Unit # 5 Unit Cabling Area/Erection of CableTrays

|

Unit# 5: MIV Inlet Pipe

|

Unit # 4 CW Motor Pump

|

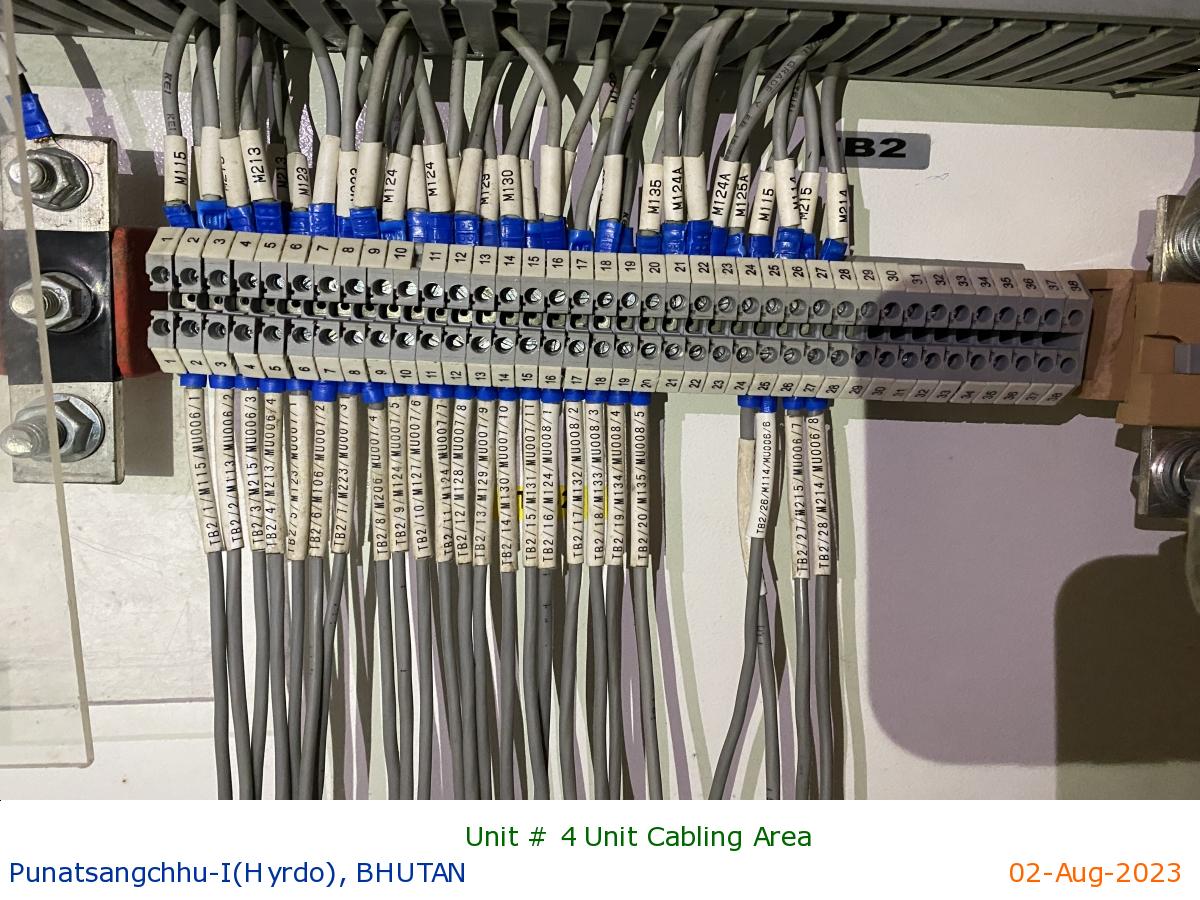

Unit # 4 Unit Cabling Area

|

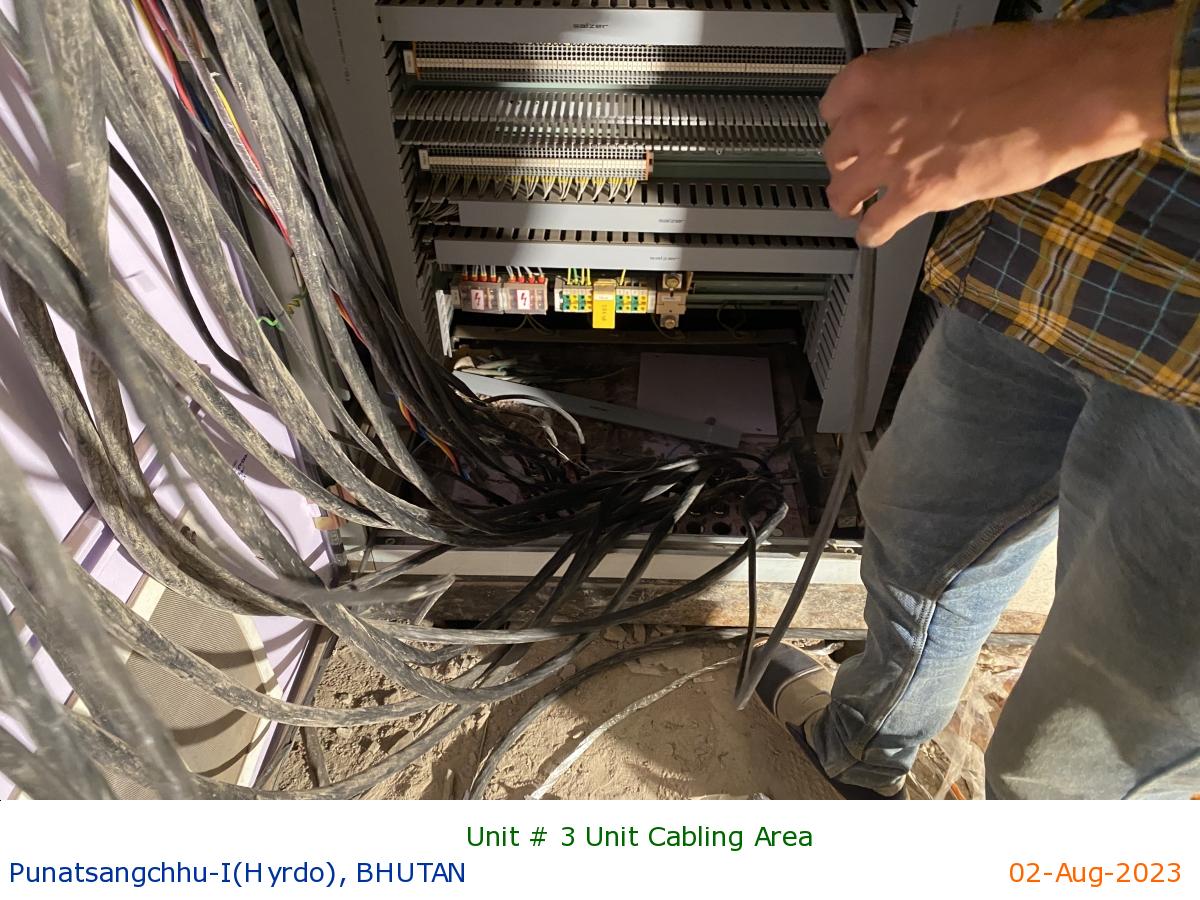

Unit # 3 Unit Cabling Area

|

Unit# 3- MIV Platform Erection

|

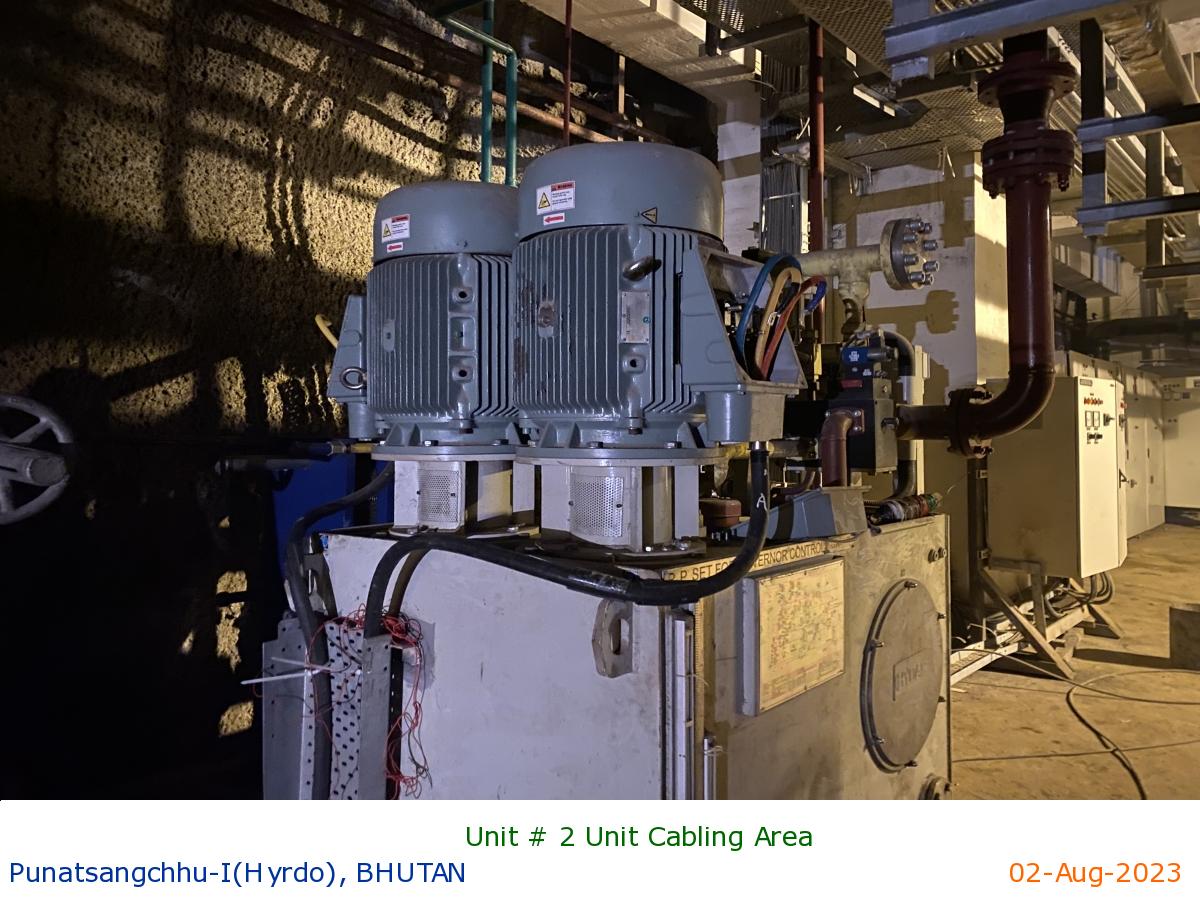

Unit # 2 Unit Cabling Area

|

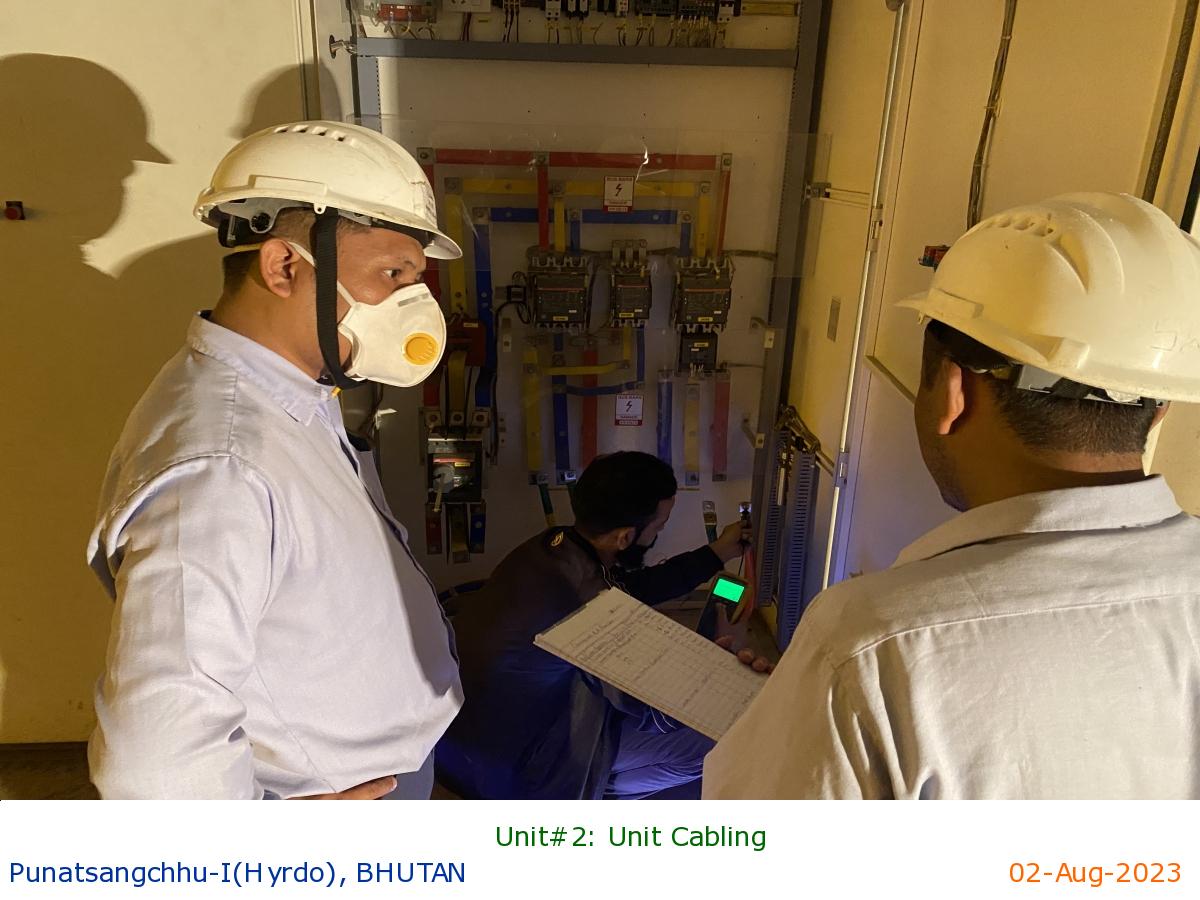

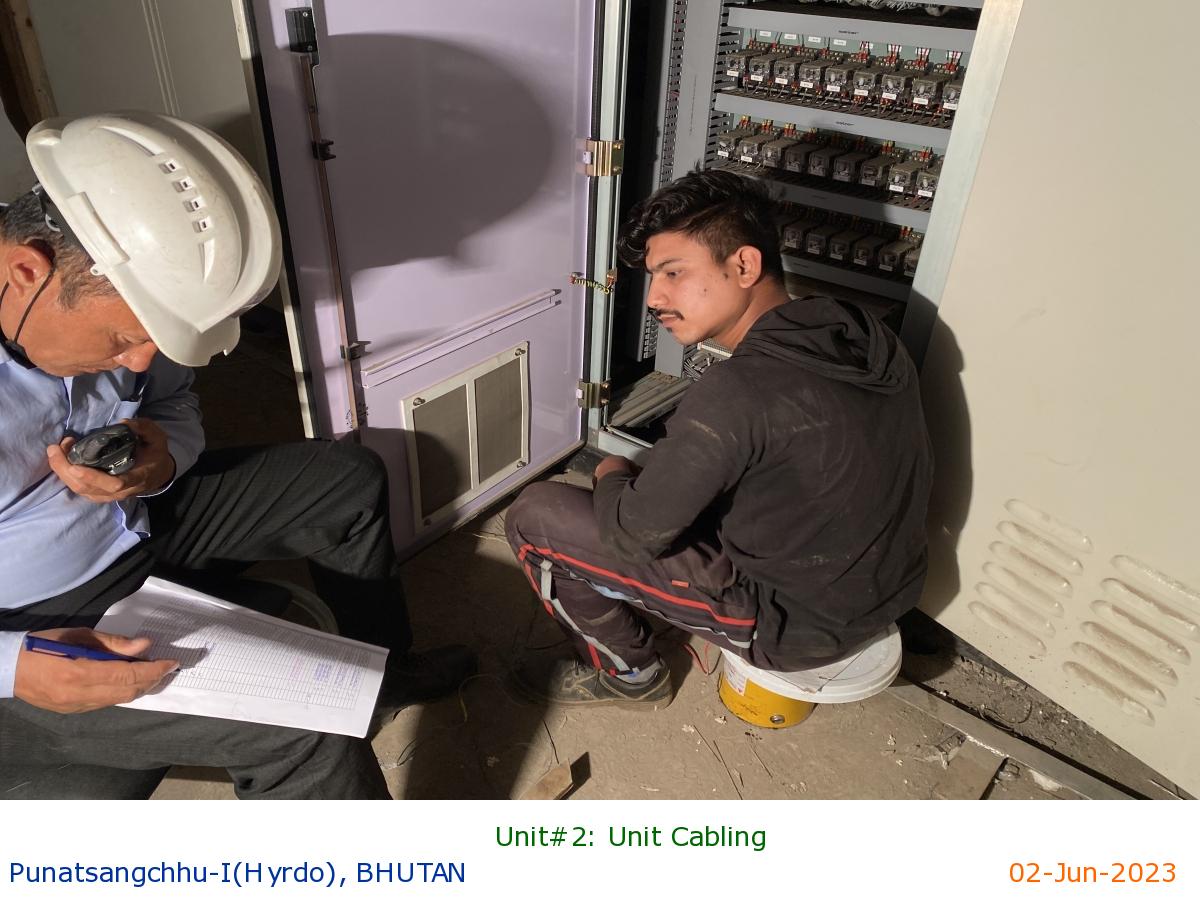

Unit#2: Unit Cabling

|

Common- HV AC Pump

|

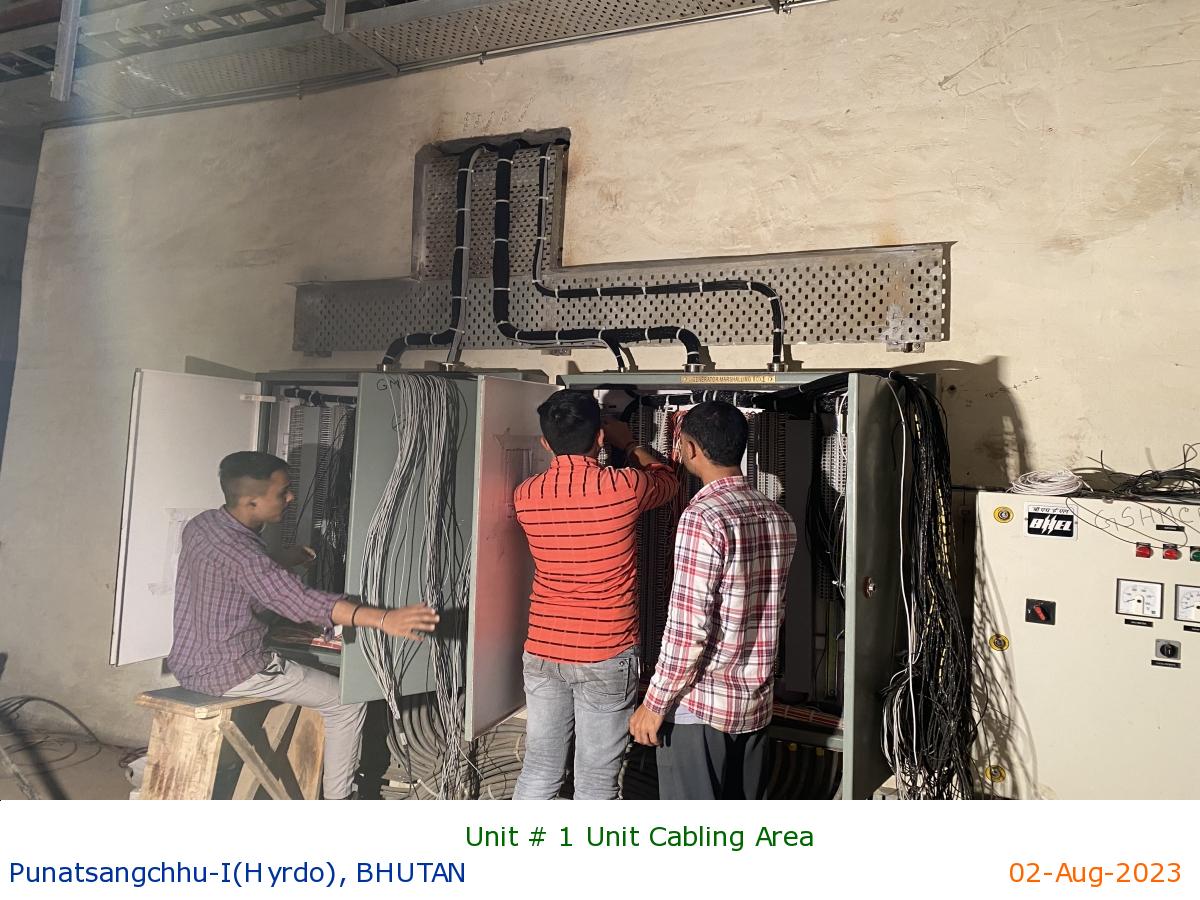

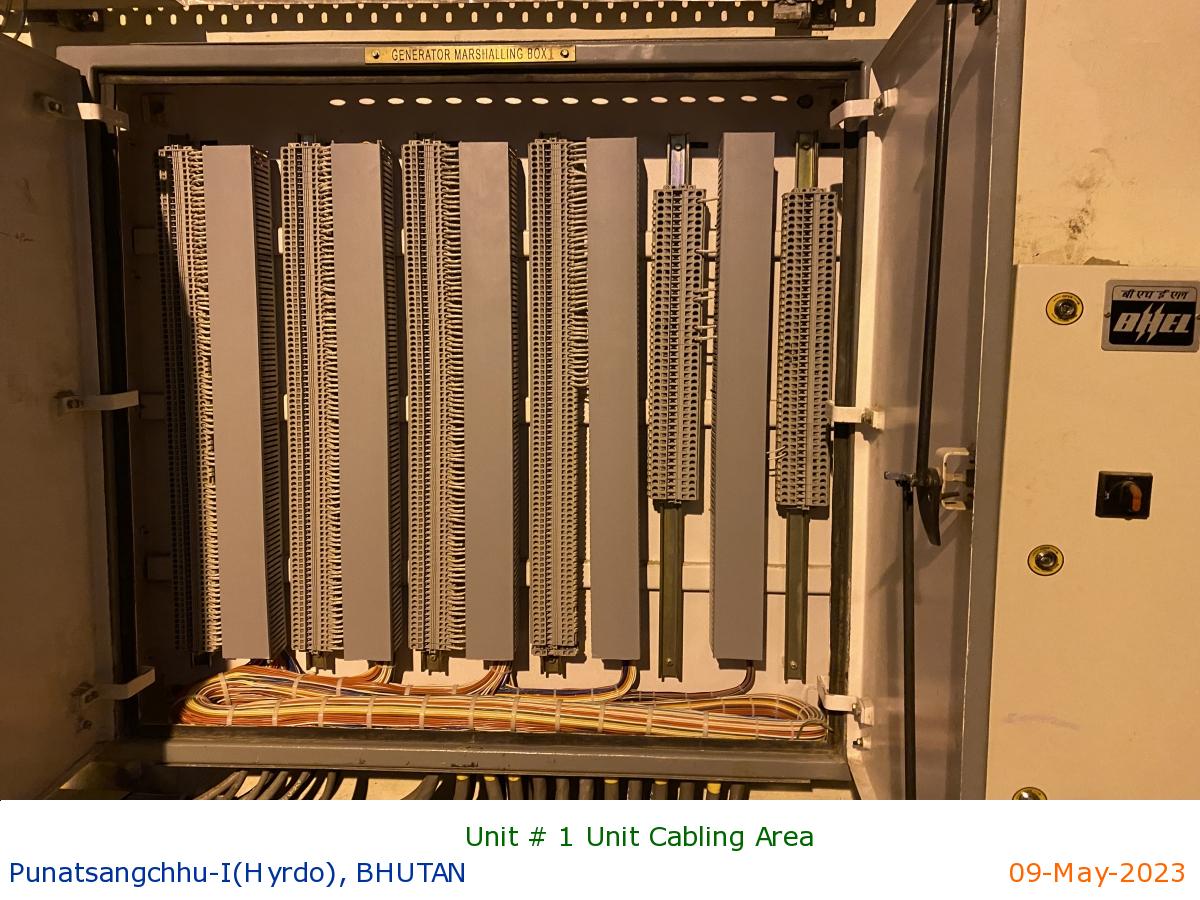

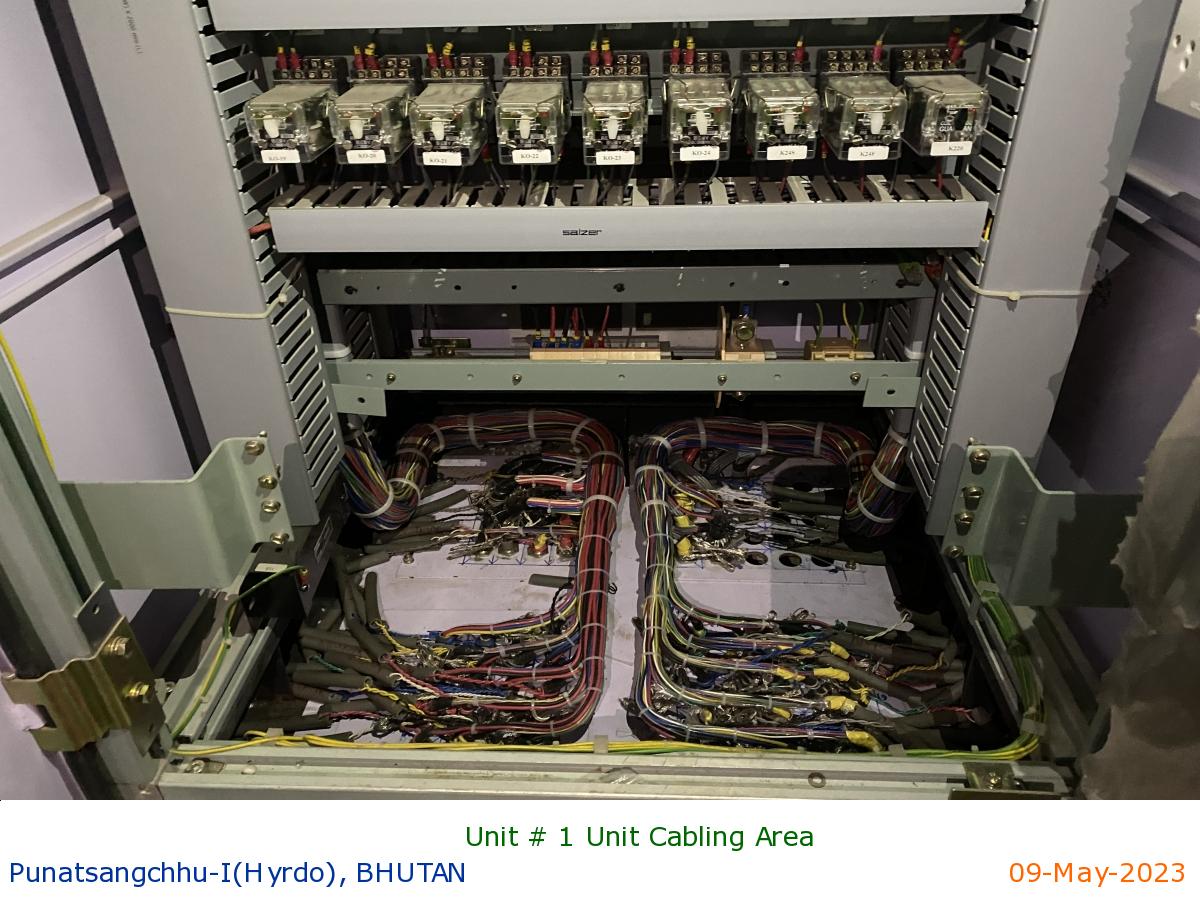

Unit # 1 Unit Cabling Area

|

U# 1- Dowelling of GV Servomotor

|

Unit-4: Motor Alignment of CW Pump

|

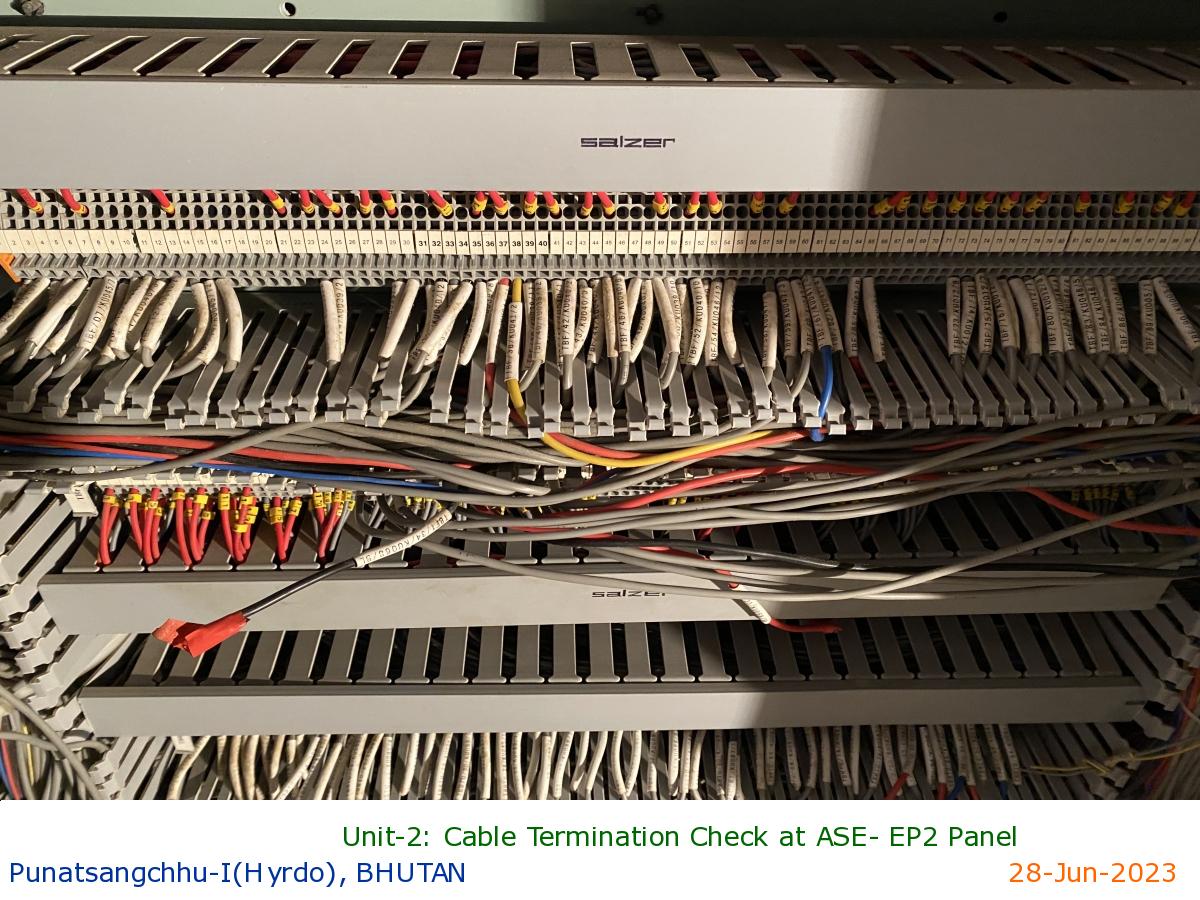

