U#4 Top air guide installation

|

U#4 Impeller nut guard final assembly and levellin

|

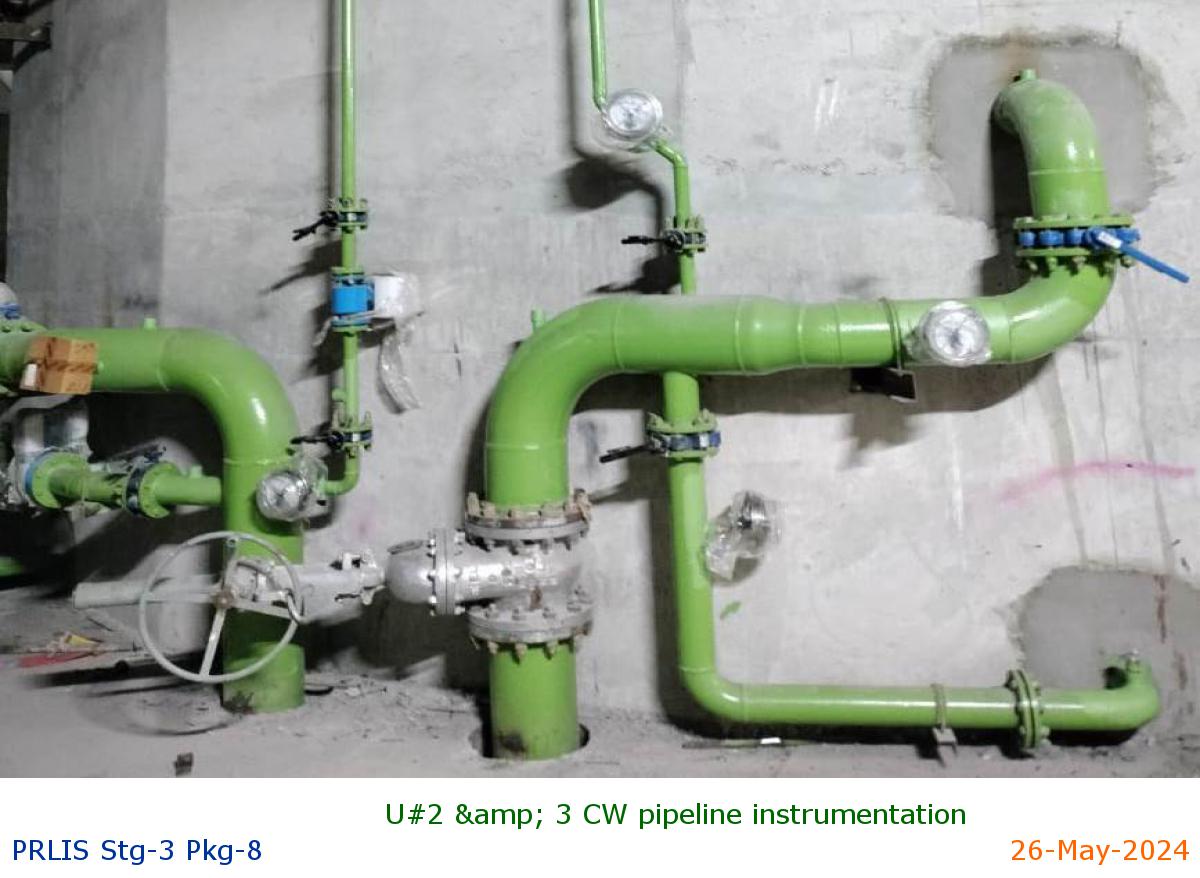

U#2 & 3 CW pipeline instrumentation

|

U#3 Turbine oil cooler water piping

|

U#4 Machine centering and locking ocmpleted

|

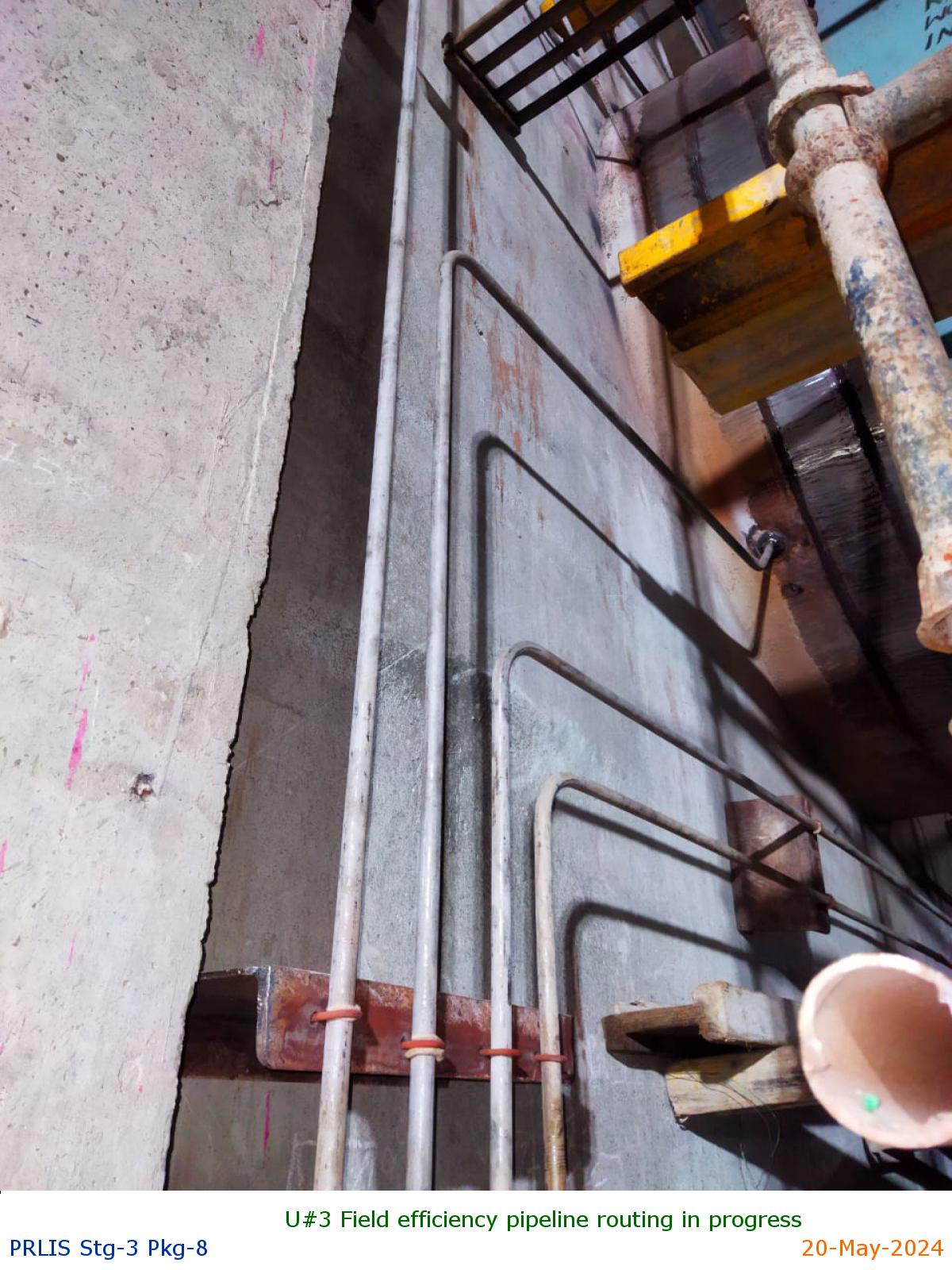

U#3 Field efficiency pipeline routing in progress

|

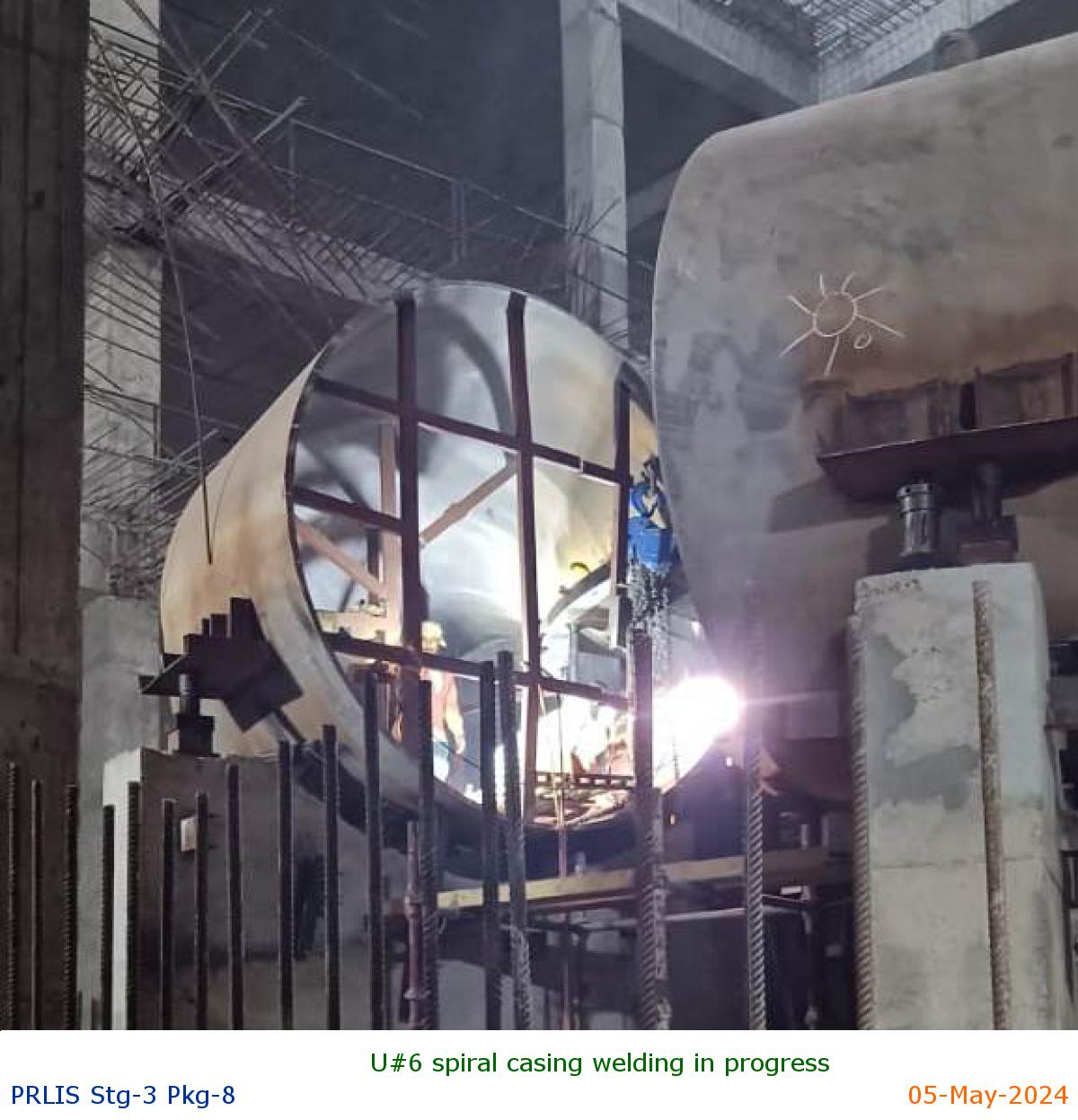

U#6 spiral casing welding in progress

|

U#3 Cyclone separator drain pipeline routing

|

U#3 UGB oil retainer installation in progress

|

U#3 GV pressure receiver air pipeline routing i/p

|

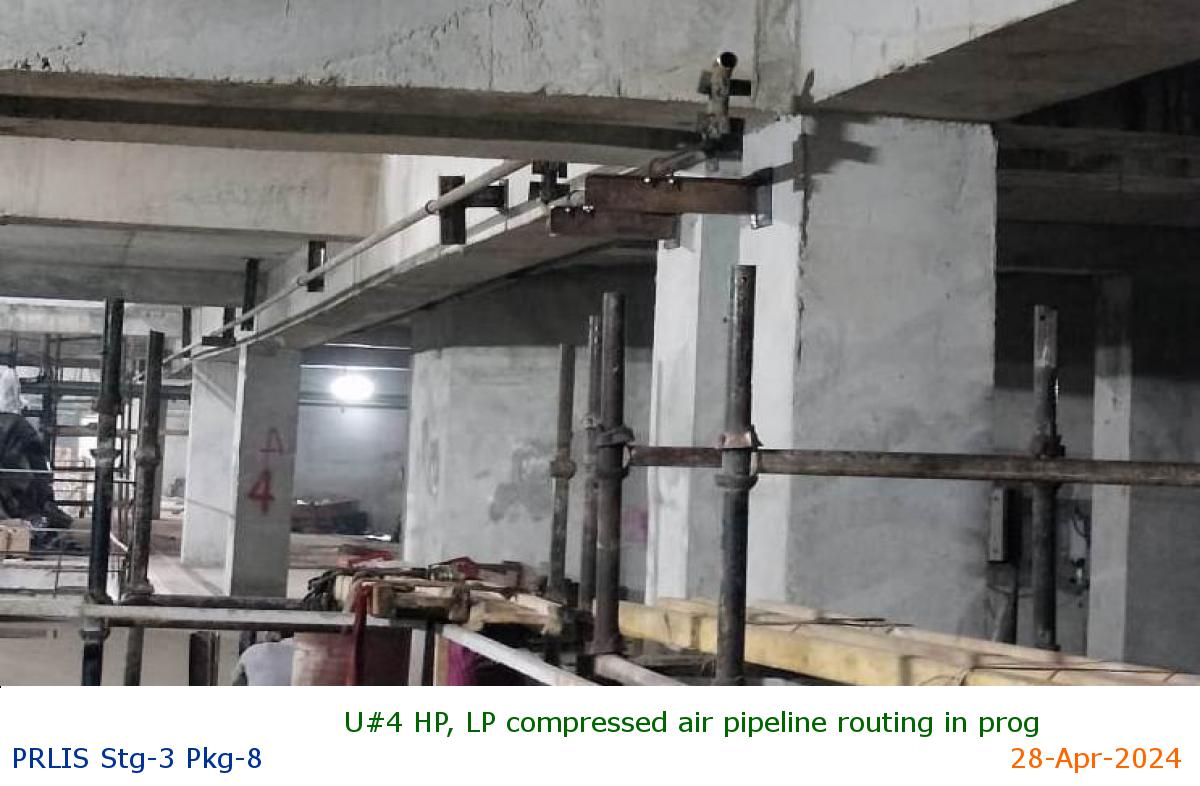

U#4 HP, LP compressed air pipeline routing in prog

|

U#1&2 Busduct CT`s pre erection testing

|

U#3 MDV penstock makeup piece installation

|

U#2 Temporary CW line routing is completed

|

U#3 Compressed air pipeline routing in progress

|

U#3 Impeller band drain valve

|

U#3 Top oil vapour piping

|

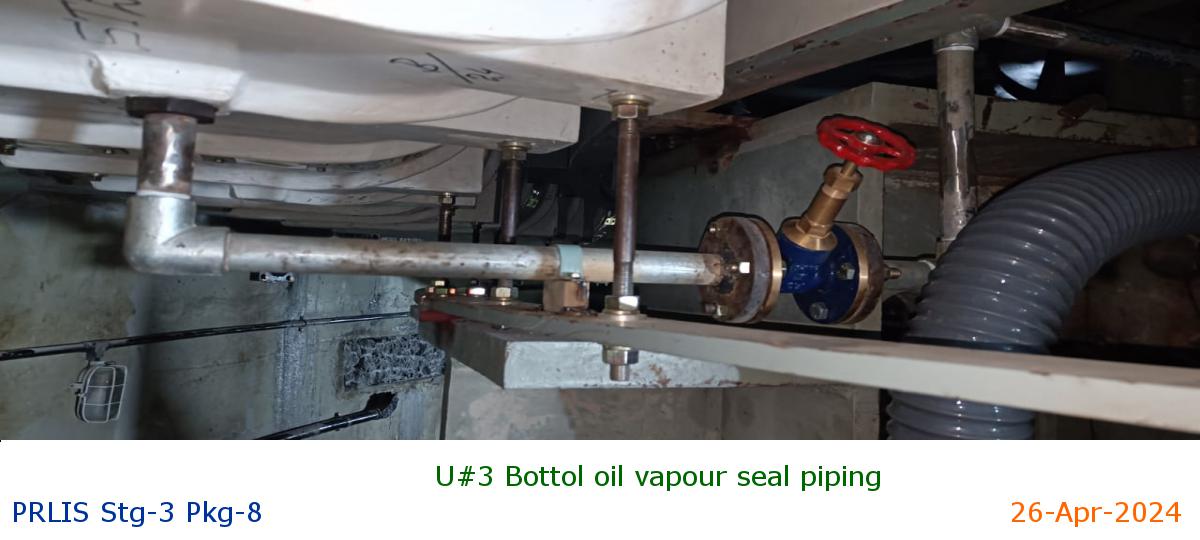

U#3 Bottol oil vapour seal piping

|

U#3 Water depression pipeline routing in progress

|

U#1 GV Air receiver leak test in progress

|

U#3 Unit oil manifold pipeline routing in progress

|

U#3 Impeller band drain pipeline routing completed

|

U#5 HS pipeline routing and testing completed

|

U#3 MDV inlet pipe welding in progress

|

U#3 servooperated valve 10nb pipeline routing i/p

|

U#4 Pit air seal installation in progress

|

U#3 LGB vapour seal installation completed

|

