal work in progress

|

Unit 4 CW line Piping work in progress

|

Unit 4 ESP Column Erection work in progress

|

Unit 3 Bunker Drain Chute Erection

|

Unit 4 Mill pit work for Foundation

|

Unit 4 Mill Column Erection work in progress

|

Unit 4 Condenser bottom plate assembly Bad ern

|

UNit 4 APH duct lifting

|

Unit 3 BFP C Insulation work completed

|

Unit-3 Hot PA Insulation Work in progress

|

Unit 4 CW line Piping work in progress

|

Unit-4 ESP Column Erection work in progress

|

Unit-4 FD Fan Foundation work in progress

|

Unit-4 ESP Control Panel Room Erection in progress

|

Unit- 4 FD Fan B Foundation work in progress

|

Unit 4 FD Fan B Foundation work in progress

|

Unit- 3 Mill G Coupled trial run taken

|

Unit 4 FD Fan A Foundation Work in progress

|

Unit 4 ESP Column Erection work in progress

|

Unit 3 Wall Blower Commissioning in progress

|

Unit- 3 Hot PA Insulation(Sheeting) work in progress

|

Unit 4 PA Fan Foundation work in progress

|

Unit 4 grouting work for Mill Foundation

|

Unit- 3 Mill G Cone Welding in progress

|

Mill F Roller Spring Setting work in progress

|

Unit-4 ESP Column Erection work in progress

|

Unit 3 Hot PA Duct lagging work in progress

|

Unit 3 Work on Wall Blower alignment in progress

|

Unit 3 Wall Deslagger alignment is in progress

|

Unit 4 ESP Column lifting in progress

|

Unit 3 BFP C readiness is in progress

|

Unit-3 CEP Discharge Orifice plate fixing

|

Unit-3 DCS Panel Installation in Control Room

|

Unit- 3 ESP Ash Hopper Erection work

|

Unit- 4 ESP Column Erection work

|

Unit- 3 Attending ATT Leakage

|

Unit-3 ESP Insulation work

|

Unit-3 TG House Keeping work

|

Unit-4 PA Fan Foundation Work

|

Unit-3 Governing Rack Charging

|

Unit-4 PA Fan and FD Fan Foundation work

|

Unit-3 PA line Support Work in progress

|

Unit-3 Insulation Work in TG Area

|

Unit-3 steam line insulation work in progress

|

Unit-3 Control room readiness

|

Seal air fan line erection work in progress

|

Unit-4 ESP column erection work in progress

|

Unit-3 ESP insulation and cladding in progress

|

Unit#3 TG deck adjacent floor

|

Unit#4 Furnace to ESP duct

|

Unit#4 ID Fan A foundation status

|

Unit#4 ESP foundation status

|

Unit-3 Mill- F & G readiness

|

Unit-3 Seal air fan motor alignment work

|

Unit-3 Insulation in duct from ID fan B to chimney

|

Unit-4 ESP control room status

|

Unit#4 Condenser foundation status

|

Unit#4 TG AB bay status

|

Unit#4 Mill A, B, C foundation status

|

Unit#3 Insulation work in LP Heater

|

Unit-3 ID Fan A duct erection

|

Unit-3 & 4 Control room

|

Unit-3 Swing check and CRO check of generator shaft

|

Unit#4 Turbine floor status

|

Unit#4 FD fan- A foundation status

|

Unit#4 Mill - A, B, C & D foundation status

|

Unit#3 Boiler to ESP inlet duct

|

Unit#4 Mill- E, F & G foundation status

|

Unit# 3 Status of ID fan - A

|

Unit#3 Insulation work from ESP O/L to ID fan- B

|

Unit# 3 PA Fan- A work progress

|

Unit-3 Duct from Mill to ESP inlet

|

Unit-3 ESP- C & D outlet Insulation work

|

Unit-3 Hot PA Duct erection

|

Unit-3 ID Fan-A rotor erection work

|

Unit-3 Hot PA Duct erection

|

U#3 TG Deck Floating compeleted

|

U#3 Right side Duct Support structure

|

U#3 Hot PA Duct erection

|

Unit-3 ID Fan-A Rotor assembly work progress