Unit-2: Cable Termination Check at ASE- EP2 Panel

|

U# 5-Welding of Inlet Pipe & MIV

|

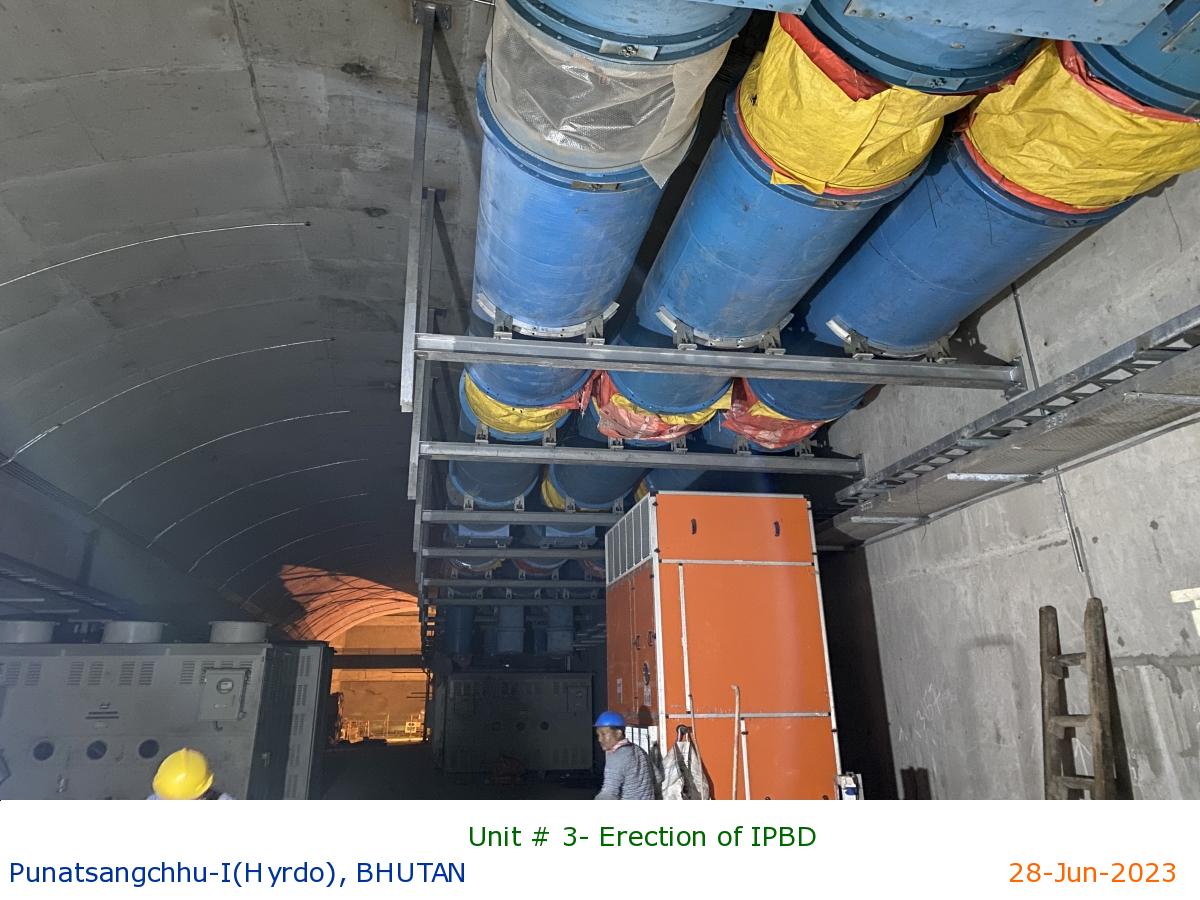

Unit # 3- Erection of IPBD

|

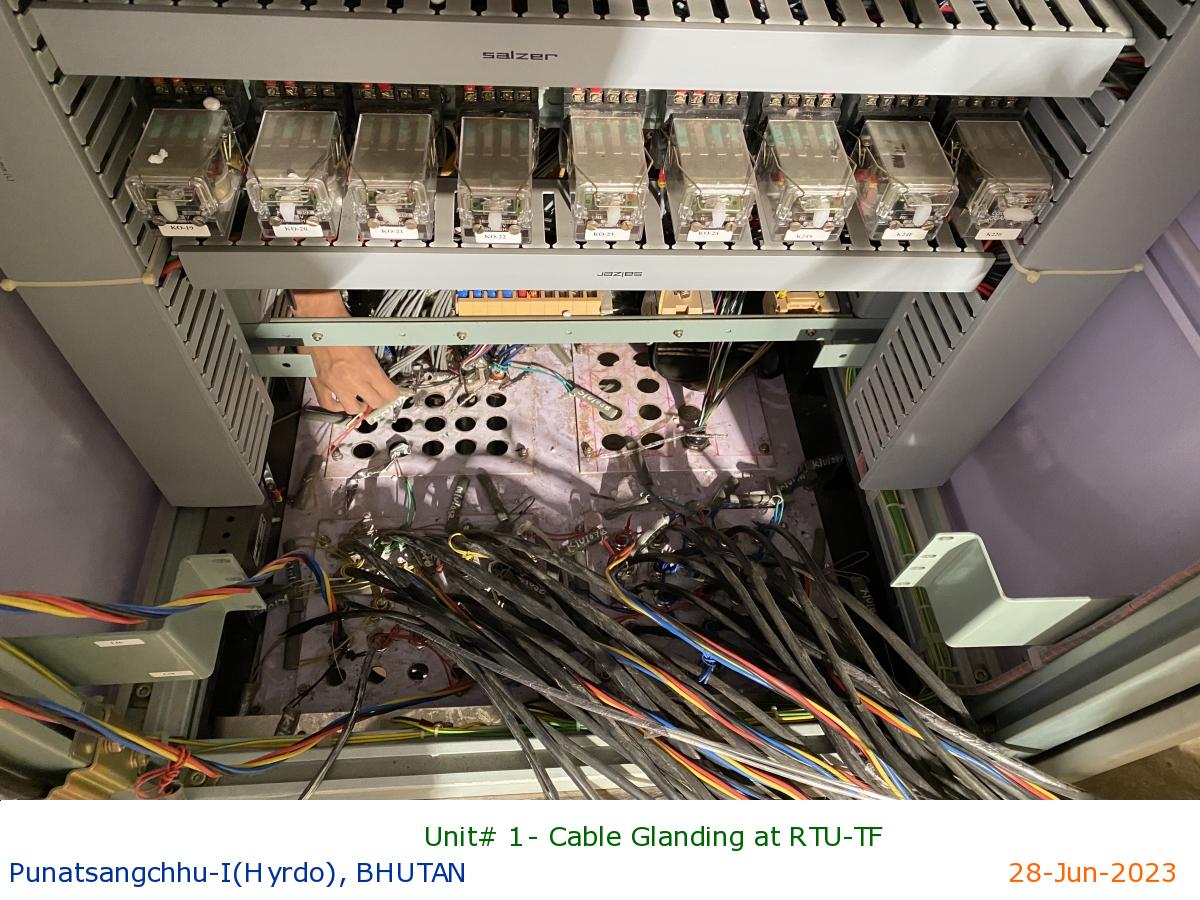

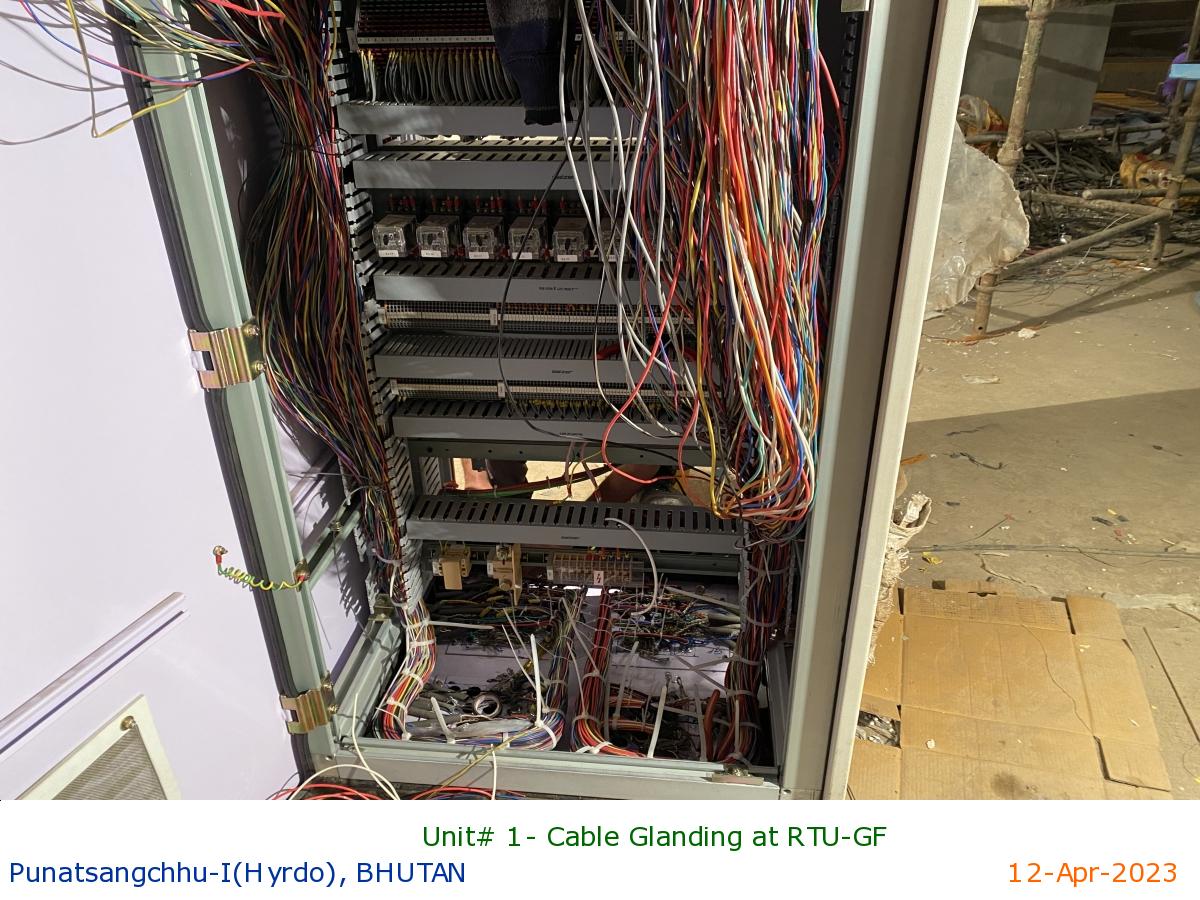

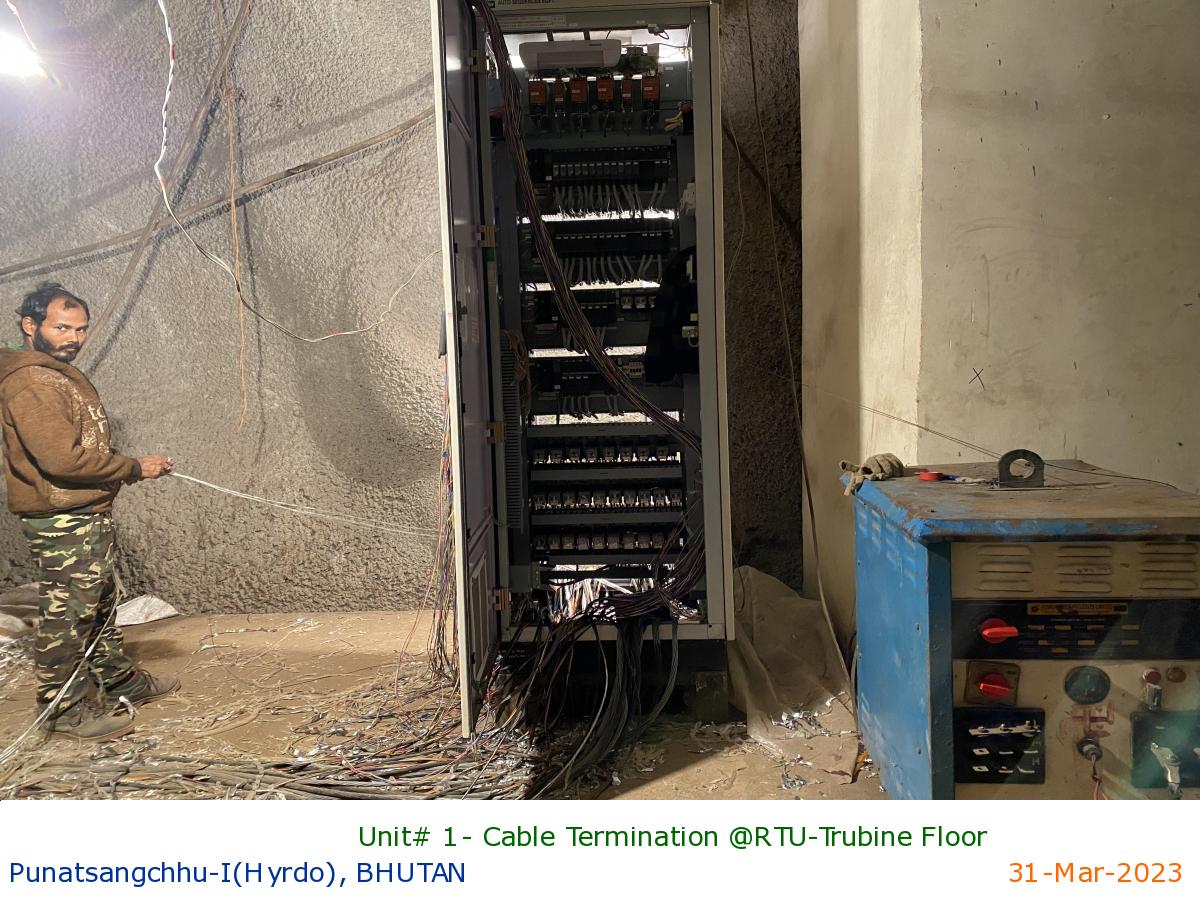

Unit# 1- Cable Glanding at RTU-TF

|

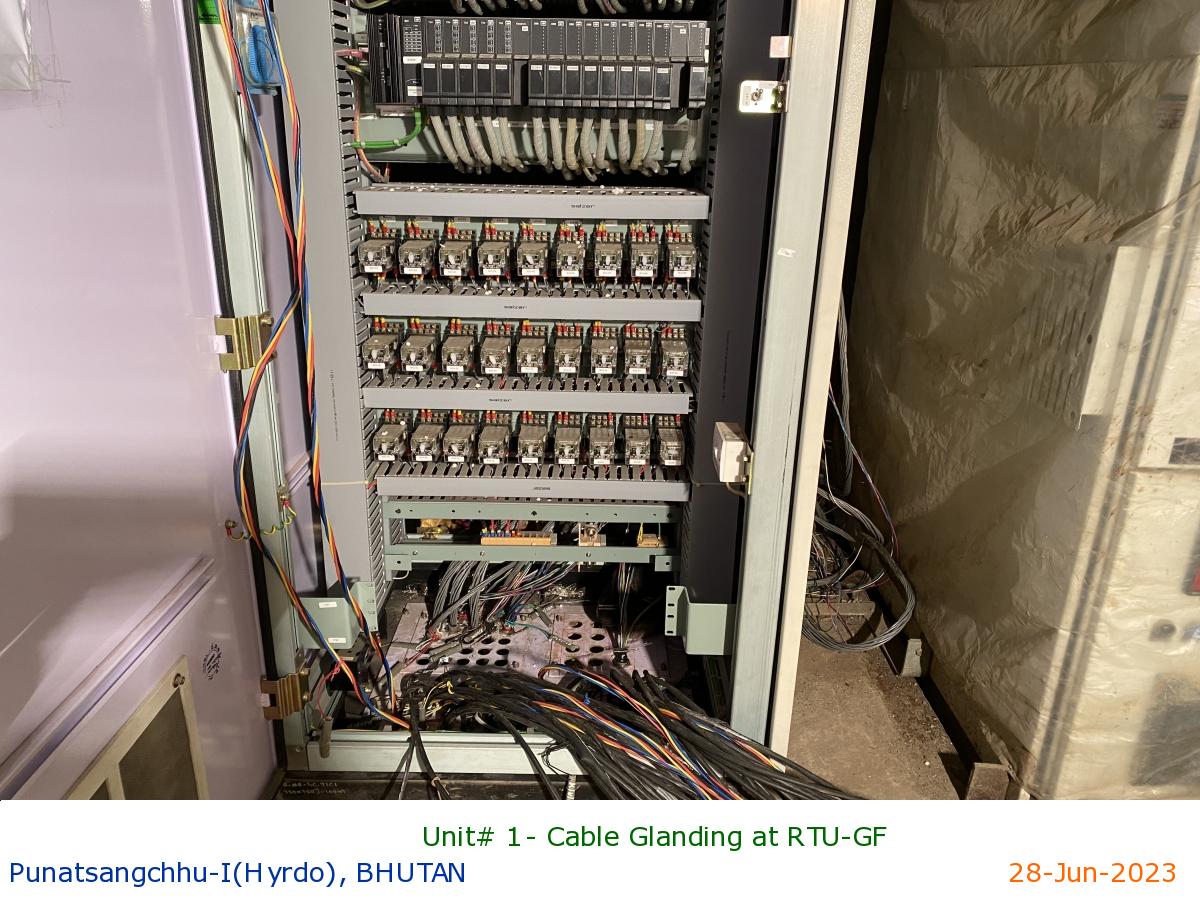

Unit# 1- Cable Glanding at RTU-GF

|

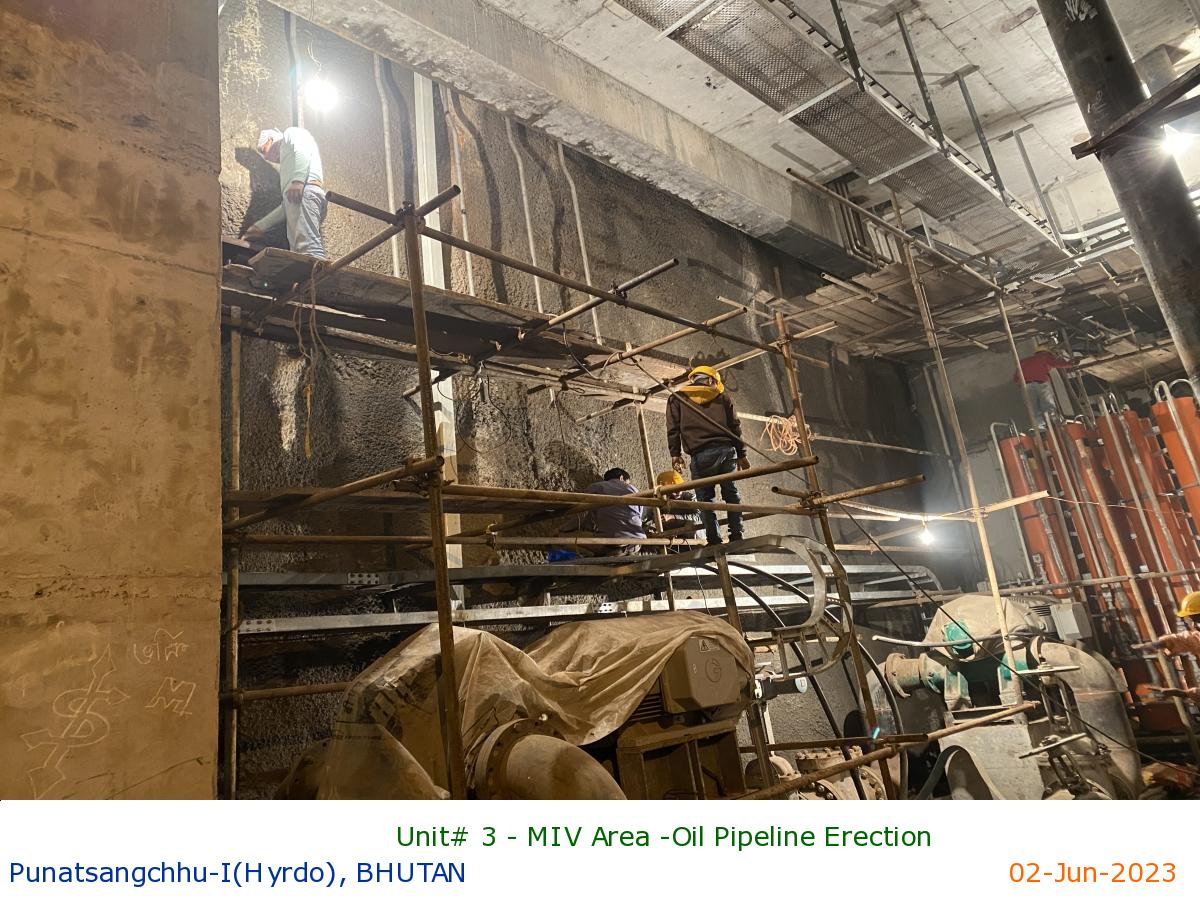

Unit# 3 - MIV Area -Oil Pipeline Erection

|

Unit # 3: Unit Cabling Area

|

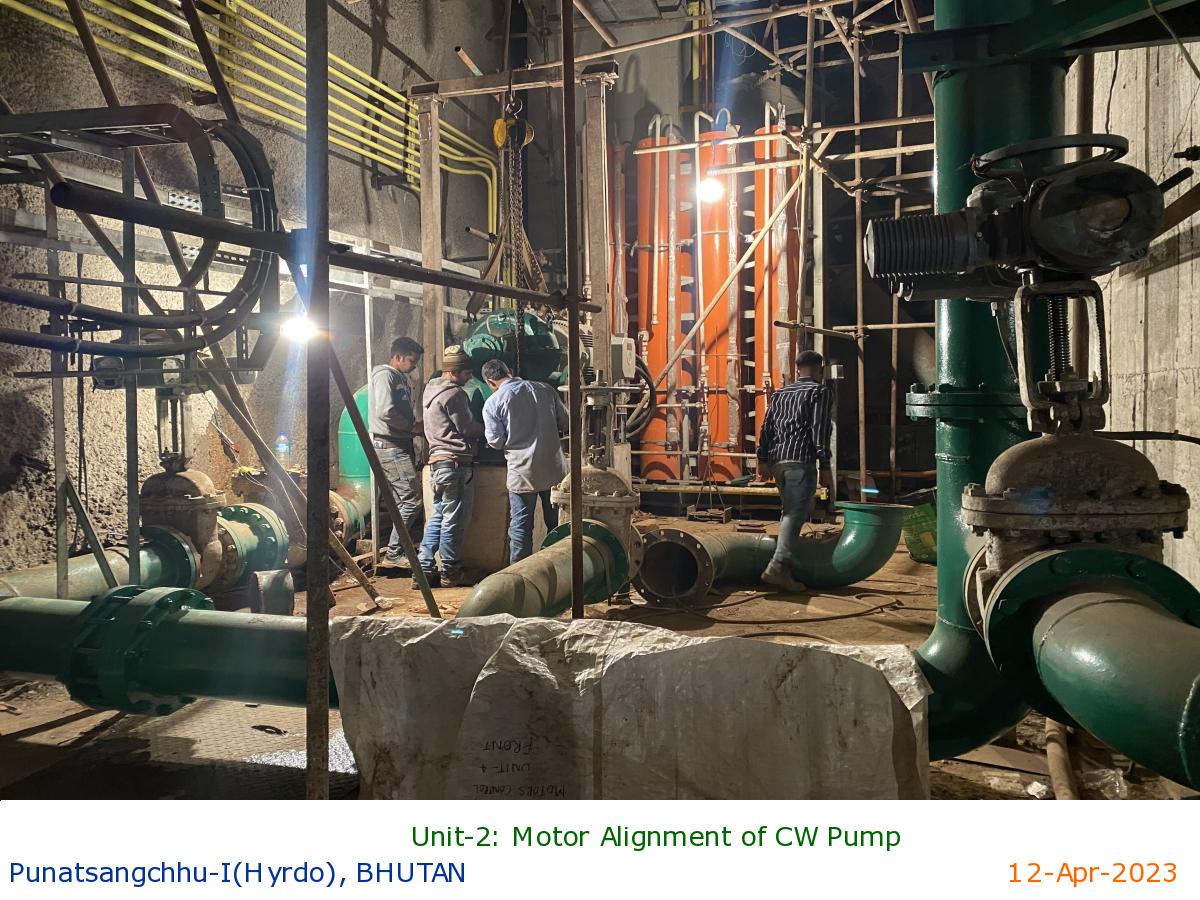

Unit#2: CW Area- Motor Pump Alignment

|

Unit#2: Unit Cabling

|

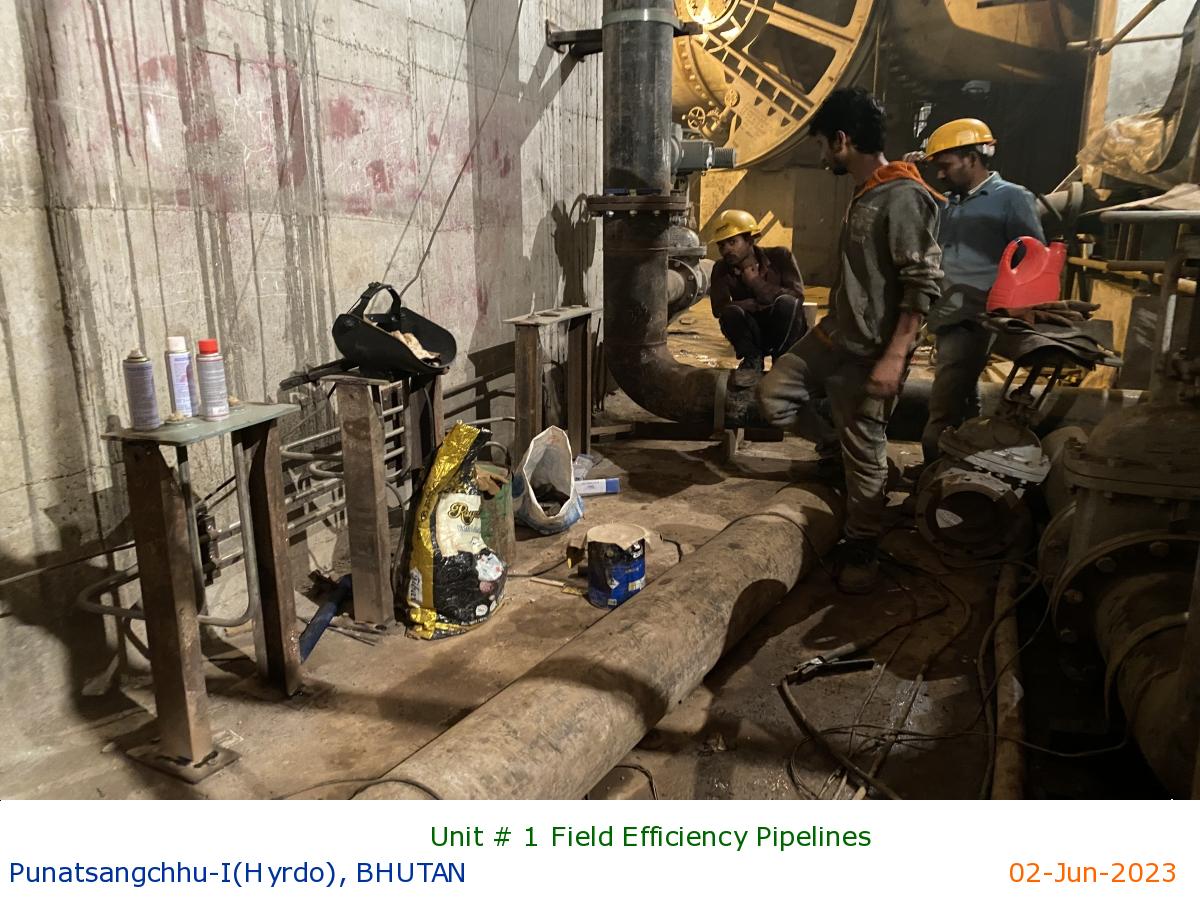

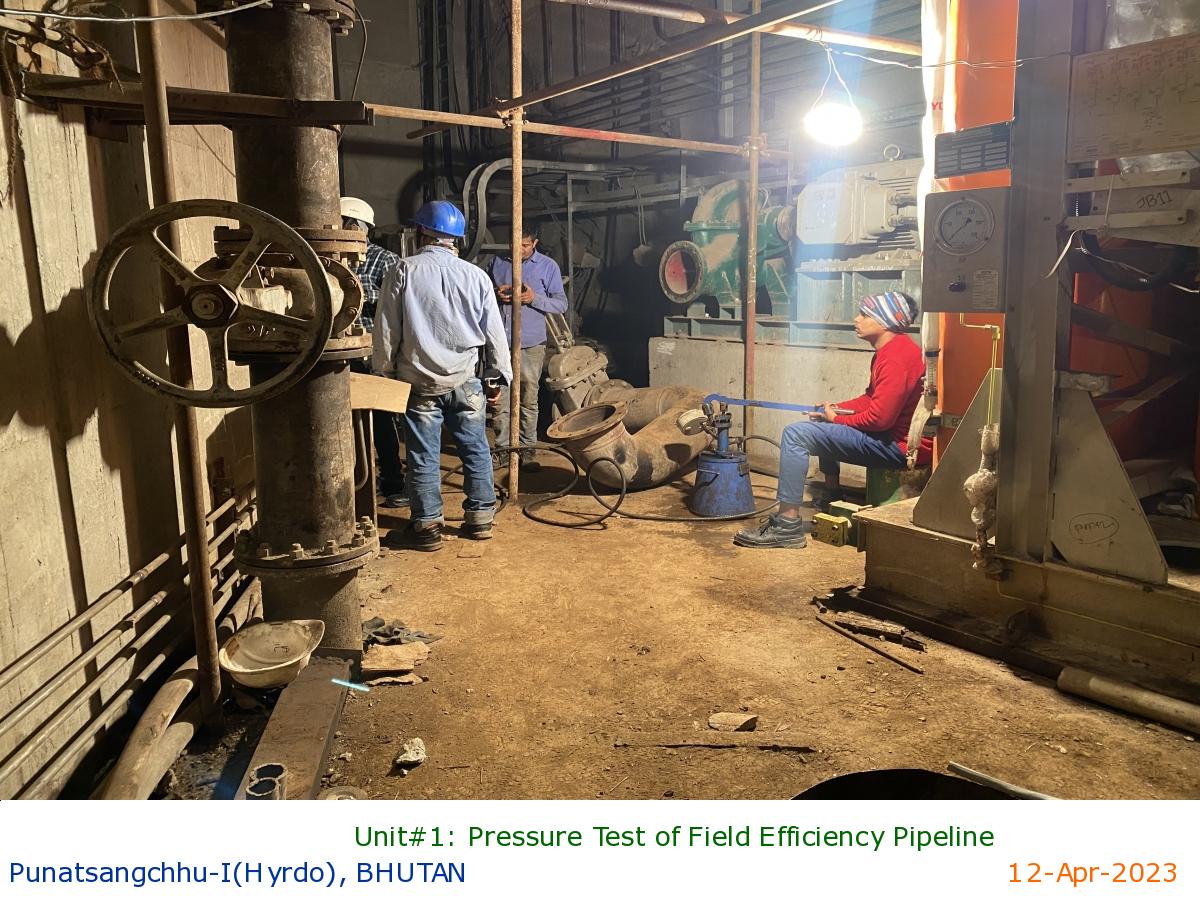

Unit # 1 Field Efficiency Pipelines

|

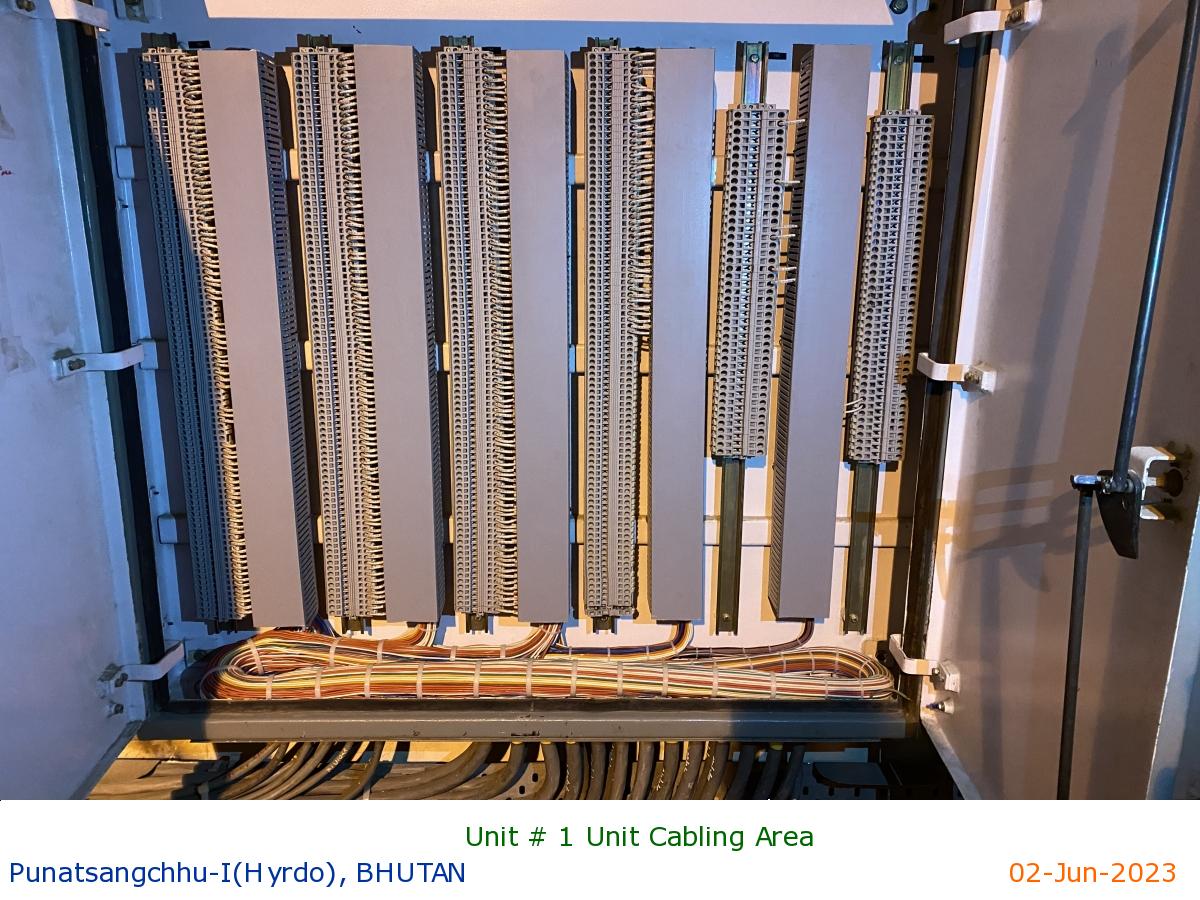