U#6 spiral segments backstrip welding in progress

|

U#5 rotor rim building in progress

|

U#5 brake jack hydraulic testing in progress

|

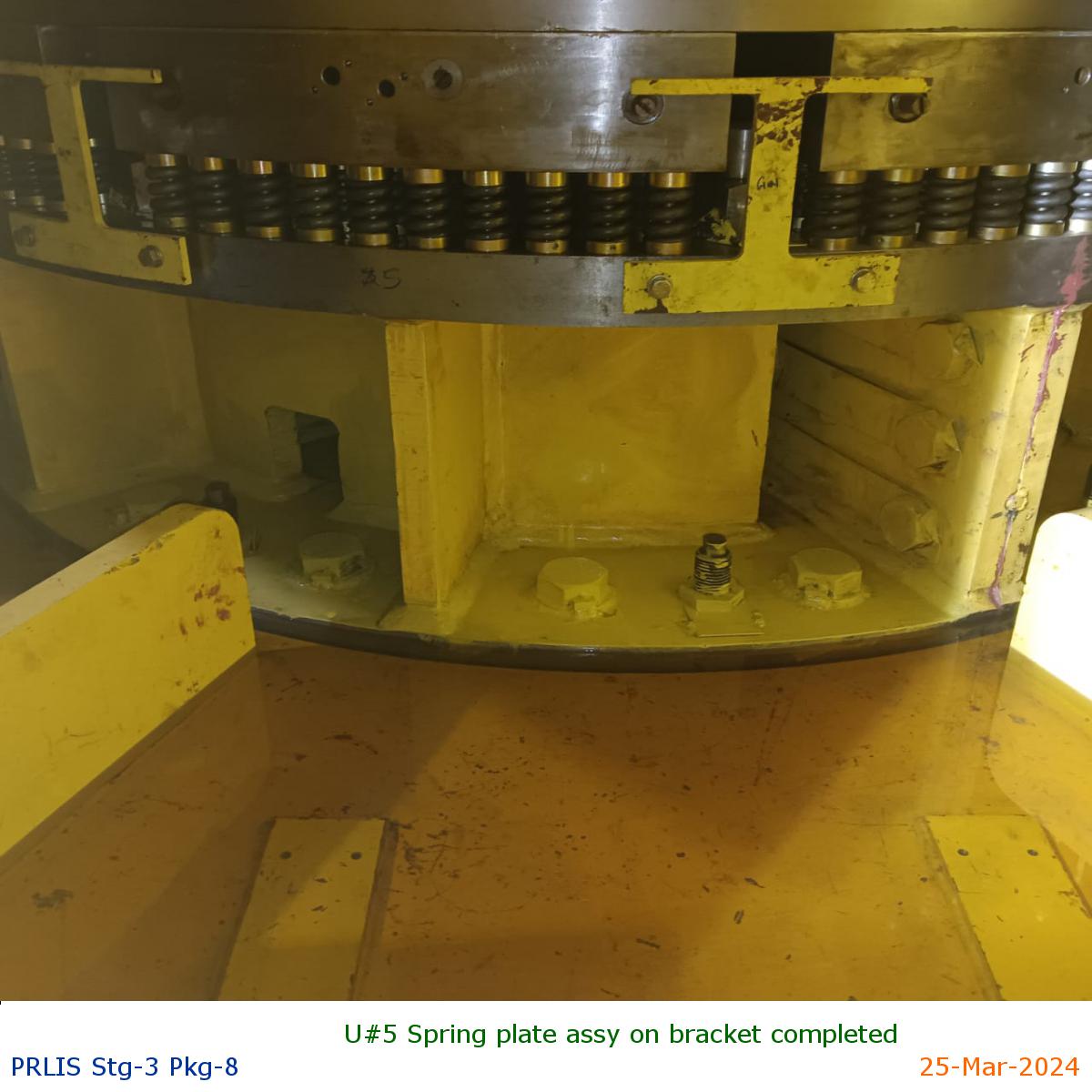

U#5 Spring plate assy on bracket completed

|

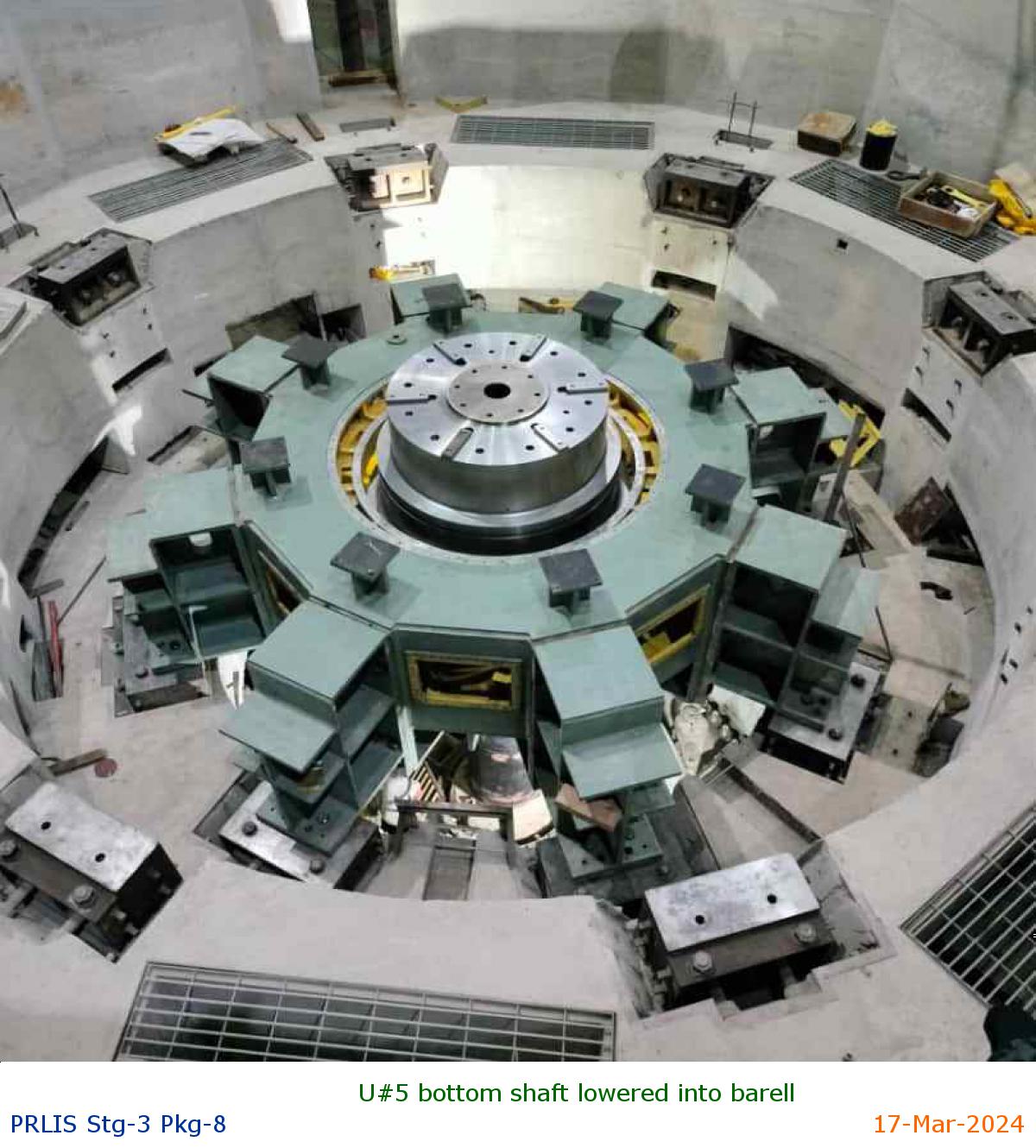

U#5 bottom shaft lowered into barell

|

U#3 WDS pipeline routing in progress

|

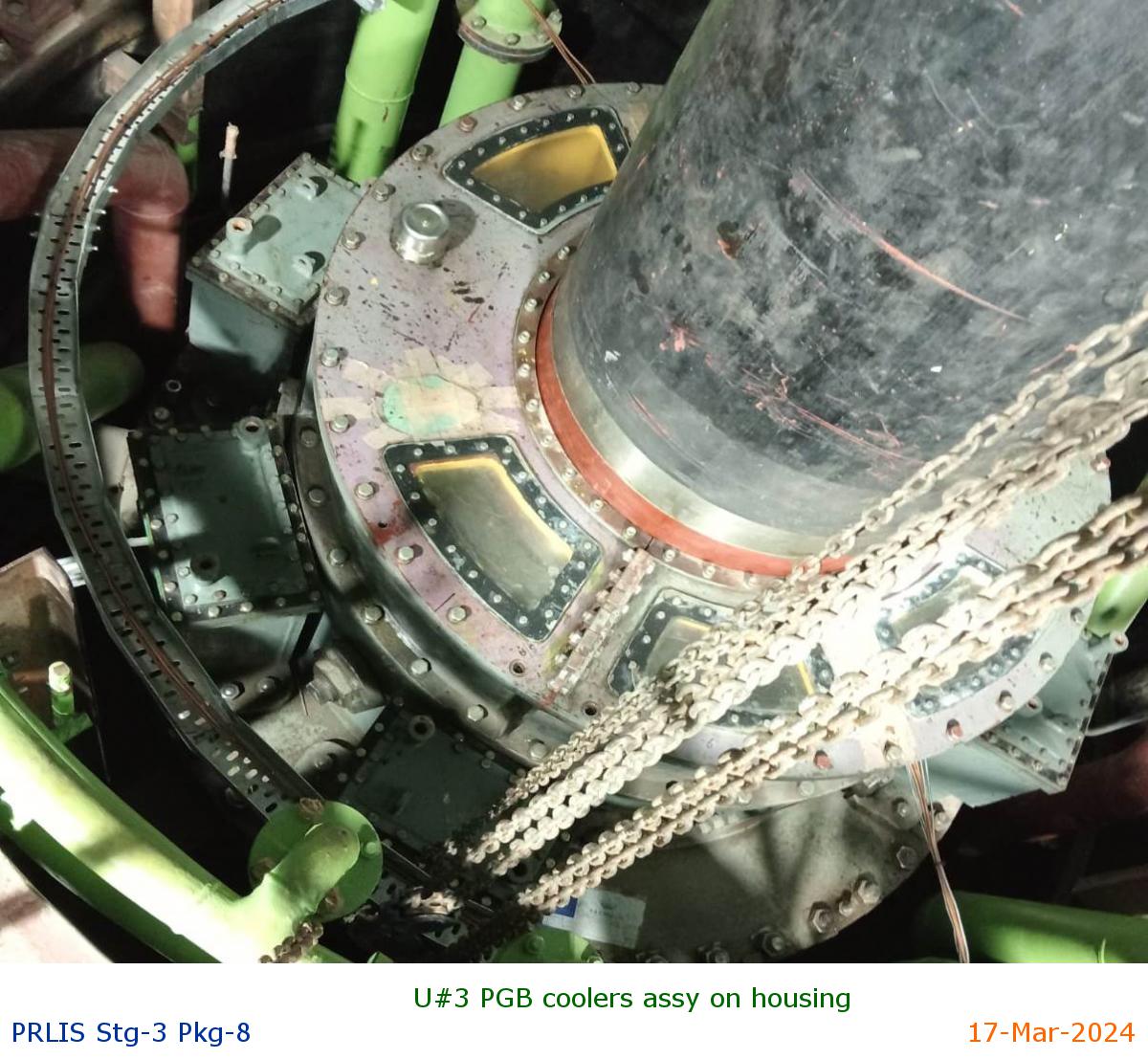

U#3 PGB coolers assy on housing

|

U#3 pgb oil cooler hydraulic testing in progress

|

U#3 mdv inlet pipe welding in progress

|

U#3 GV oil pipelines acid cleaning in progress

|

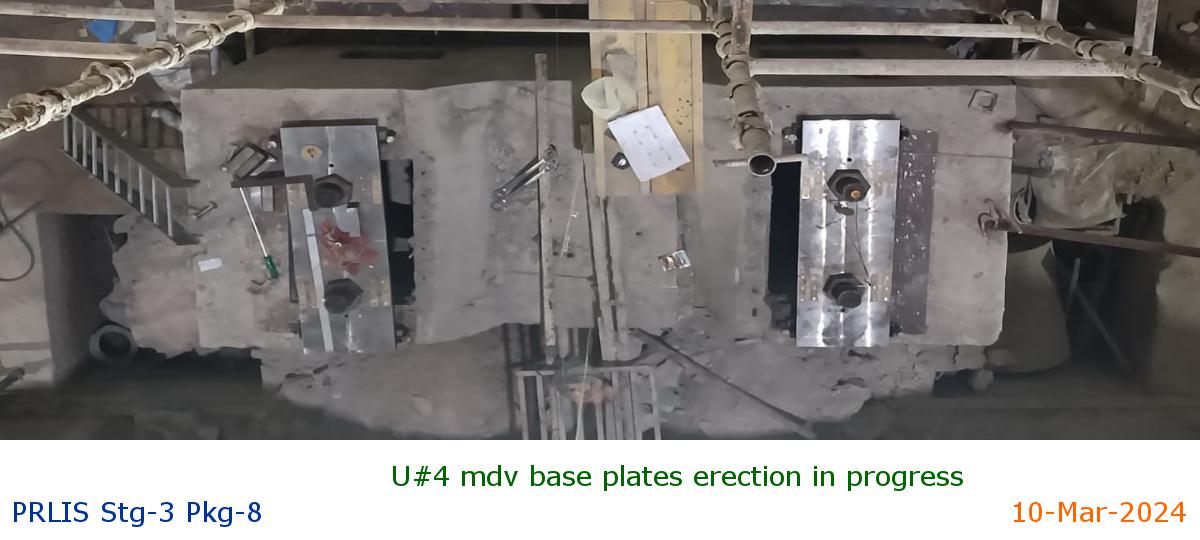

U#4 mdv base plates erection in progress

|

U#6 spiral segments positioning in progress

|

U#5 spring plate assy around shaft in progress

|

U-3 LGB coolers final assy in progress

|

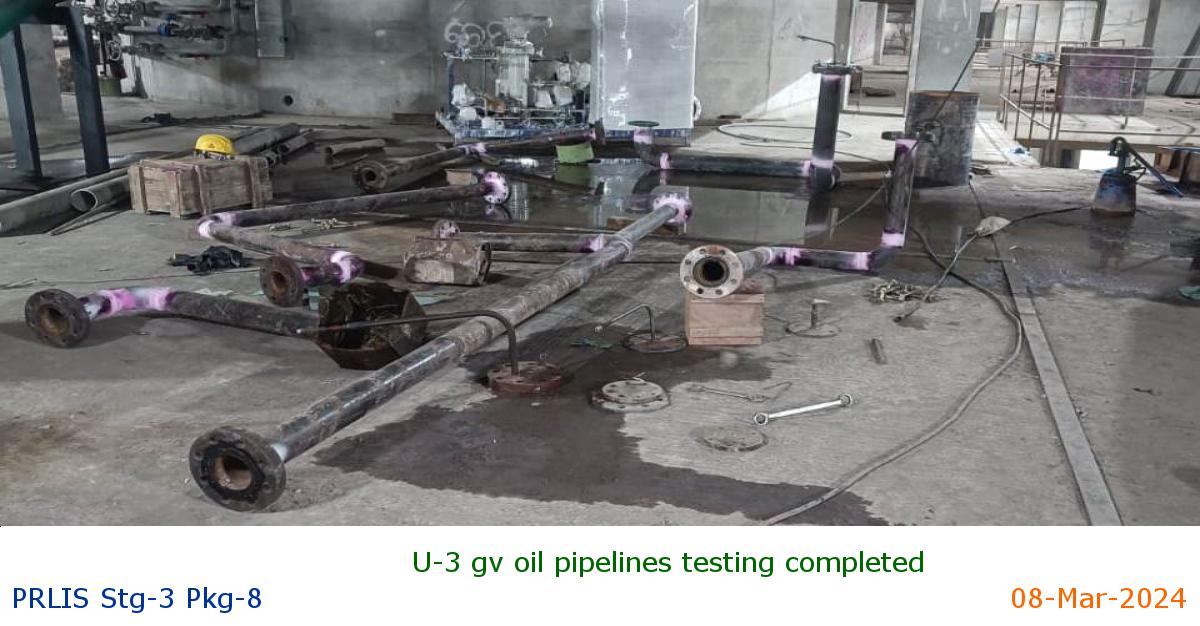

U-3 gv oil pipelines testing completed

|

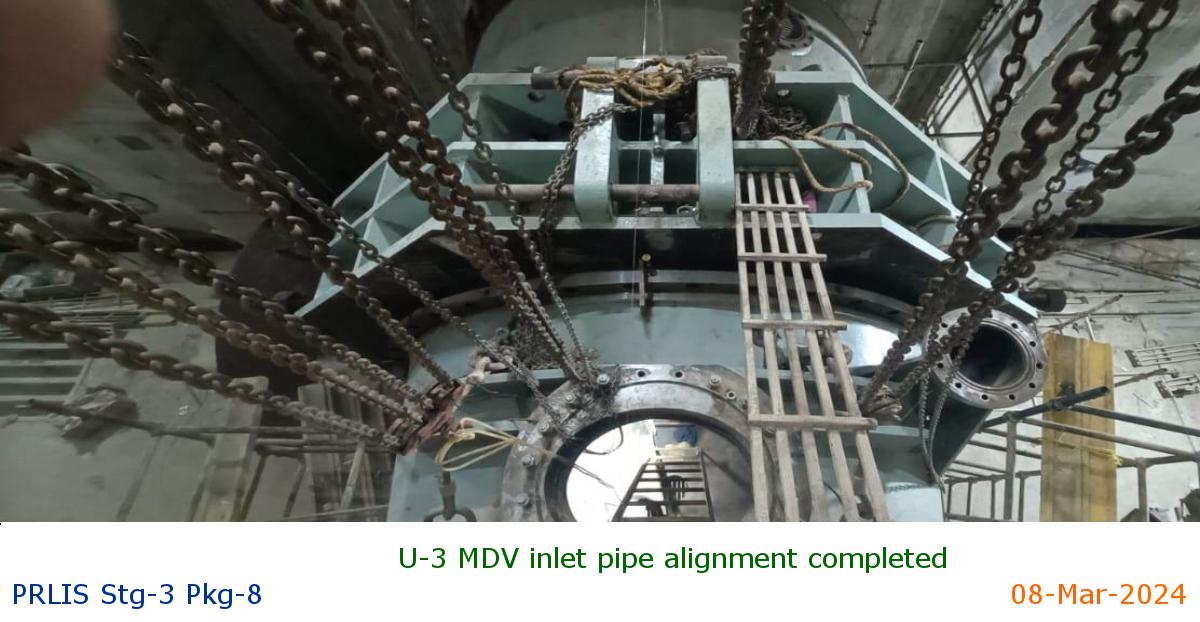

U-3 MDV inlet pipe alignment completed

|

U-6 spiral segments positioning in progress

|

U-5 Bottom bracket lowered into barell

|

U-5 Sole plates levelling completed

|

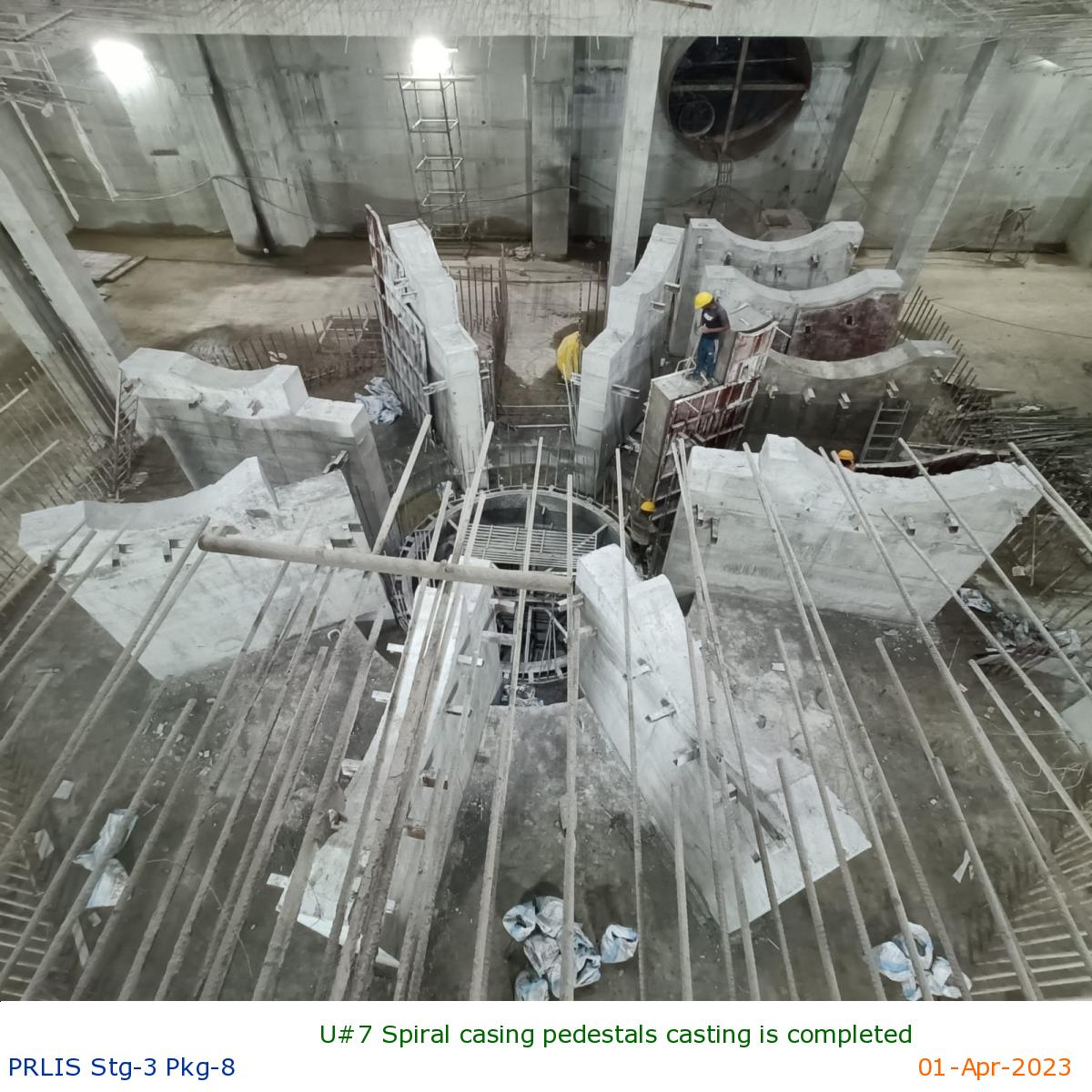

U#10 spiral casing pedestals casting

|

U#6 stay ring halves welding

|

U#2 Discahrge valve pipelines

|

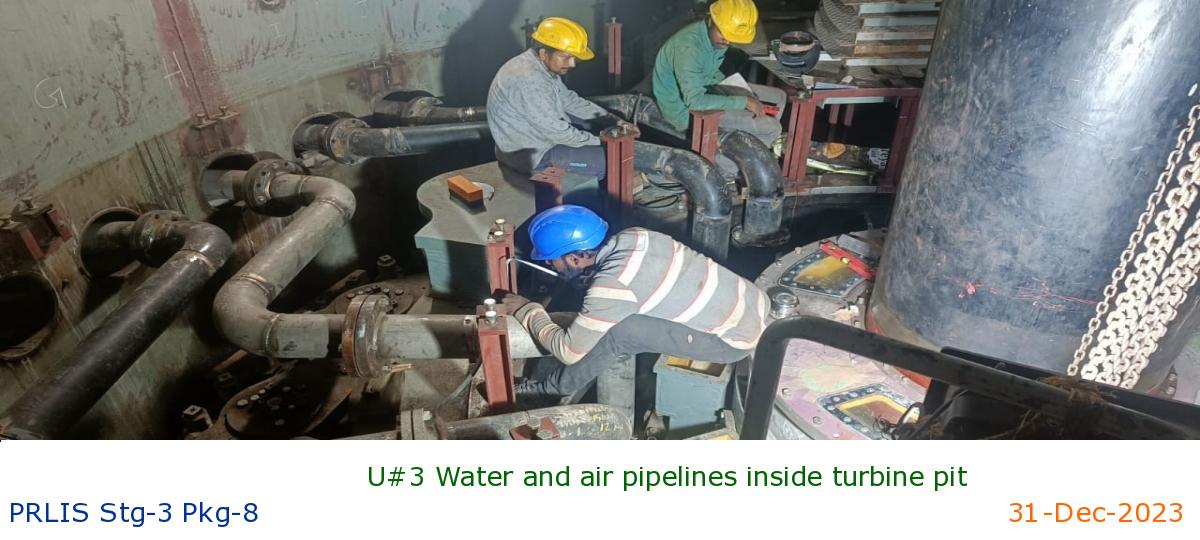

U#3 Water and air pipelines inside turbine pit

|

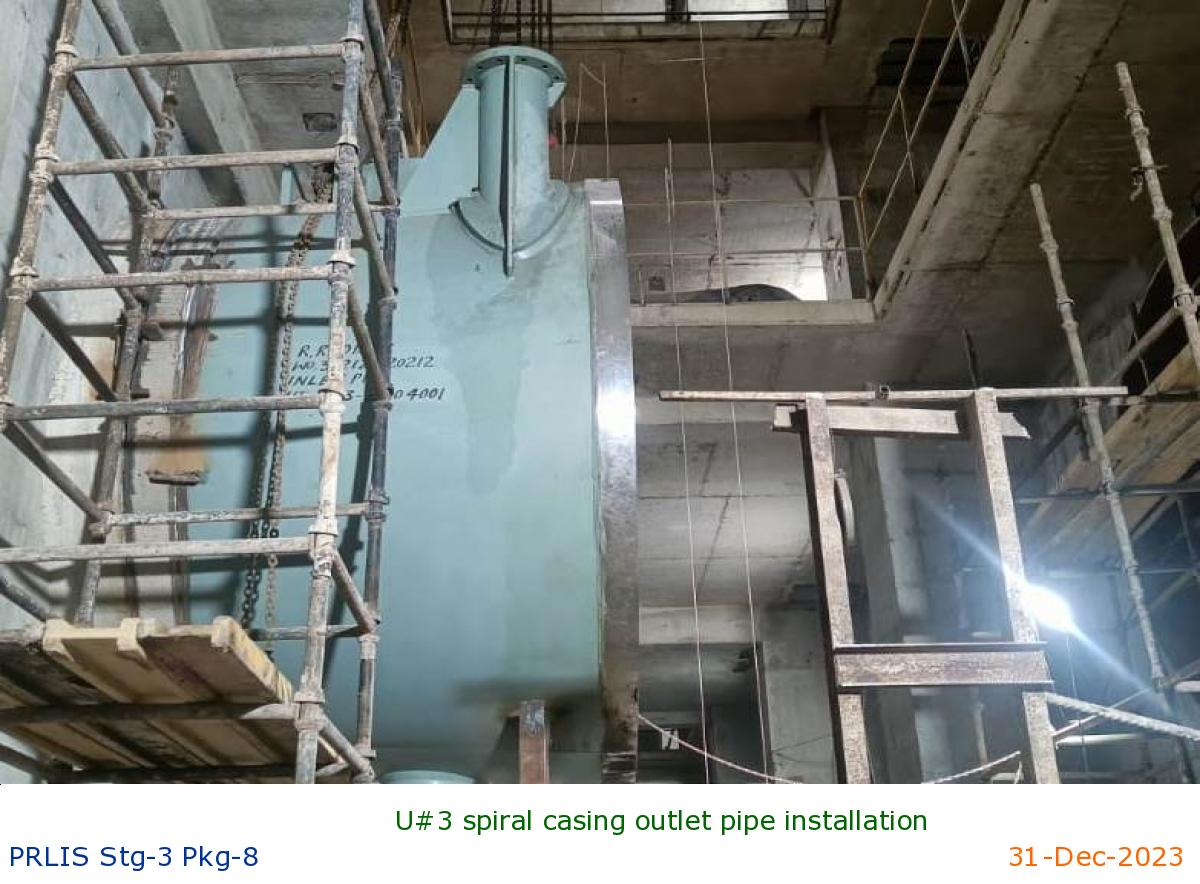

U#3 spiral casing outlet pipe installation

|

U#3 spiral casing outlet pipe installation