|

Unit-3 ID Fan-A Spiral casing erection done

|

Unit-3 Duct Insulation from ID Fan-A to Chimney

|

Unit-3 Duct from Mill to ESP inlet

|

Unit-3 Hot PA Duct erection

|

Unit-3 Duct from Mill to ESP inlet

|

Unit-3 Duct Insulation from ID Fan-B to Chimney

|

Unit-3 Duct from ESP outlet to ID fans

|

Unit-3 Duct Insulation from ESP outlet to ID Fan-B

|

Unit-3 Hot PA Duct erection

|

Unit-4 ESP Control room readiness

|

Unit-4 Mill foundation readiness

|

Unit-3 FD Fan-A & PA Fan-A readiness

|

Unit-3 Hot PA Duct erection

|

Unit-3 Duct Insulation from ID Fan-B to Chimney

|

Unit-3 Duct from Mill to ESP inlet

|

Unit-3 Hot PA Duct erection

|

U#3 Duct Insulation from ESP outlet to ID Fan-B

|

U#3 Hot PA Duct erection

|

U#3 Duct from Mill to ESP inlet

|

U#3 Duct and Insulation from ESP oulet to ID fans

|

Unit-3 Duct Insulation from ID Fan-B to Chimney

|

Unit-3 Mill Motor readiness

|

Unit-3 Coal pipe erection

|

Unit-3 Hot PA Duct erection

|

Unit-3 Hopper erection ESP Pass-A

|

Unit-3 Duct Insulation from BOF to Mill

|

Unit-3 Duct Insulation from ID Fan-B to Chimney

|

Unit-3 Duct from ESP outlet to ID fans

|

Unit-4 Mill A & B motor coupled trial readiness

|

Unit-3 Duct Insulation from BOF to Mill

|

Unit-3 Hot PA Duct erection

|

U#3 CENTRAL CONTROL ROOM READINESS

|

U#3 FD Fan-A & PA Fan-A readiness

|

U#3 MS, CRH, HRH INSULATION READINESS

|

Unit-4 PA Duct readiness

|

Unit-4 BFPs readiness

|

Unit-3 MS,CRH,HRH Insulation Readiness

|

Unit-3 Programmer room readiness

|

Unit-3 Central Control Room Rreadiness

|

Unit-3 TG Deck readiness

|

Unit-3 BFP-A readiness

|

Unit-3 Duct Insulation from ID Fan-B to Chimney

|

Unit-3 Duct from ESP outlet to ID fans

|

Unit-3 Control room readiness

|

Unit-3 TG readiness

|

Unit-3 ID Fan-A motor erection done

|

Unit-3 Duct Insulation from ID Fan-B to Chimney

|

Unit-3 ESP-A pass hopper plate erection

|

Unit-3 Duct from ESP oulet to ID fans

|

Unit-3 Duct from Mill to ESP inlet

|

Unit-3 Coal pipe erection

|

Unit-3 Hot PA Duct erection

|

Unit-3 BFP-A Coupled trial under progress

|

Unit-3 ID Fan-A motor erection done

|

Unit-3 Bunker hopper area

|

Unit-3 VFD Transformer foundation (right side)

|

Unit-3 TG Deck readiness

|

Unit-3 CER room readiness

|

Unit-3 Control room readiness

|

Unit-3 FD Fan-A & PA Fan-A area

|

Unit-3 Duct Insulation from FD Fan to APH

|

Unit-3 Mill Motor readiness

|

Unit-3 Duct erection from Mill to ESP Inlet

|

Unit-3 Coal pipe erection & PA Duct erection

|

Unit-3 Duct Insulation from BOF to Mill

|

Unit-3: 0 meter SG ECW motor area

|

Unit-3 seal air area foundation

|

Unit -3 battery room area

|

Unit-3 & 4 control desk room area

|

Unit-4 ESP Pass-B,C,D area

|

Unit-3 Mill area 3.5 meter

|

Unit -3 mills area

|

Unit-4 VFD Building

|

Unit-4 Boiler and Mill area

|

Unit-3 ESP pass C and D area

|

Unit-3 Seal Air fan-A Foundation area

|

Unit-3 VFD Building area

|

Unit-4 DCS Panel Room

|

Unit-4 TG Floor 13.5 Meter

|

Unit-3 TG ECW Area

|

Unit-3 BFP-C area

|

Unit-3 BFP-A area

|

Unit-4 Mill area

|

Unit-4 Boiler

|

Unit-3 Mill area

|

Unit-3 Feeder Floor area

|

Unit-4 ESP Control Room

|

Unit-4 TG Deck Foundation

|

Unit-3 Control Room

|

Unit-3 ESP Outlet

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|