Unit # 1 Unit Cabling Area

|

Unit # 1 Unit Cabling Area

|

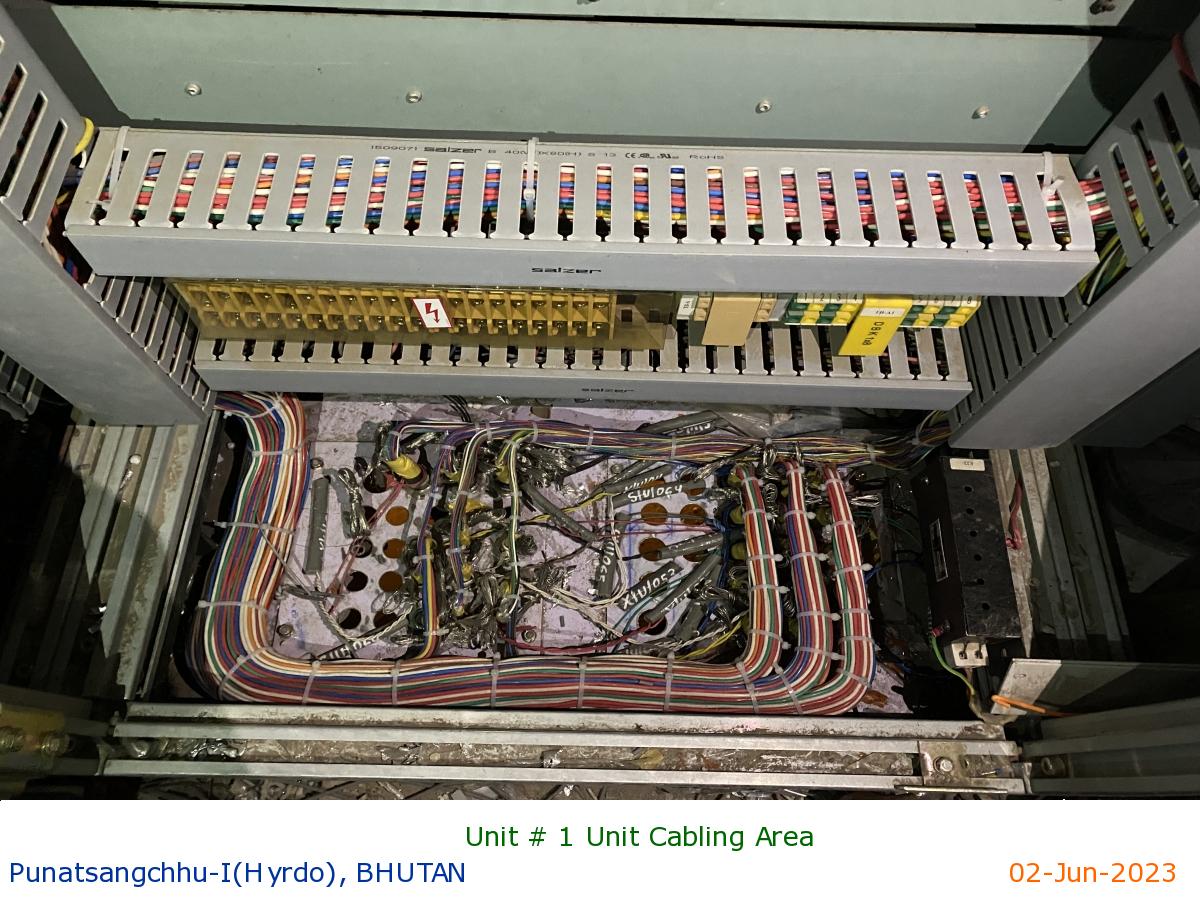

Unit # 6 Unit Cabling Area

|

Unit# 5 Welding of Inlet Pipe of MIV with Penstock

|

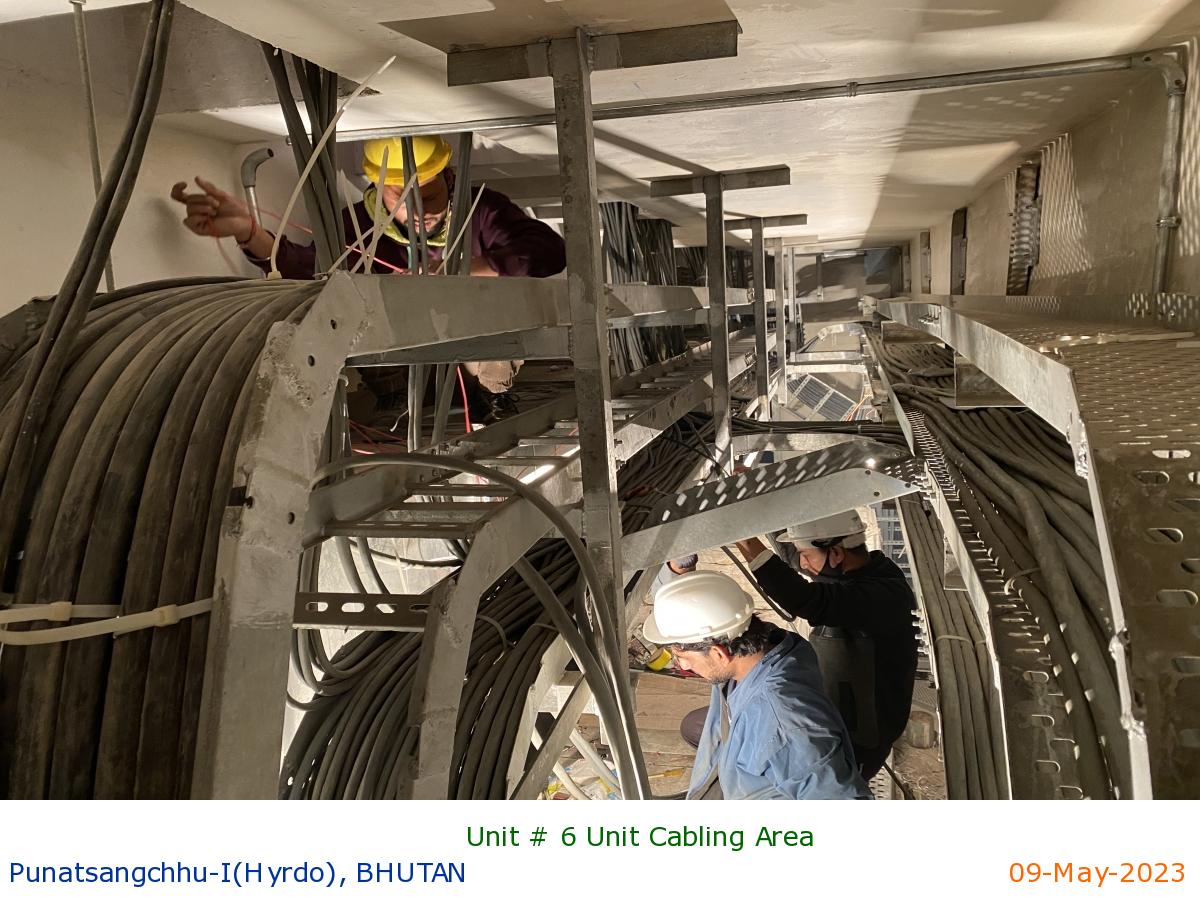

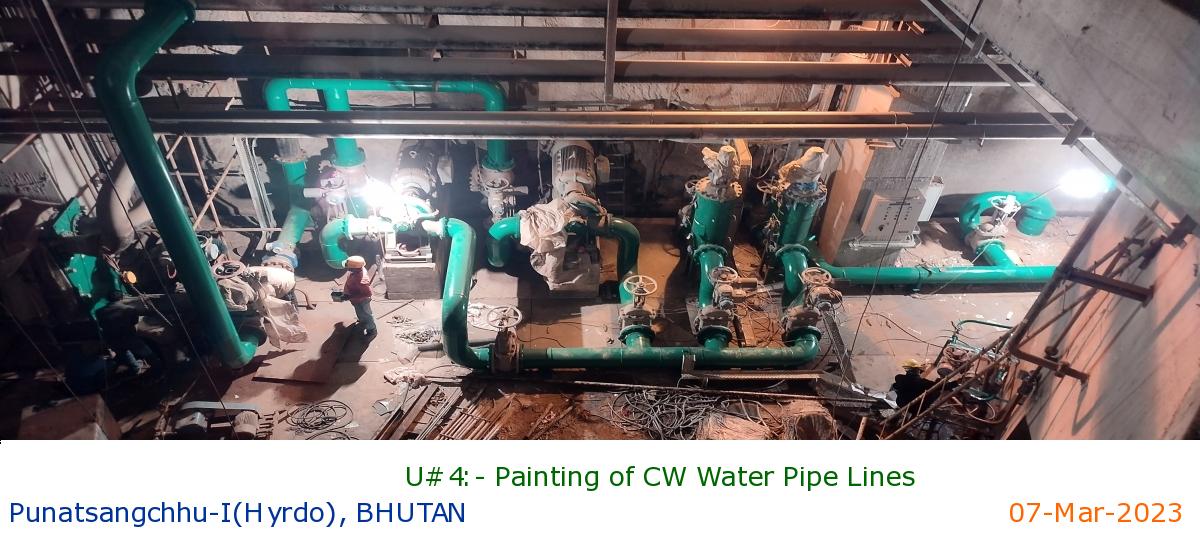

Unit# 4- Painting of CW Pipelines

|

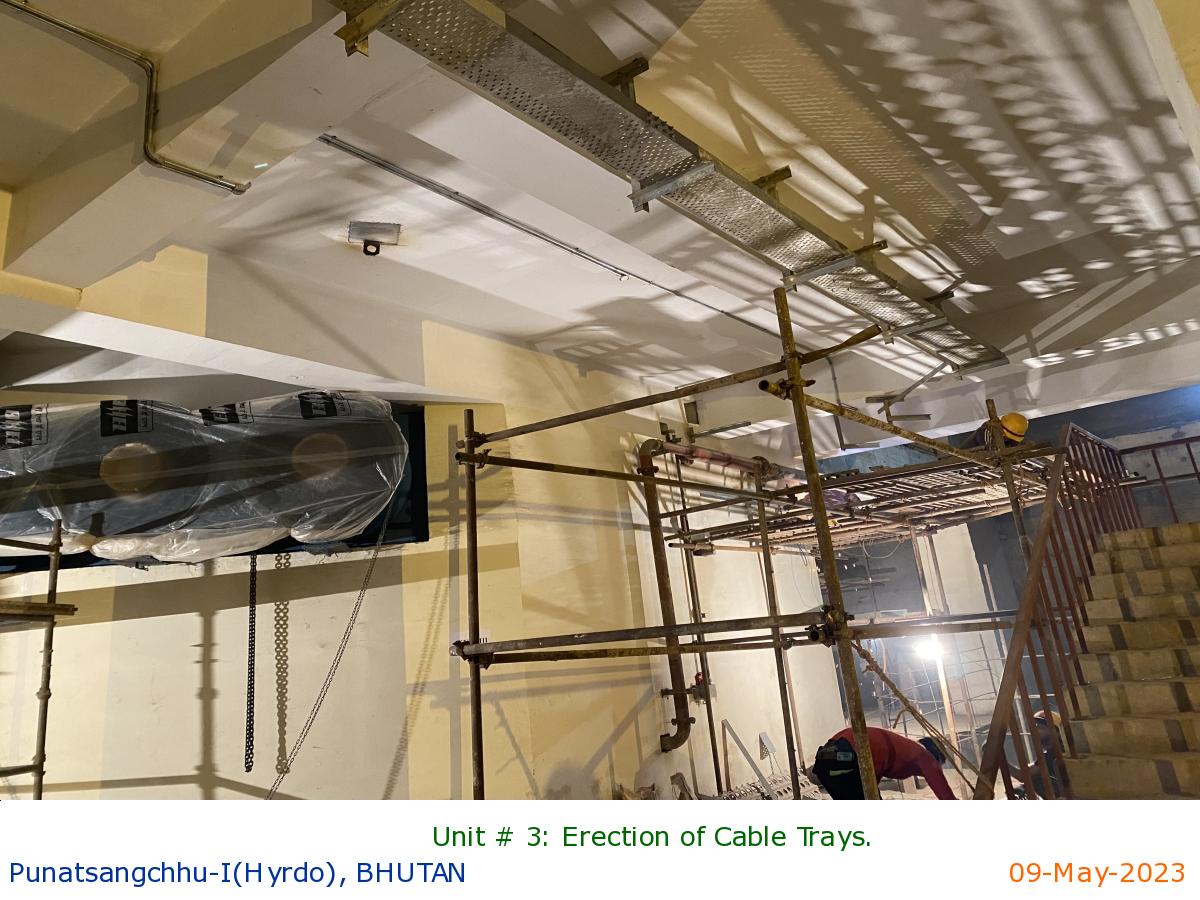

Unit # 3: Erection of Cable Trays.

|

Unit #3: Oil and Water Pipelines in MIV Area

|

Unit#2: Alignment of CW Motor Pumps

|

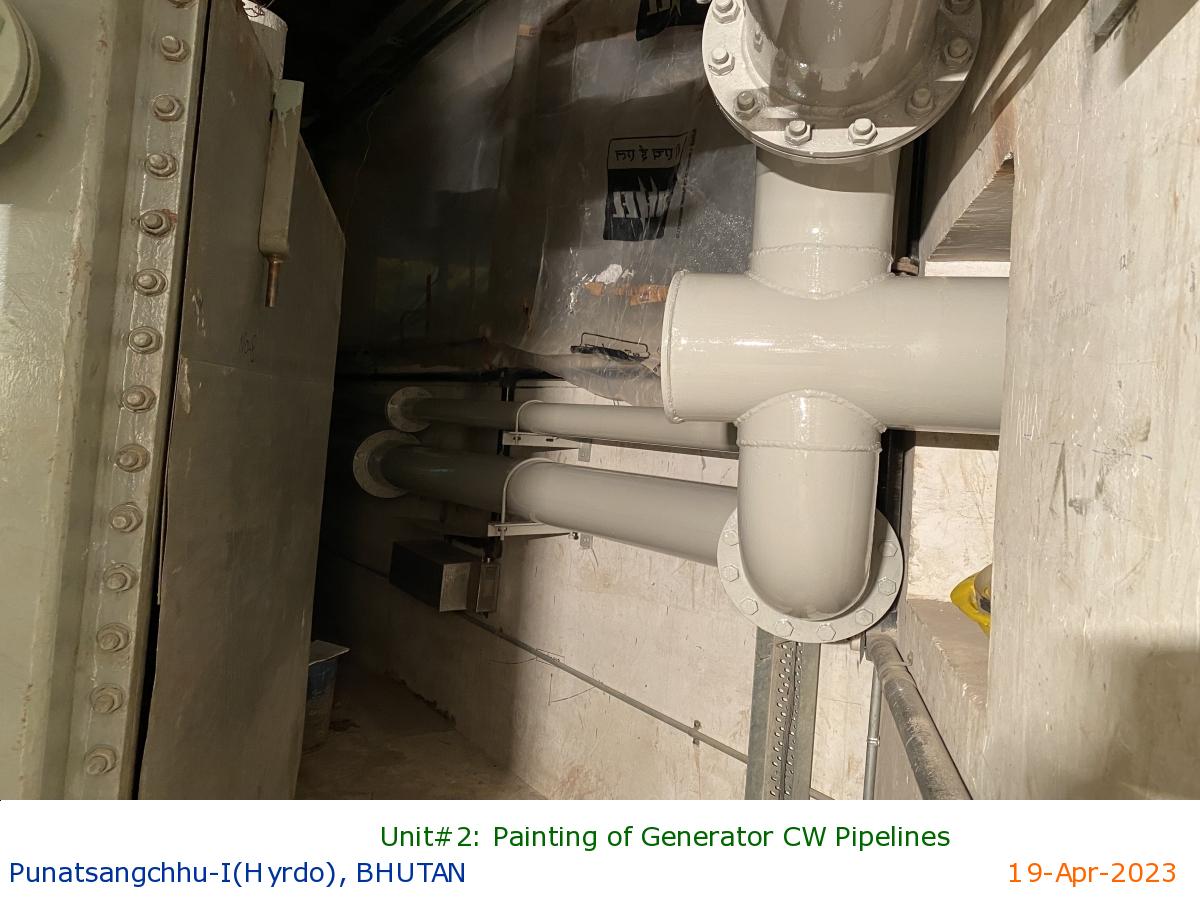

Unit # 2 Painting of Generator CW Pipelines

|

Unit # 1: Pipeline Erection in MIV Area

|

Unit # 1 Unit Cabling Area

|

Unit # 1 Unit Cabling Area

|

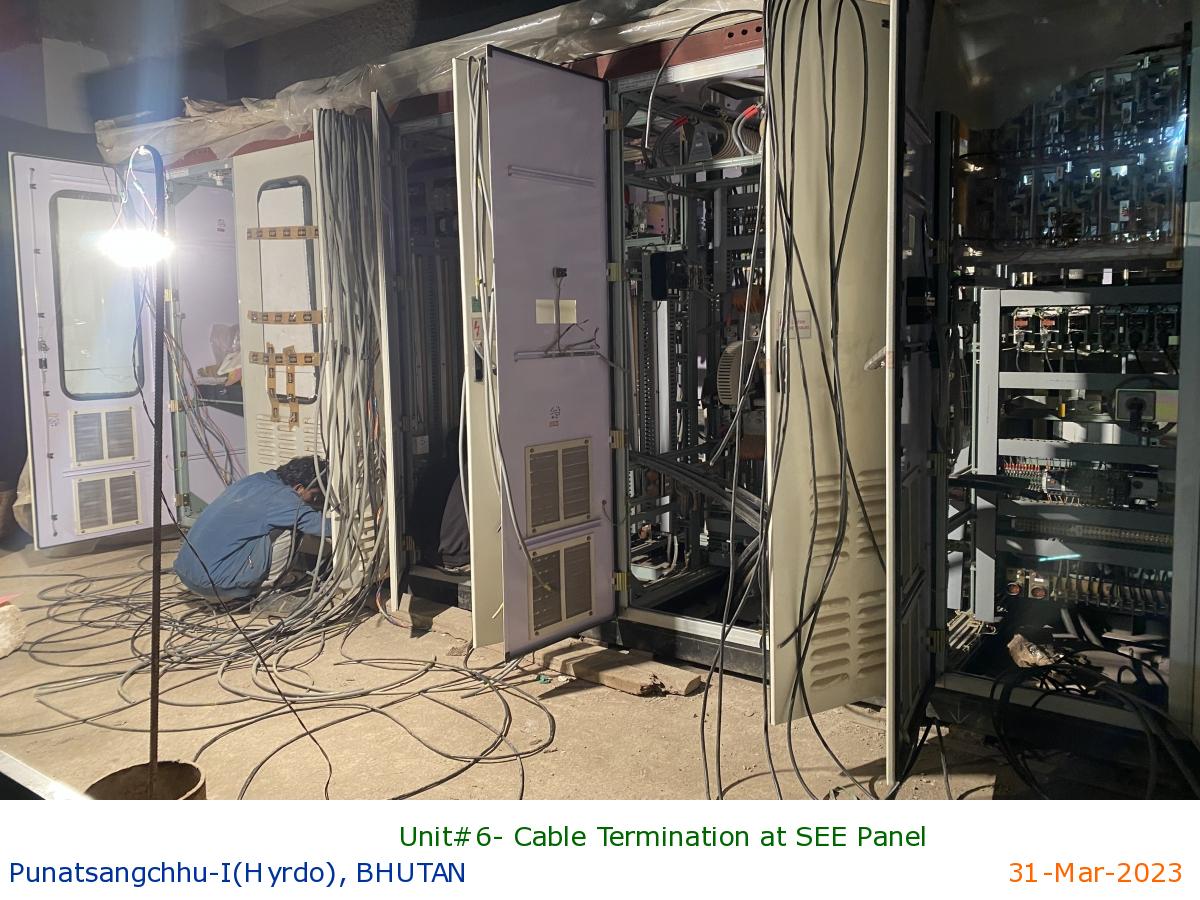

U#6: Cable Termination Works under progress.