|

U#2 MDV Servomotor secondary concreting completed

|

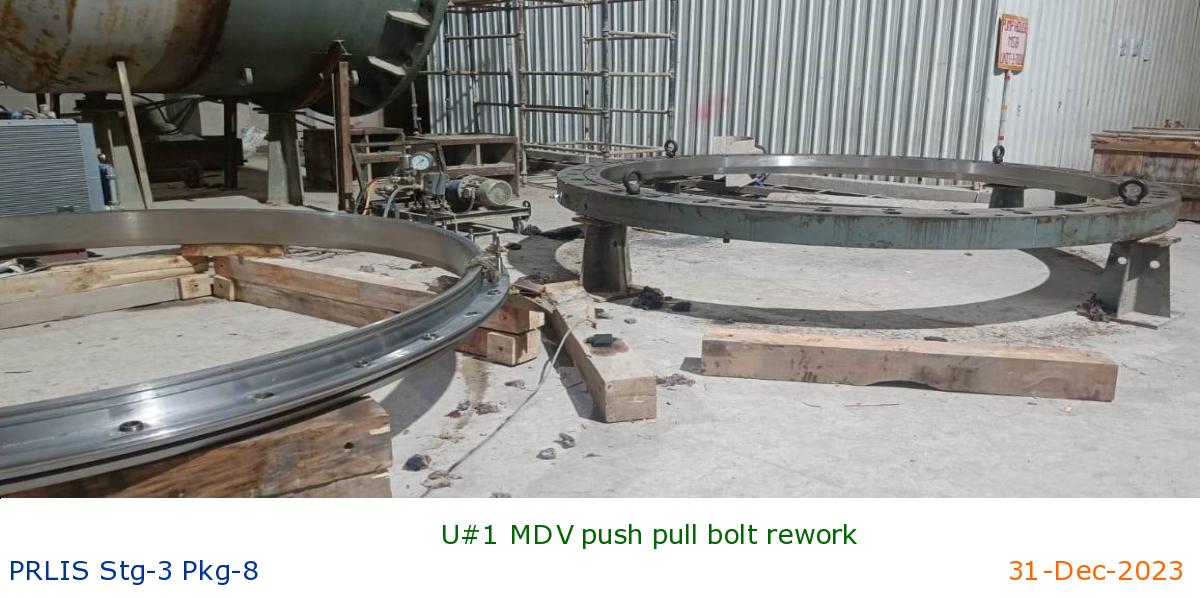

U#1 MDV push pull bolt rework

|

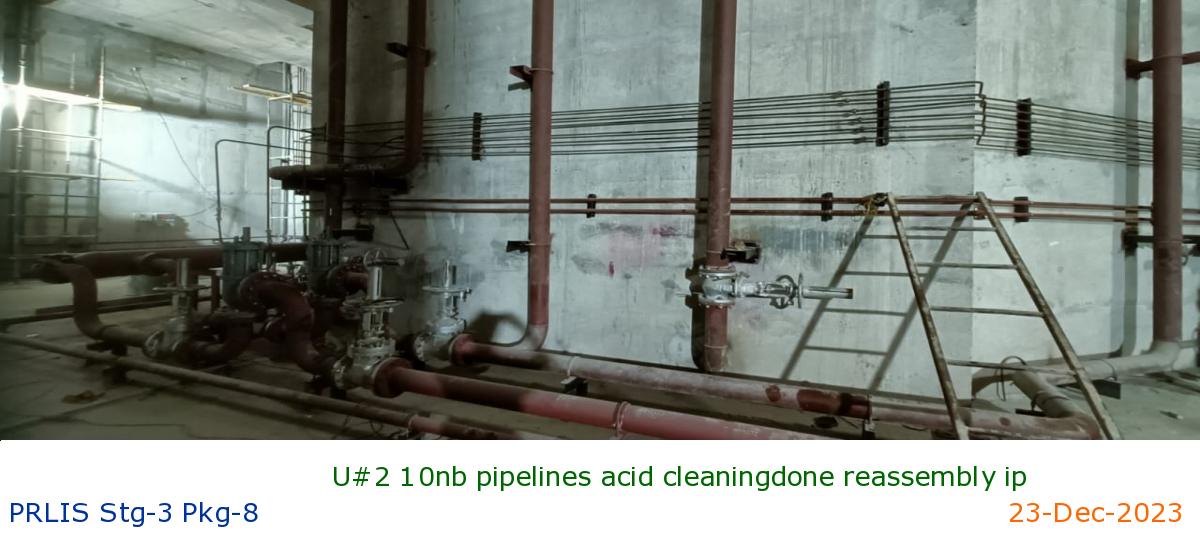

U#2 10nb pipelines acid cleaningdone reassembly ip

|

U#10 spiral casing pedestal casting in progress

|

U#3 Turbine bearing gap setting completed

|

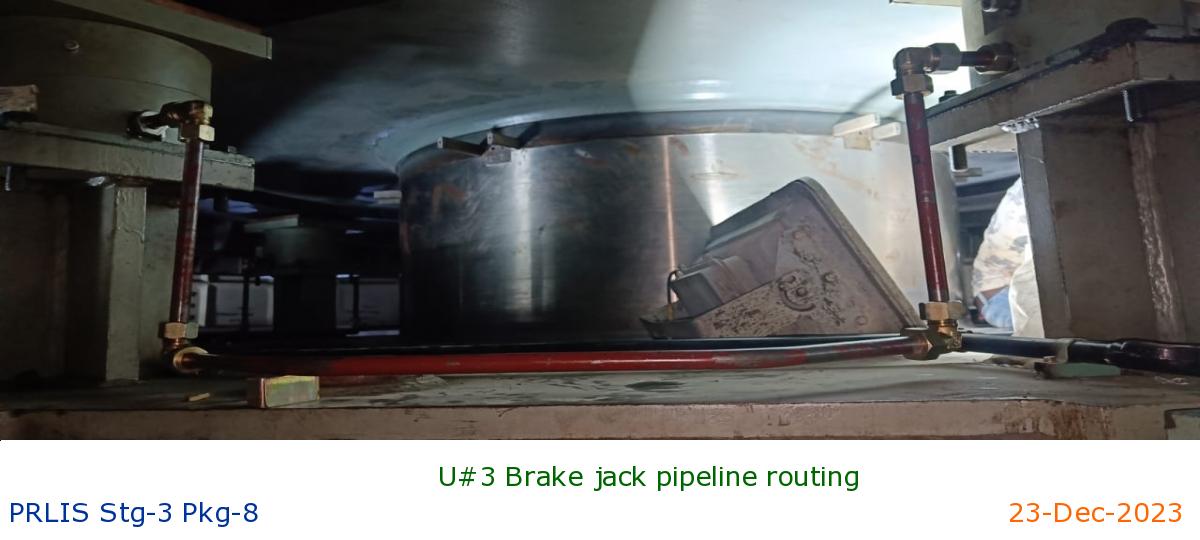

U#3 Brake jack pipeline routing

|

U#2 Water pipelines inside turbine pit

|

U#2 MDV Servomotor alignment completed

|

U#6 stay ring levelling and joining

|

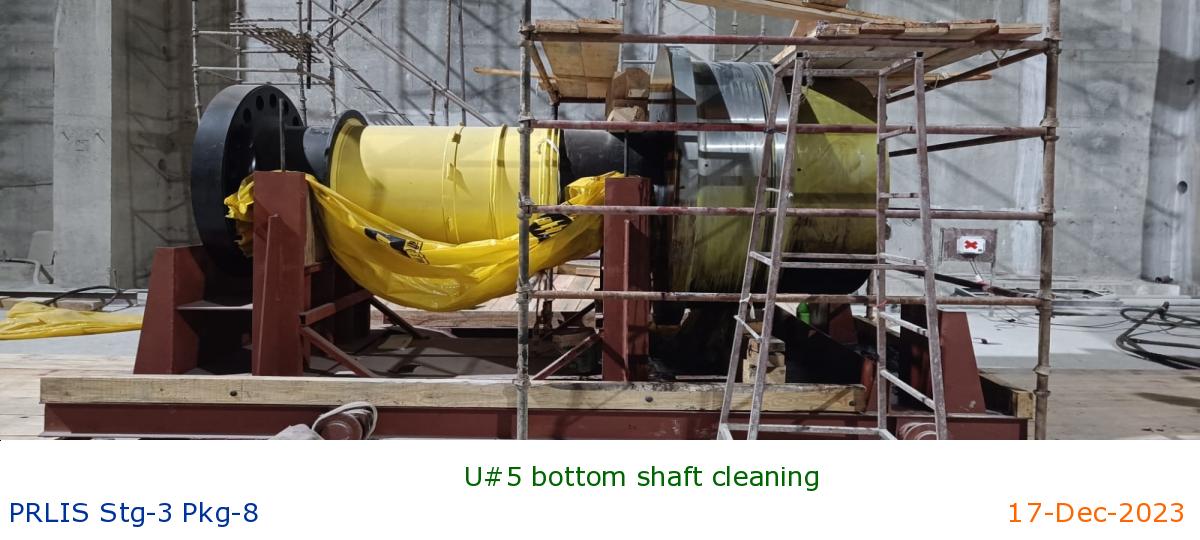

U#5 bottom shaft cleaning

|

U#3 spiral makeup piece edge preparation

|

U#3 UGB Pads installation

|

U#3 PGB Housing leak test

|

U#2 GV Servomotor oil pipelines

|

U#2 MDV Servomotor alignment

|

U#2 bypass valve 300nb pipeline

|

400NB Dewatering header pipeline routing

|

U#5 Stator winding cap filling

|

U#3 UGB Pads assembly

|

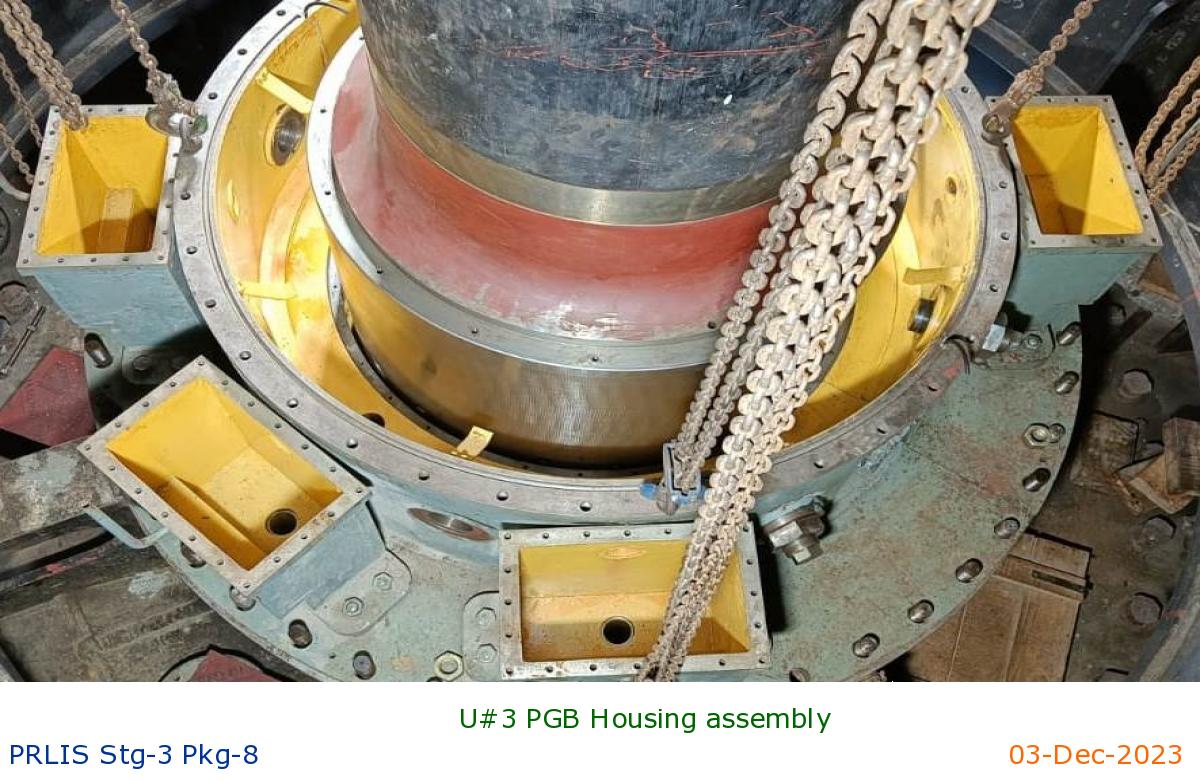

U#3 PGB Housing assembly

|

U#1 Stator Dowelling

|

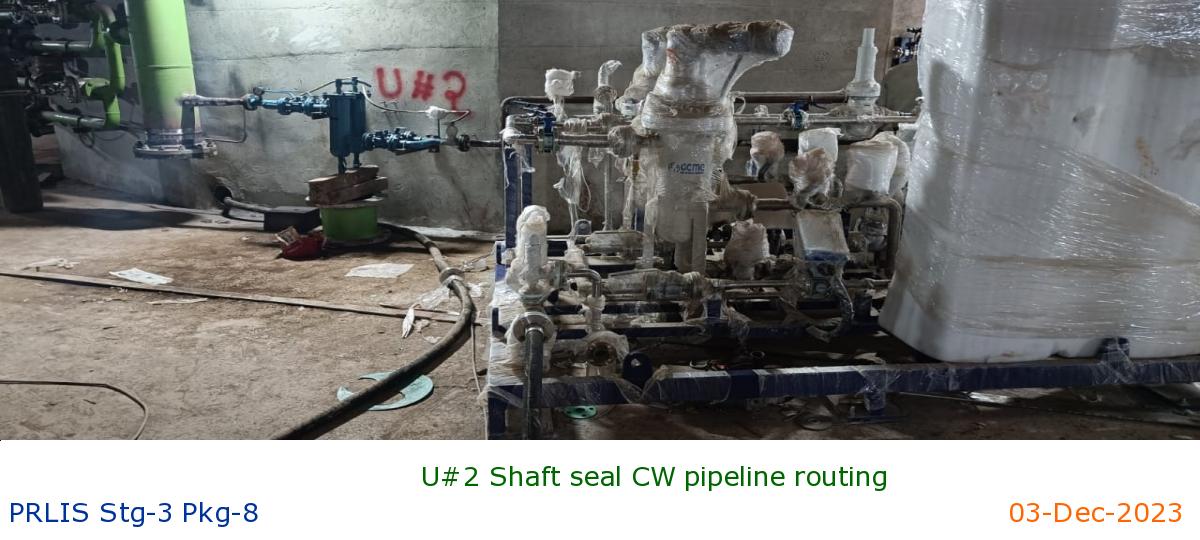

U#2 Shaft seal CW pipeline routing

|

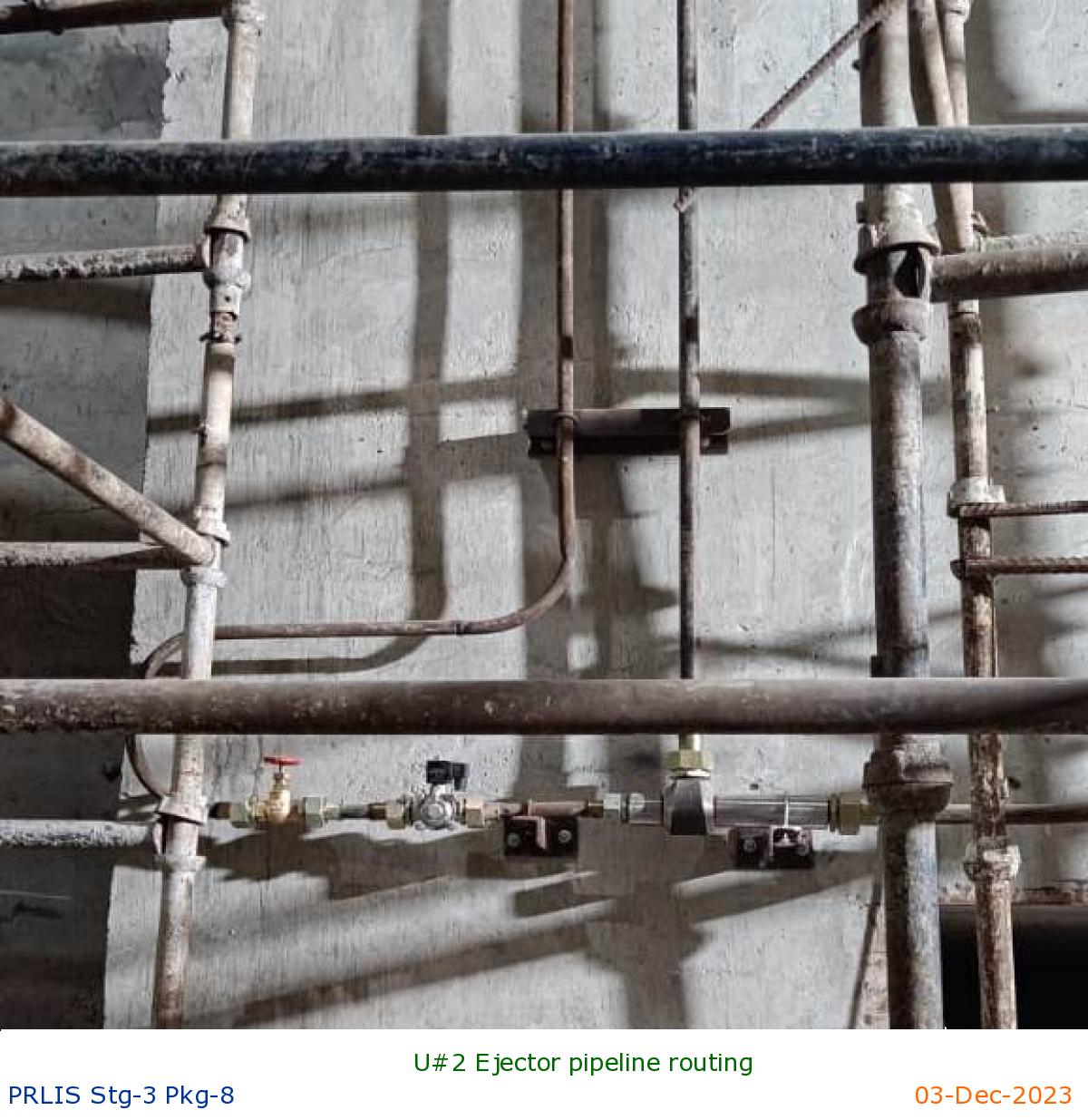

U#2 Ejector pipeline routing

|

U#2 GV Servomotor oil pipeline routing

|

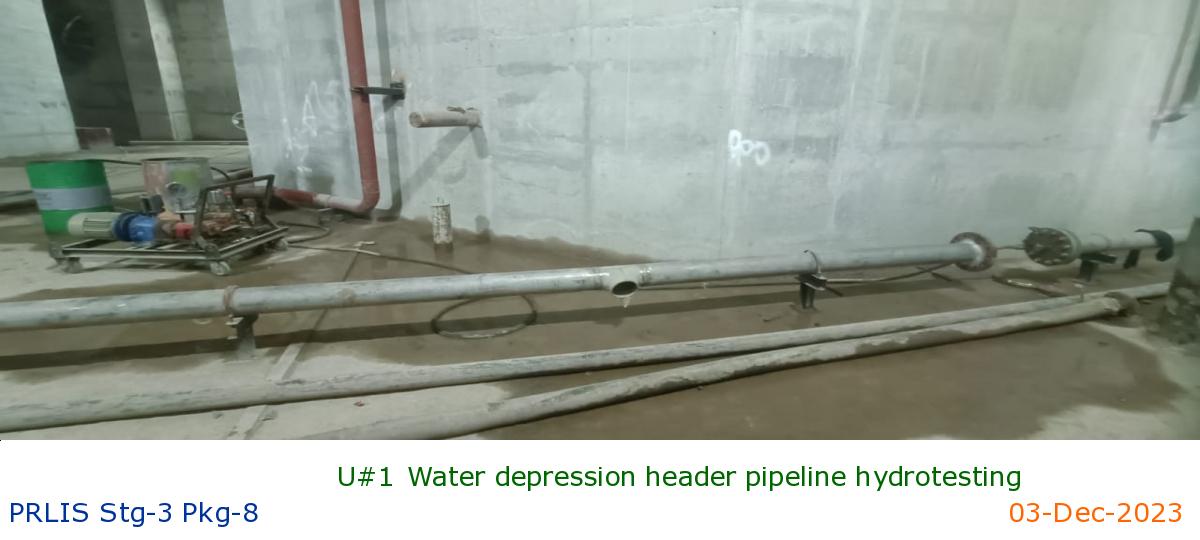

U#1 Water depression header pipeline hydrotesting

|

U#1 GV Servomotor LVDT Installed

|

D&D Sump-2 VT pump installation inprogress

|

D&D sump-1 VT Pump installed

|

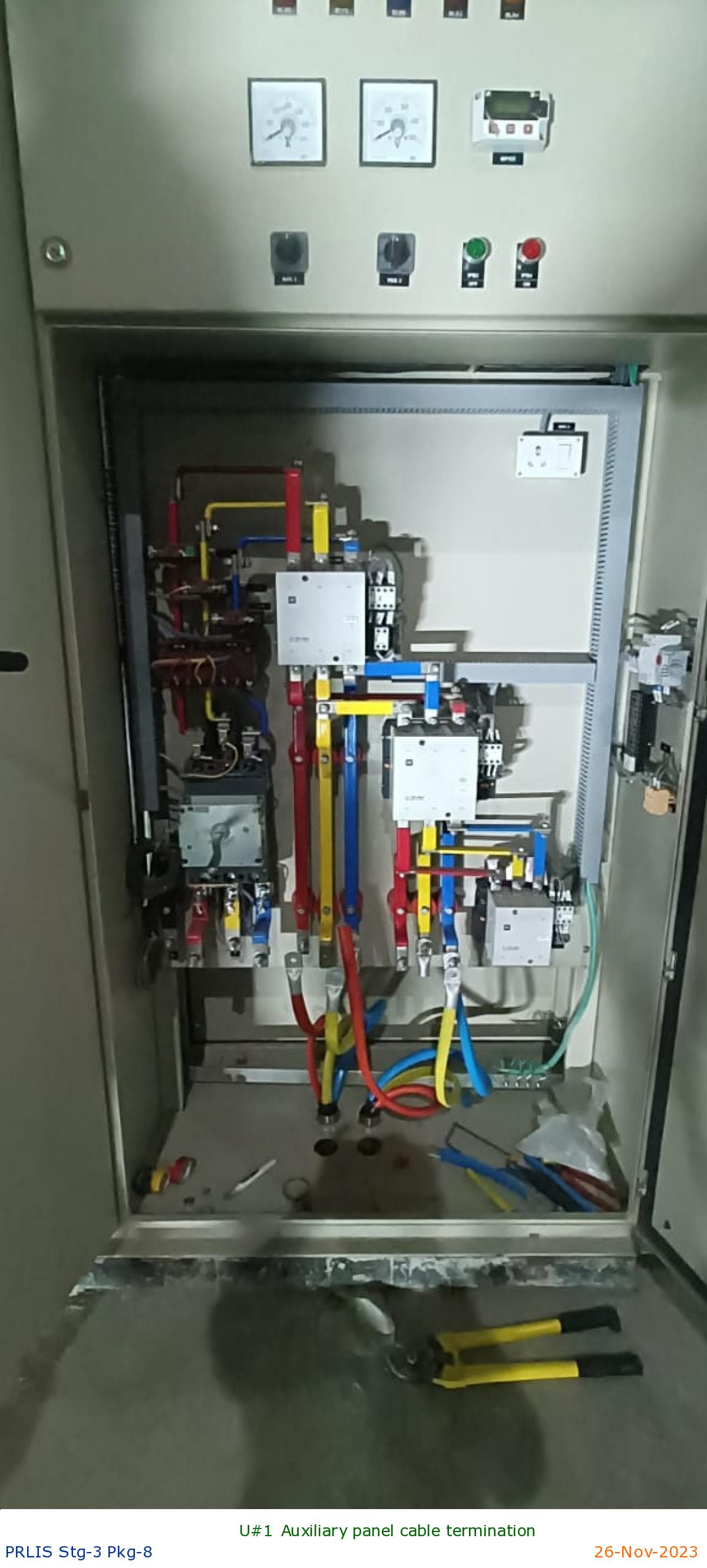