|

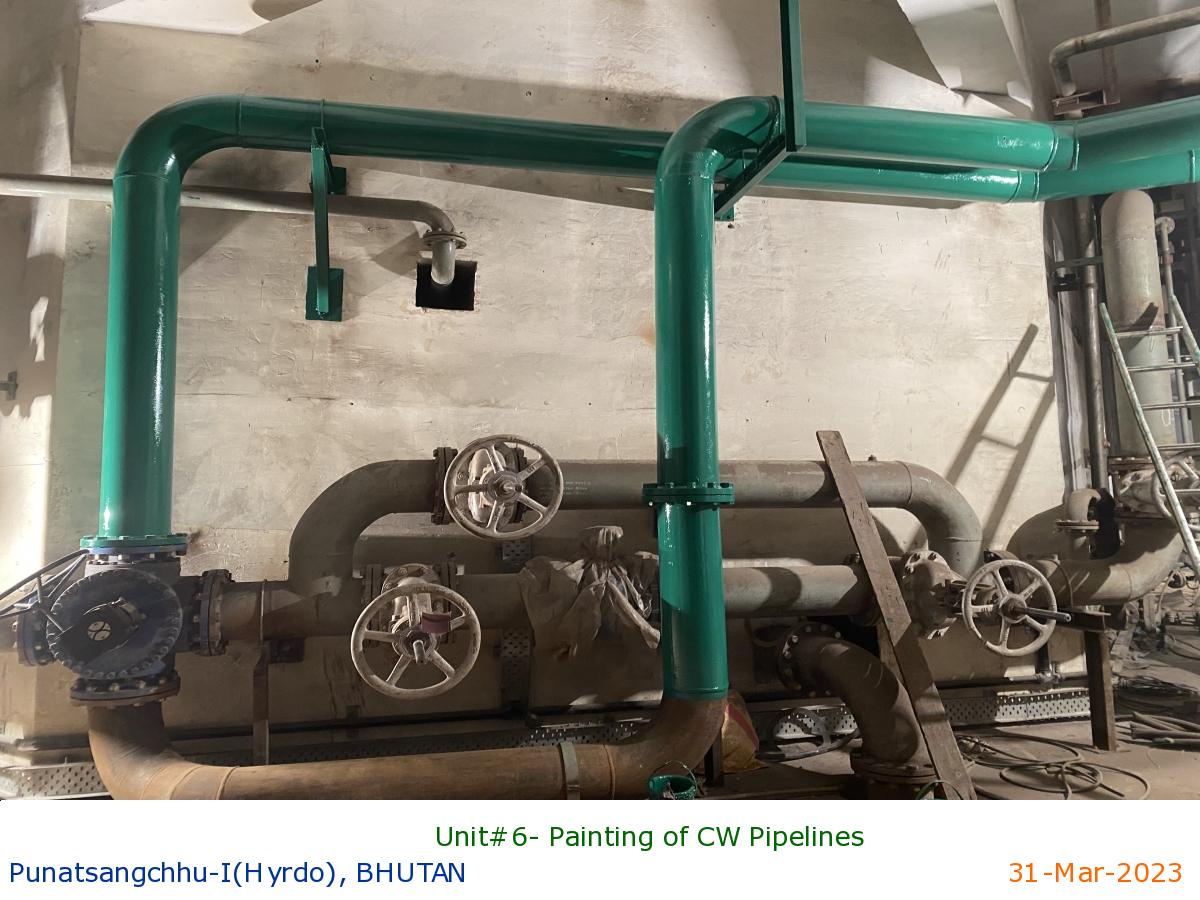

U#6: Painting of CW Pipelines

|

U# 5-Welding of Inlet Pipe of MIV with Penstock

|

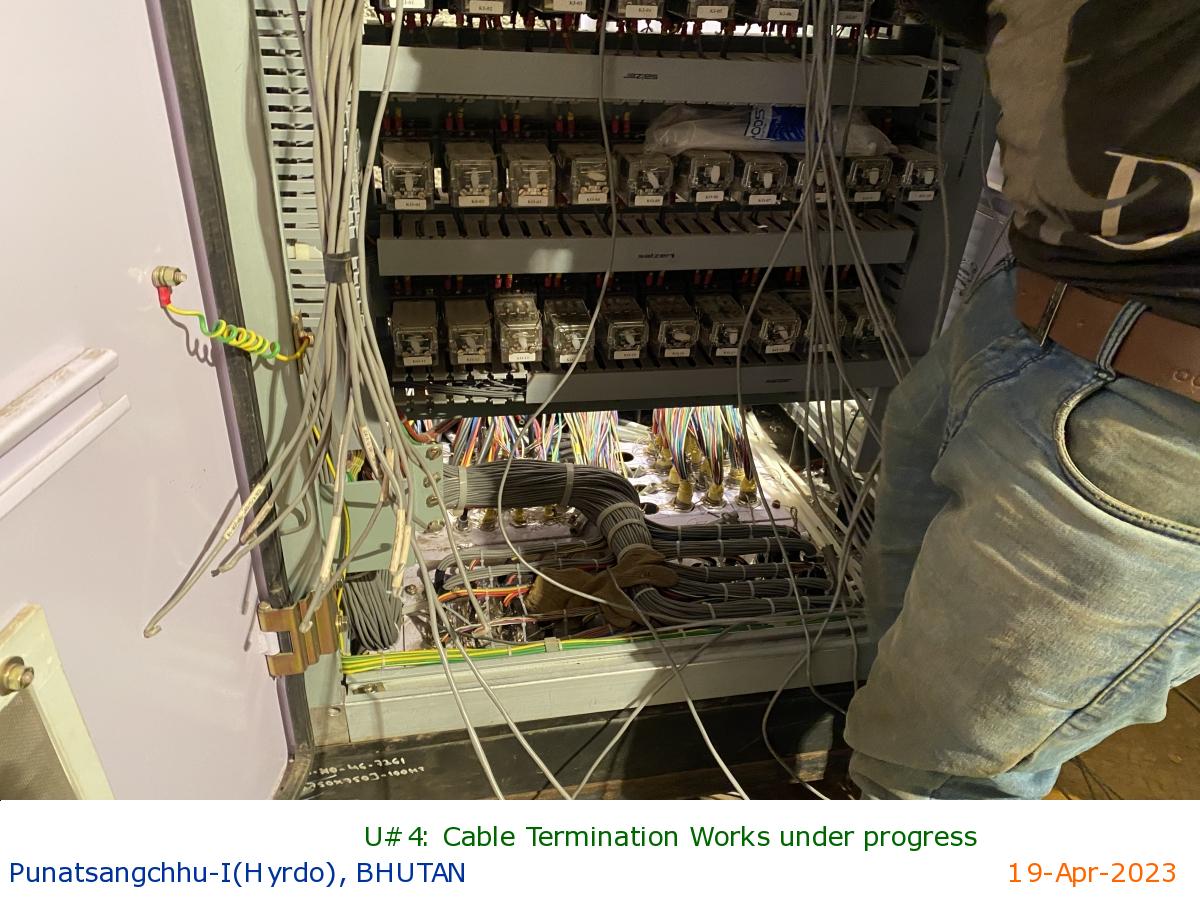

U#4: Cable Termination Works under progress

|

U#3: Installation of Oil Pipelines of MIV

|

U#3: Erection of Cable Trays in Bus Duct Gallery

|

U#3: Installation of AUX/Bypass Valve of MIV

|

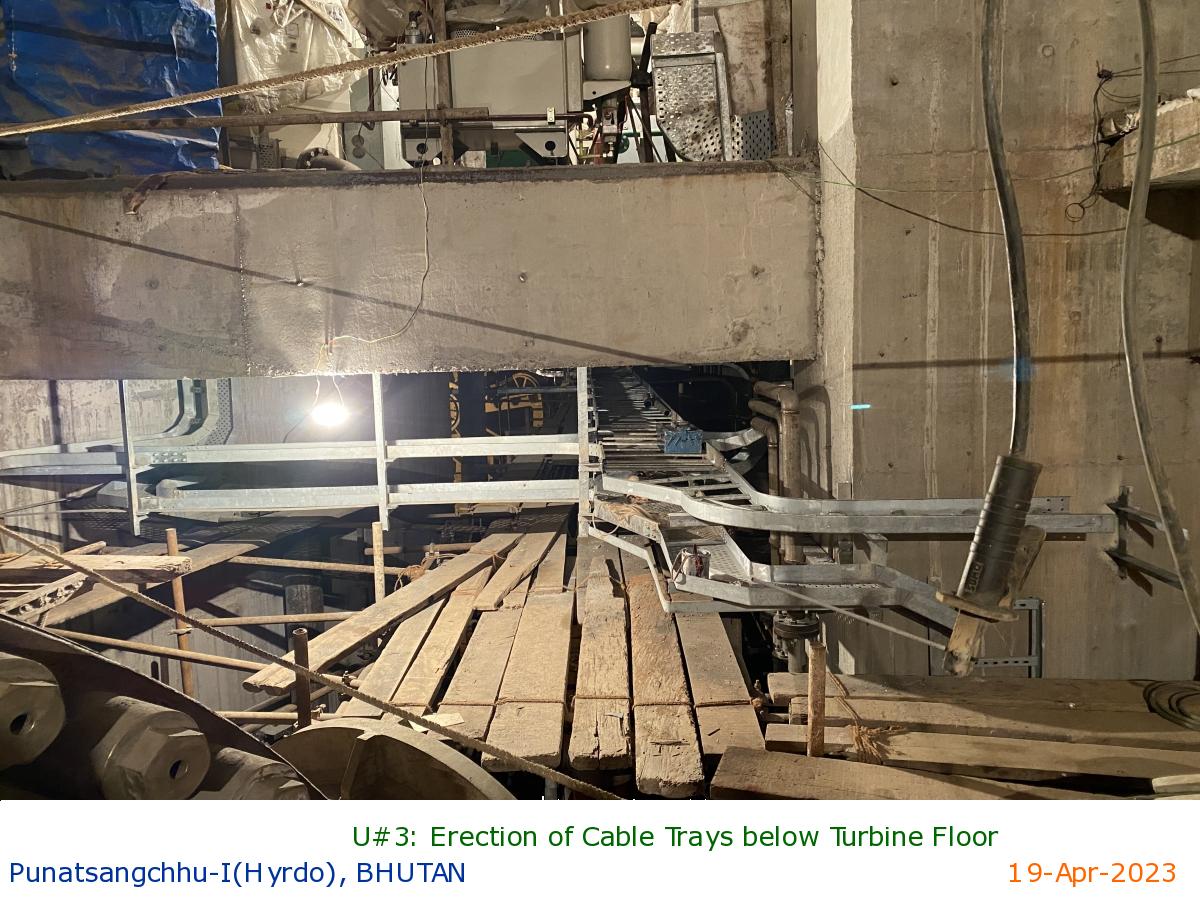

U#3: Erection of Cable Trays below Turbine Floor

|

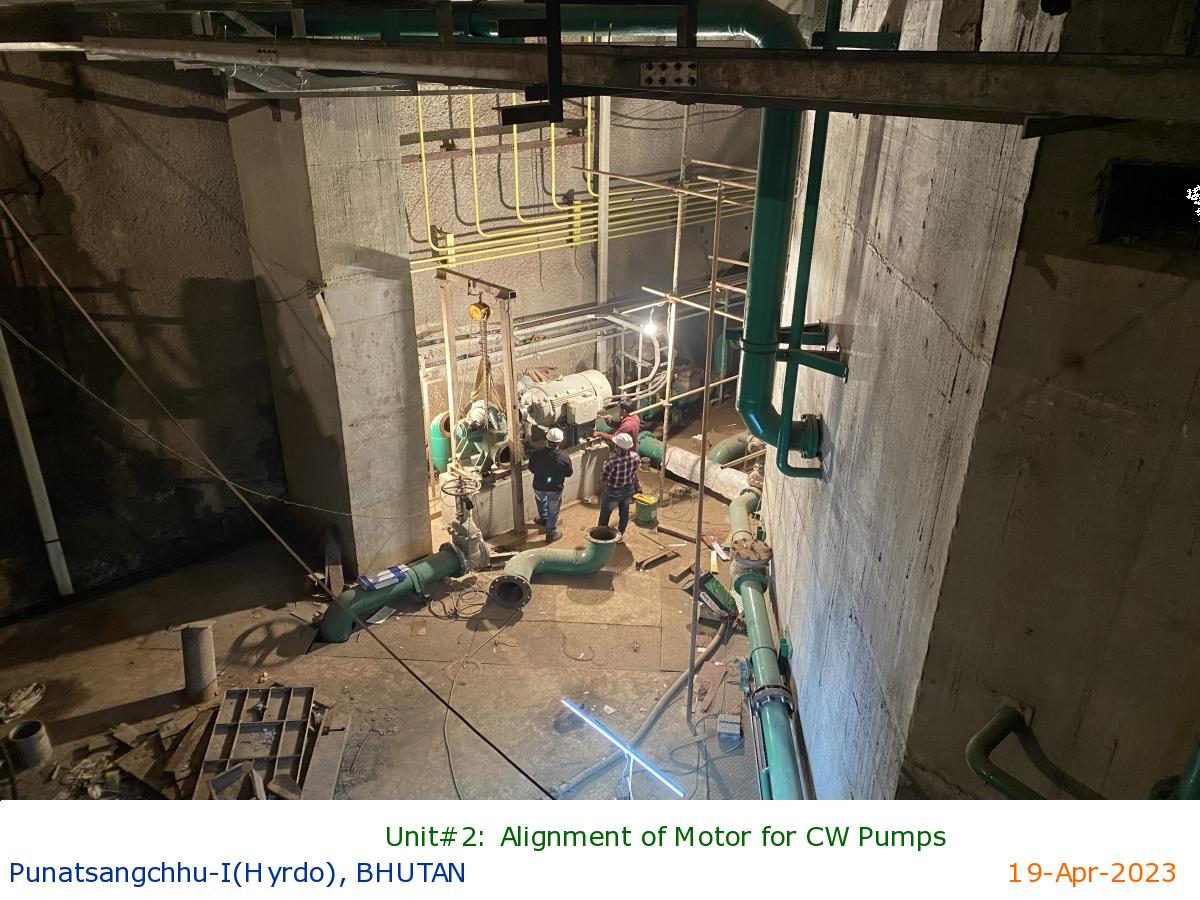

Unit#2: Alignment of Motor for CW Pumps

|

Unit#2: Painting of Generator CW Pipelines

|

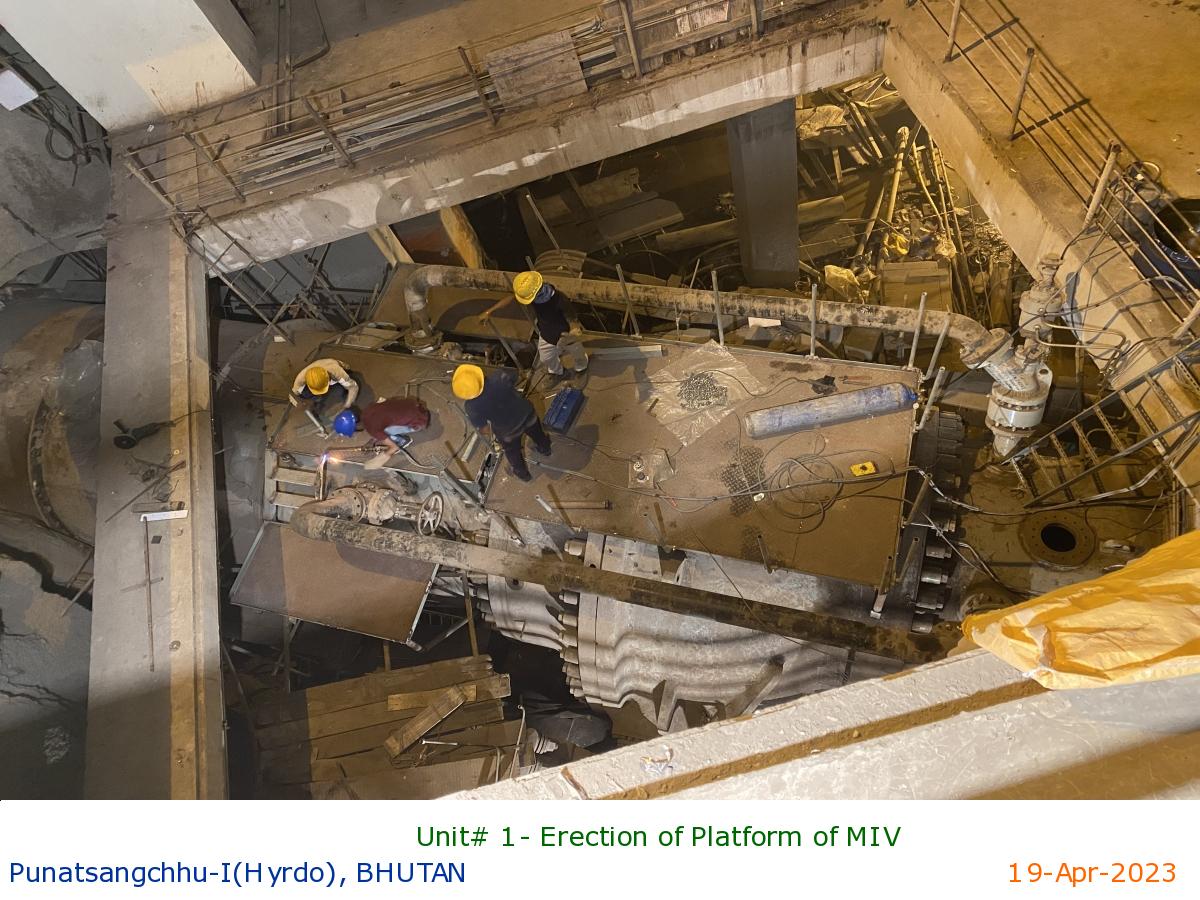

Unit# 1- Erection of Platform of MIV

|

Unit# 1- Cable Termination at GMB

|

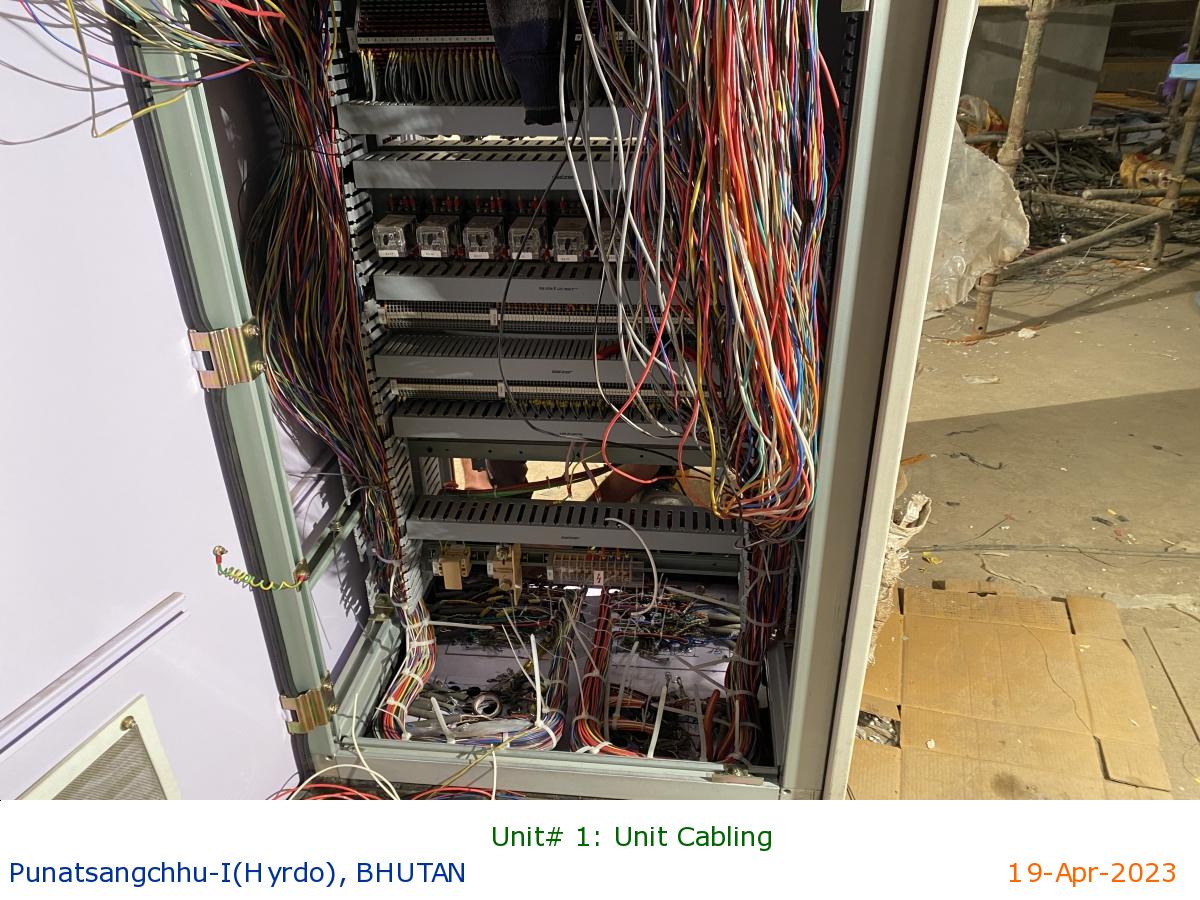

Unit# 1: Unit Cabling

|

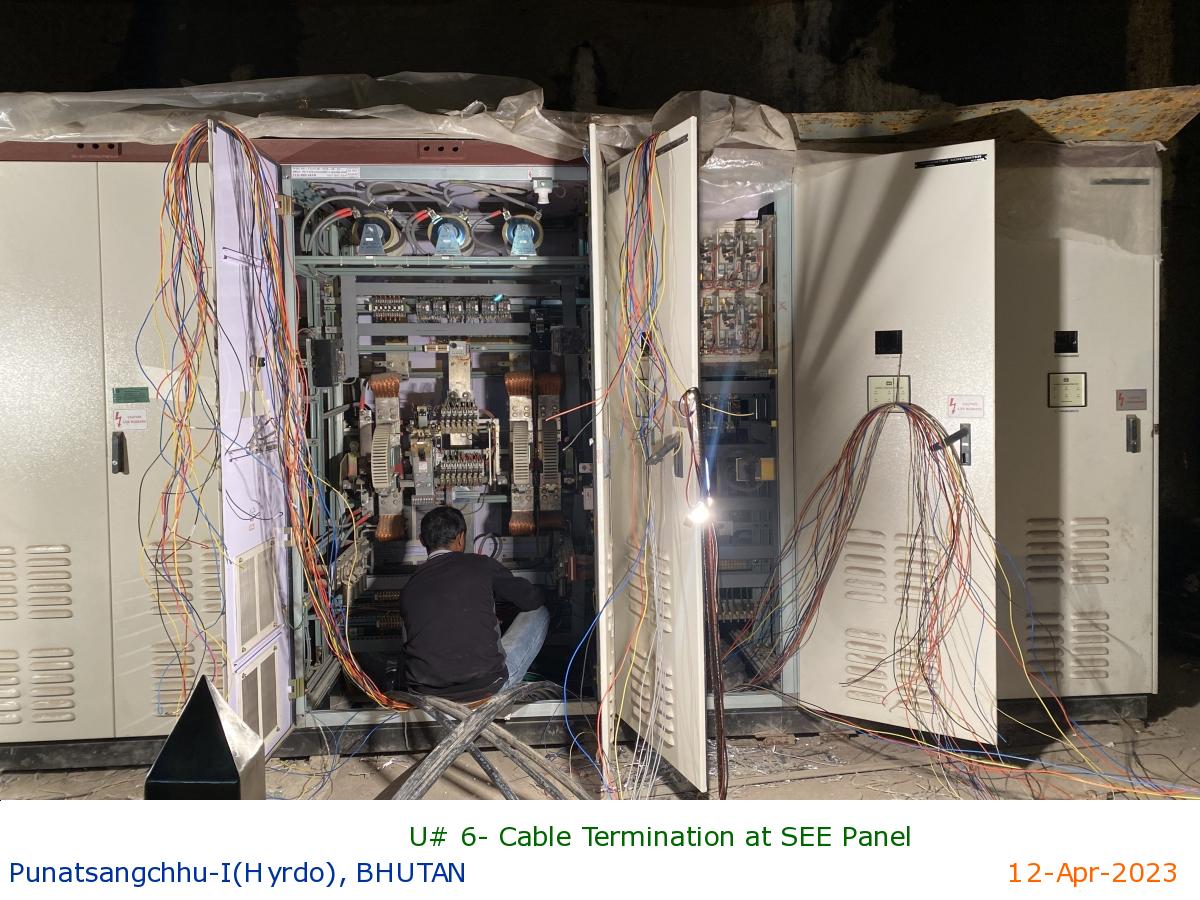

U# 6- Cable Termination at SEE Panel

|

U# 6- Painting of CW Pipelines

|

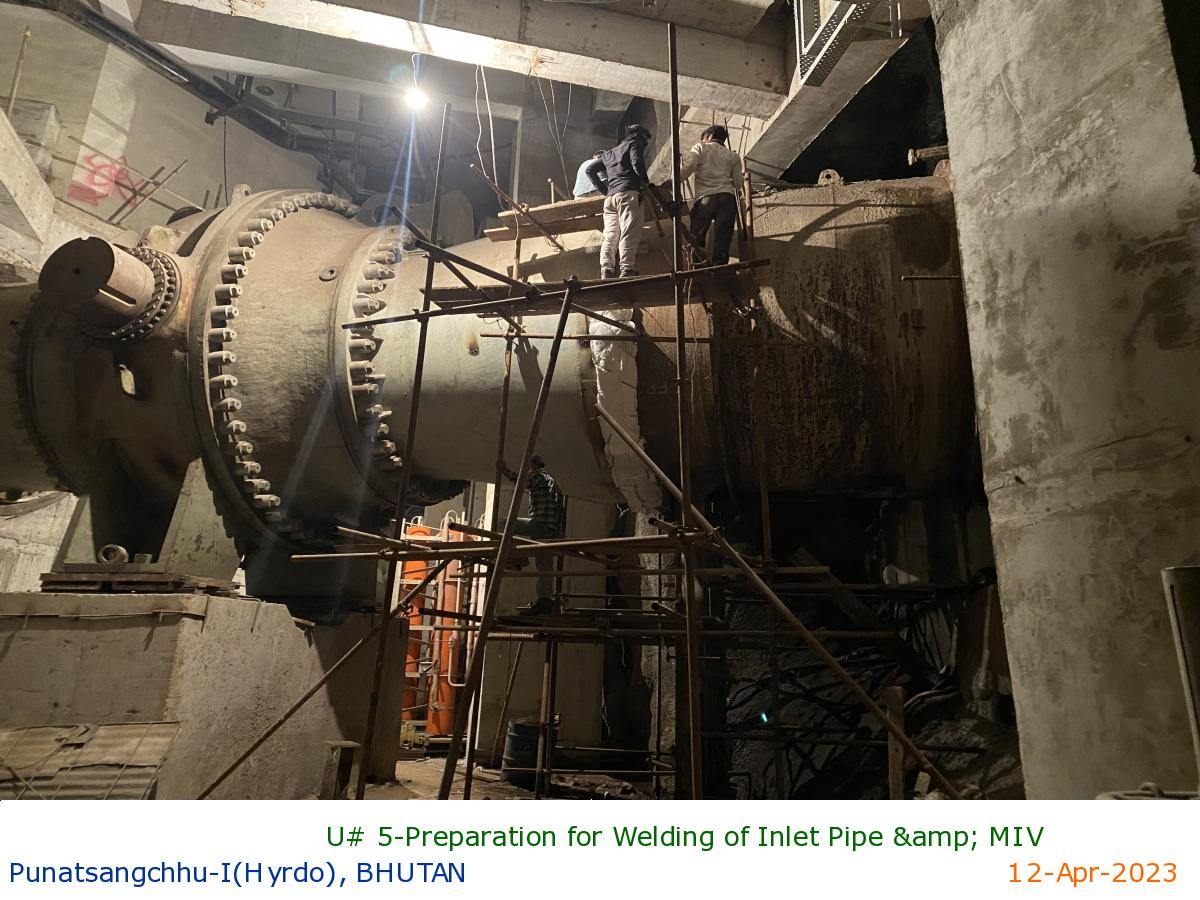

U# 5-Preparation for Welding of Inlet Pipe & MIV

|

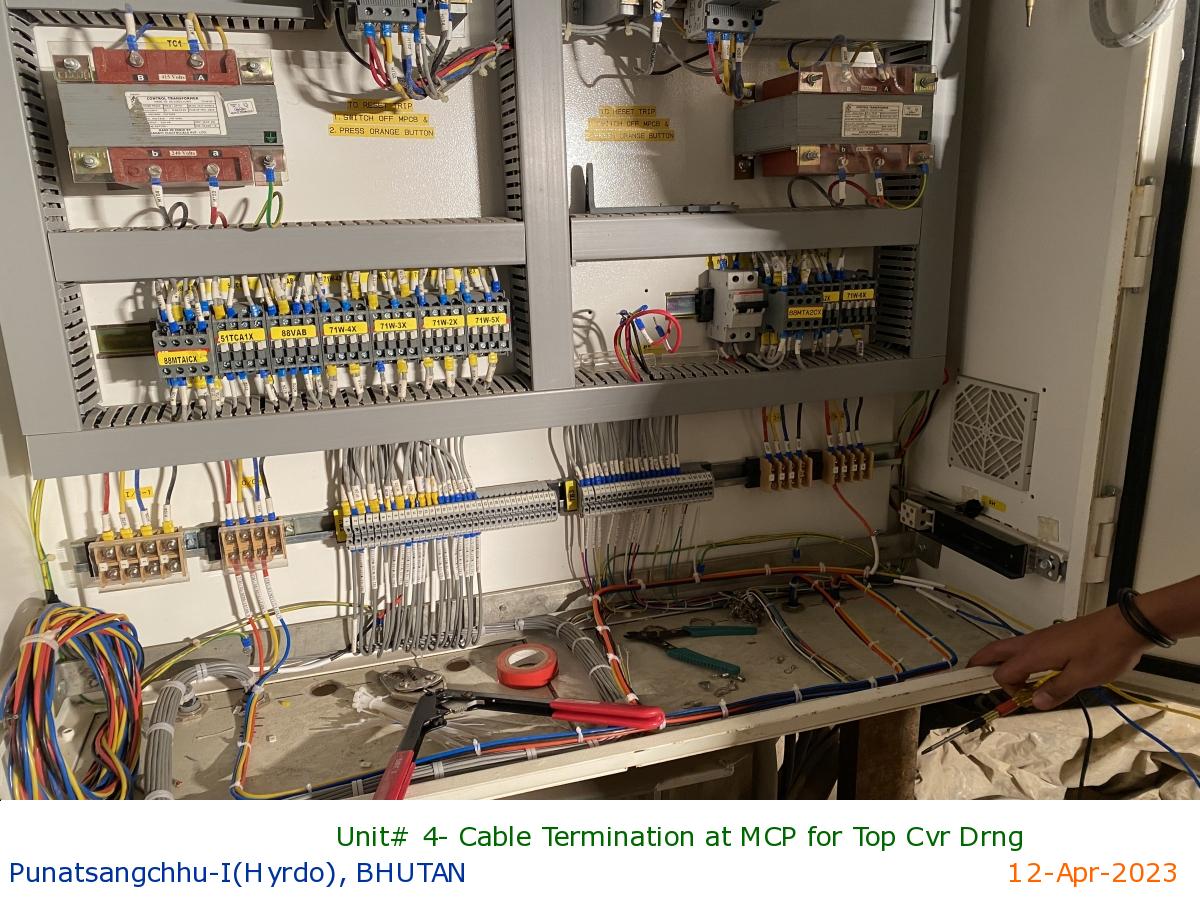

Unit# 4- Cable Termination at MCP for Top Cvr Drng

|

Unit# 4- Cable Termination of Governor OPU Pump

|

Unit# 3- Erection of Cable Trays below Turbine Flr

|

Unit#1: Pressure Test of Field Efficiency Pipeline

|

Unit# 3- Erection of Drain Pipelines of MIV

|

Unit-2: Motor Alignment of CW Pump

|

Unit# 1- Cable Glanding at RTU-GF

|

Unit#6- Cable Termination at SEE Panel

|

Unit#6- Painting of CW Pipelines

|

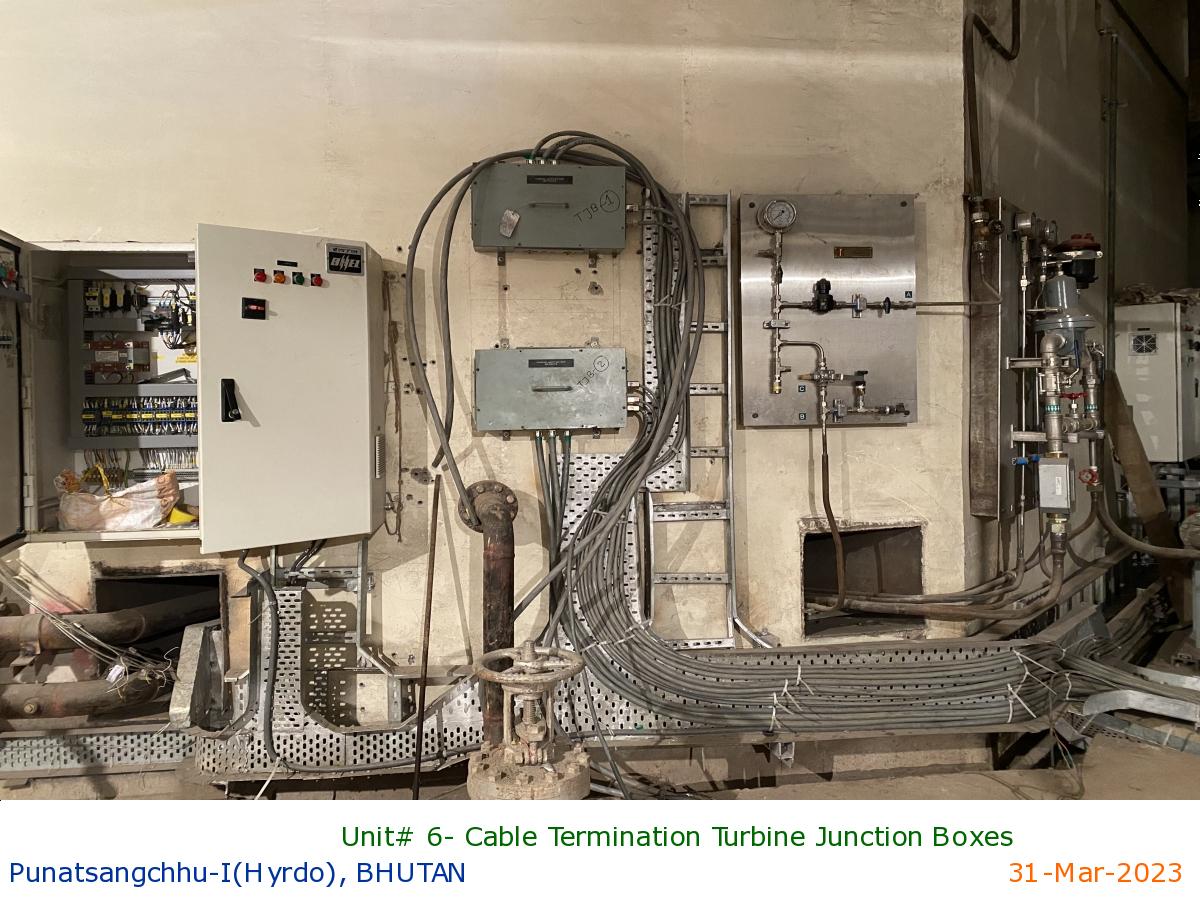

Unit# 6- Cable Termination Turbine Junction Boxes

|

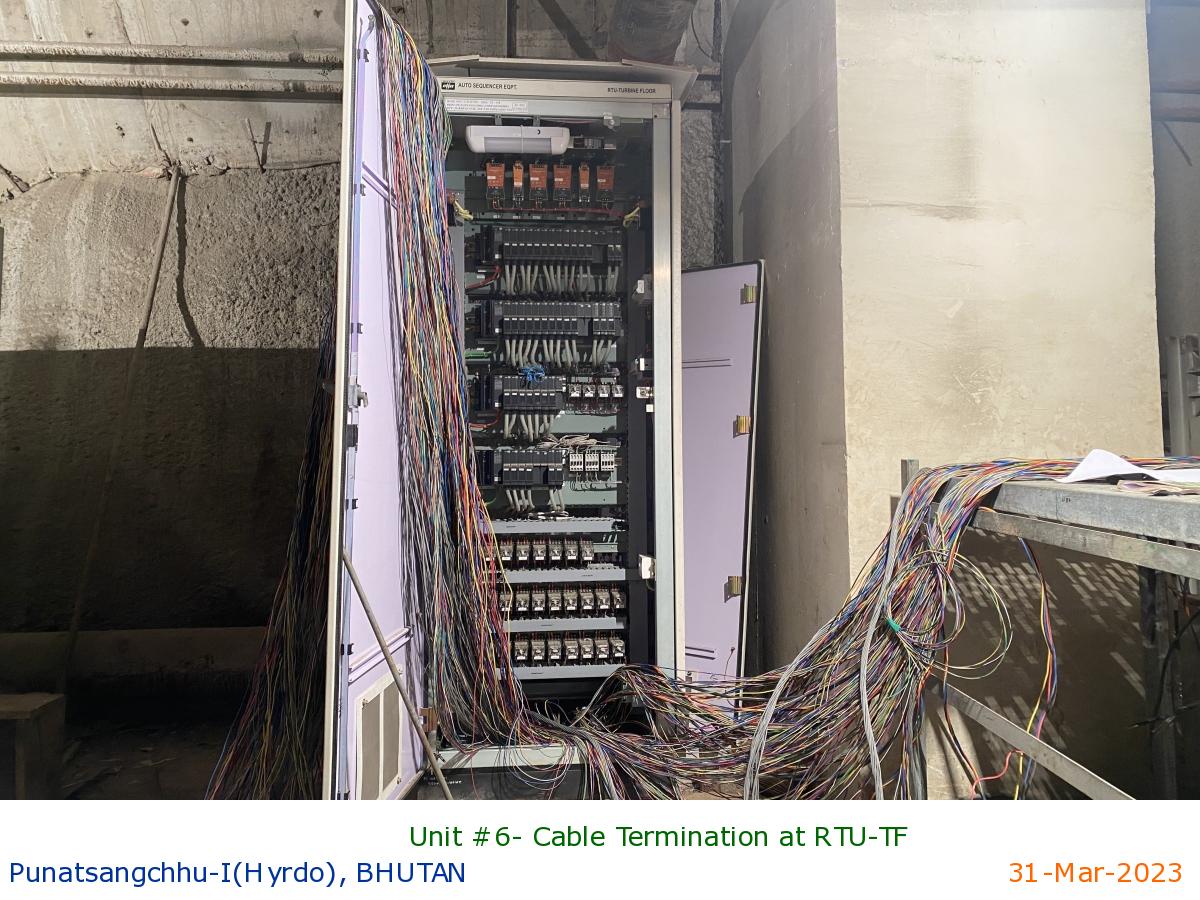

Unit #6- Cable Termination at RTU-TF

|

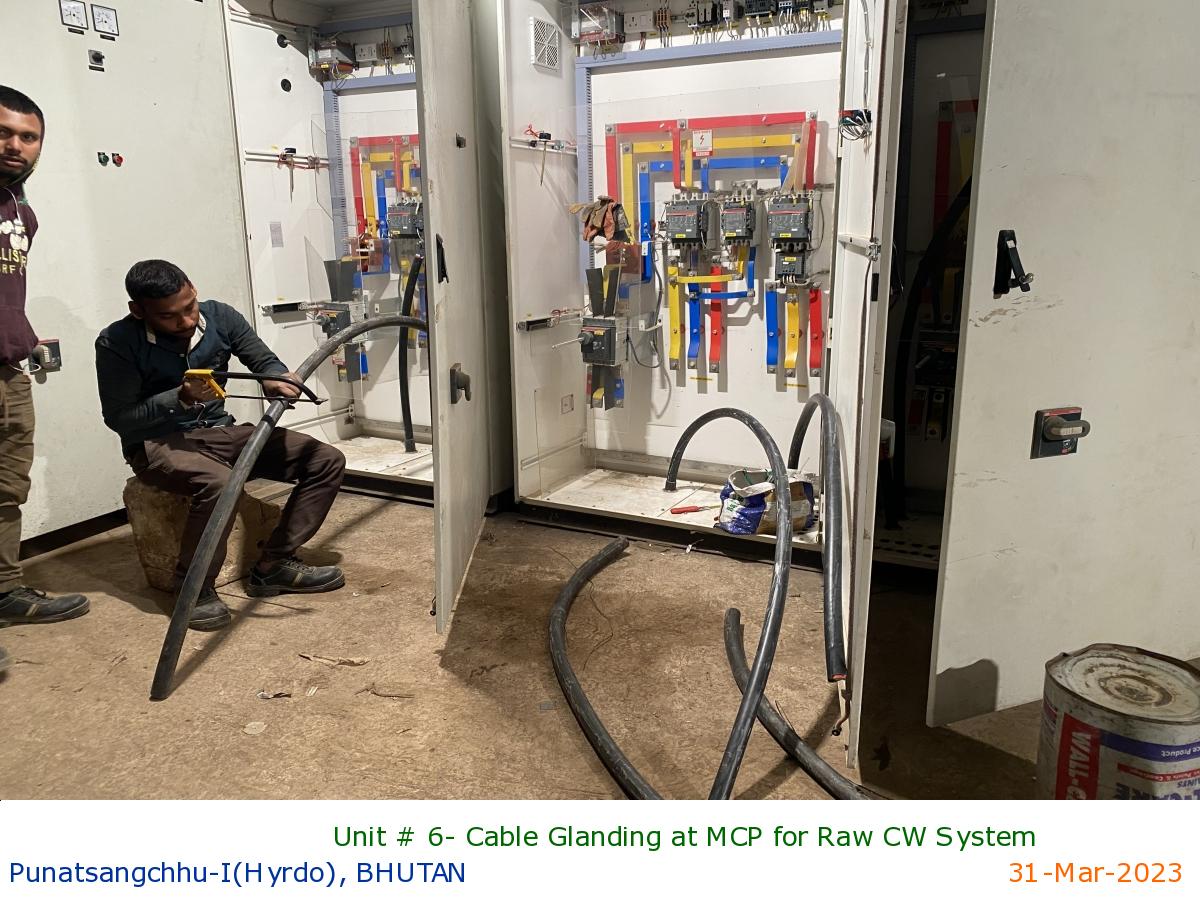

Unit # 6- Cable Glanding at MCP for Raw CW System

|

Unit # 4- Painting of CW Pipelines

|

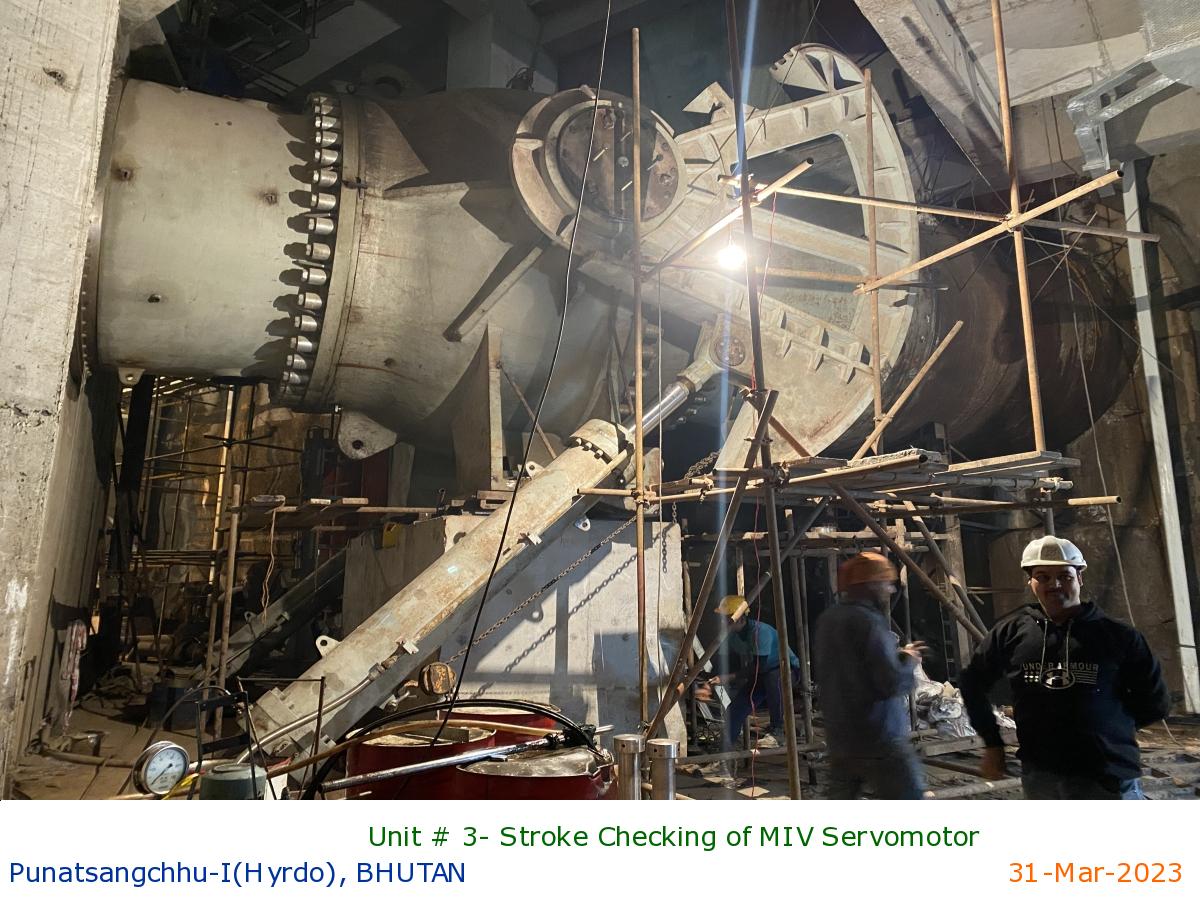

Unit # 3- Stroke Checking of MIV Servomotor

|

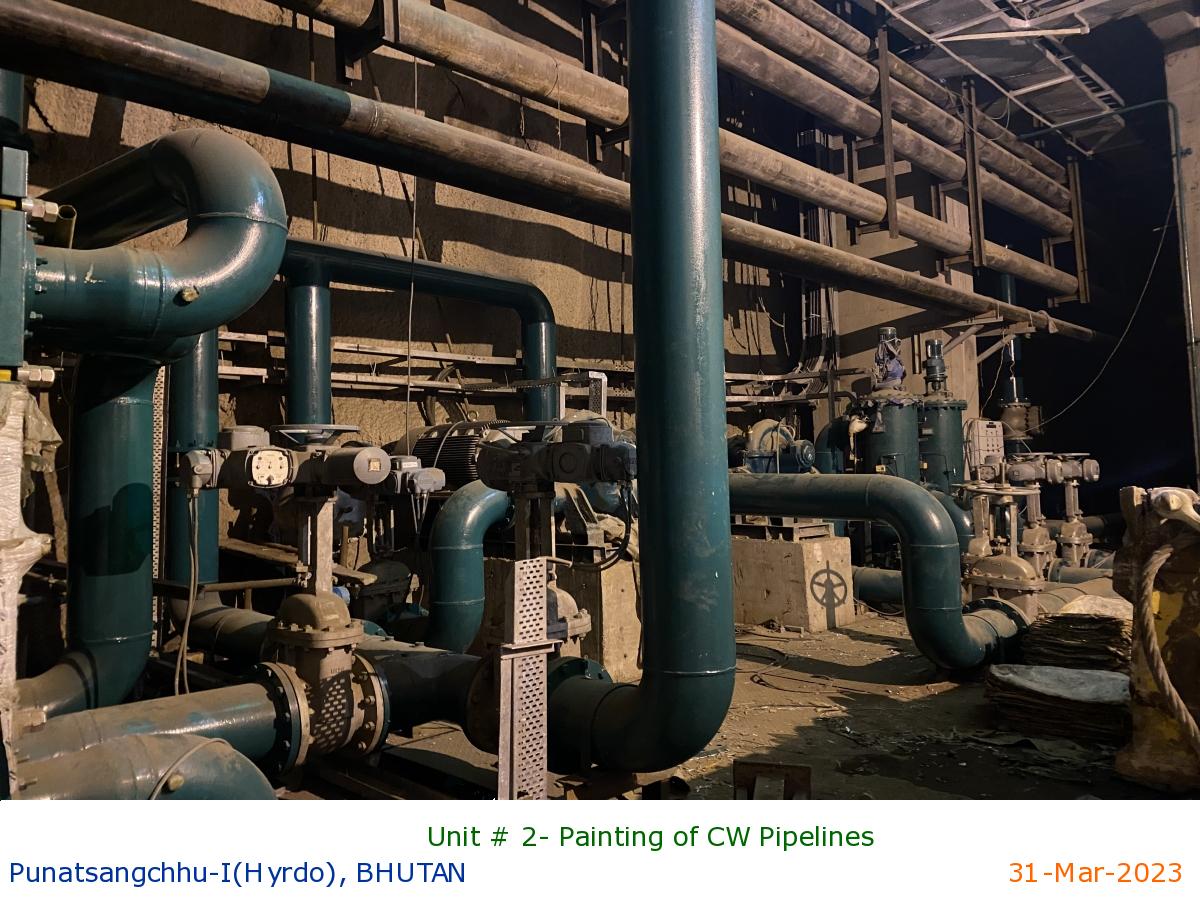

Unit # 2- Painting of CW Pipelines

|

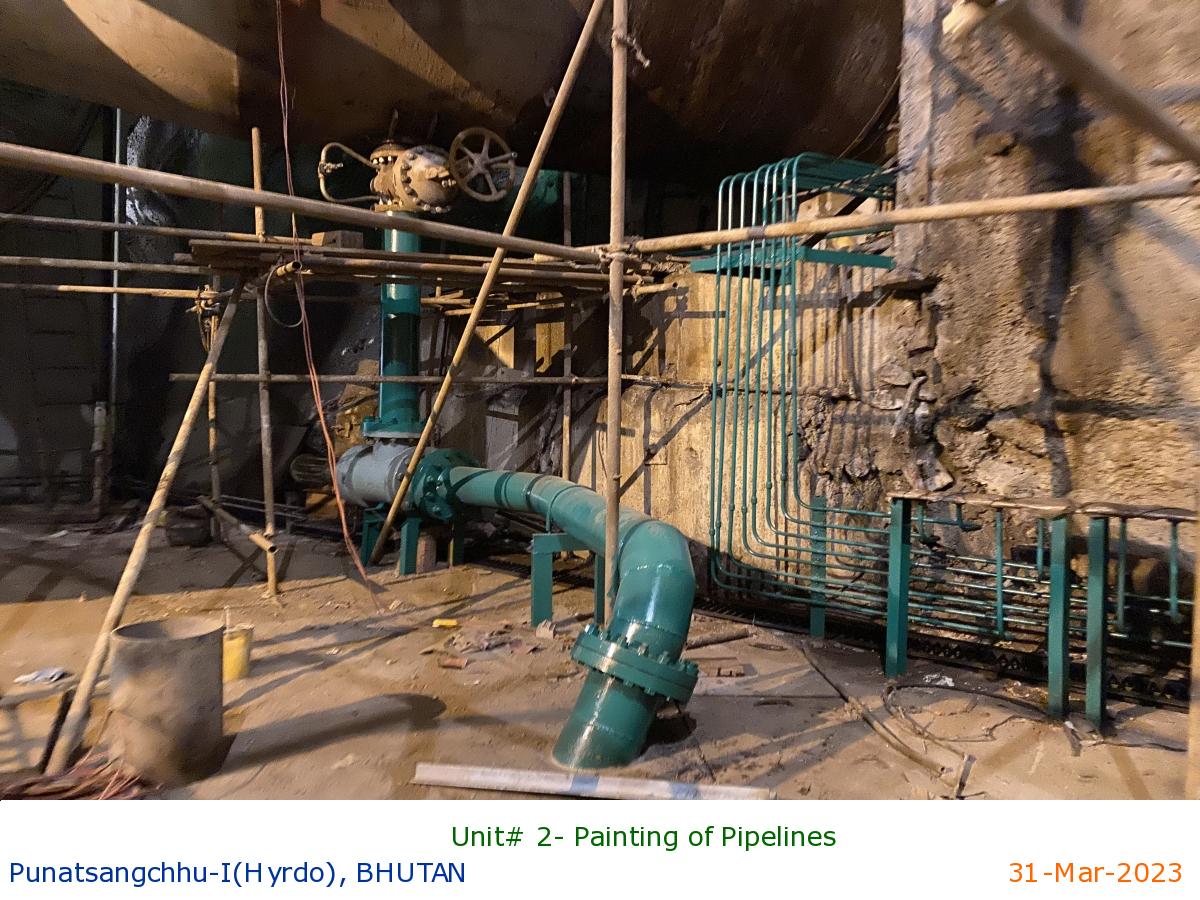

Unit# 2- Painting of Pipelines

|

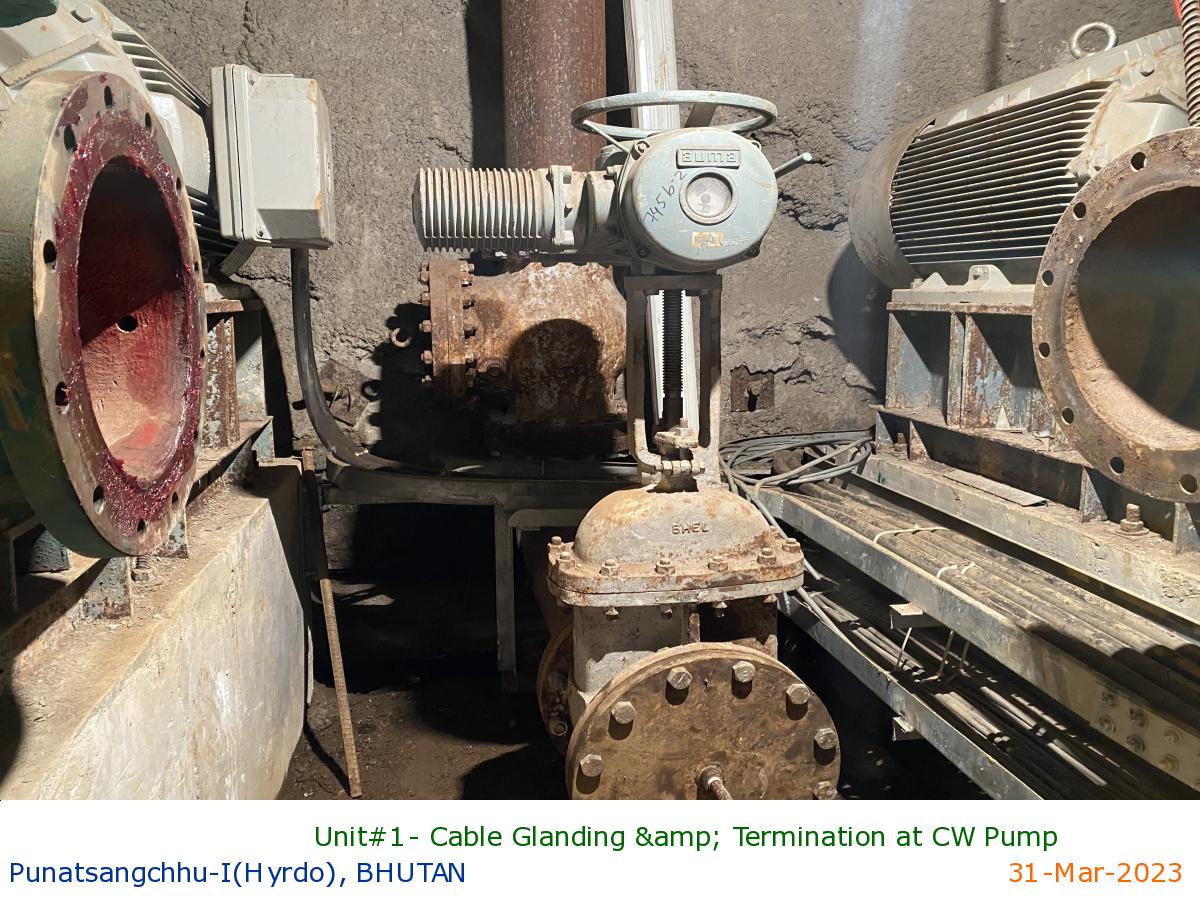

Unit#1- Cable Glanding & Termination at CW Pump

|

Unit#1- Clamping of CW Water Pipelines

|

Unit# 1- Cable Termination @RTU-Trubine Floor

|

U#2:- Penstock Drain Valve and Pipe Assy.

|

U#4:- Painting of CW Water Pipe Lines

|

U#4:- Painting of MIV Oil Pipe lines

|

U#2:- Painting of Oil & Water Pipes (Turbine Pit)

|

View of Machine Hall as seen from S/B Area.

|

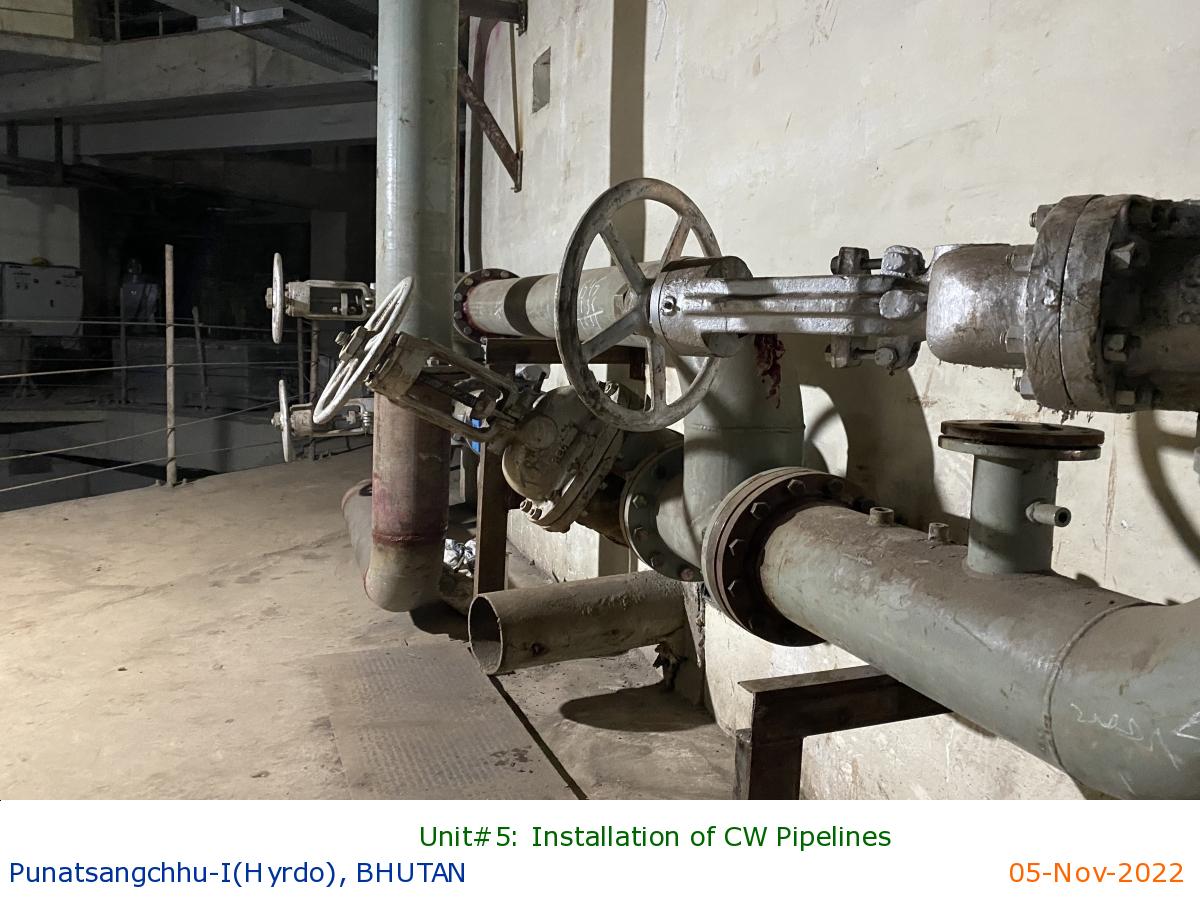

Unit#5: Installation of CW Pipelines

|

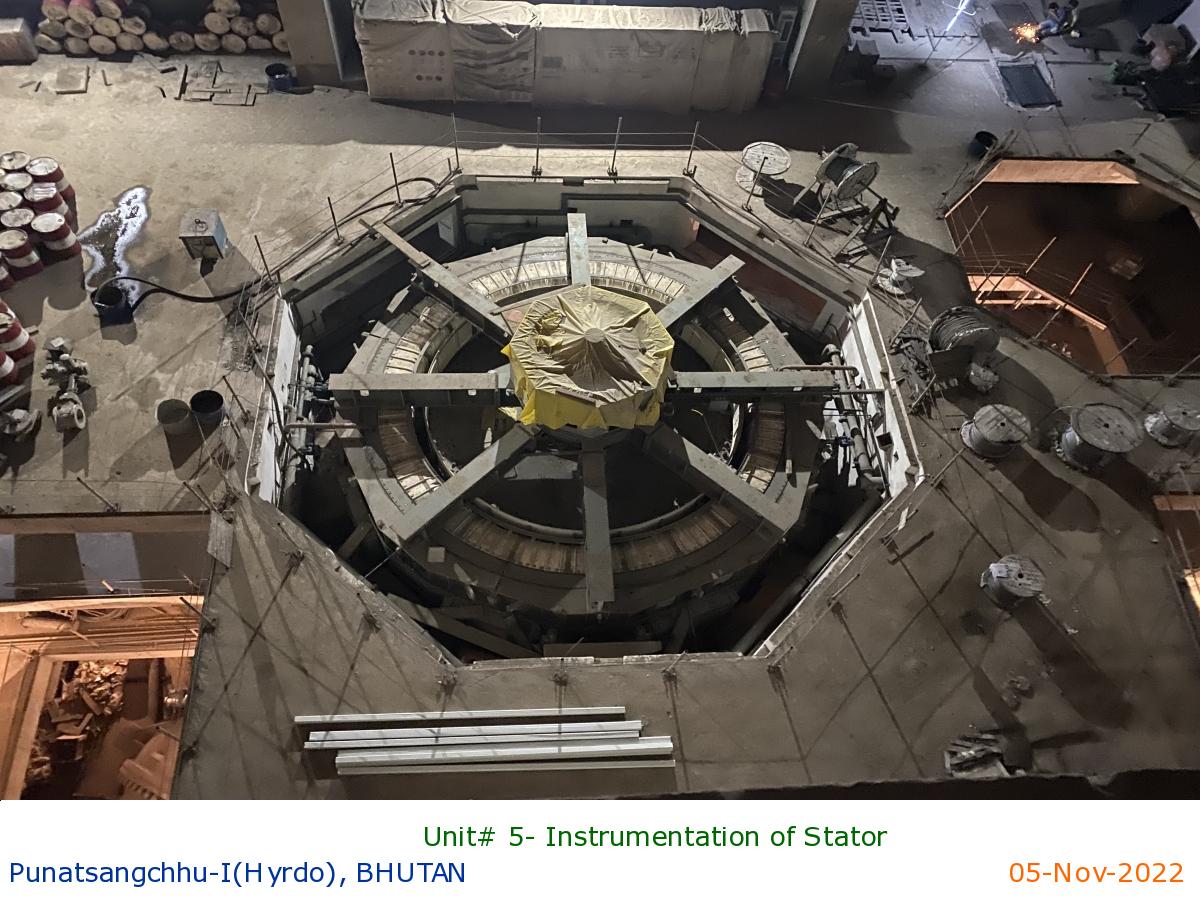

Unit# 5- Instrumentation of Stator

|

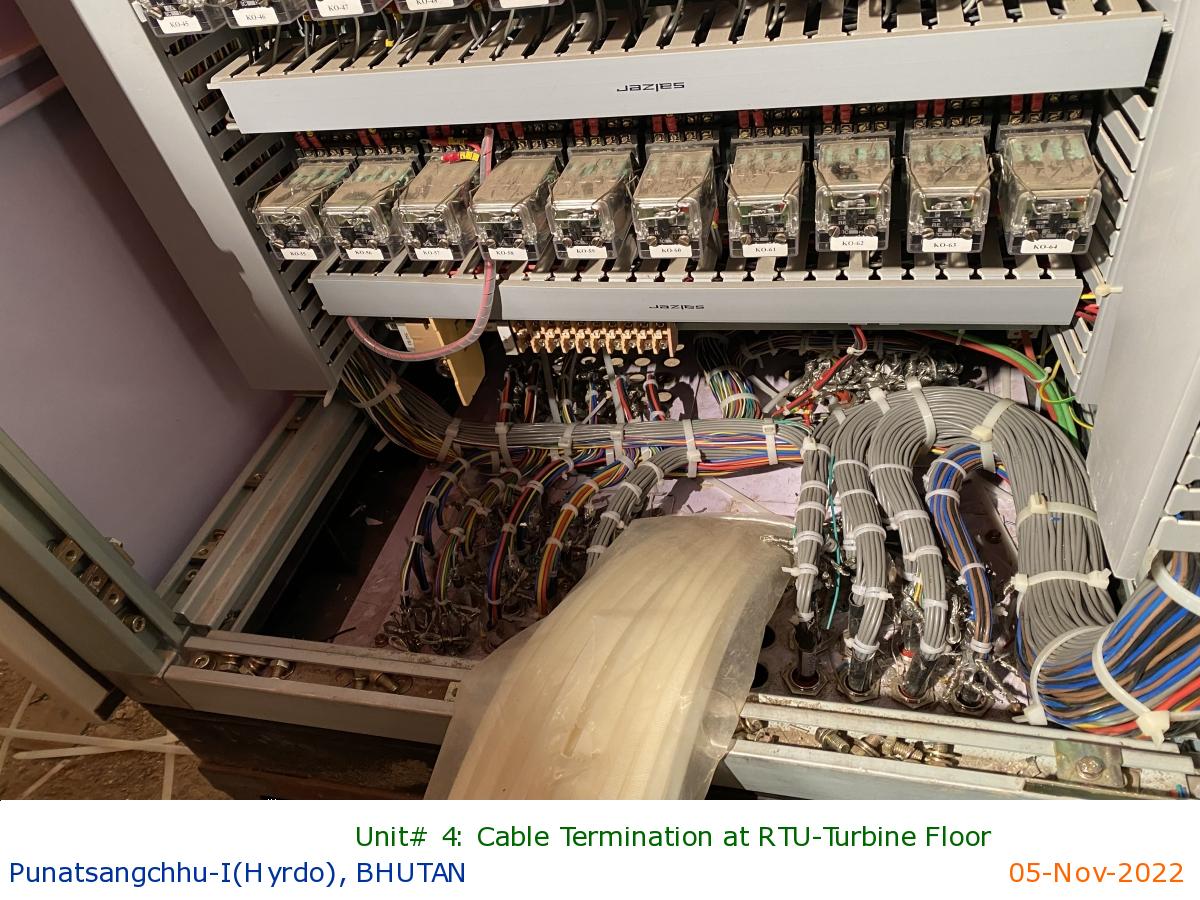

Unit# 4: Cable Termination at RTU-Turbine Floor

|

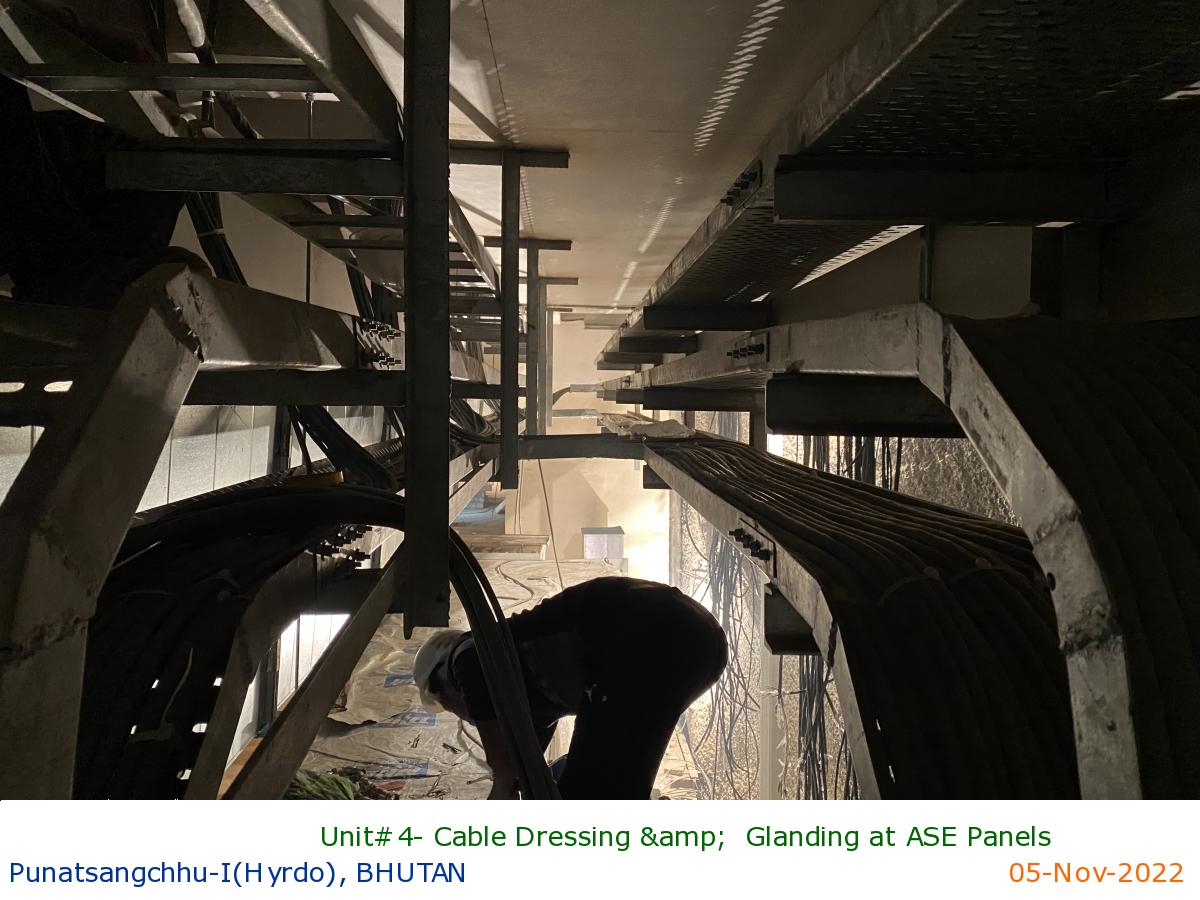

Unit#4- Cable Dressing & Glanding at ASE Panels

|

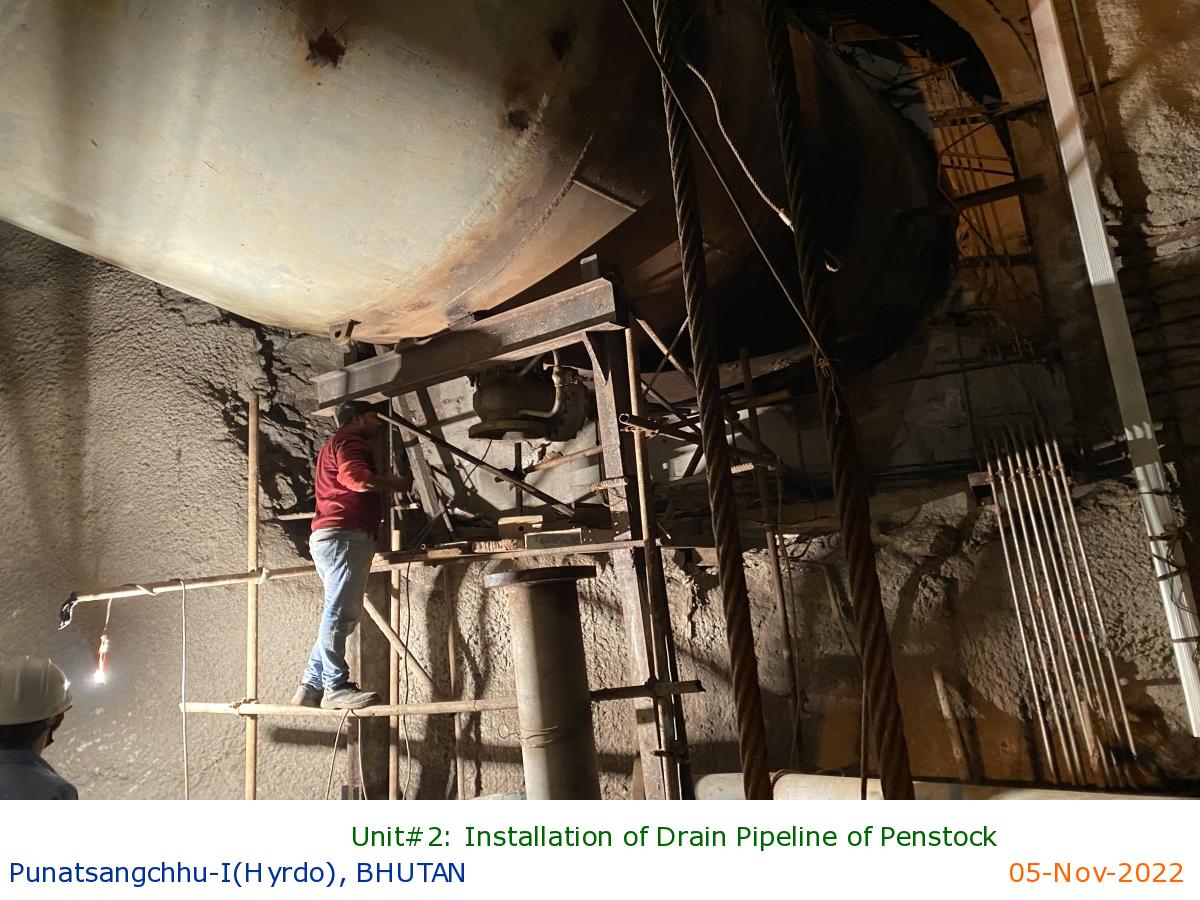

Unit#2: Installation of Drain Pipeline of Penstock

|

Unit# 2: Installation of N2 Pipelines of MIV

|

Unit # 2: Erection of Cable Trays at Bus Duct Area

|

Unit#2: Cable Glanding & Termination at GMB

|

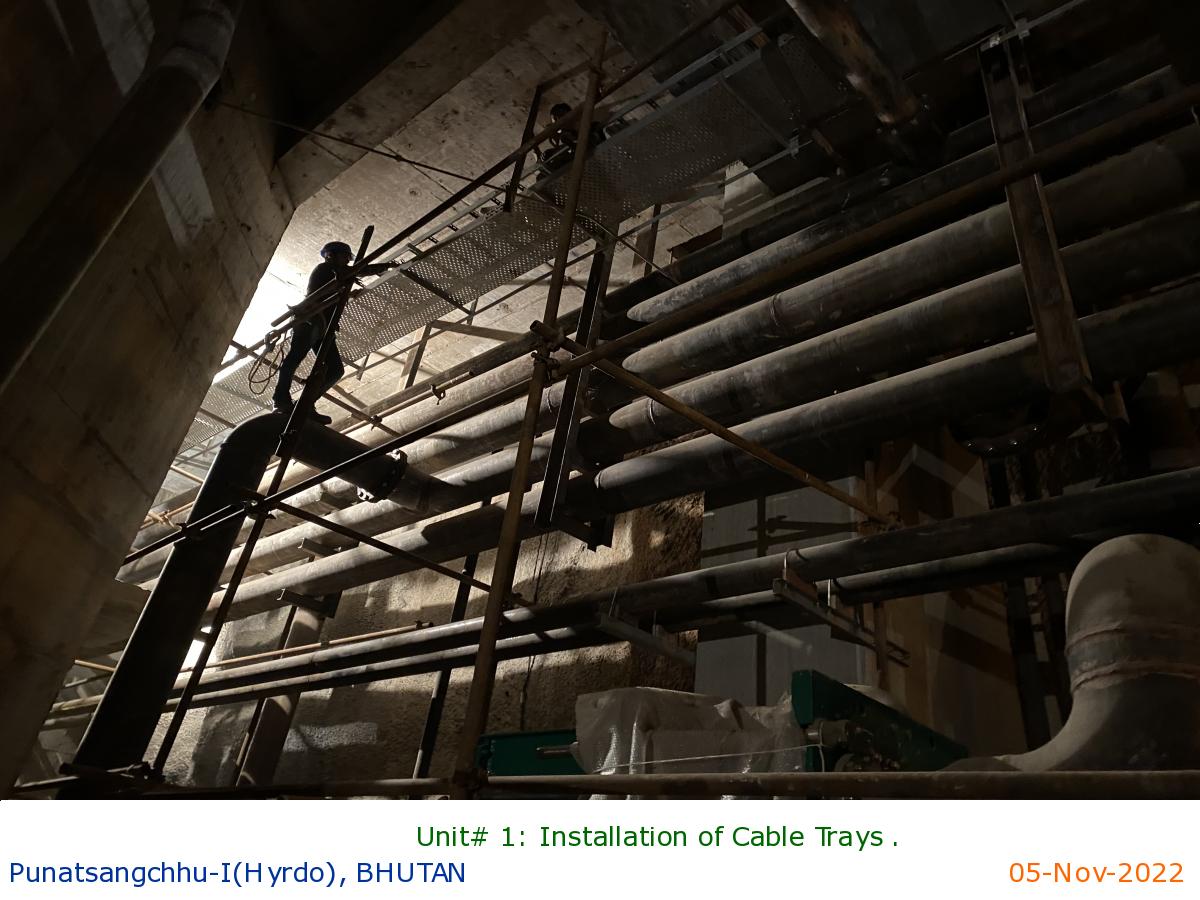

Unit# 1: Installation of Cable Trays .