U#1 Auxiliary panel cable termination

|

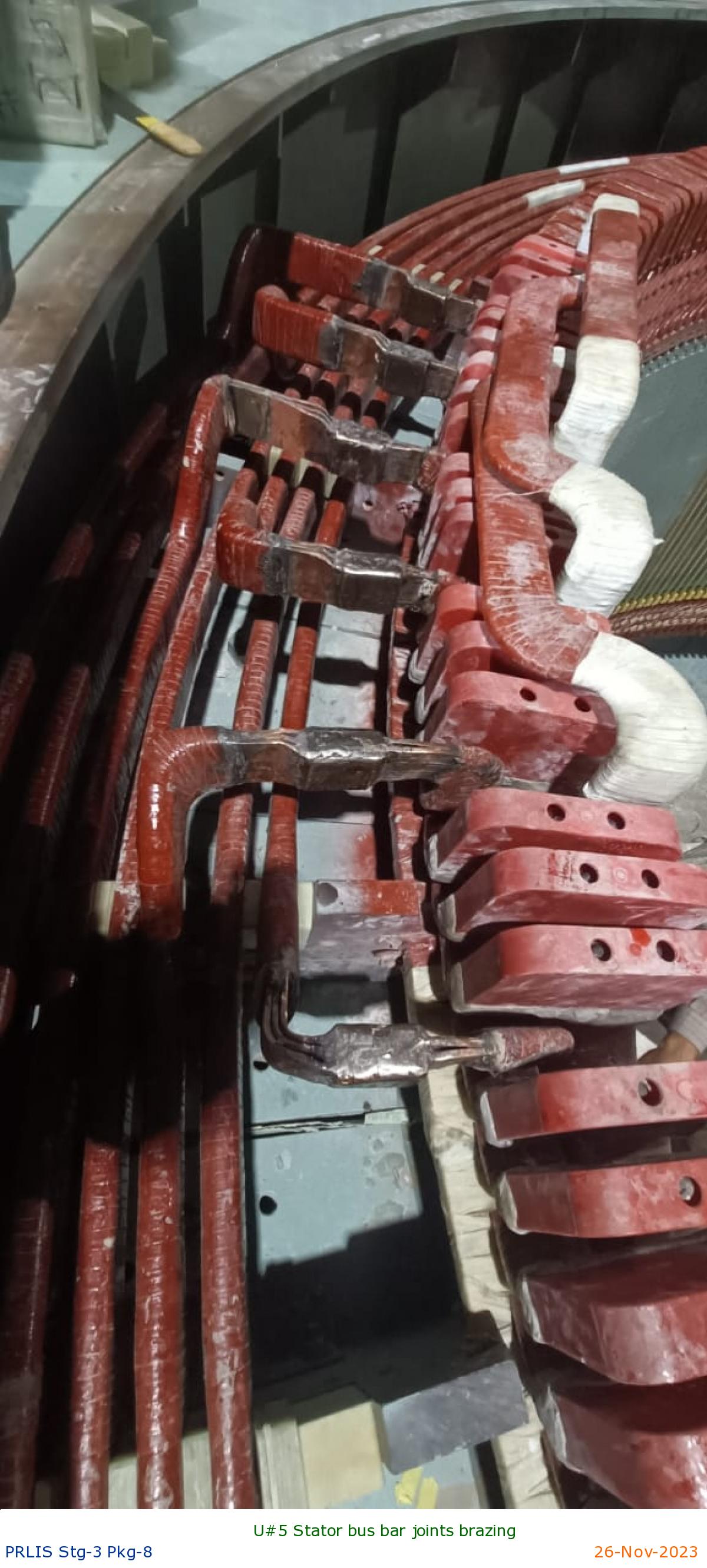

U#5 Stator bus bar joints brazing

|

U#3 PGB oil sump assembly

|

U#2 MDV and Servomotor

|

U#2 stator sole plate doweliing

|

U#2 LP air line tapping to brake panel

|

U#1 Auxiliaries cable termination

|

U#1 MDV Base plates secondary concreting

|

U#1 MDV Base plates secondary concreting

|

water depression system main air header routing

|

Starion air and WDS compressor system in service b

|

U#3 Bottom air guide installation in progress

|

U#2 ET LAVT positioned at ground level

|

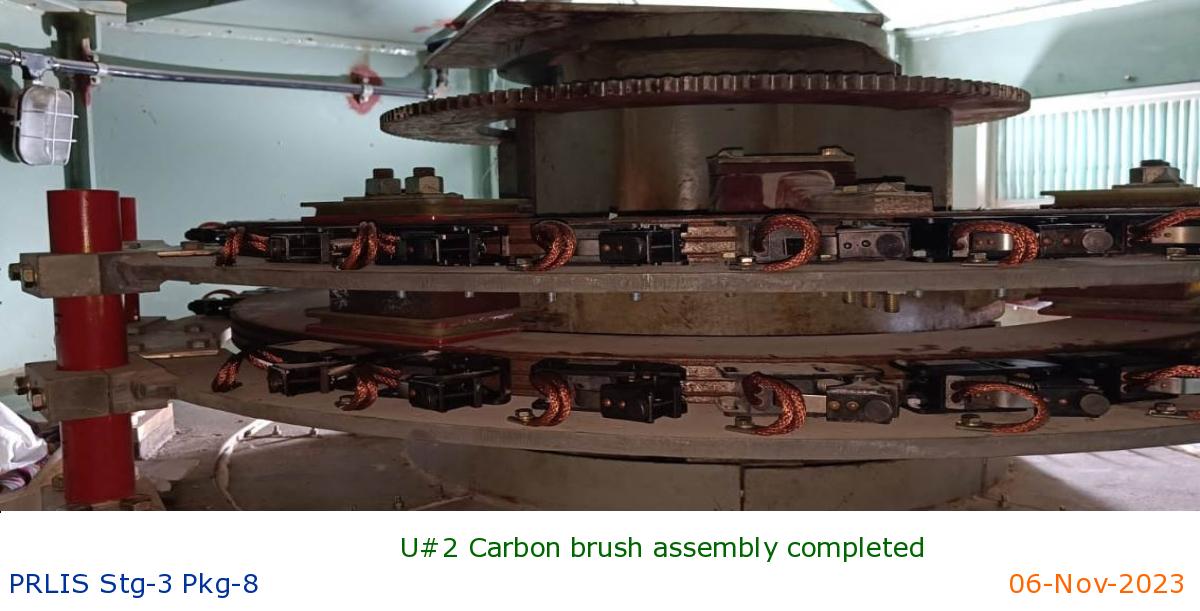

U#2 Carbon brush assembly completed

|

U#2 GV Servomotor oil pipelines hydraulic testing

|

U#1 MDV Pipelines routing

|

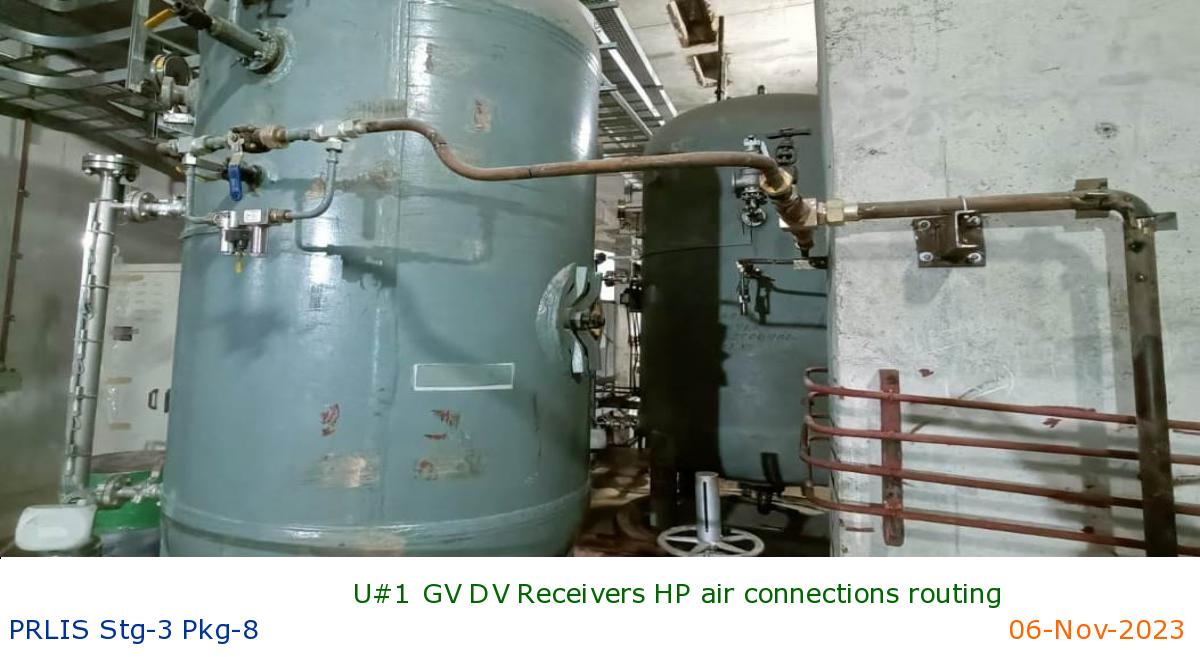

U#1 GV DV Receivers HP air connections routing

|

U#1 MDV Outlet pipe, penstock welding i/p

|

U#1 Shaft seal panel CW line routing completed

|

U#1 Bypass valve installed and pipeline routing

|

U#1 LAVT and ET positioned at ground level

|

U#5 Stator top and bottom bars brazing

|

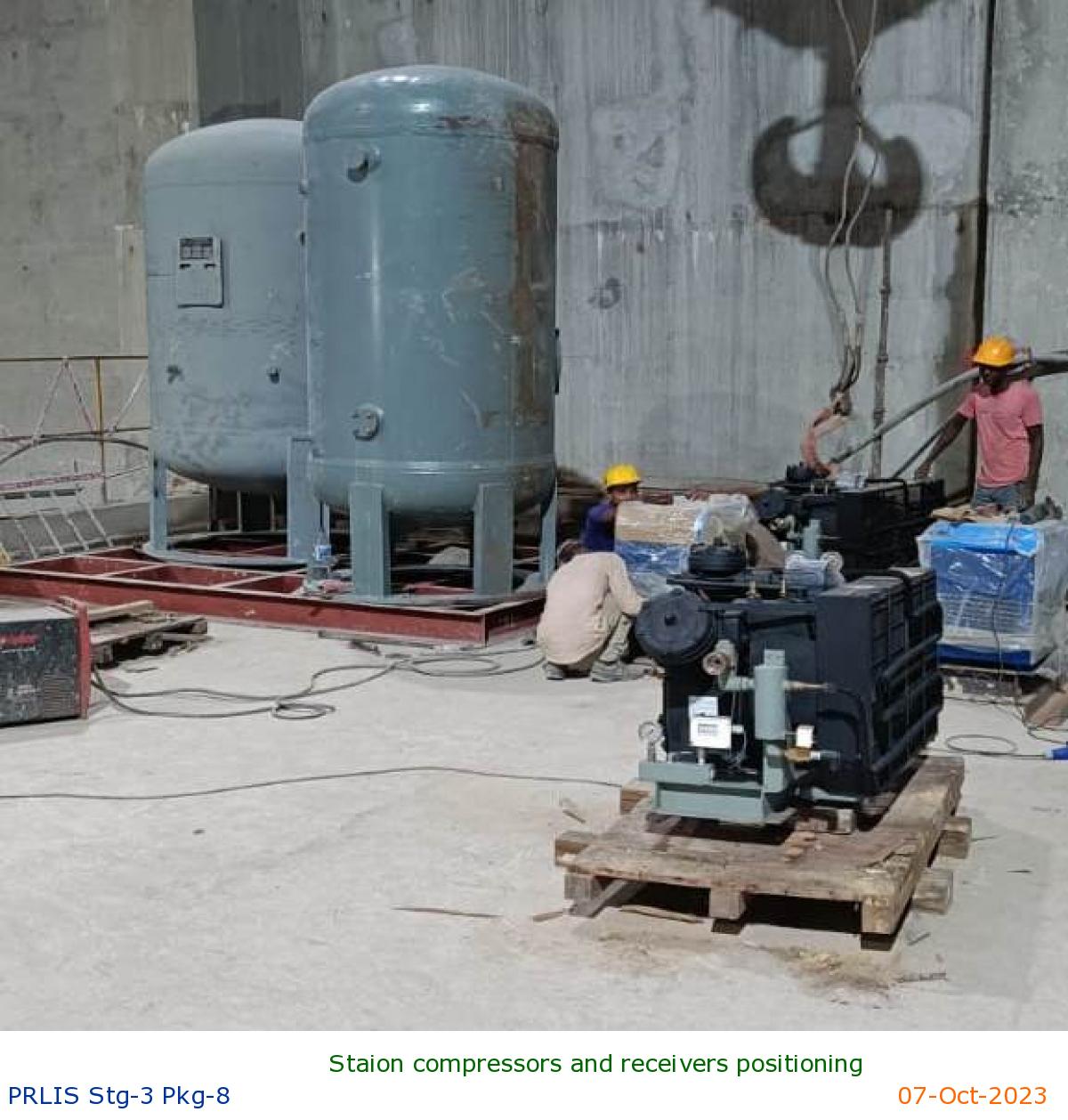

Staion air compressors and receivers

|

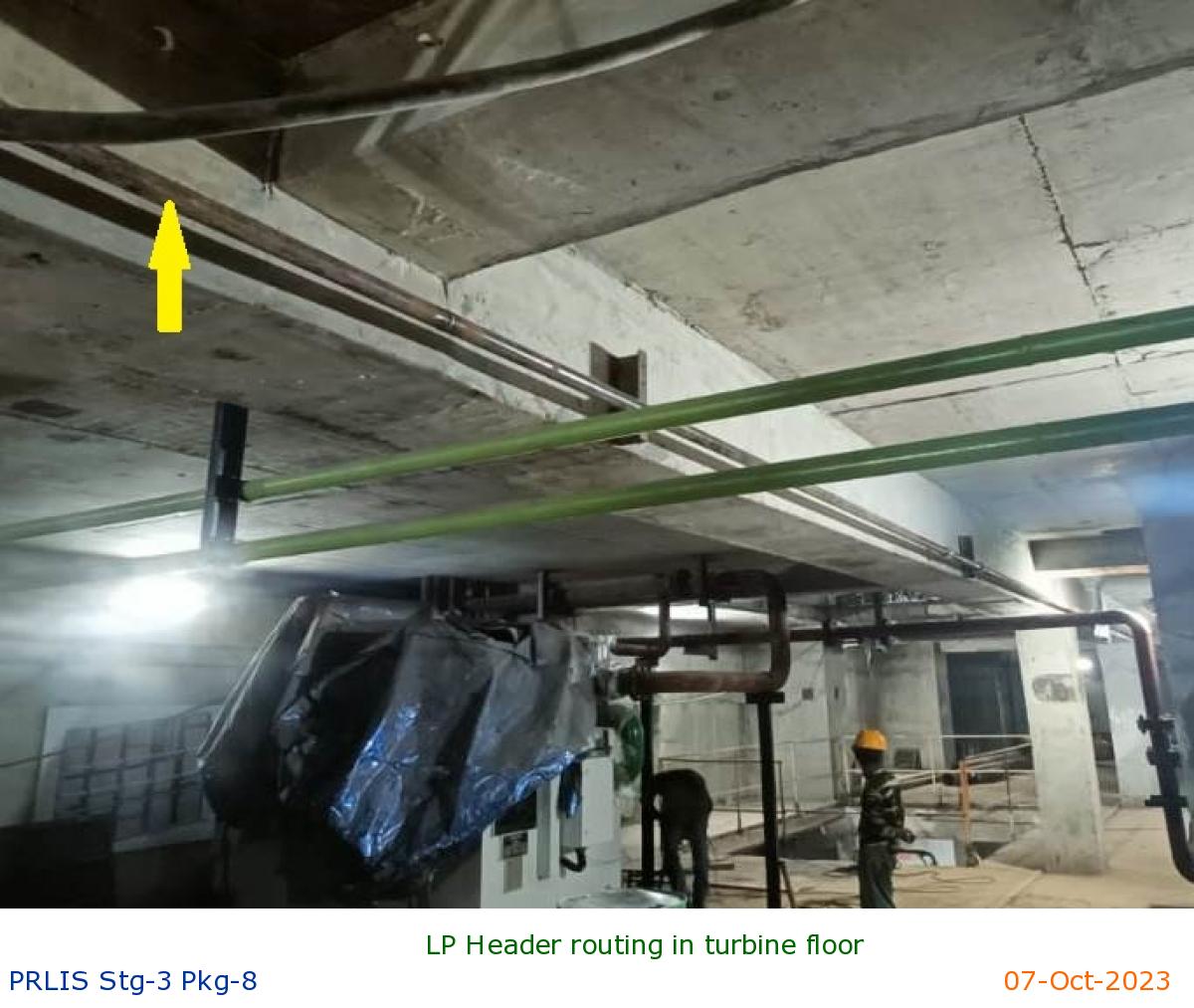

LP Header routing in turbine floor

|

Staion compressors and receivers positioning

|

U#2 MDV outlet pipe welding i/p

|

U#2 LGB Vapour seal assy in progress

|

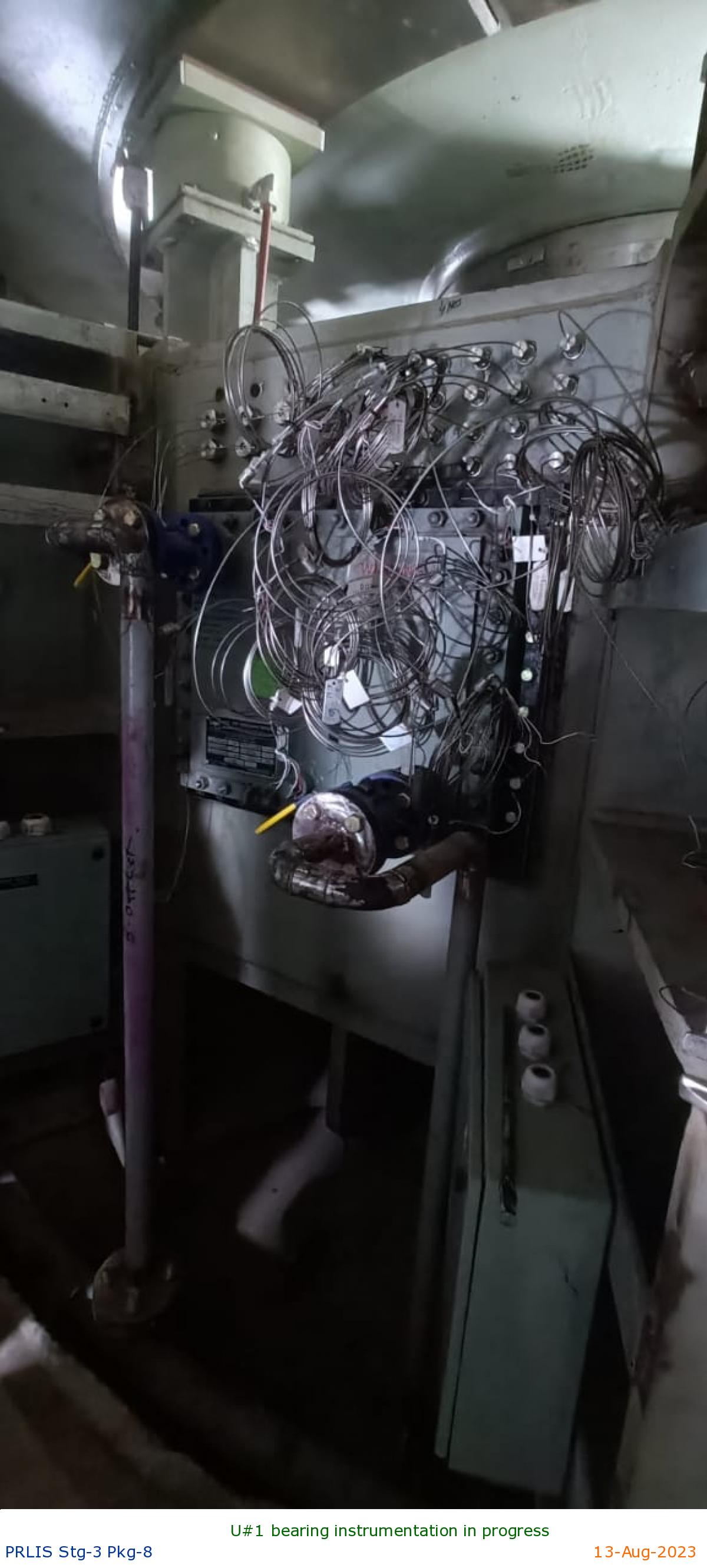

U#2 Top bearing instrumentation completed

|