|

Unit# 1: Installation of Cable Trays .

|

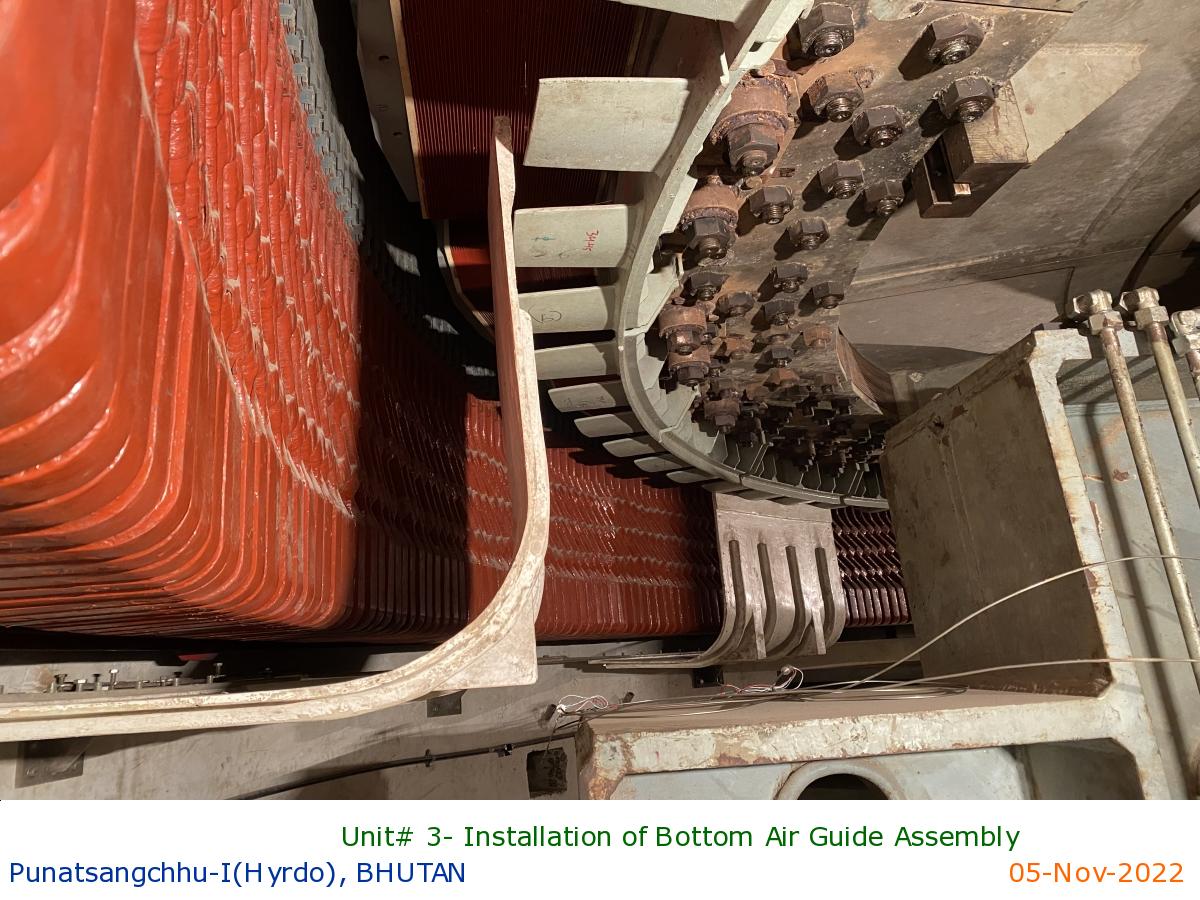

Unit# 3- Installation of Bottom Air Guide Assembly

|

Unit# 3- Erection of TGB Coolers CW Pipelines.

|

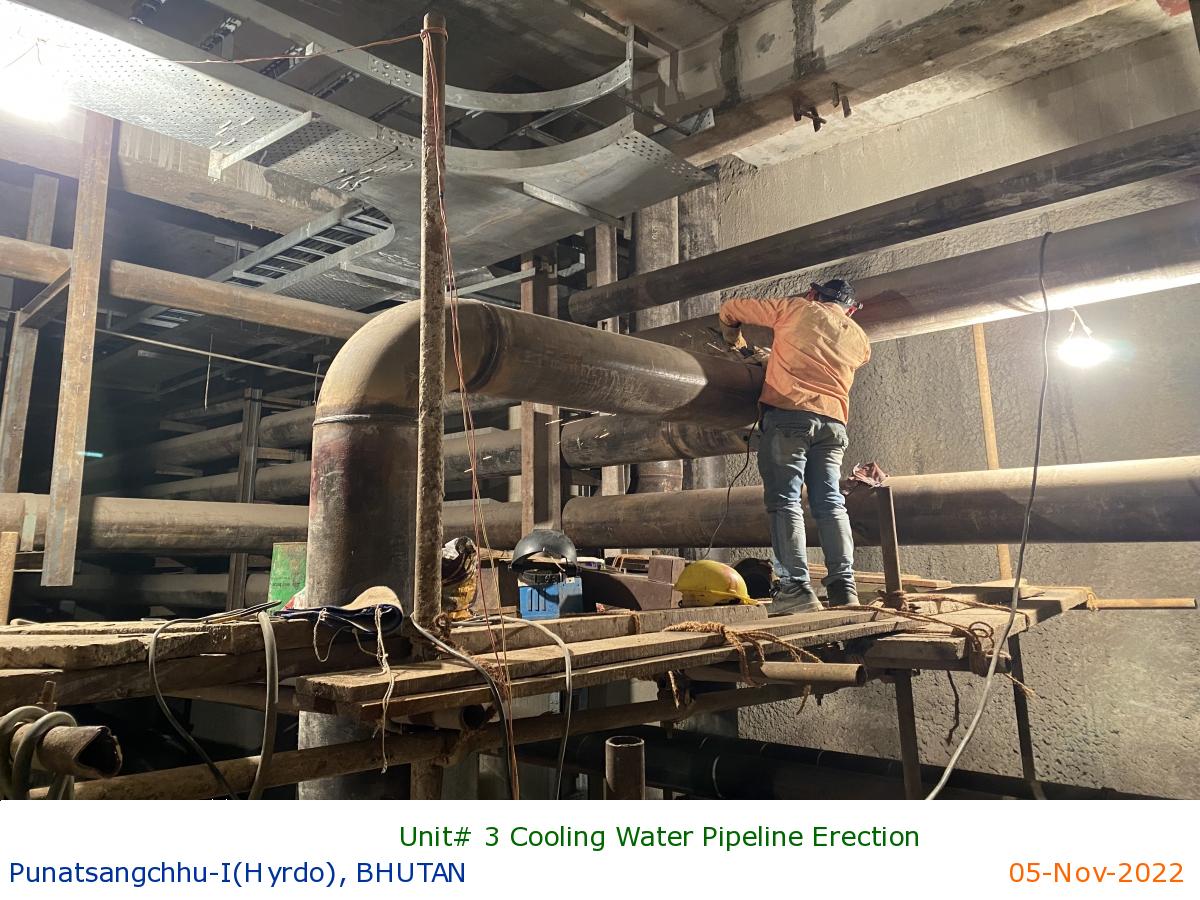

Unit# 3 Cooling Water Pipeline Erection

|

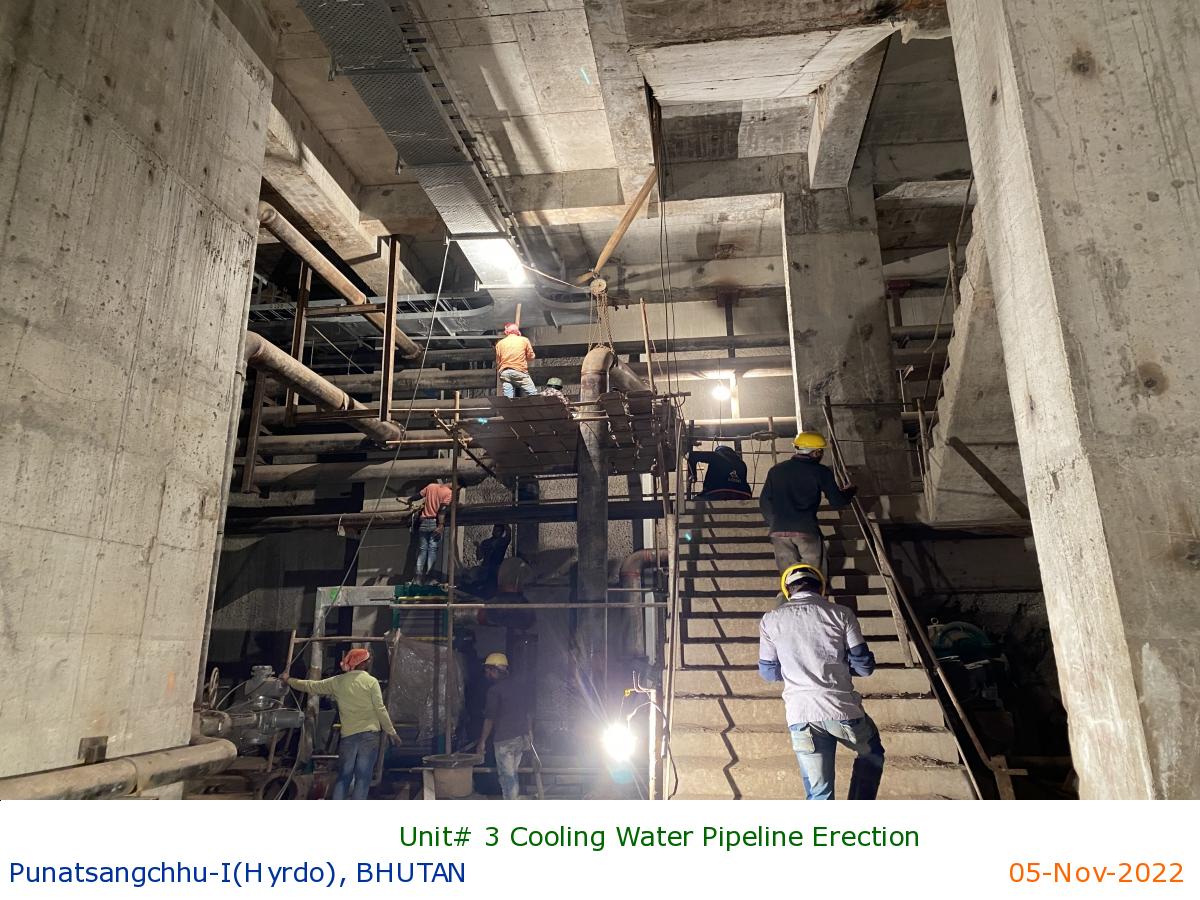

Unit# 3 Cooling Water Pipeline Erection

|

Pre-Erection Test of Dry Type Transformer in BD-2

|

Unit#5: Oil Filling of LGB under progress.

|

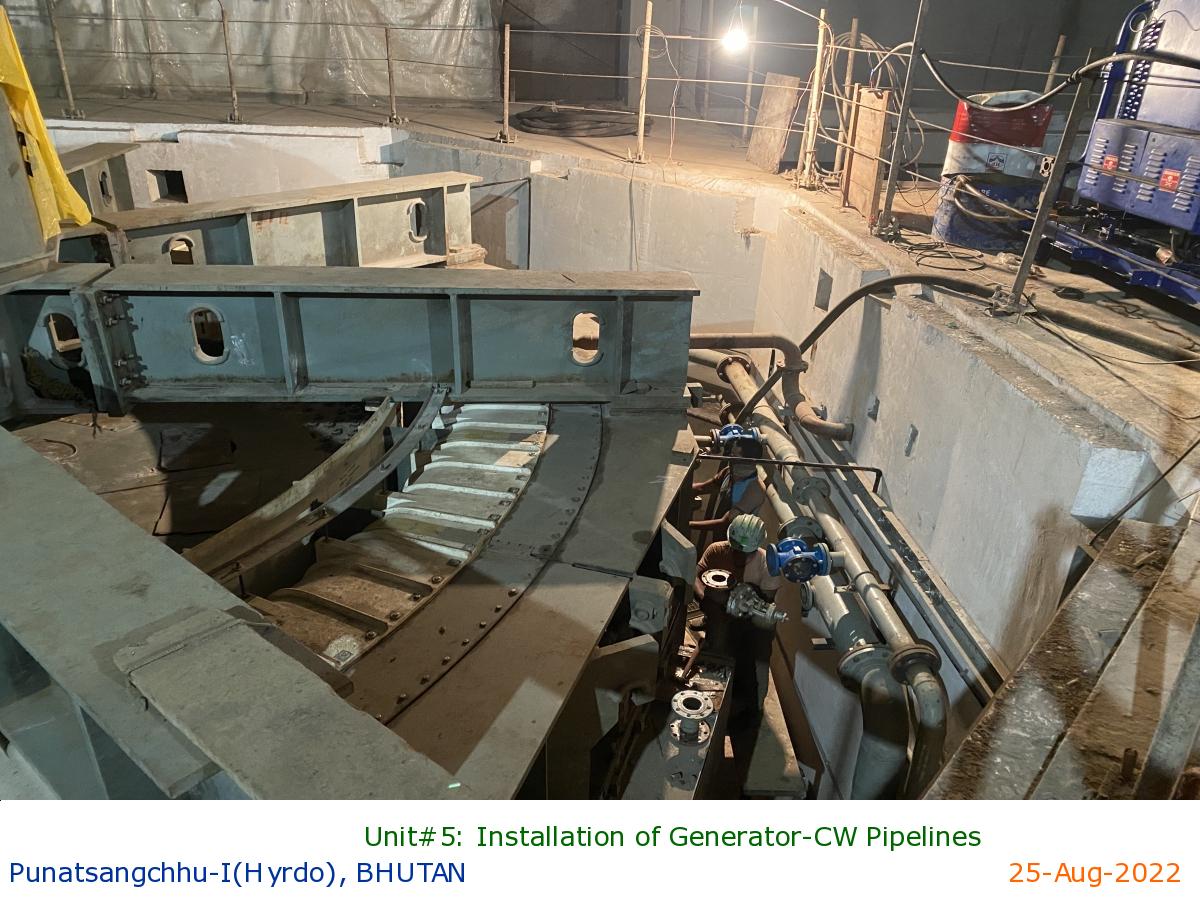

Unit#5: Installation of Generator-CW Pipelines

|

Unit #4: Cabling of UCS/ ASE

|

Unit# 2: Installation of MIV Counterwight

|

Unit # 3: Final Assy. of DT Cone

|

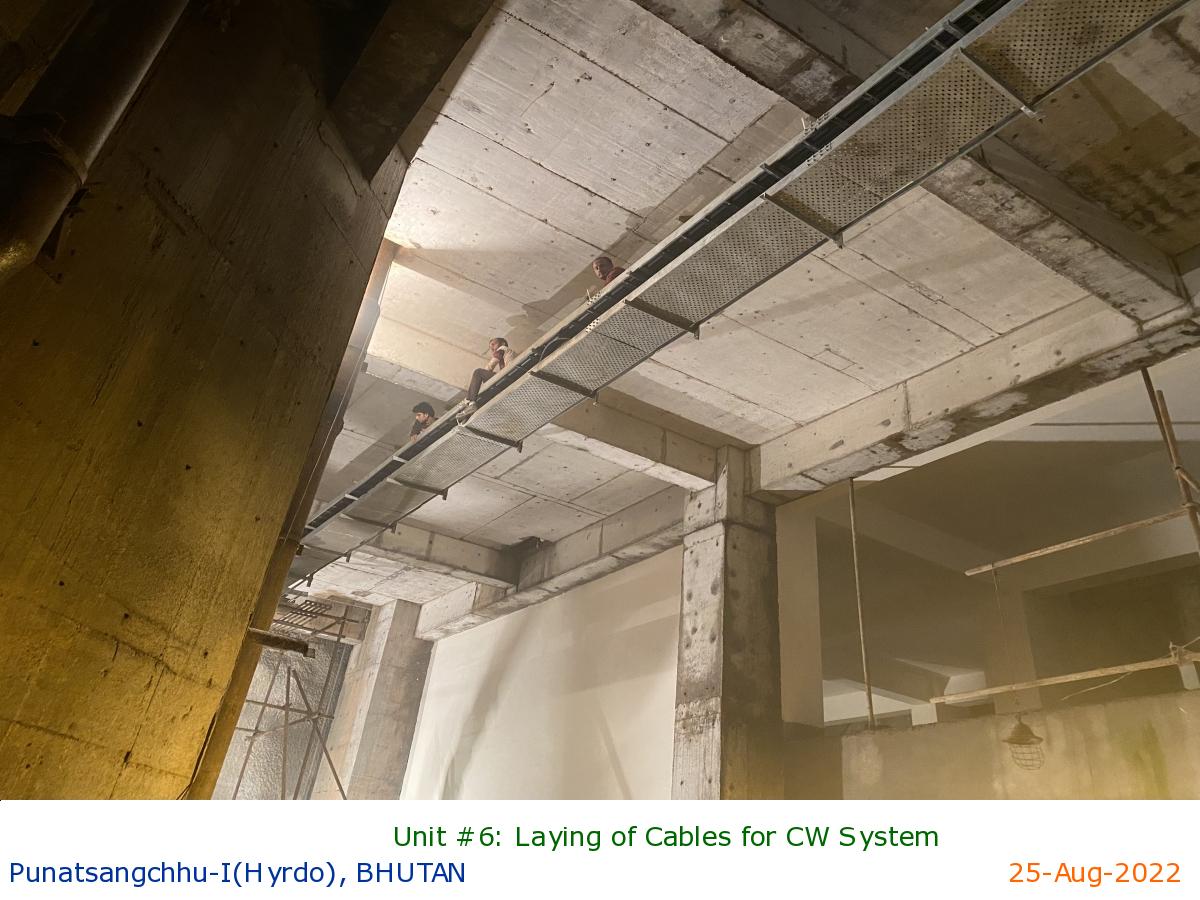

Unit #6: Laying of Cables for CW System

|

Unit#6: CW Pipelines- Clamping under progress.