U#1 Brake dust collector flexible piping

|

U#1 Water and air pipelines routing

|

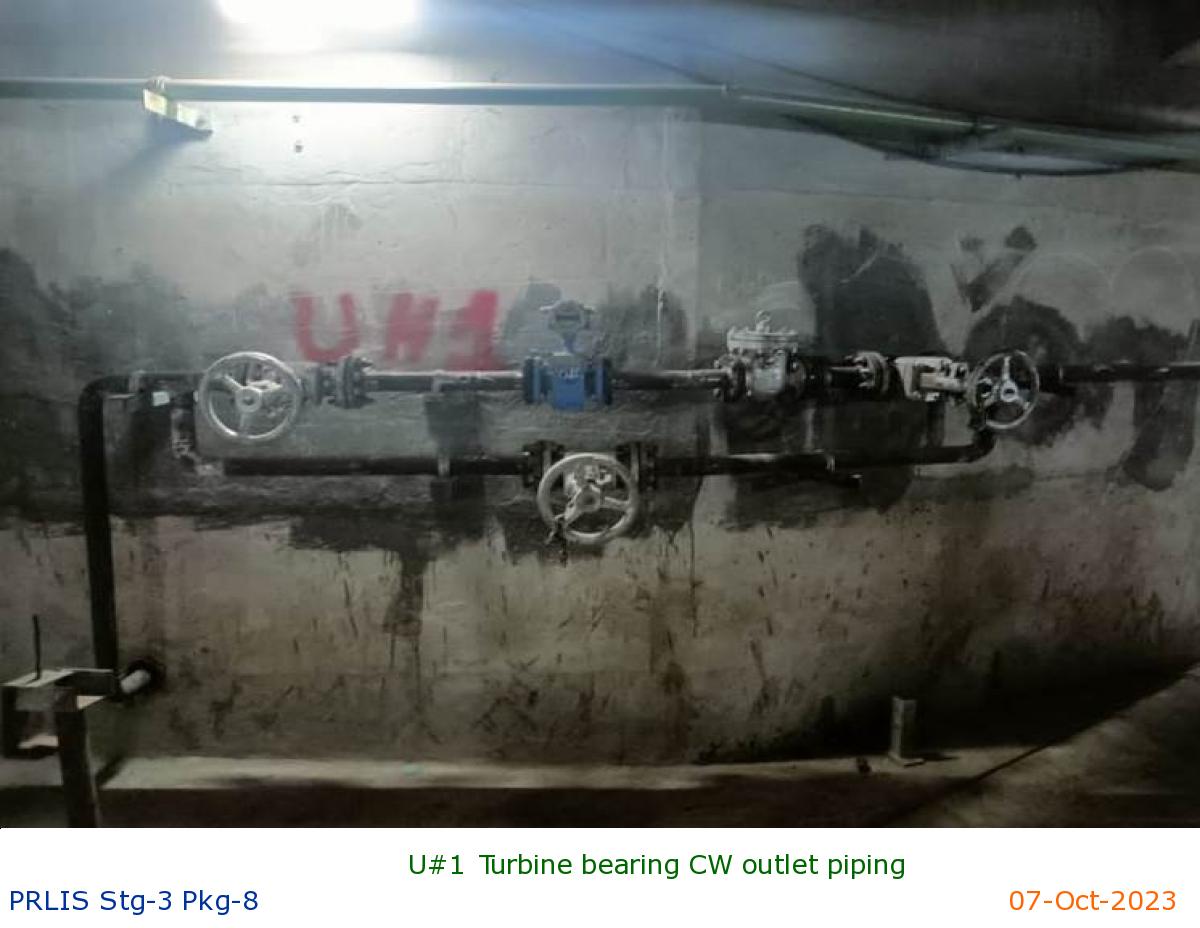

U#1 Turbine bearing CW outlet piping

|

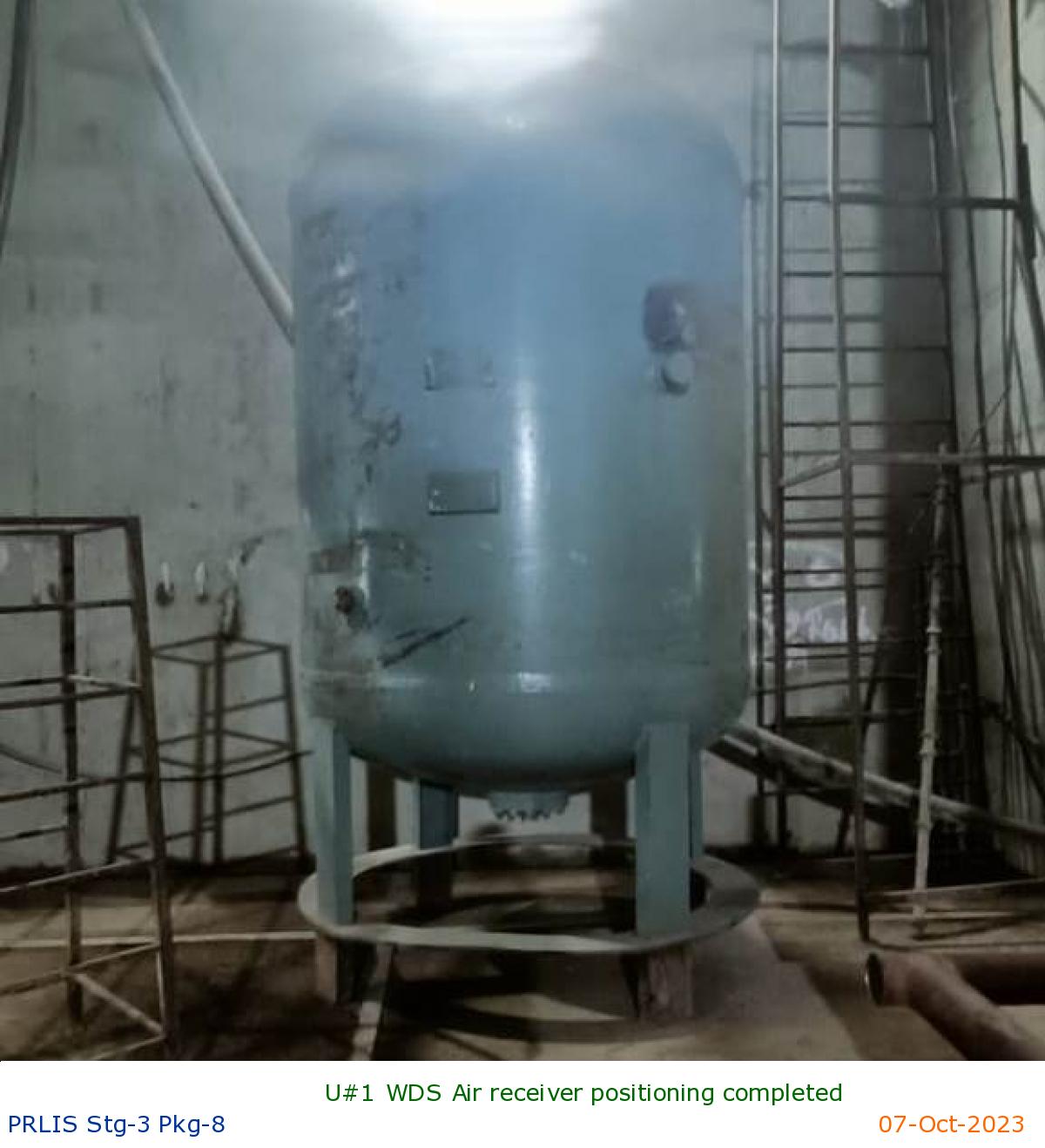

U#1 WDS Air receiver positioning completed

|

U#2 Water air pipelines routing i/p

|

U#1 band drain pipeline routing is completed

|

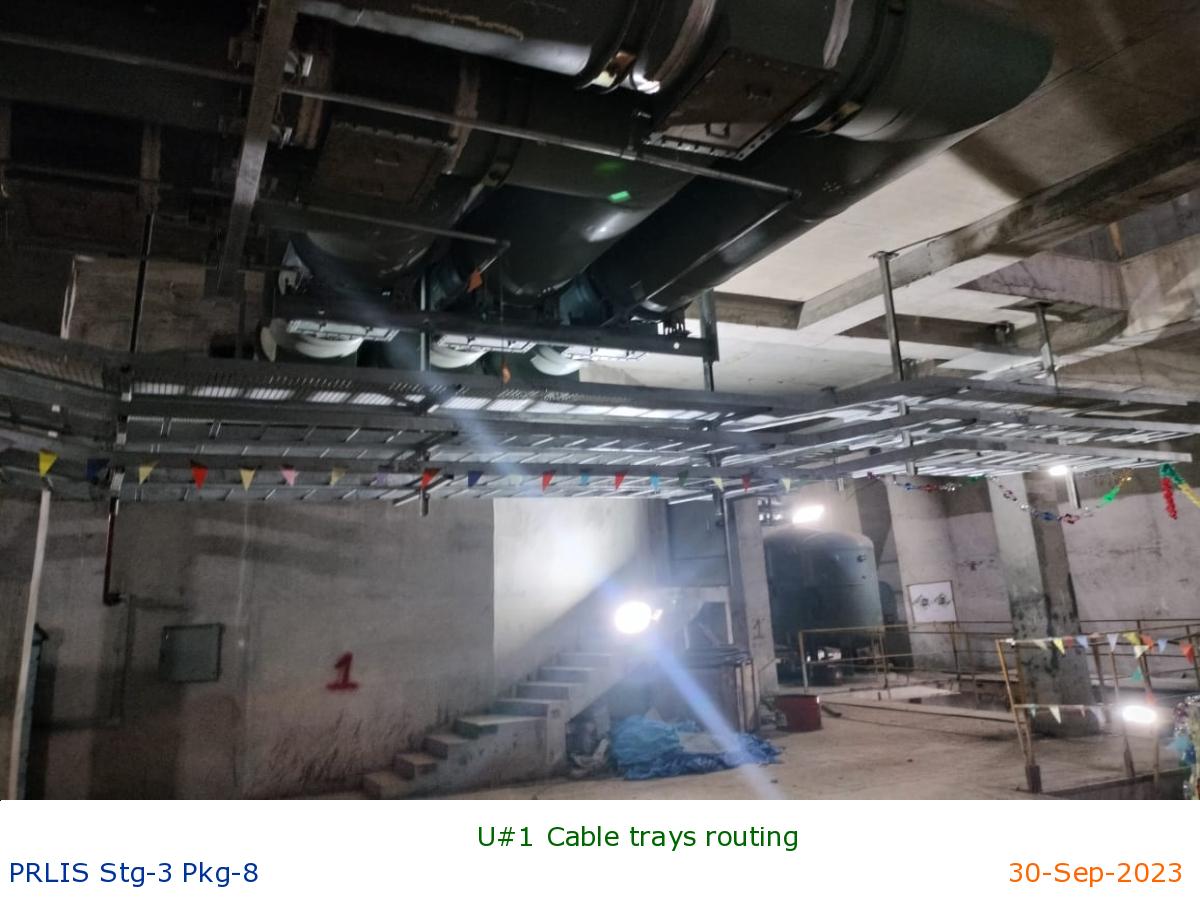

U#1 Cable trays routing

|

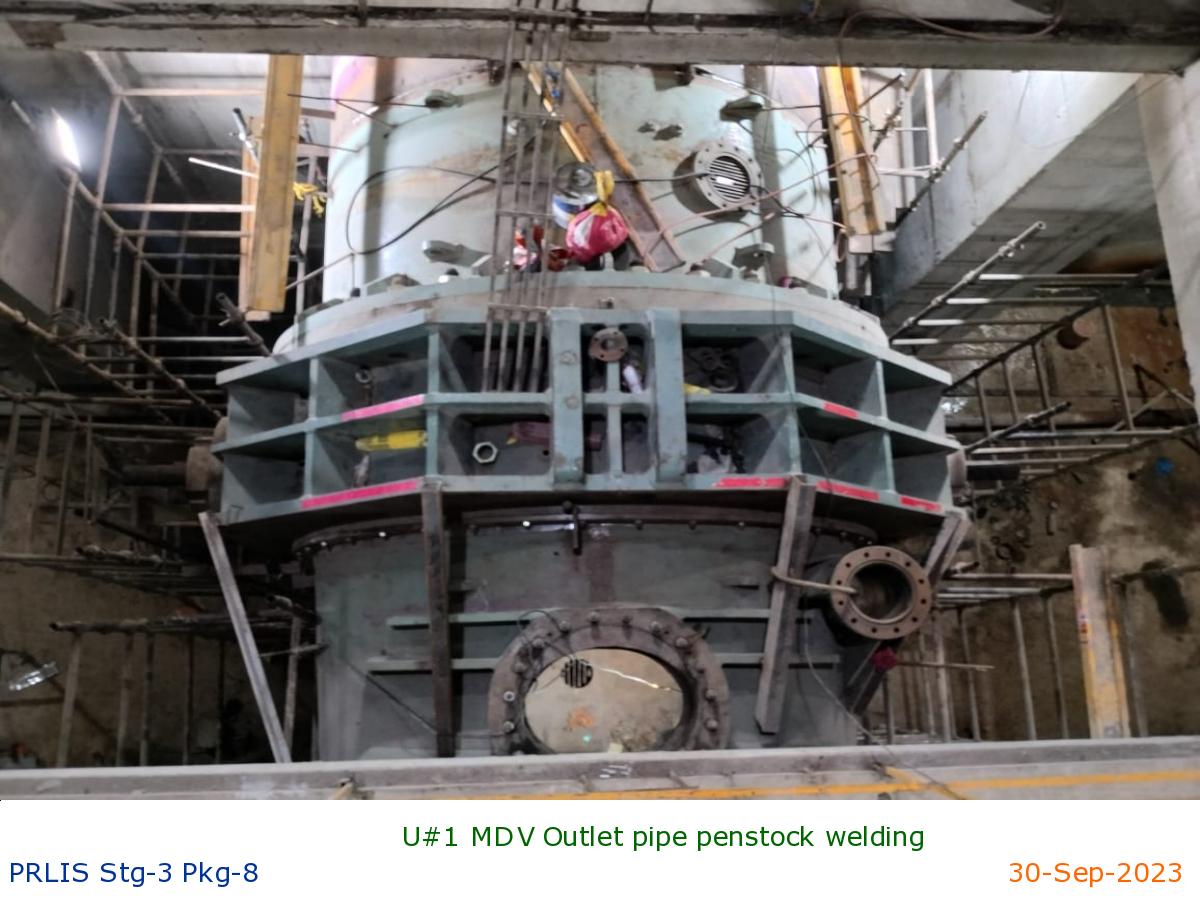

U#1 MDV Outlet pipe penstock welding

|

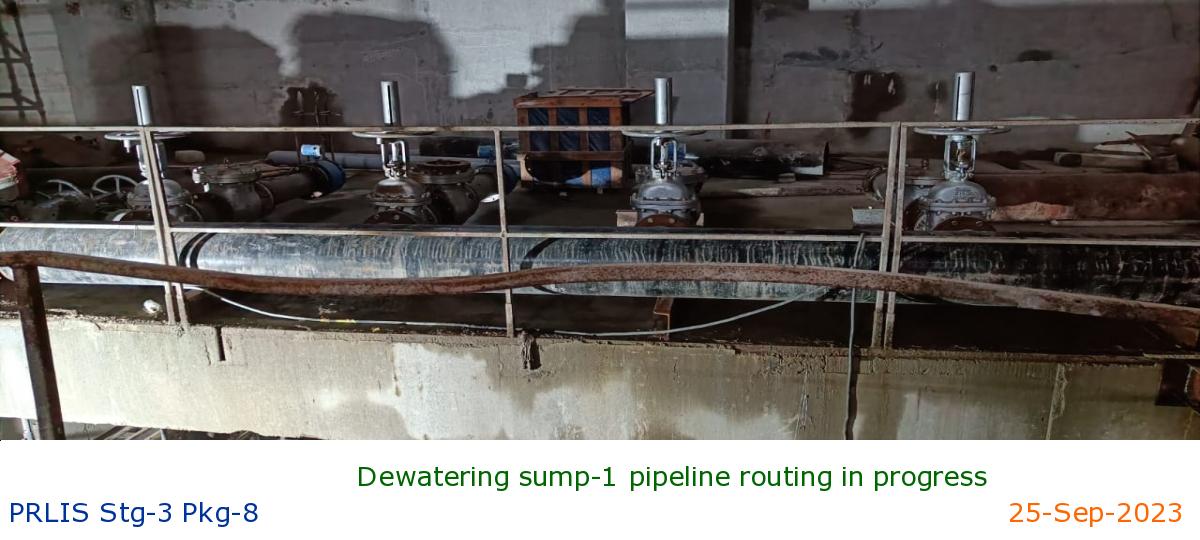

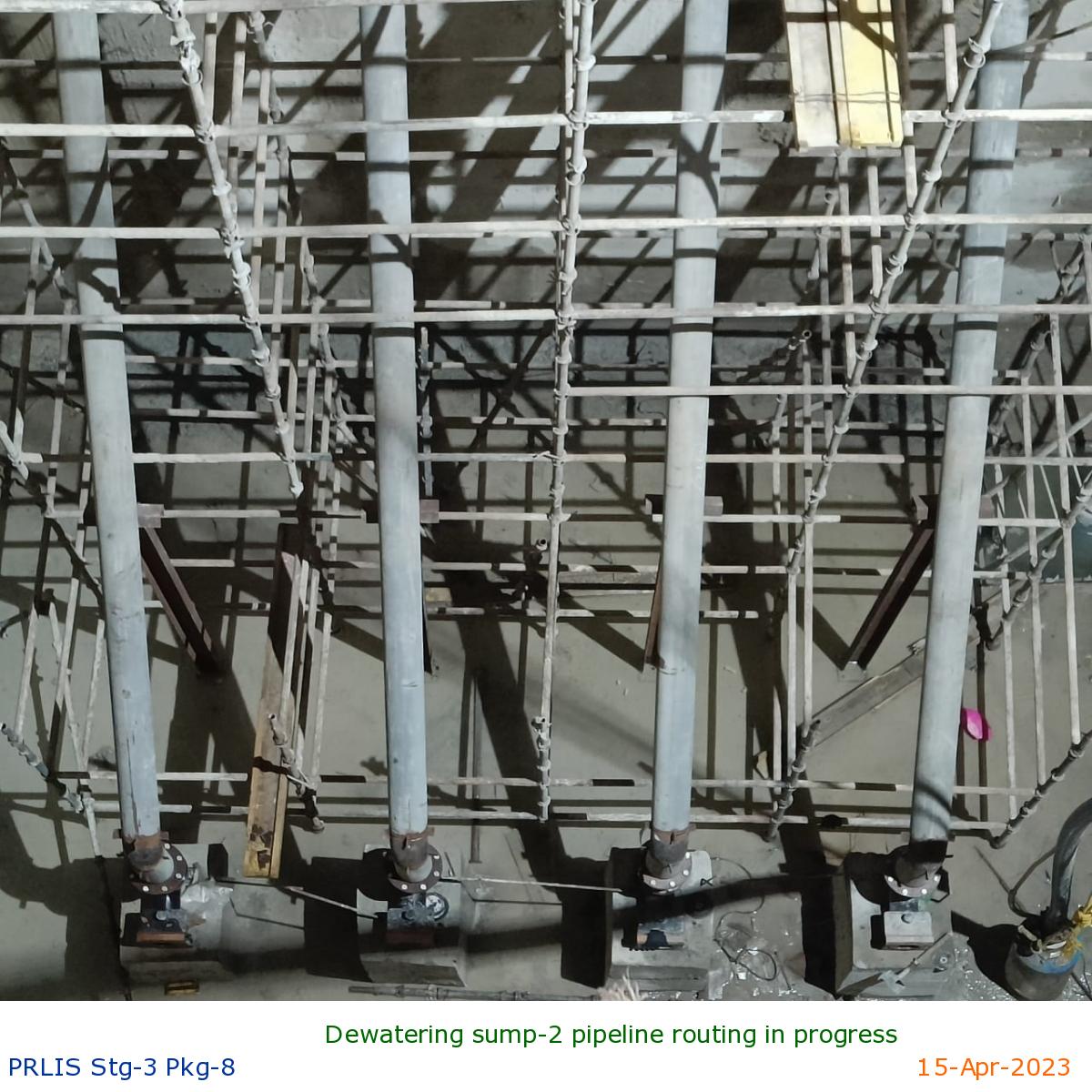

Dewatering sump-1 pipeline routing in progress

|

U#10 dt liner alignment in progress

|

U#2 DT Drain valves installation in progress

|

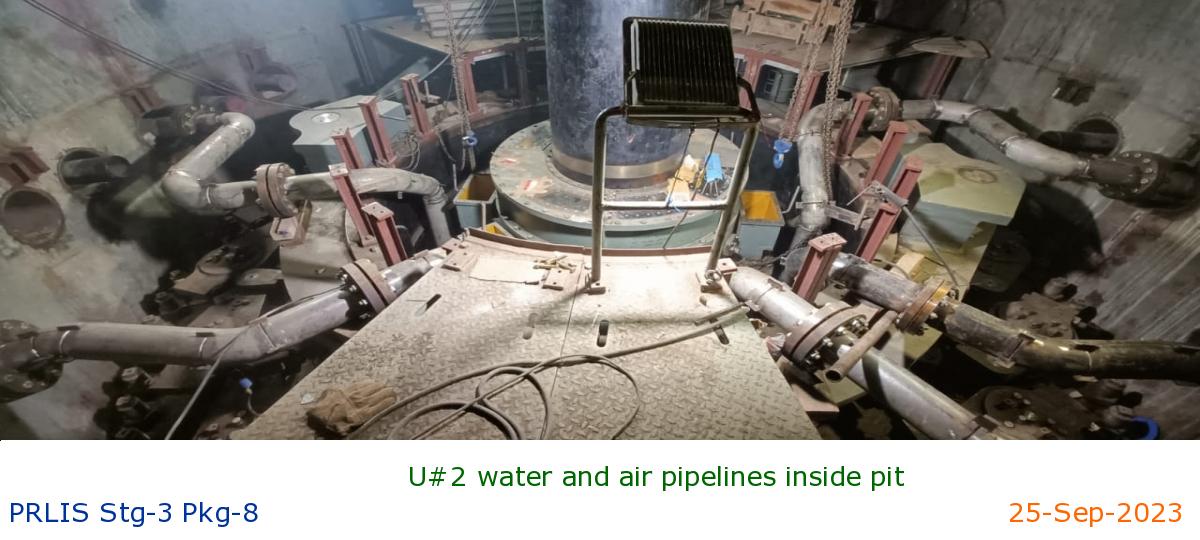

U#2 water and air pipelines inside pit

|

U#2 water depression air release pipeline

|

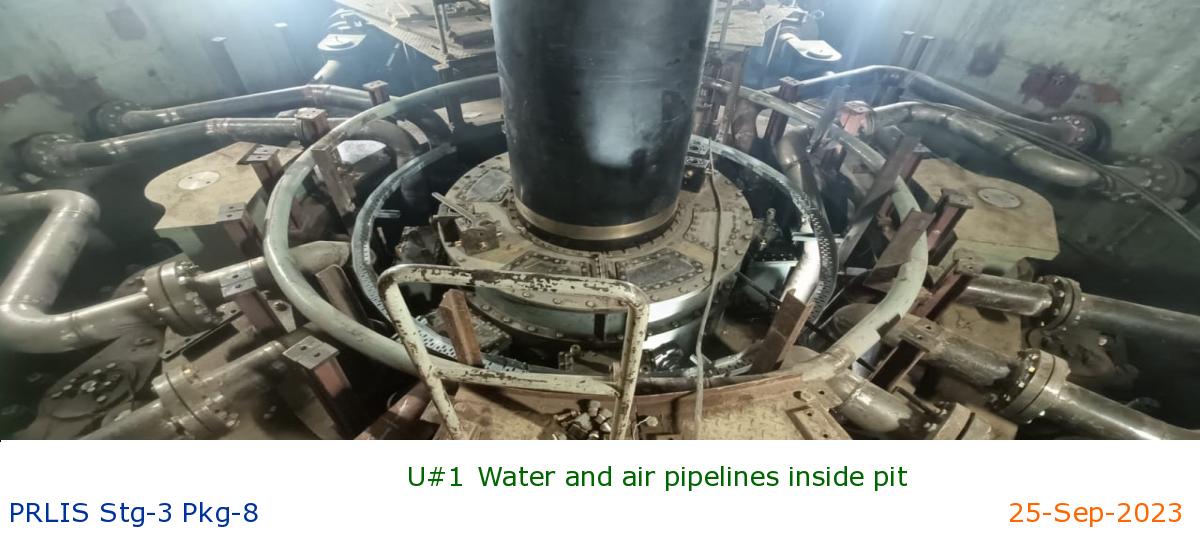

U#1 Water and air pipelines inside pit

|

U#1 MDV Servomotor pipeline routing

|

U#1 Water depression receiver positioning i/p

|

U#1 cyclone seperator drain pipeline

|

U#1 shaft seal cw pipeline

|

U#1 UGB oil filling and filtration

|

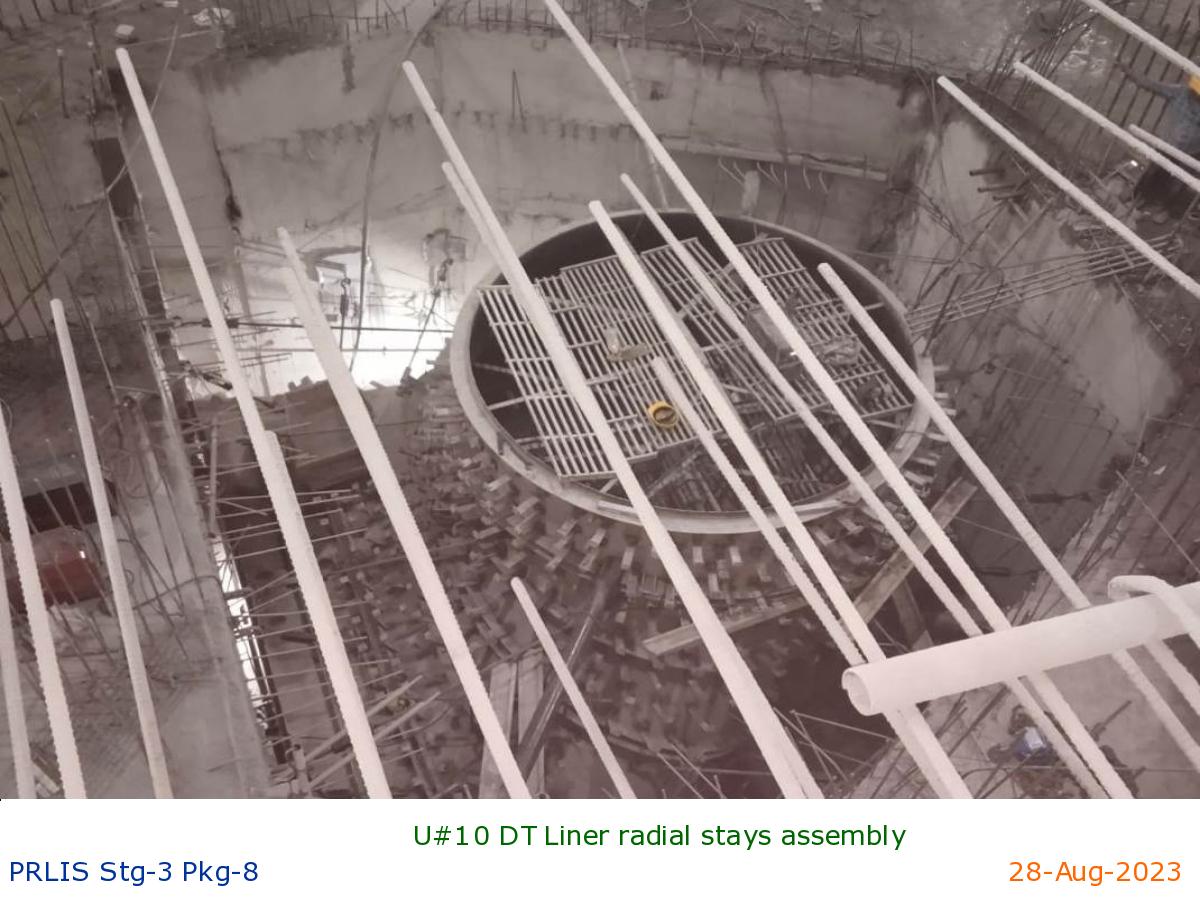

U#10 DT Liner radial stays assembly

|

U#6 DT Cone lowering completed

|

U#5 stator top bar laying in progress

|

U#3 Top air guide installation in progress

|

U#3 Shaft seal installation in progress

|

U#2 TGB Housing leak test completed

|

U#1 Water and air pipelines routing

|

U#1 Water depression air release pipeline routing

|

U#1 LGB Instrumentaion works in progress

|

U#1 UGB Instrumentation works in progress

|

D&D sump-1 400nb header pipe routing in progress

|

D&D sump-1 pump pedestals erectioncompleted

|

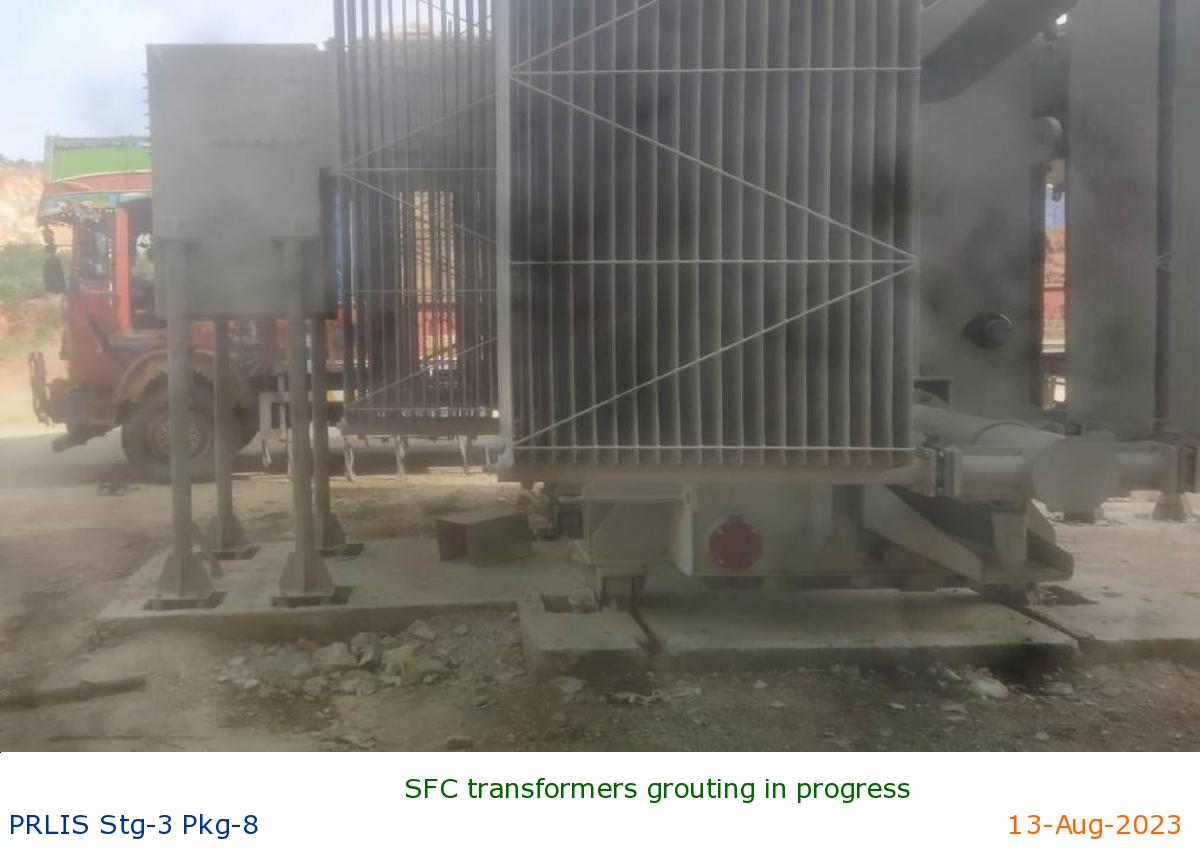

SFC transformers grouting in progress

|

U#2 turbine bearing housingassy completed

|

U#2 bottom bearing assy in progress

|

U#2 Top bearing assy is in progress

|

U#1 GV Lever stopper positioning and welding

|

U#1 water and air pipeline assy in turbine pit

|

U#1 bearing instrumentation in progress

|

U#1 busduct welding at surface level in progress

|

U#1 motor transformer oil filtration in prorgess

|

U#4 CW system works in progress

|

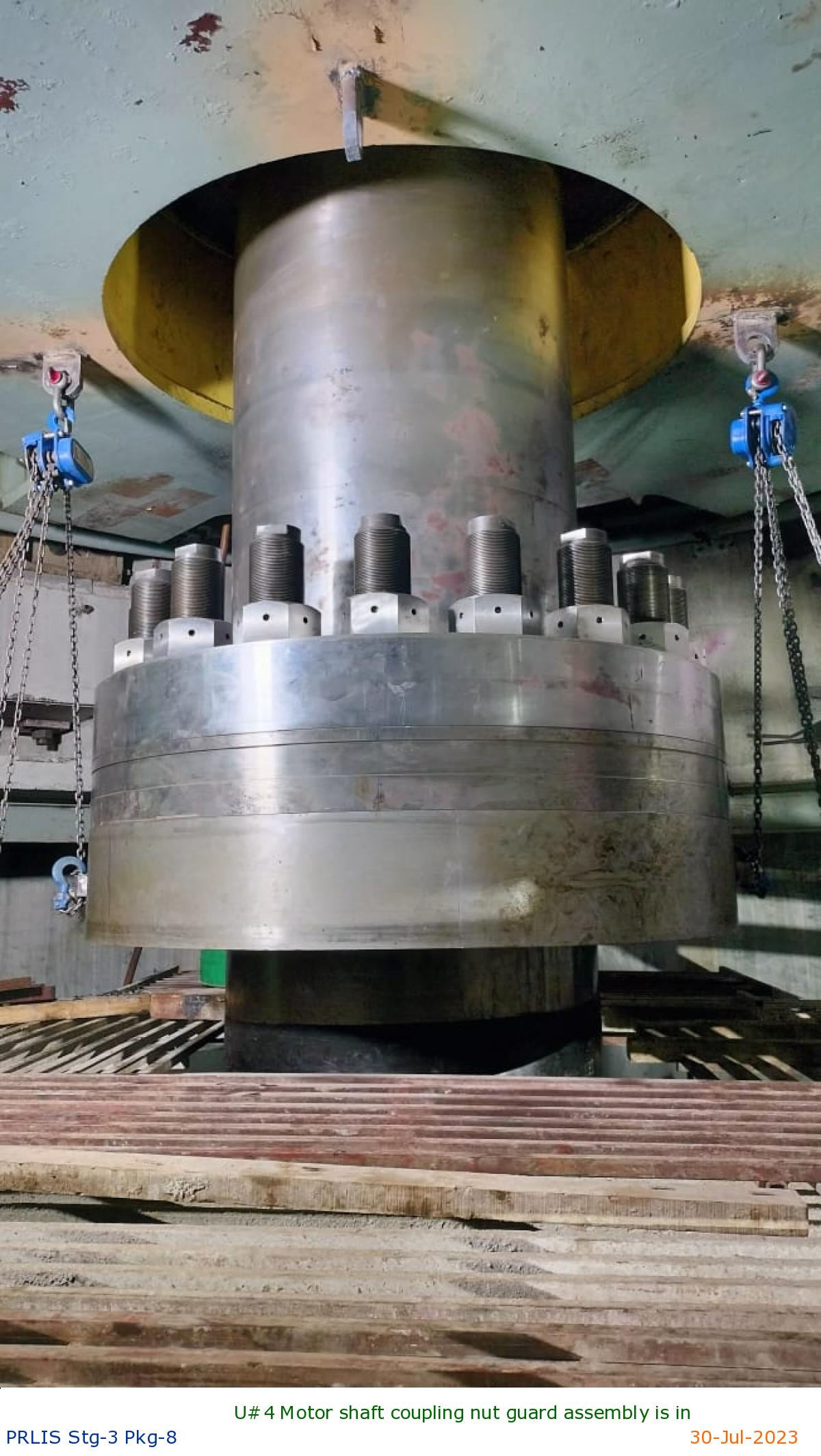

U#4 Motor shaft coupling nut guard assy is complet

|

U#3 LGB sole plates locking is completed

|

U#2 turbine bearing housingassy in progress

|

U#1 oil manifold pipeline routing is completed

|

U#1 LGB assembly completed

|

U#1 UGB assembly completed

|

U#7 DT segments alignment with unit axis is in pro

|

U#5 GV sevomotor reassembly is completed

|

U#4 Motor shaft coupling nut guard assembly is in

|

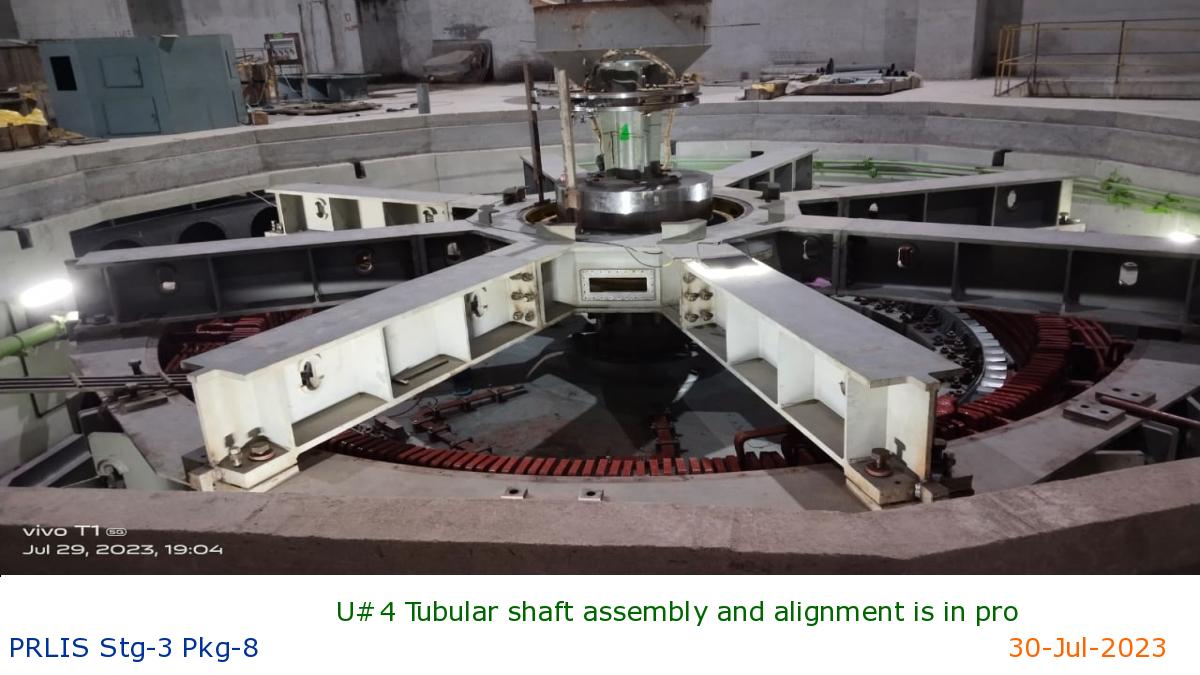

U#4 Tubular shaft assembly and alignment is in pro

|

U#3 Installation of shaft seal is in progress

|

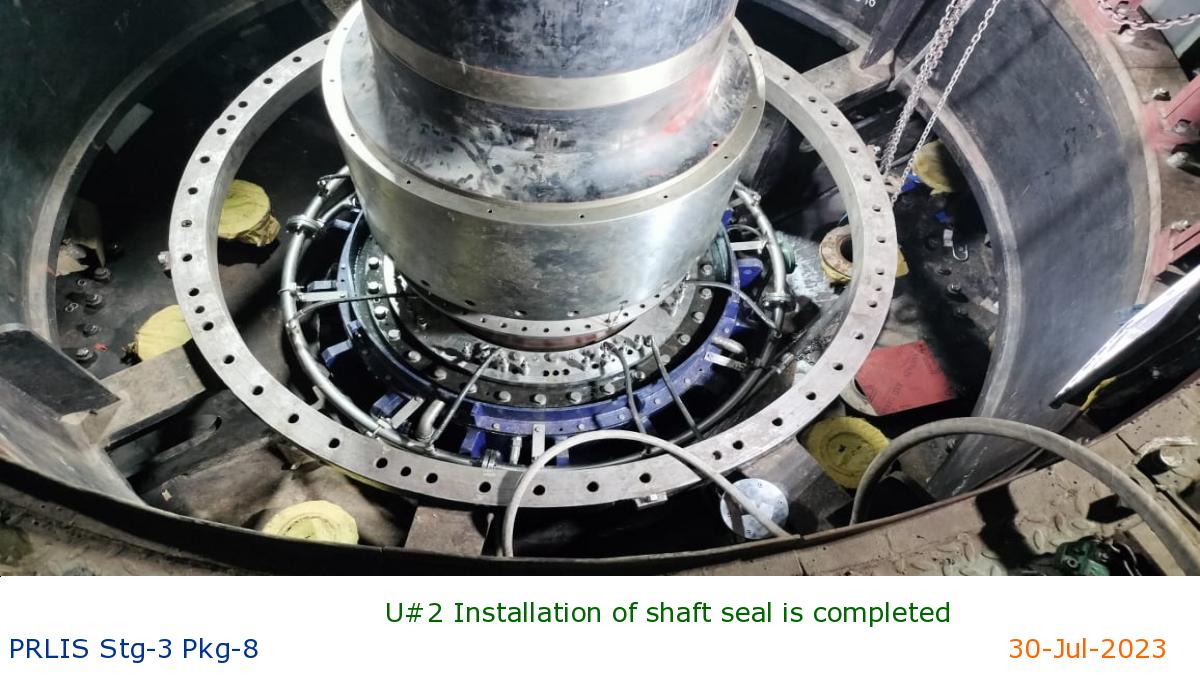

U#2 Installation of shaft seal is completed

|

U#1 LGB coolers and pipeline assembly is in progre