|

Unit #5: Raw CW Pipelines

|

Unit#5: Regulating Ring

|

Unit# 3: Cable Tray Erection- Generator Floor

|

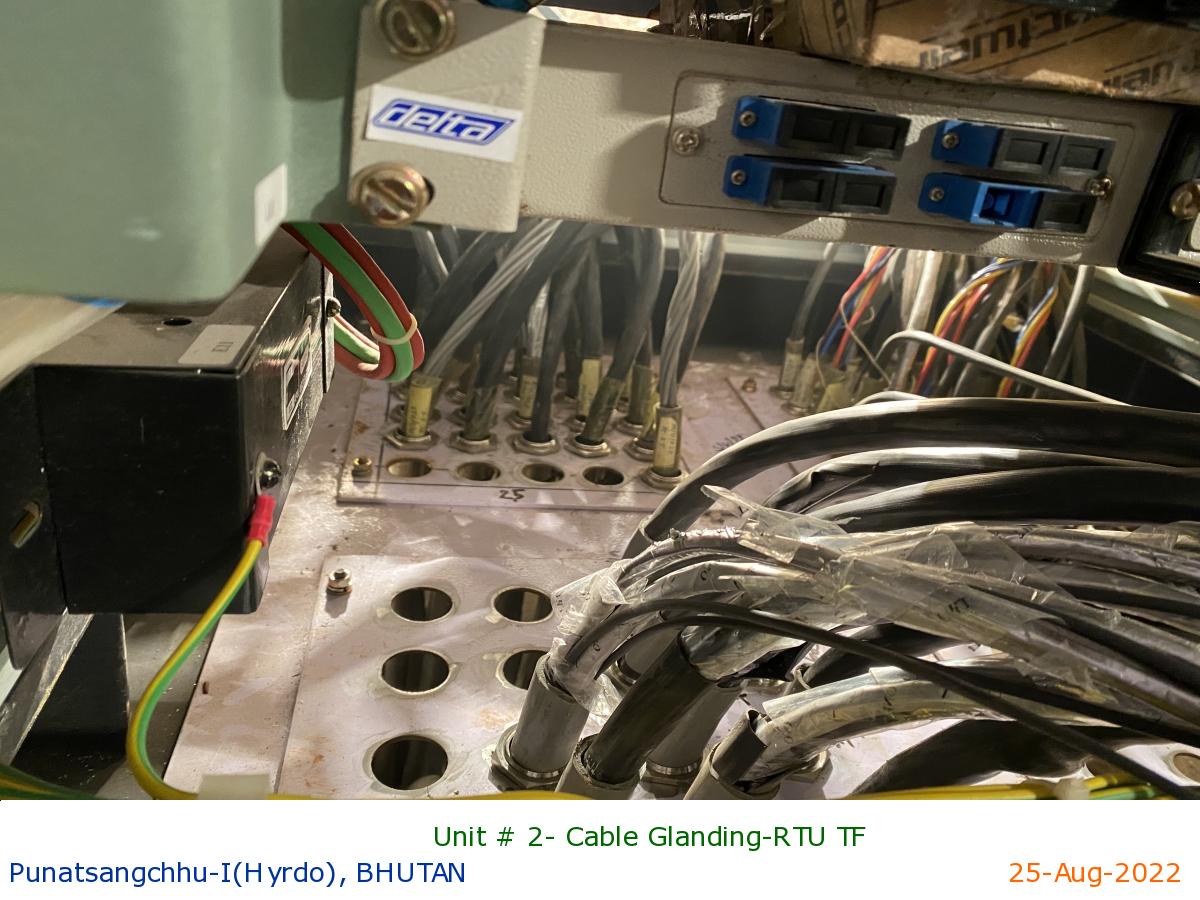

Unit # 2- Cable Glanding-RTU TF

|

Unit # 1: Instrumentation of Stator

|

Unit # 5- Installation of CW Pipelines

|

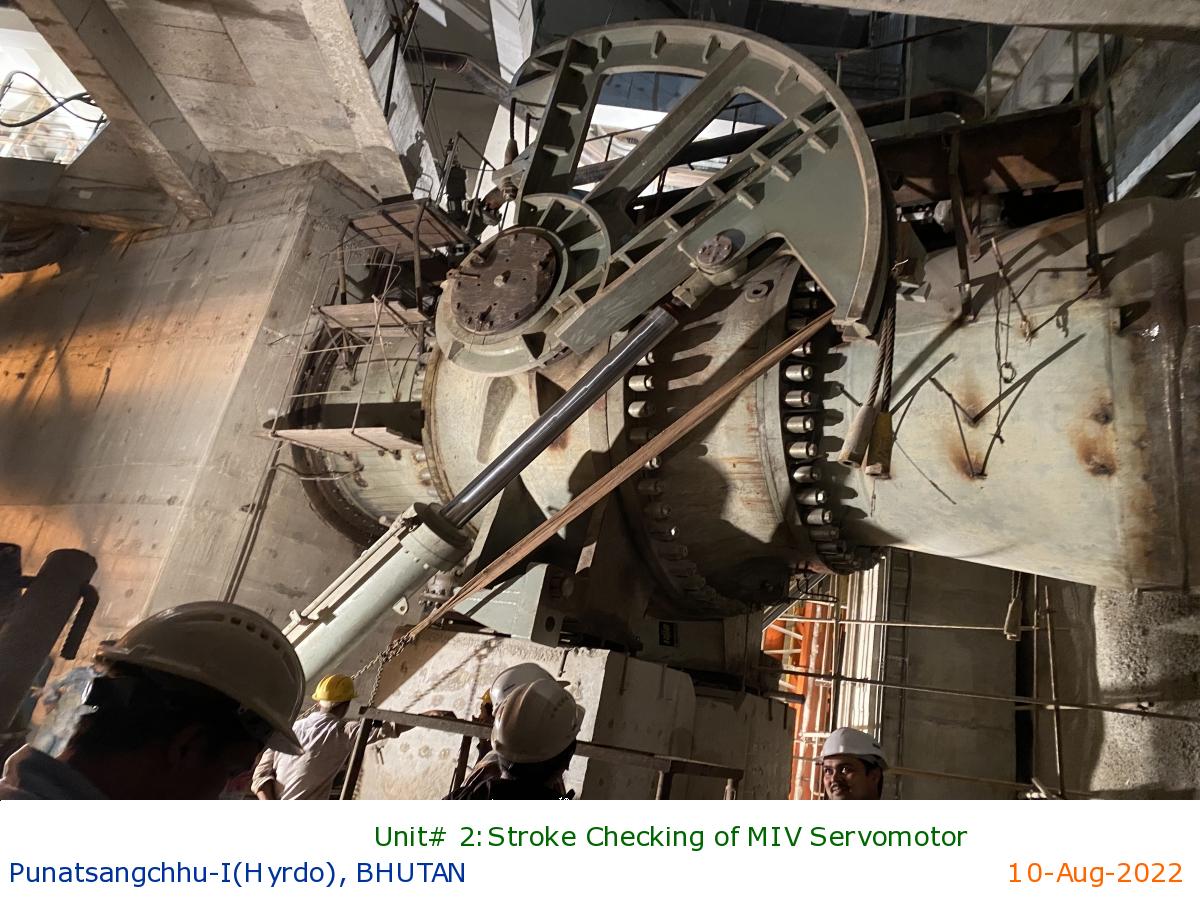

Unit# 2:Stroke Checking of MIV Servomotor

|

Unit # 5: Installation of LGB Oil Coolers

|

Unit#5: Installation of Air Guide & Air Baffle

|

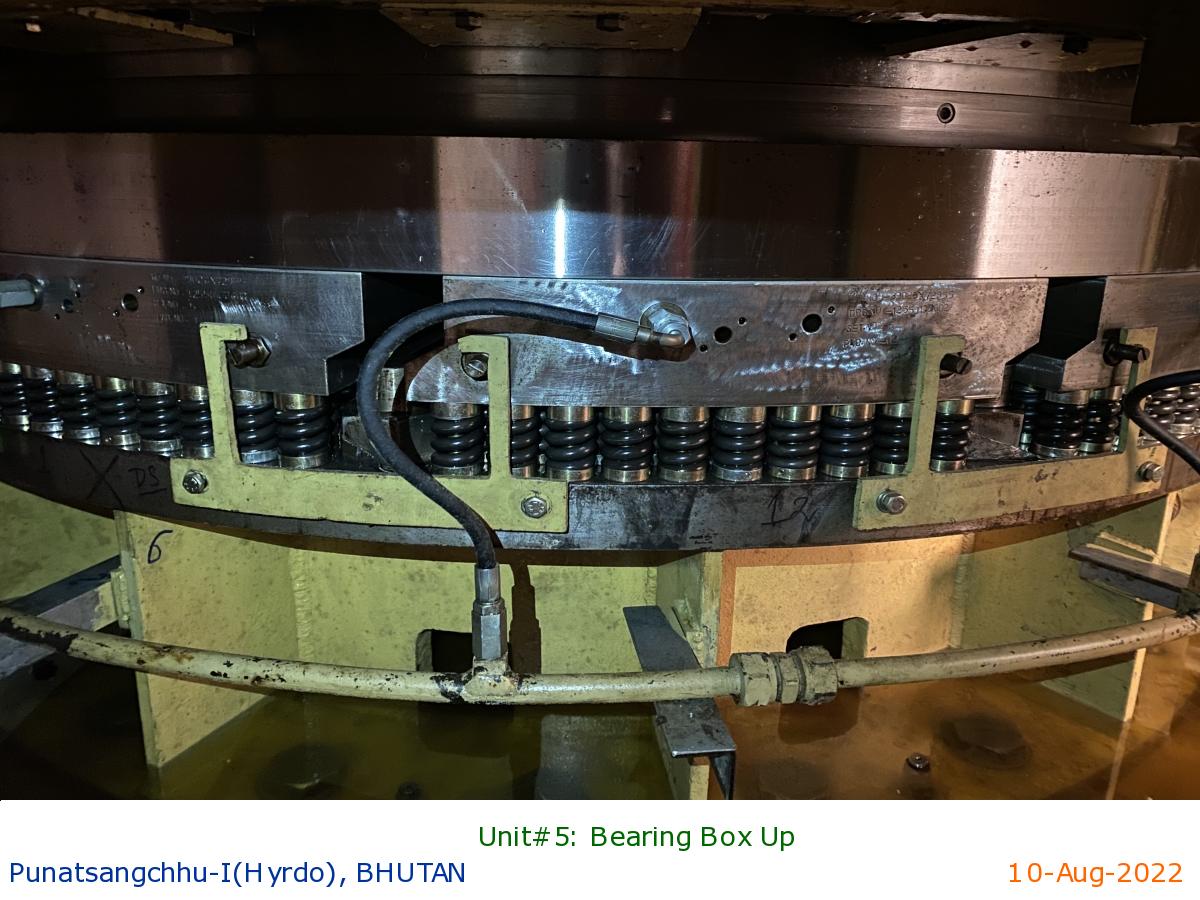

Unit#5: Bearing Box Up

|

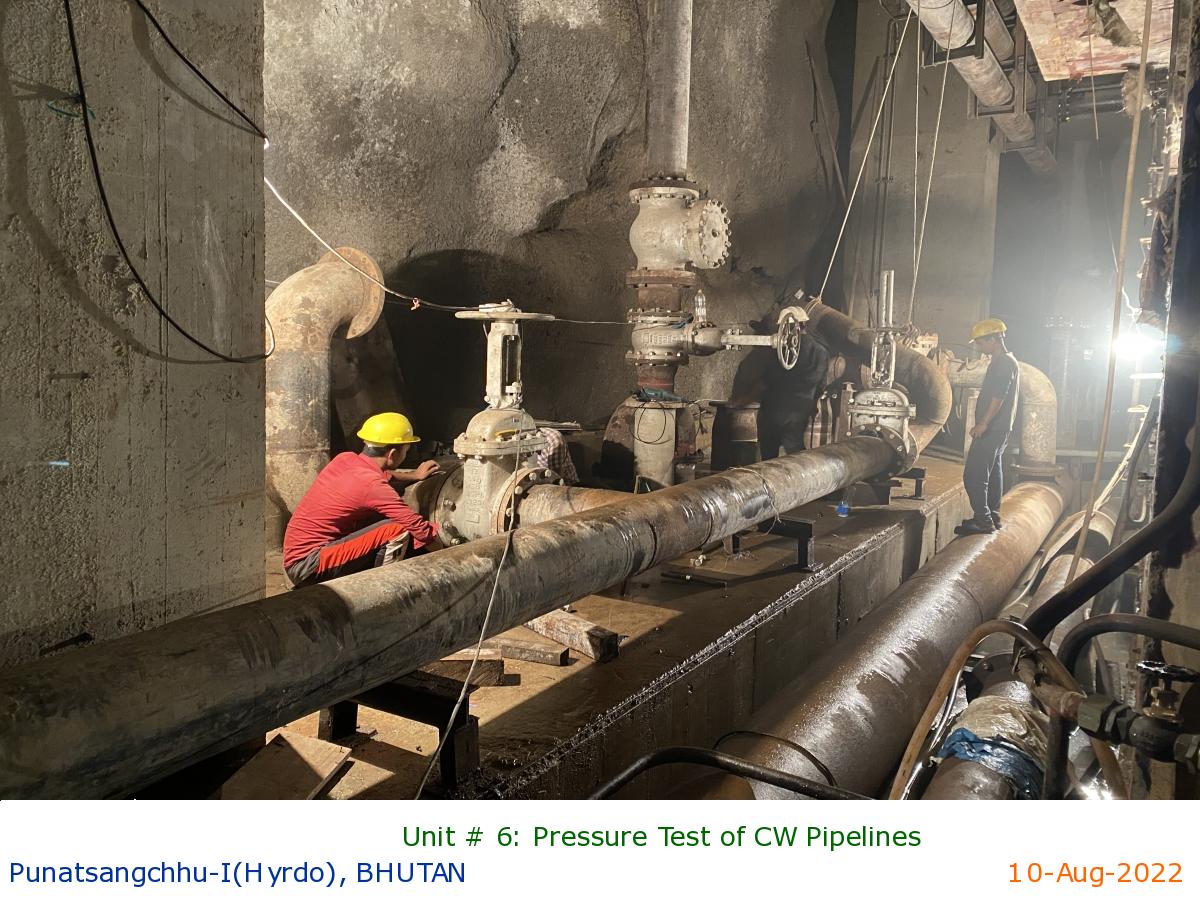

Unit # 6: Pressure Test of CW Pipelines

|

Unit #4: Laying of Cables running below Gen. Floor

|

U#2: Installation of Excitation Transformer

|

U#6: Trays for Cable Running Below MH Floor

|

Unit # 5- Lowering of Top Bracket Assy. on Stator

|

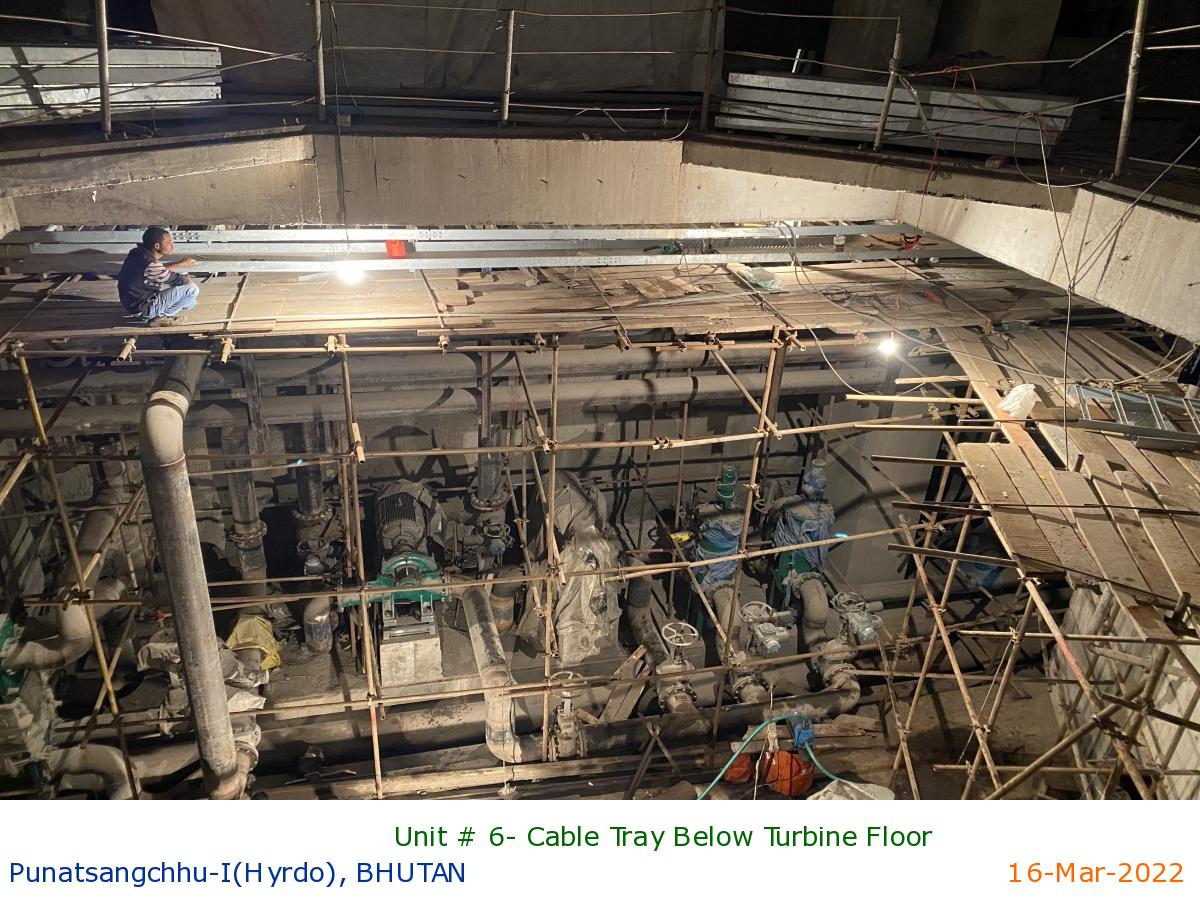

Unit # 6- Cable Tray Below Turbine Floor

|

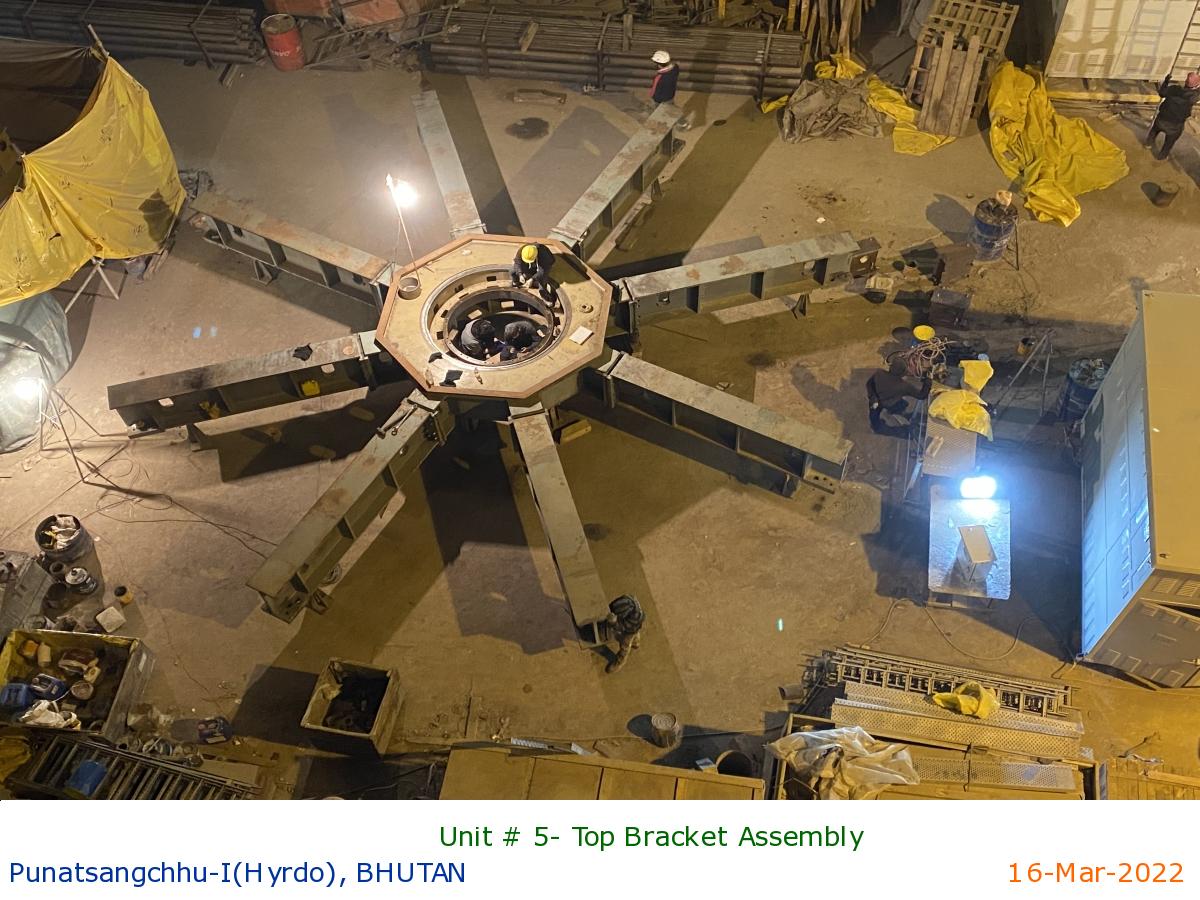

Unit # 5- Top Bracket Assembly

|

Unit # 5- Lowering Generator Top Shaft

|

Service Bay Area

|

Service Bay - Repainting of Dry Type Transformers

|

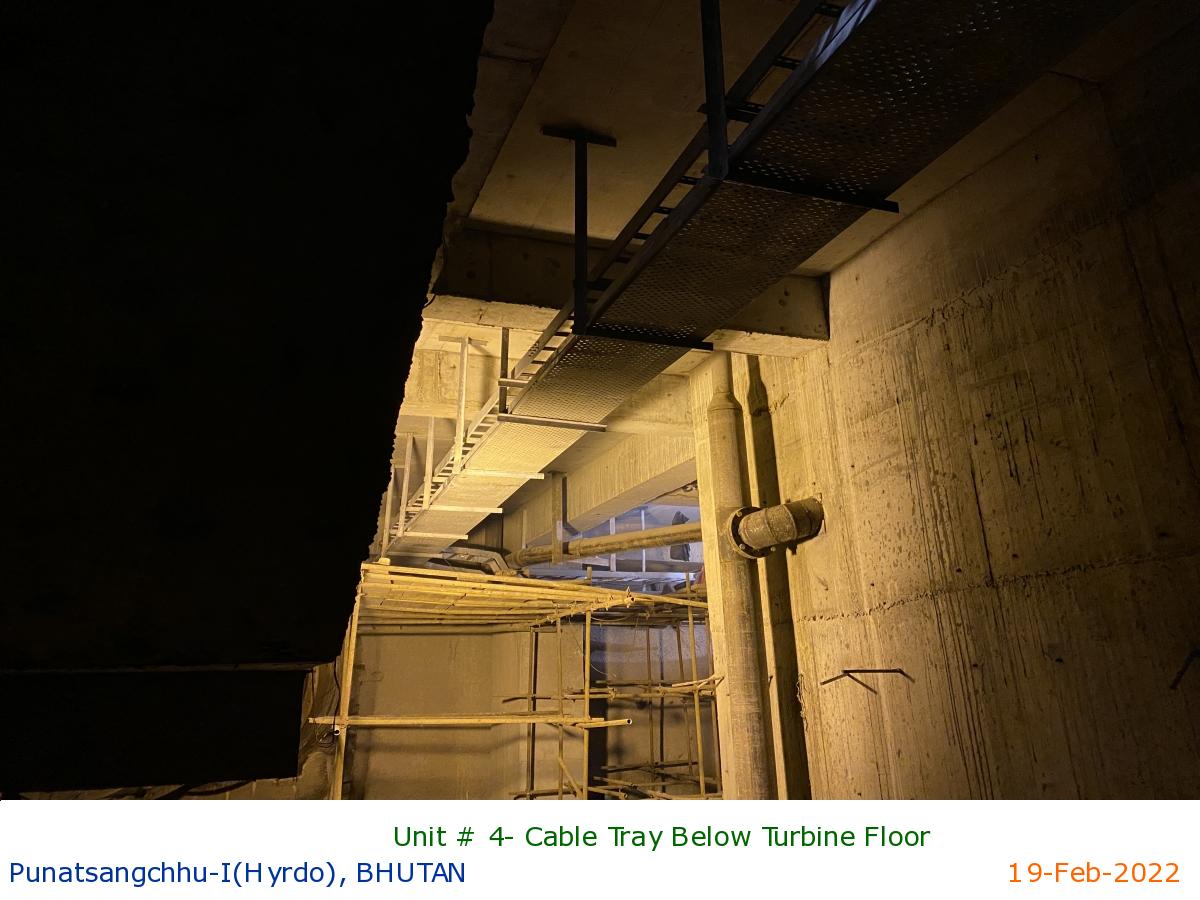

Unit # 4- Cable Tray Below Turbine Floor

|

Unit # 5- Alignment of Shafts under Progress

|

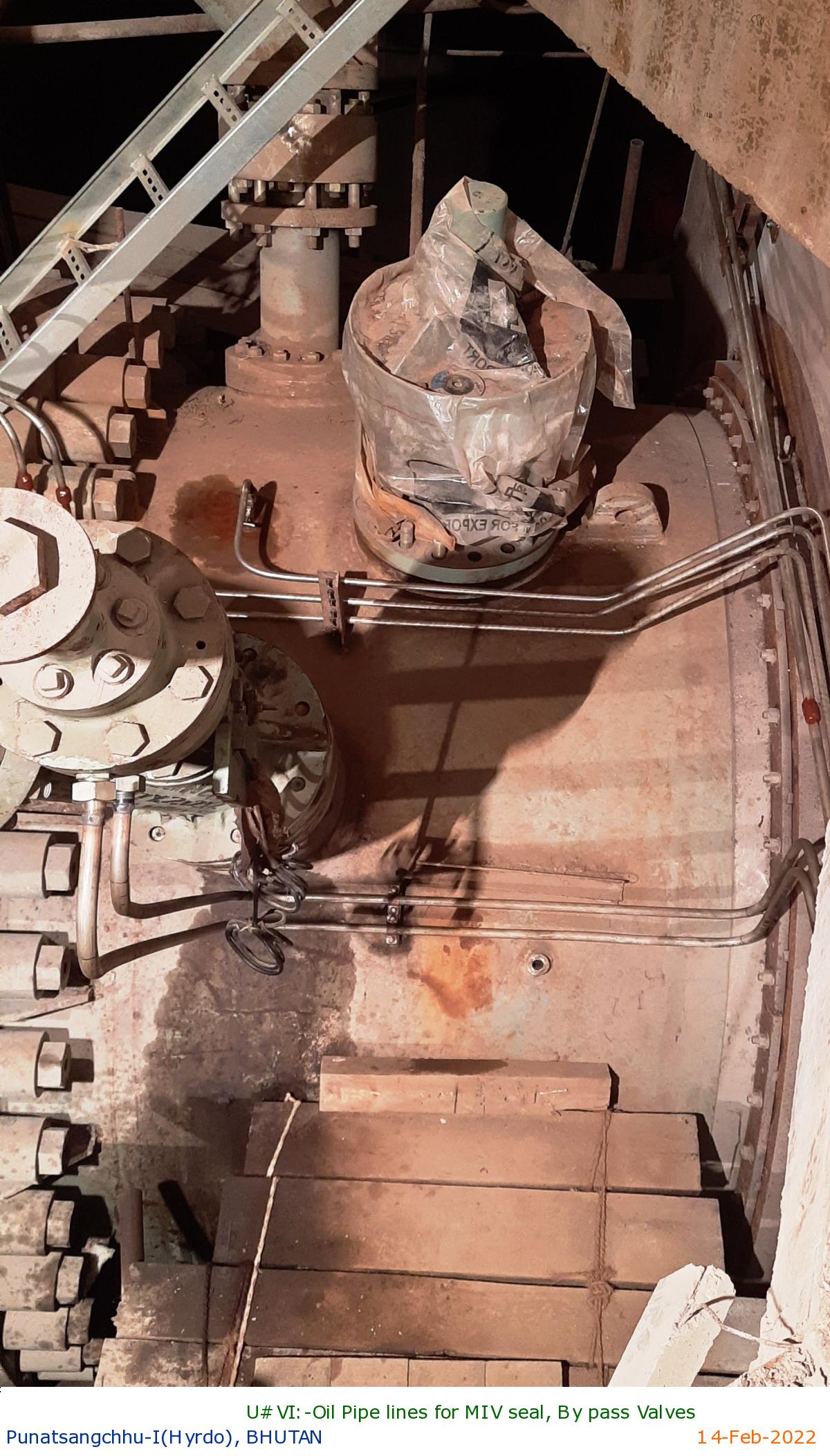

U#VI:-Oil Pipe lines for MIV seal, By pass Valves

|

U#III:- Welding and DPT on CW pipe lines

|

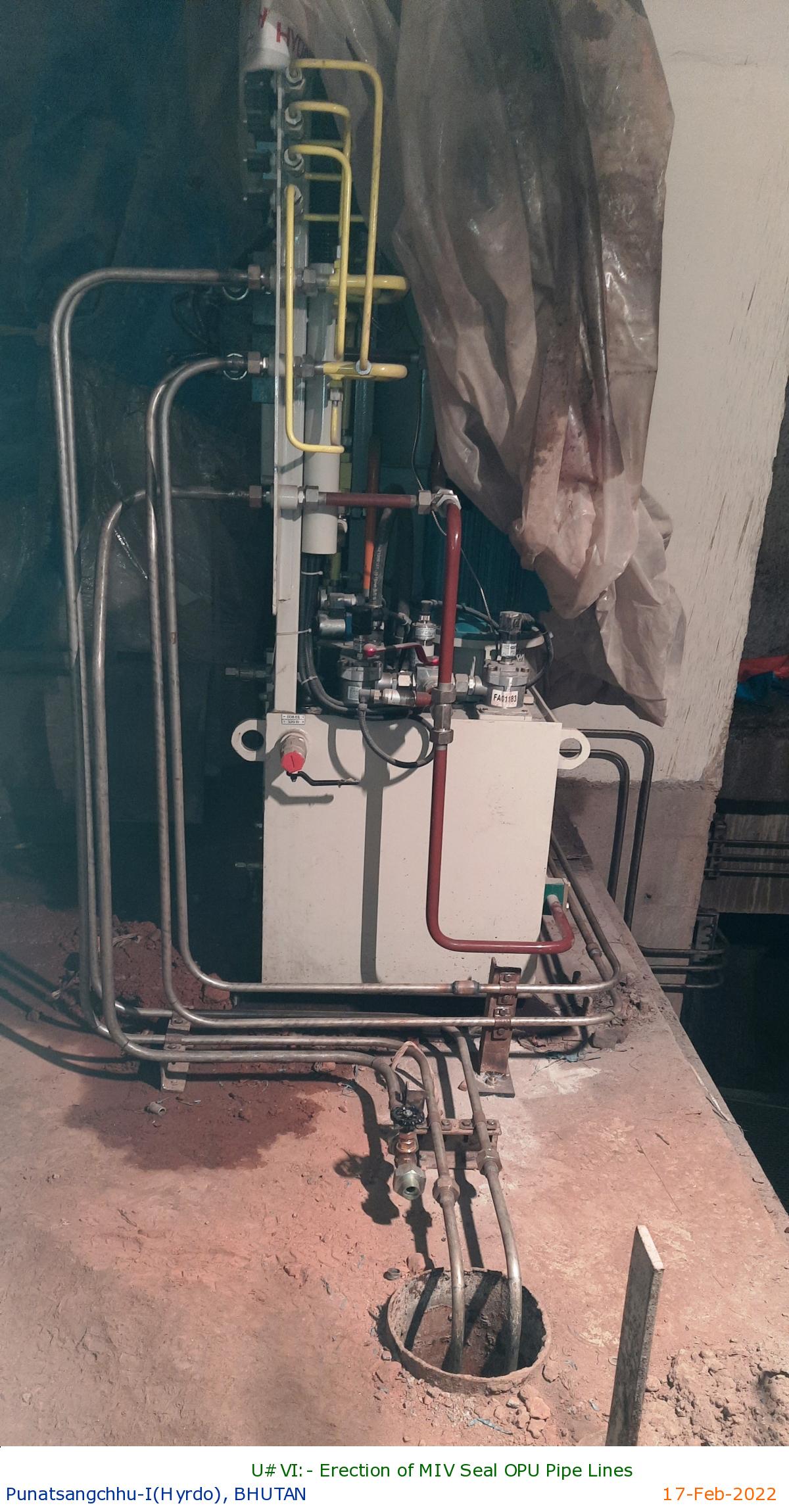

U#VI:- Erection of MIV Seal OPU Pipe Lines

|

U#VI:- Erection of MIV Platform

|

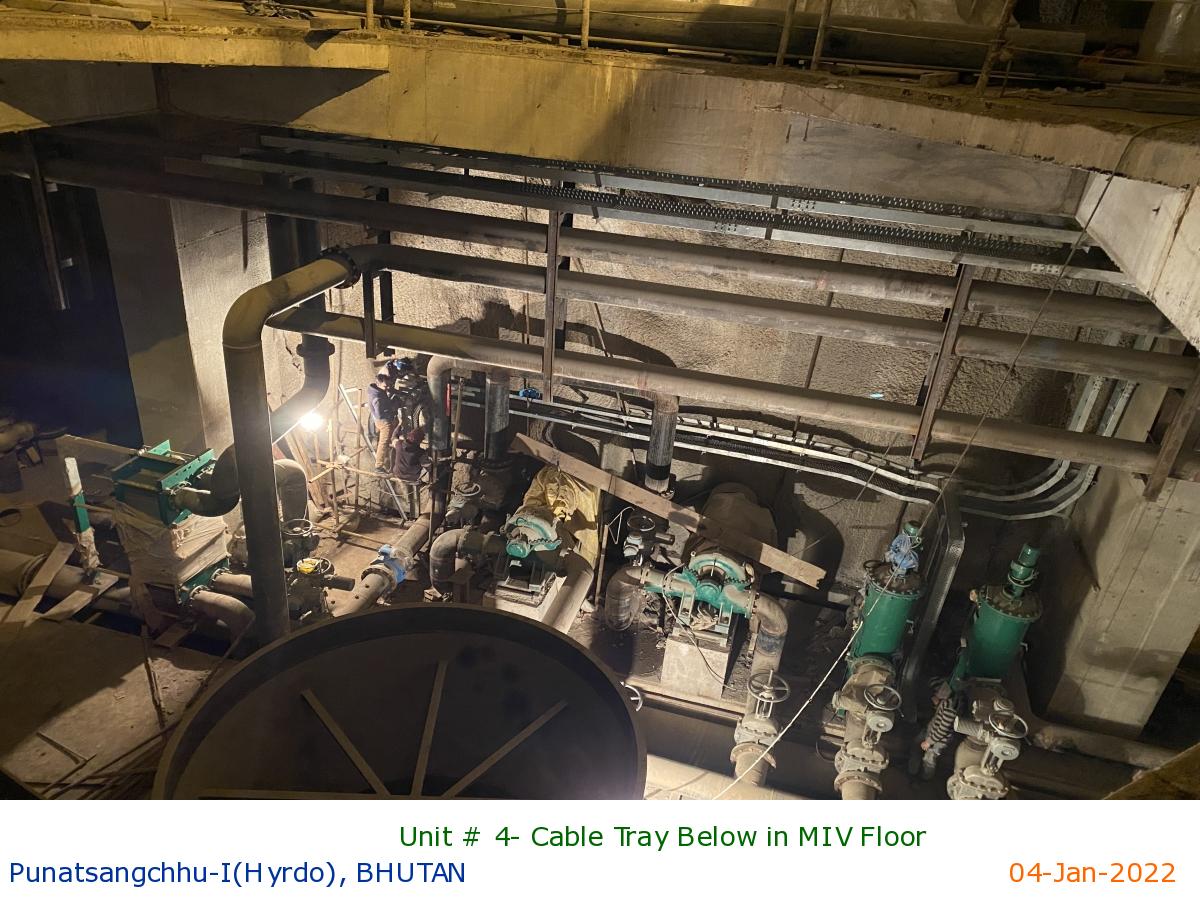

Unit # 4- Cable Tray Below in MIV Floor

|

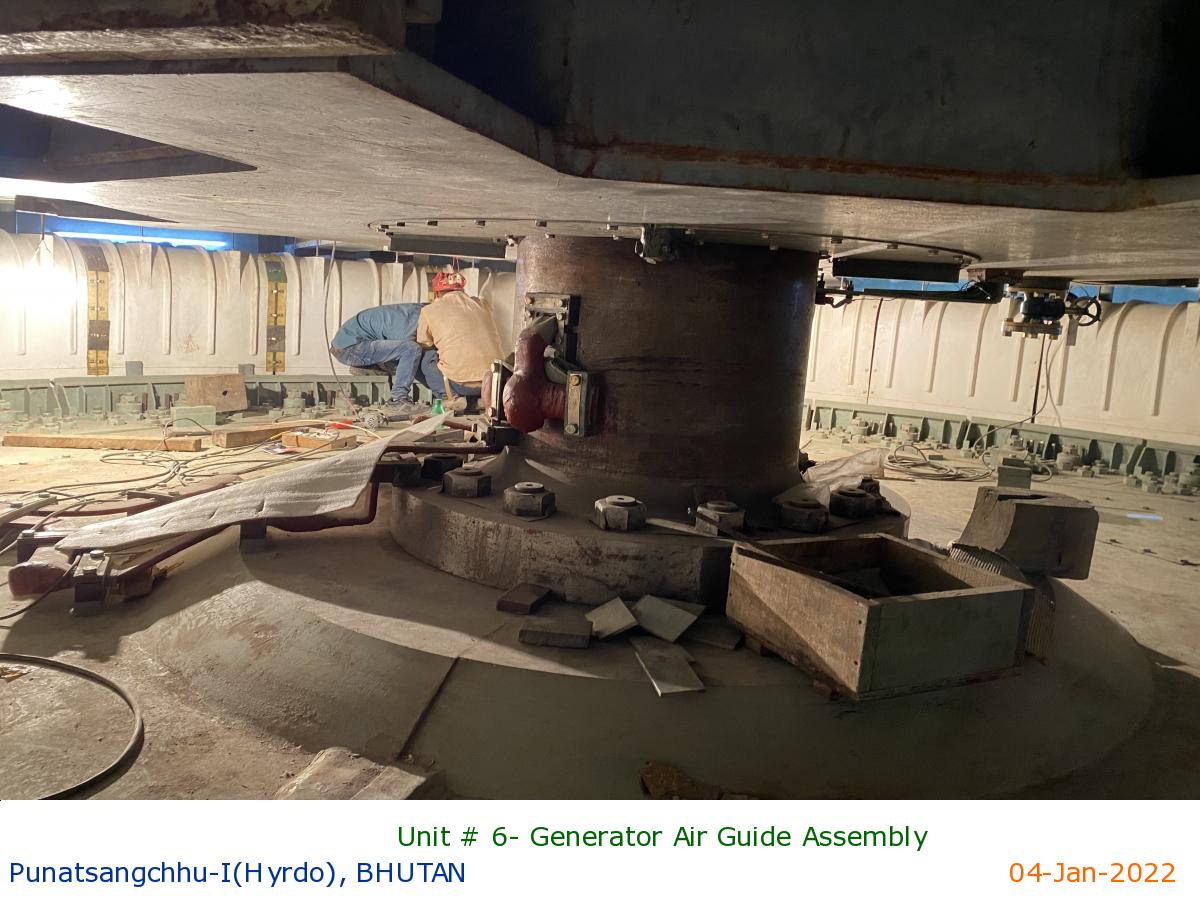

Unit # 6- Generator Air Guide Assembly

|

Lowering of U # 5- Generator- Rotor on 29-12-2021

|

Unit # 5- Generator Bottom Shaft Lowered in Pit.

|

Lowering of Unit # 5- Generator Bottom Shaft

|

Bust Duct Gallery # 2 Area

|

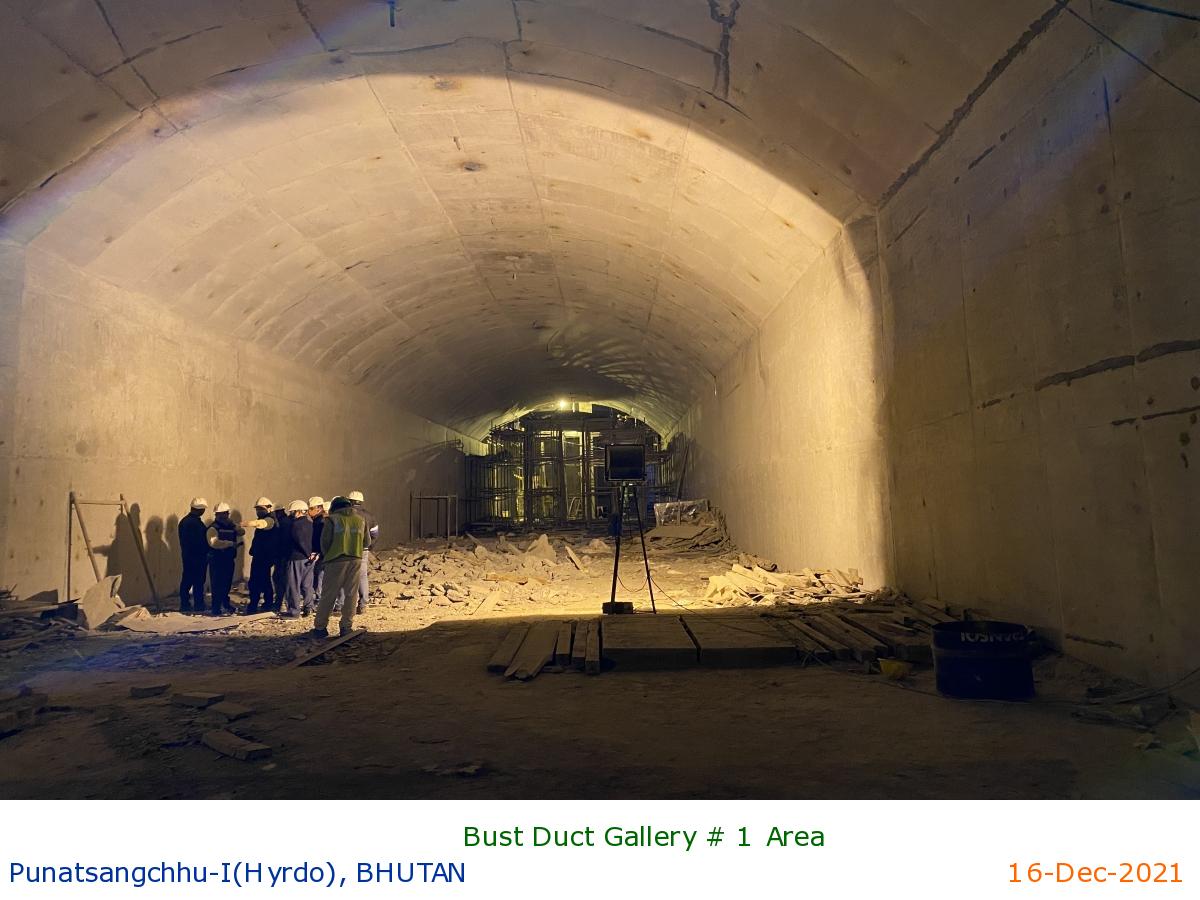

Bust Duct Gallery # 1 Area

|

U#2- Erection of Shaft seal primary filter arrangement

|

U#1- Installation of MIV servomotors

|

U#4- Final assy of pivot ring Pr. balancing pipes

|

CW system common header for all units

|

U#6:- MIV servo base plate leveling and centering

|

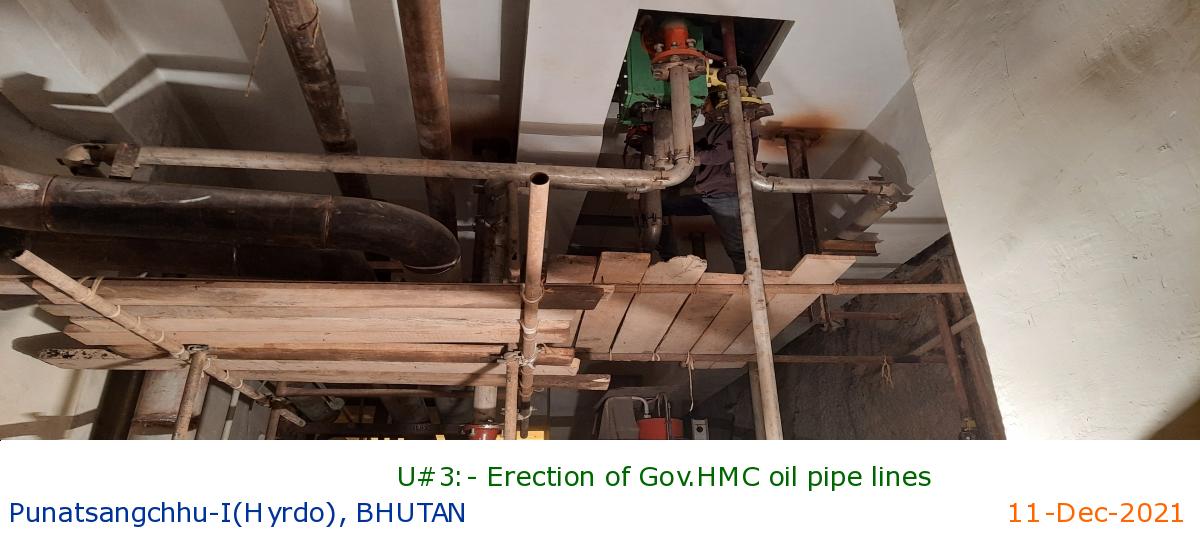

U#3:- Erection of Gov.HMC oil pipe lines

|

U#VI:- Welding on 125NB CW header

|

U#IV:- Dowelling on TGB Housing

|

U#I:- Levelling, centering of MIV servo base plate

|

Unit # 4- Cable Tray Below Machine Hall Floor

|

Unit # 1 MIV- Servomotor Area

|

U#2- Transformer coolers CW Pipe erection

|

Bust Duct Gallery # 2 Area

|

Unit # 4- Cable Tray Below Machine Hall Floor

|

Unit # 4- Turbine Pit

|

S/B Area- Assembly of U#5- Spring Plate Assembly

|

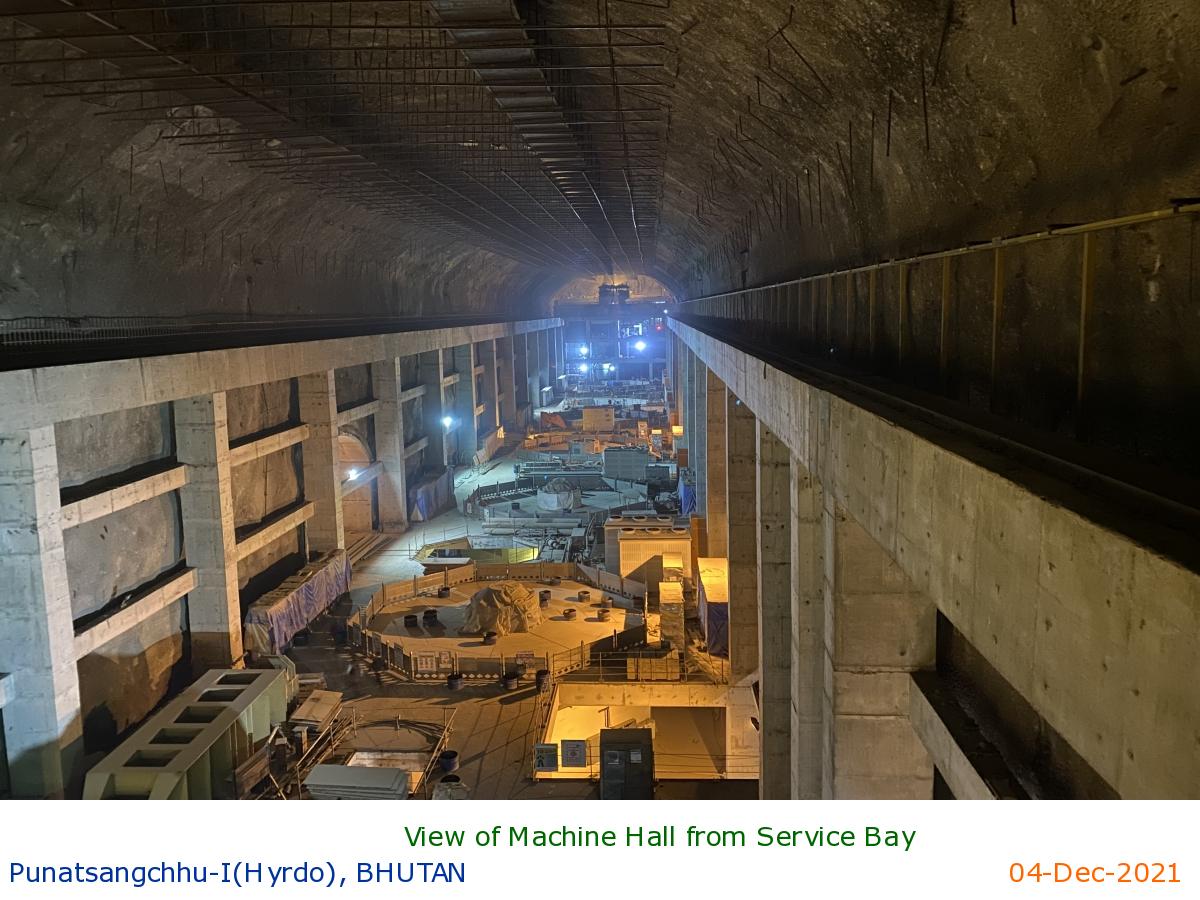

View of Machine Hall from Service Bay

|

Installation of U#4- Shaft Seal Cooling Water Pipe

|

Installation of R,Y and B Phase-HV Bushings

|

Installation of U# 6- GV Servomotor Pipelines

|

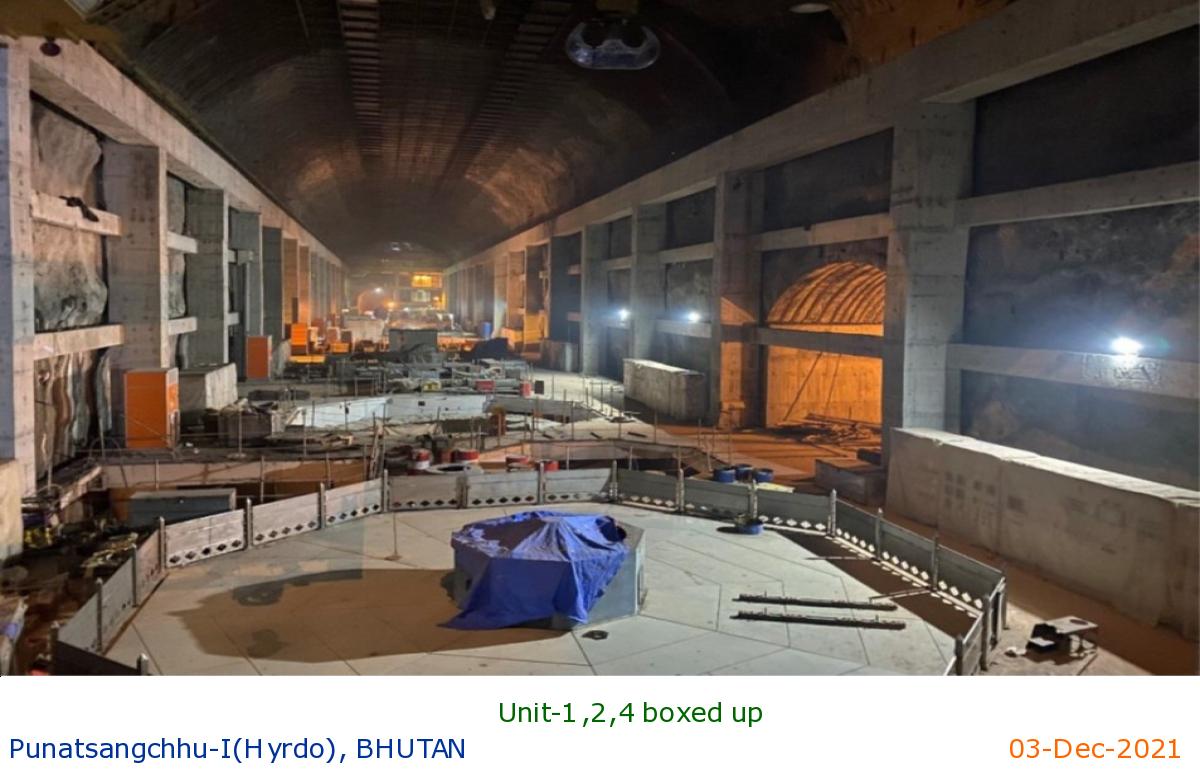

Unit-1,2,4 boxed up

|

View of Ongoing Works in U#5- Bottom Bracket Assy.

|

Installation of Cable Tray below U # 6-Generator Floor

|

Oil Filling of U#3 LGB Housing Completed.

|

Inst. of Cable Tray below U # 4-Generator Floor

|

Installation of Servo Motor of U#6 MIV

|

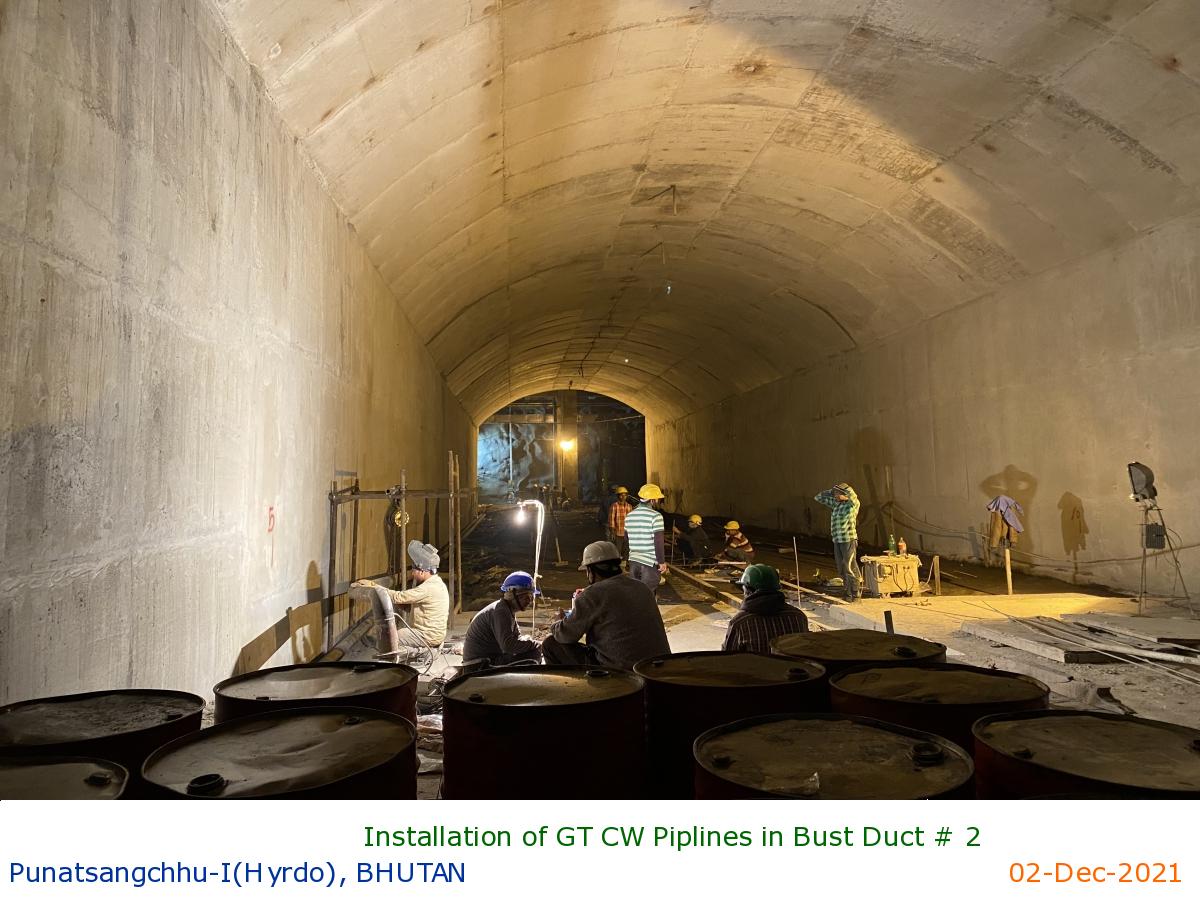

Installation of GT CW Piplines in Bust Duct # 2

|

Unit#5-View of Machine Hall Floor

|

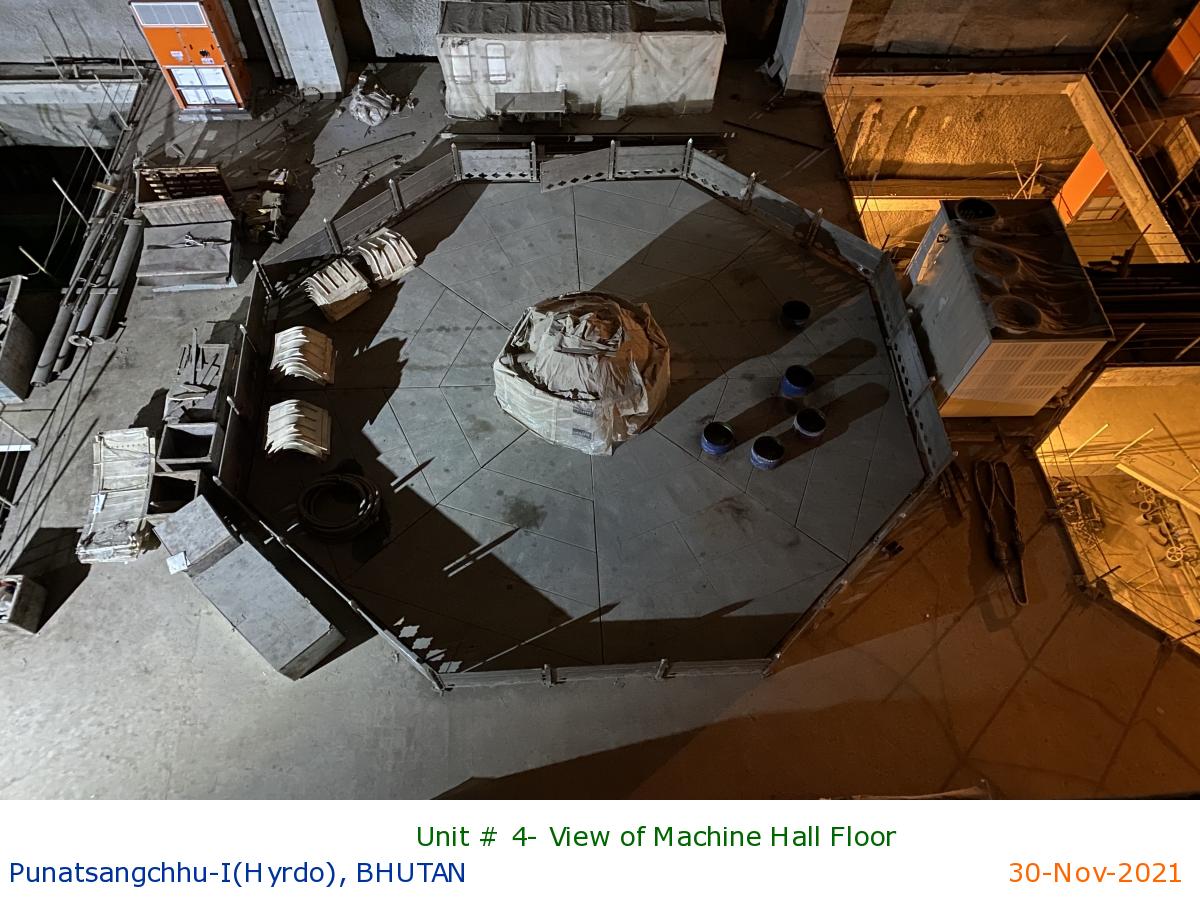

Unit # 4- View of Machine Hall Floor

|

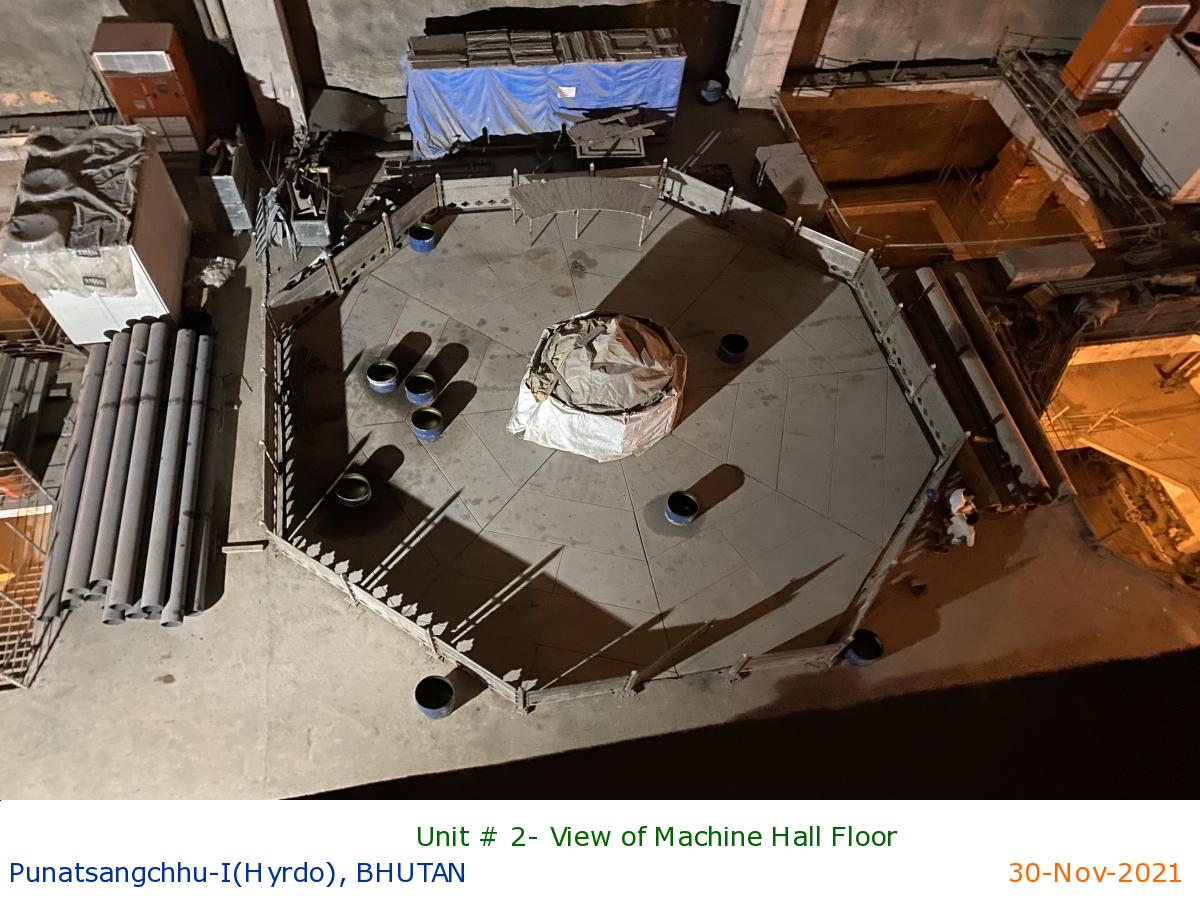

Unit # 2- View of Machine Hall Floor

|

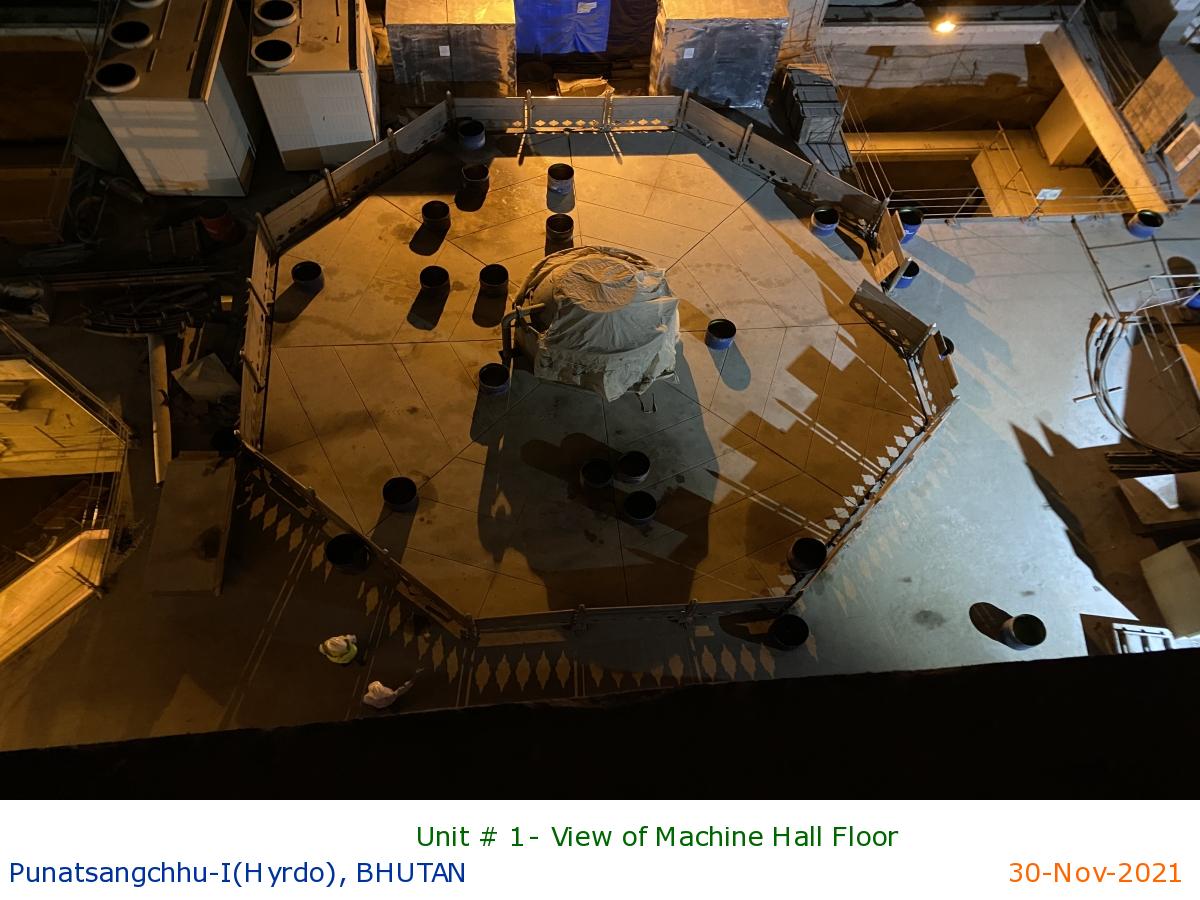

Unit # 1- View of Machine Hall Floor

|

Opening of Door of BFV# 2

|

ICTs in Pothead Yard

|

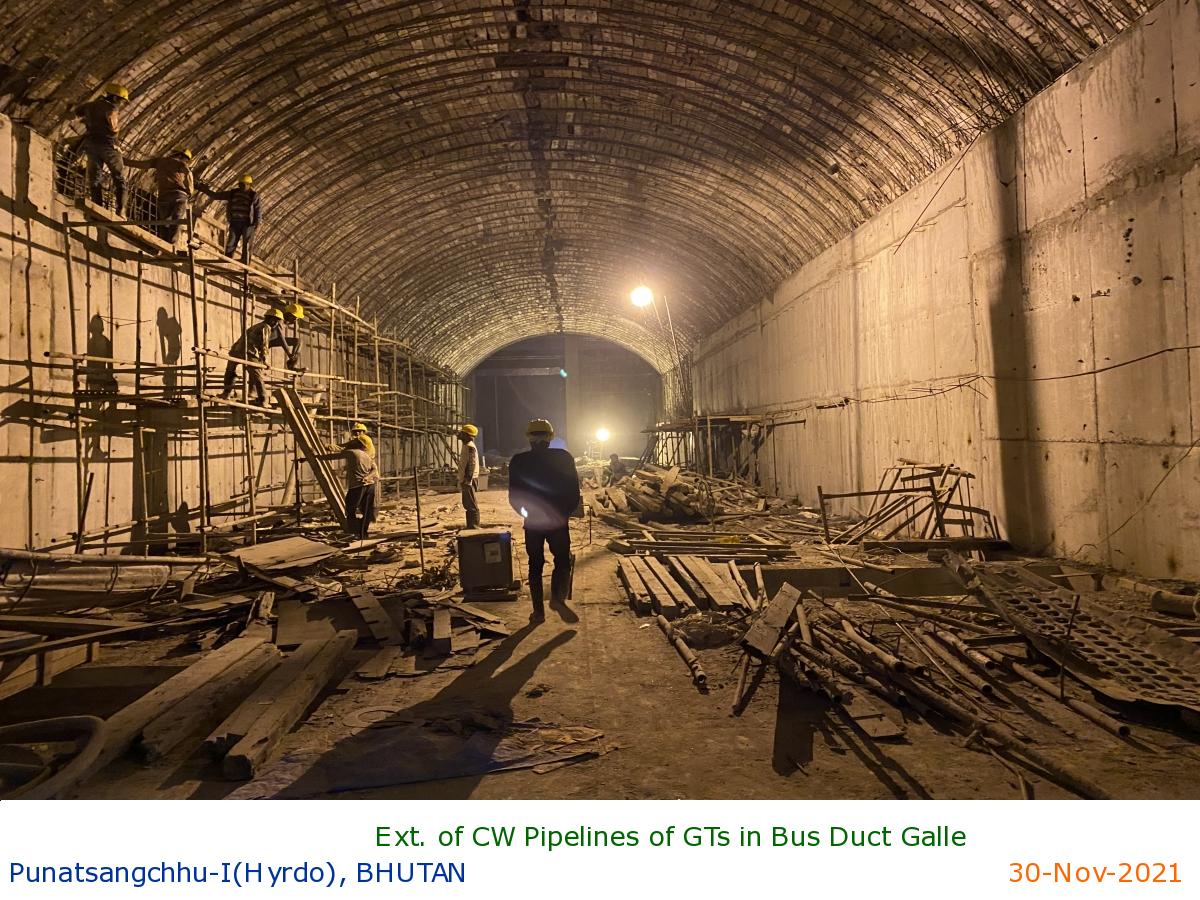

Ext. of CW Pipelines of GTs in Bus Duct Galle

|

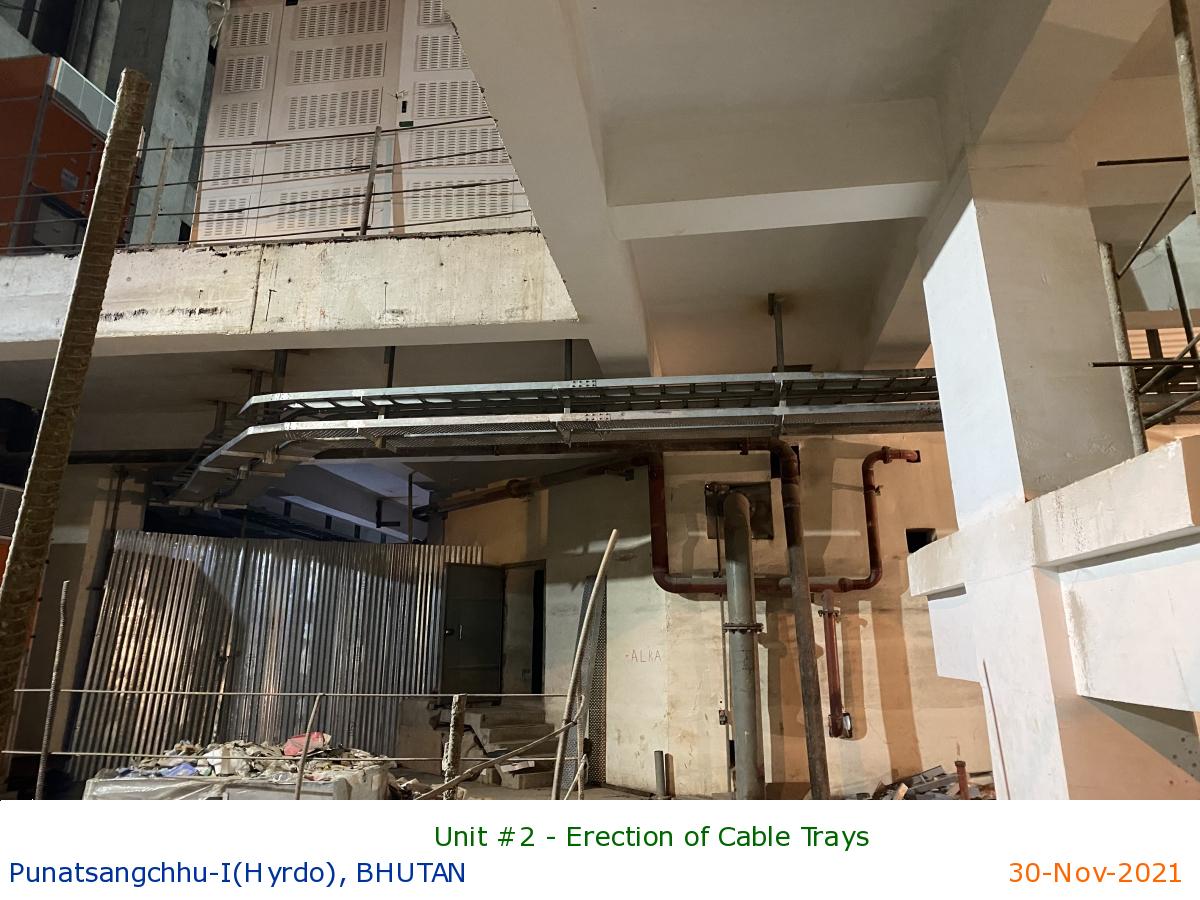

Unit #2 - Erection of Cable Trays

|

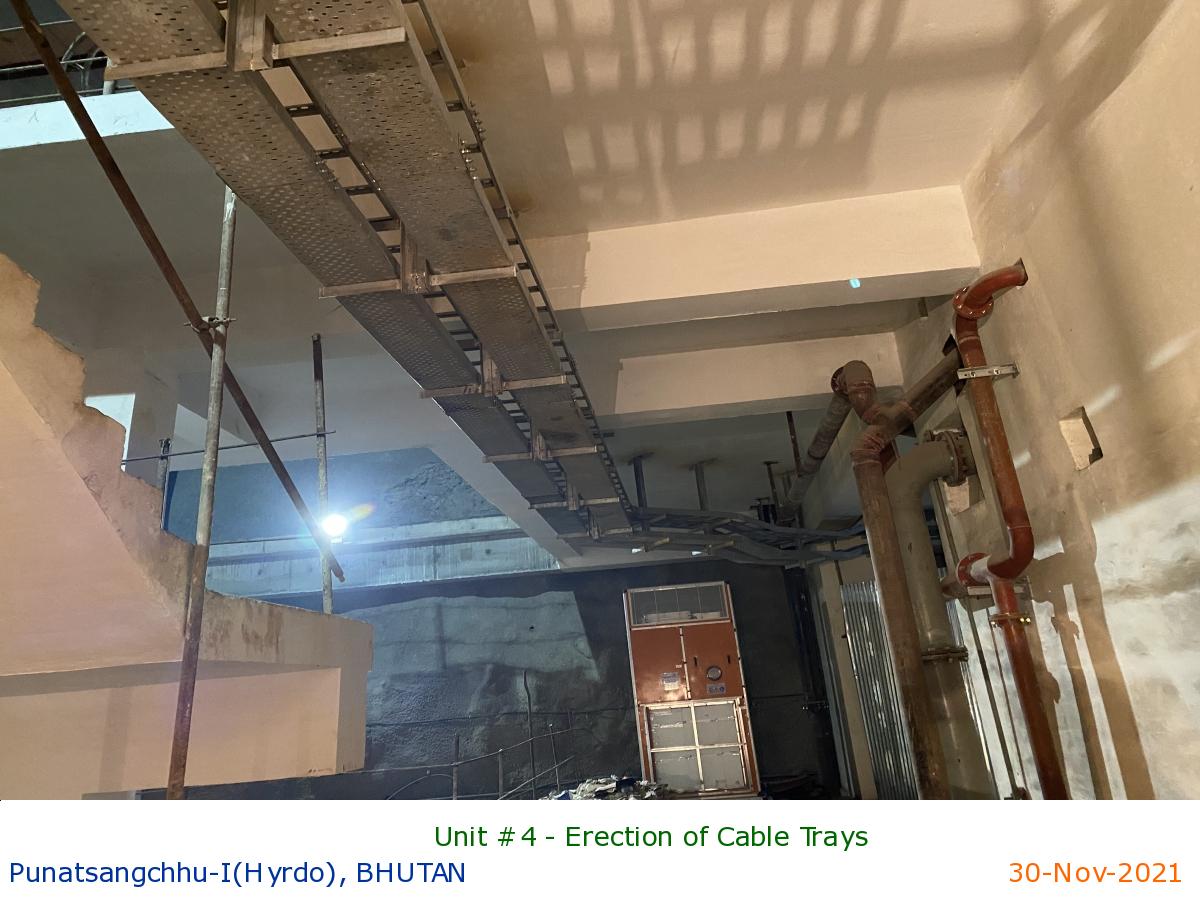

Unit #4 - Erection of Cable Trays

|

Oil Filling of U# 3-TGB Housing Completed

|

Post Weld Heat Treatment of U#6 MIV & Penstock

|

Unit # 3- Oil Filling of LGB Under Progress

|

Machine Hall View from Service Bay Area

|