|

U#1 Top coolers assembly is in progres

|

SFC Transformer LV Bushing assy completed

|

SFC Transformer hv bushing assy completed

|

U#5 gv servomotor foundation block welding i/p

|

U#5 stator segments positioning in progress

|

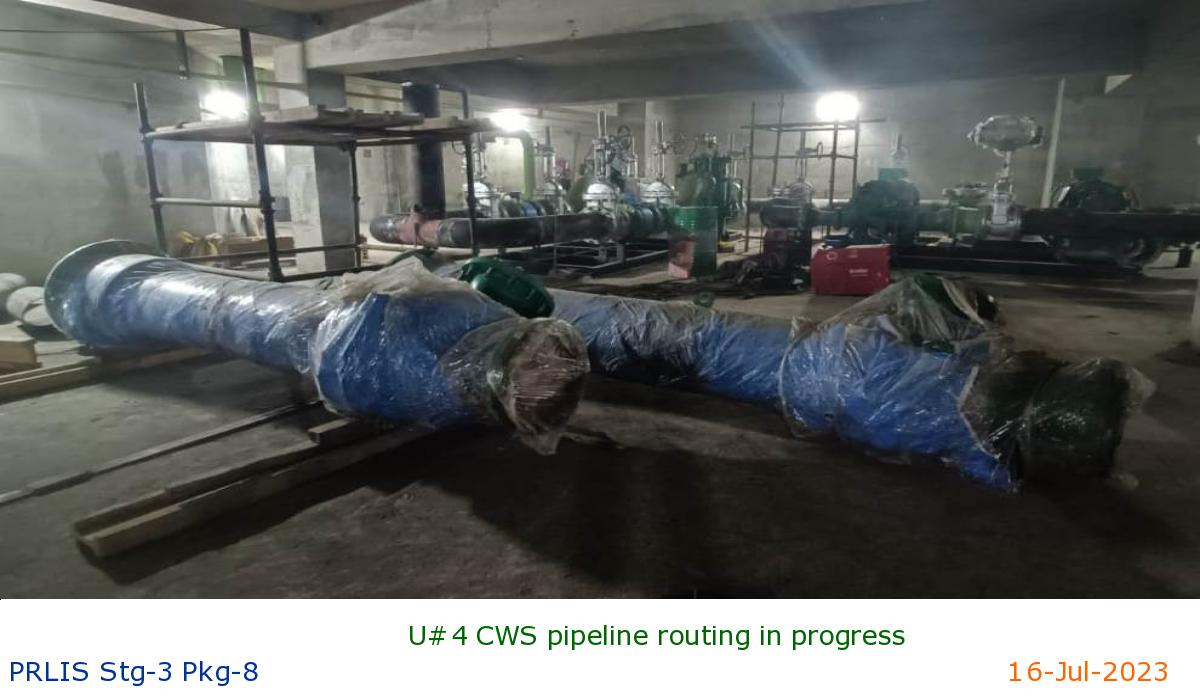

U#4 CWS pipeline routing in progress

|

U#3 impeller nutguard assy and welding in progress

|

U#2 mdv servomotor leakage test in progress

|

U#1 Cable tray laying in progress

|

U#2 shaft seal installation in progress

|

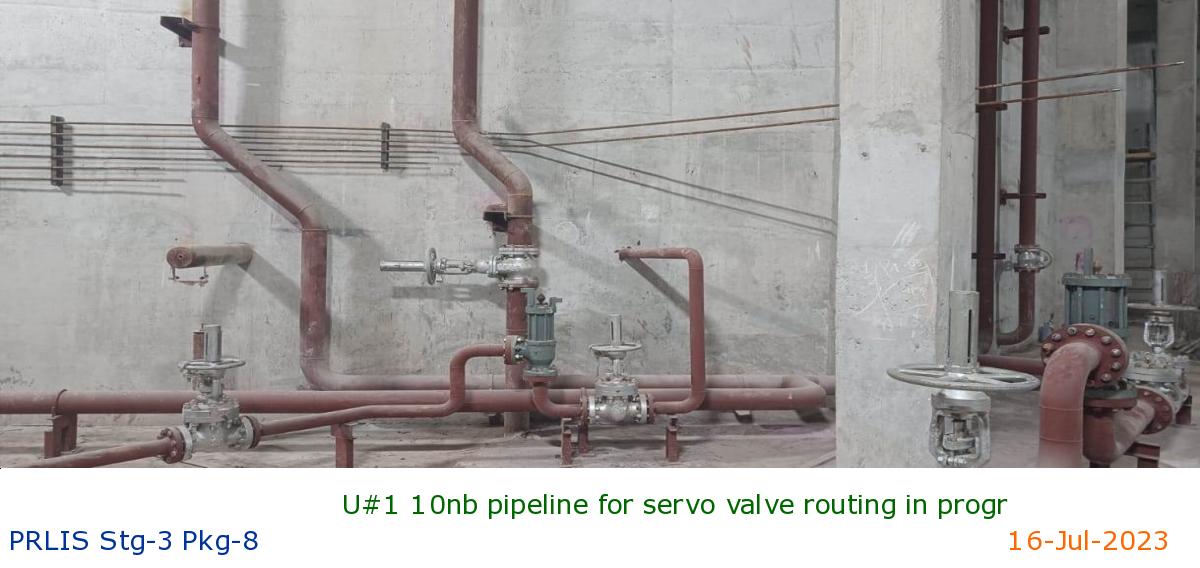

U#1 10nb pipeline for servo valve routing in progr

|

U#1 Turbine bearings assy in progress

|

Pkg-8 SFC Transformers 2 sets

|

SFC O/P Transformer HV & LV Bushings assy complete

|

U#5 GV Servomotor dowelling in progress

|

U#4 CWS pump to strainer piping in progress

|

U#4 LGB coolers testing in progress

|

U#3 Motor transformer hv bushings assy completed

|

U#2 MDV inlet pipe welding in progress

|

U#2 Motor Transformer HV Bushing assy completed

|

U#1 Cable tray laying in progress

|

U#1 TGB Housing leak test in progress

|

U#1 GV Servomotor oil pipelines routing i/p

|

U#1 LGB Cooler piping assembly in progress

|

U#1 Top bearing final assembly in progress

|

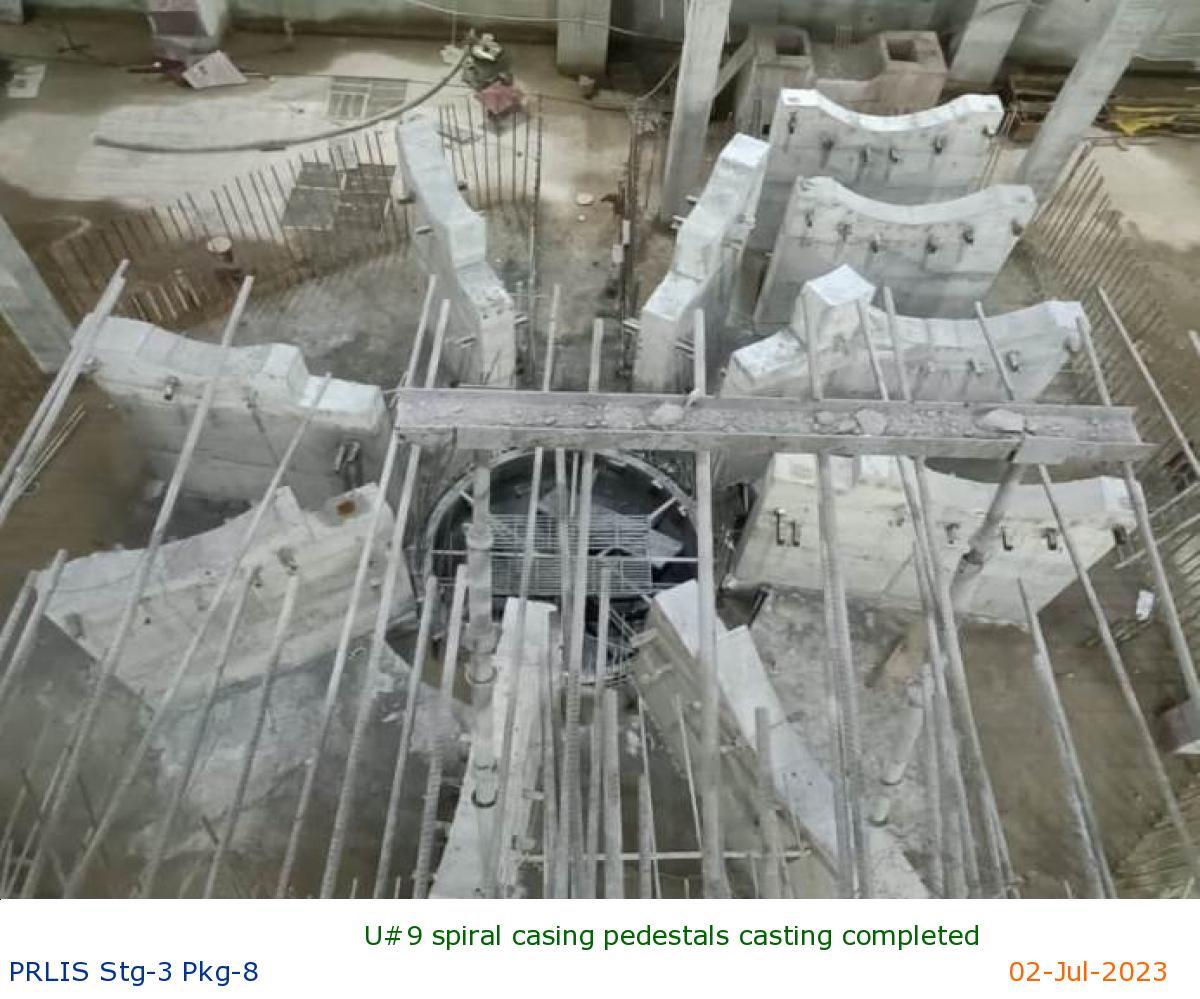

U#9 spiral casing pedestals casting completed

|

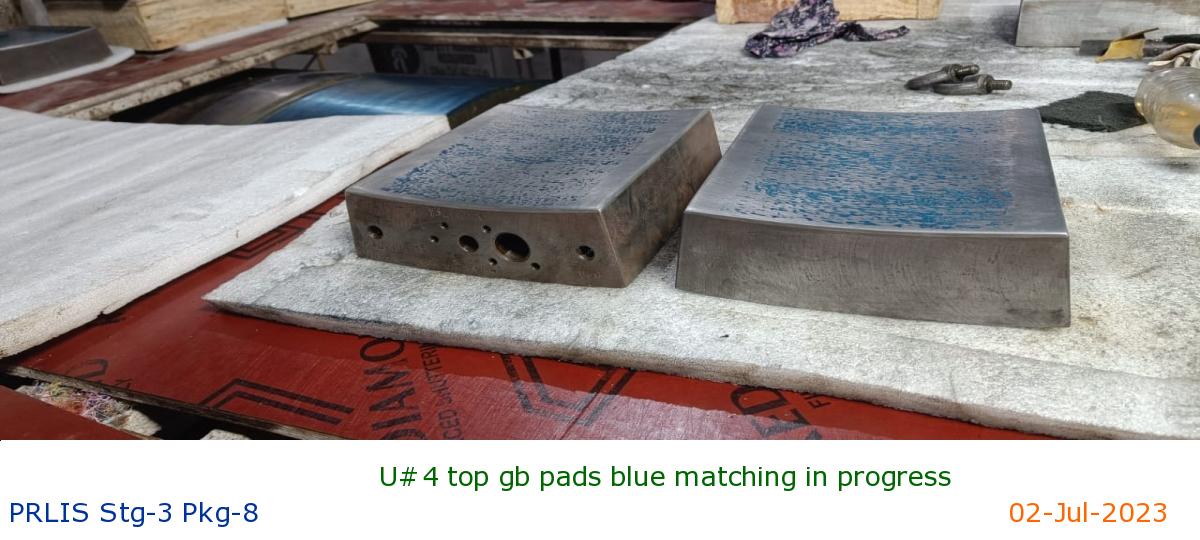

U#4 top gb pads blue matching in progress

|

U#4 CW Strainer skid works completed

|

U#4 Turbine shaft alignment completed

|

U#2 cable tray laying is in progress

|

U#2 turbine bearing sump assy in progress

|

U#1 Cable trays laying is in progress

|

U#1 Motor transformer

|

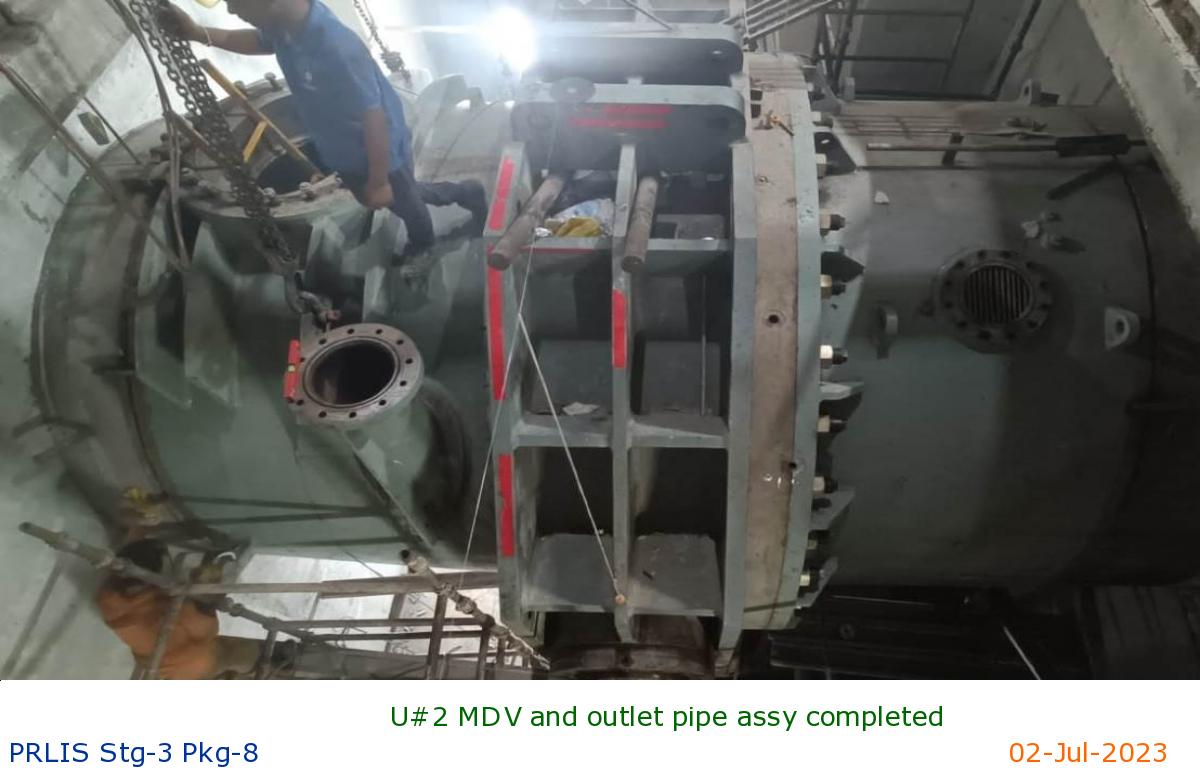

U#2 MDV and outlet pipe assy completed

|

U#1 Turbine GB Housing assembly in progress

|

U#5 GV servomotor welding is in progress

|

U#4 top gb pads blue matching in progress

|

U#4 CW pump motor skid

|

U#4 motor turbine shafts coupling in progress

|

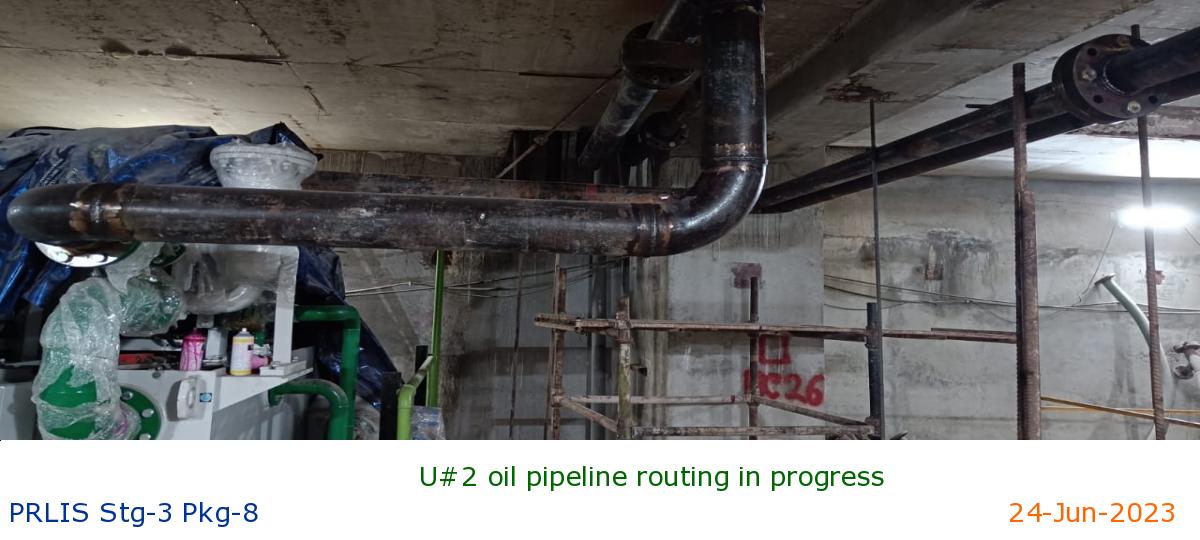

U#2 oil pipeline routing in progress

|

U#2 MDV lowering completed

|

U#1 LGB coolers assy in progress

|

U#1 Turbine GB Housing assembly in progress

|

U#5 servomotor connecting rod assy in progress

|

U#4 Top bracket lowering completed

|

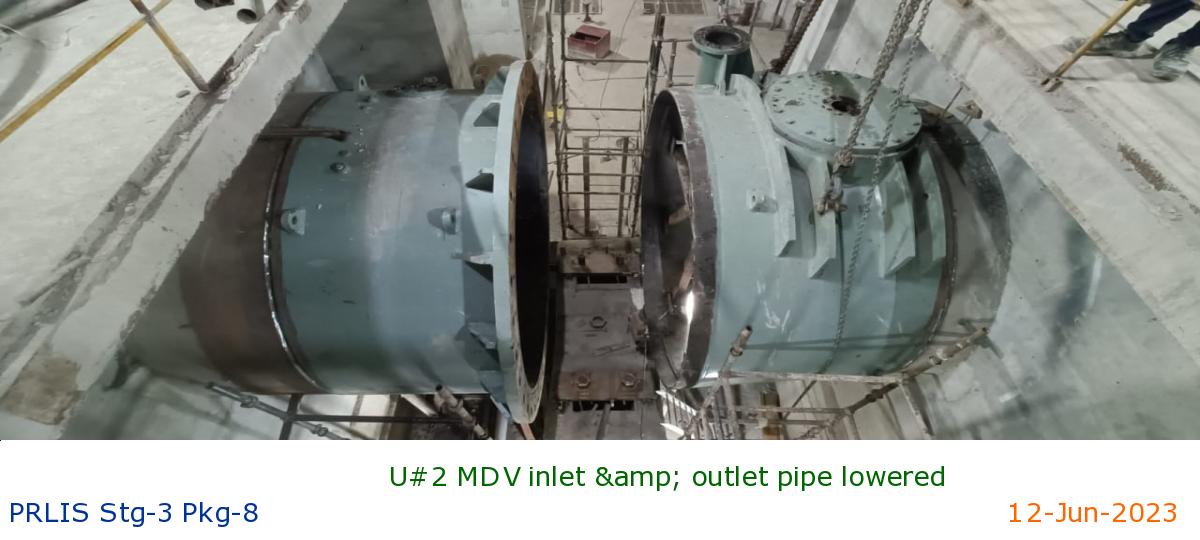

U#2 MDV inlet & outlet pipe lowered

|

U#2 oil pipeline routing in progress

|

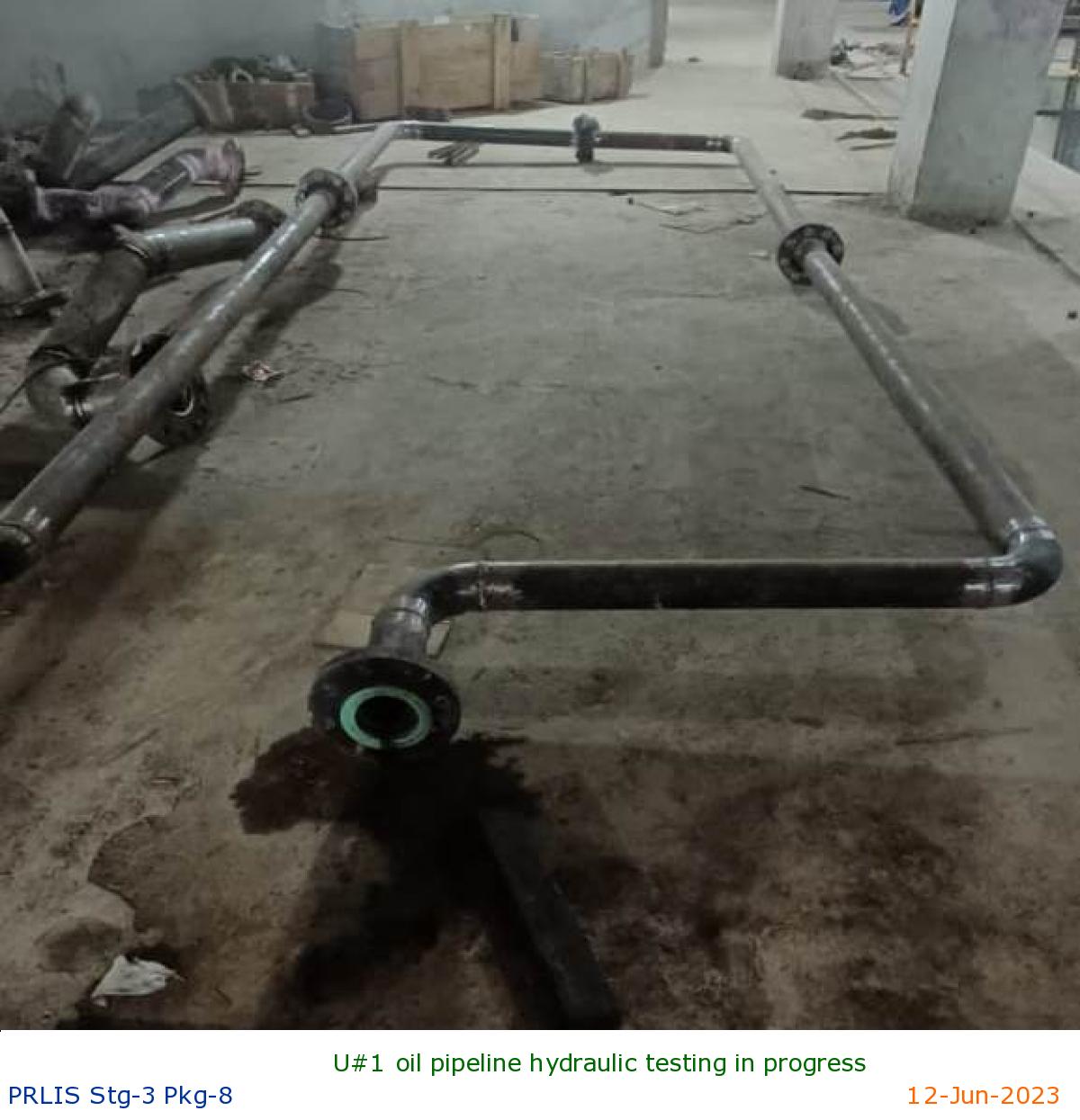

U#1 oil pipeline hydraulic testing in progress

|

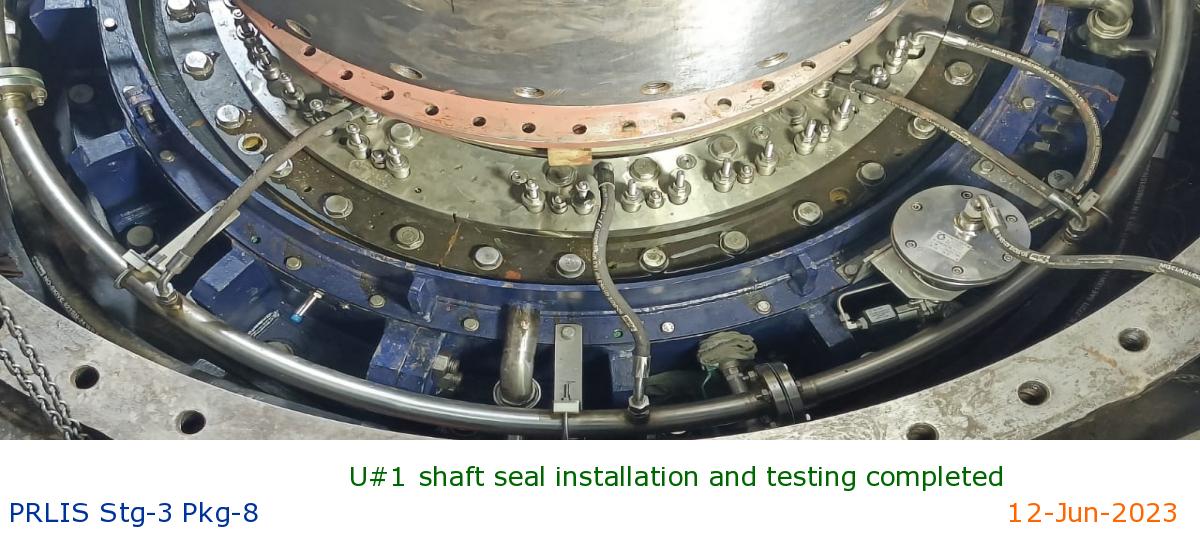

U#1 shaft seal installation and testing completed

|

U#2 Cable tray laying

in progress

|

U#1 Cable tray laying in progress

|

U#9 Spiral casing pedestals casting i/p

|

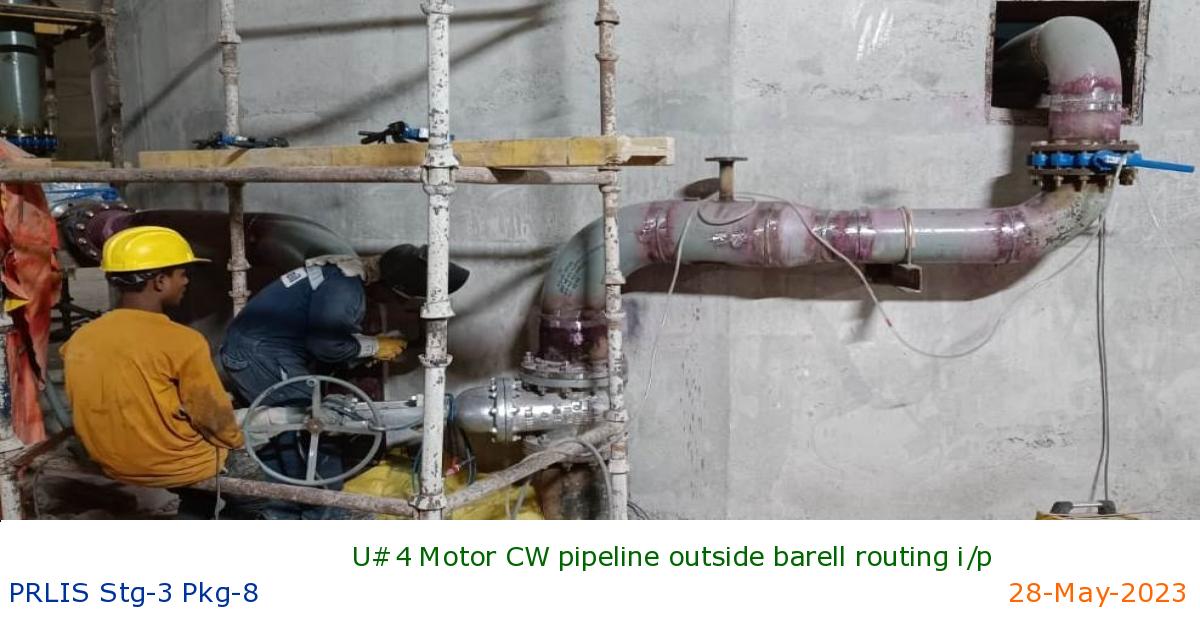

U#4 Motor CW pipeline outside barell routing compl

|

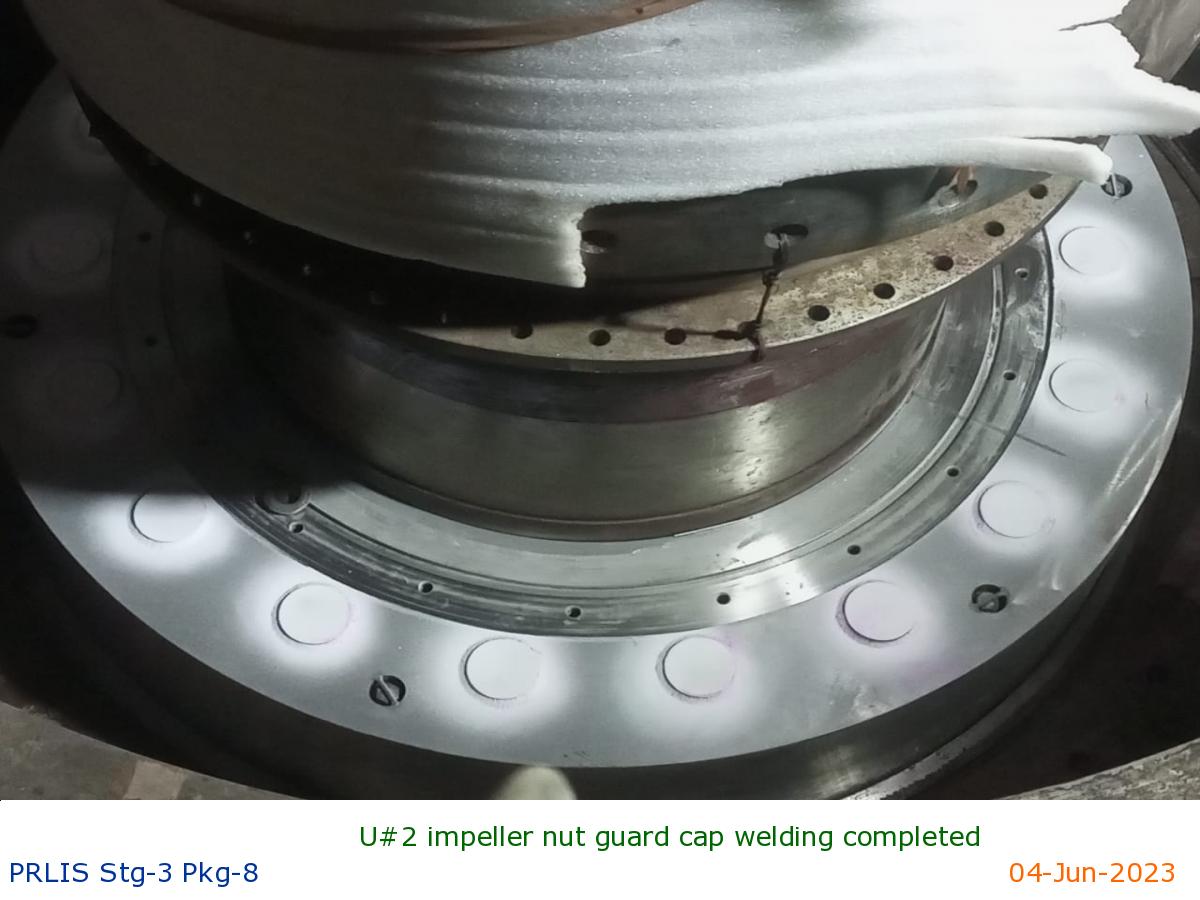

U#2 impeller nut guard cap welding completed

|

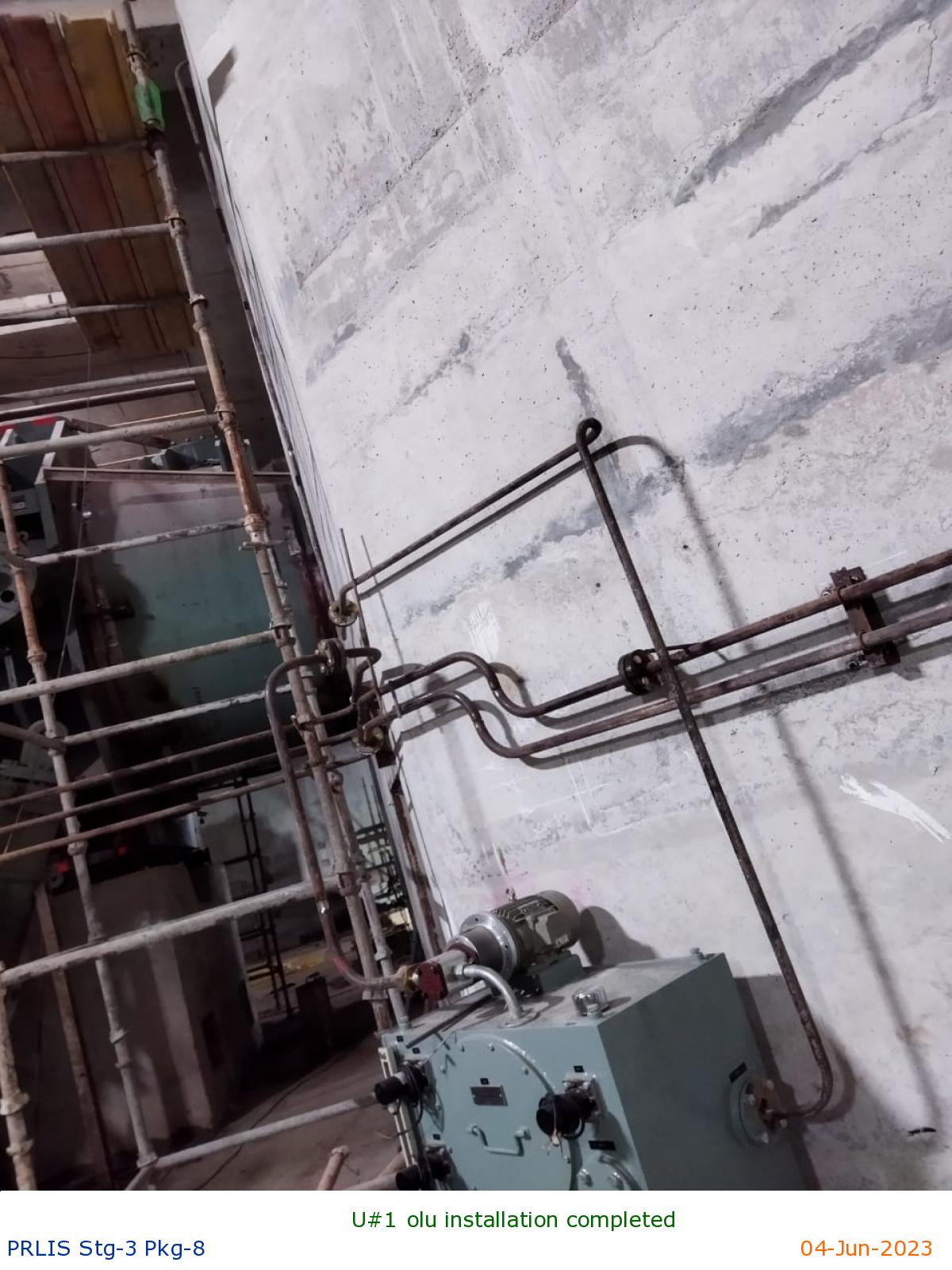

U#1 olu installation completed

|

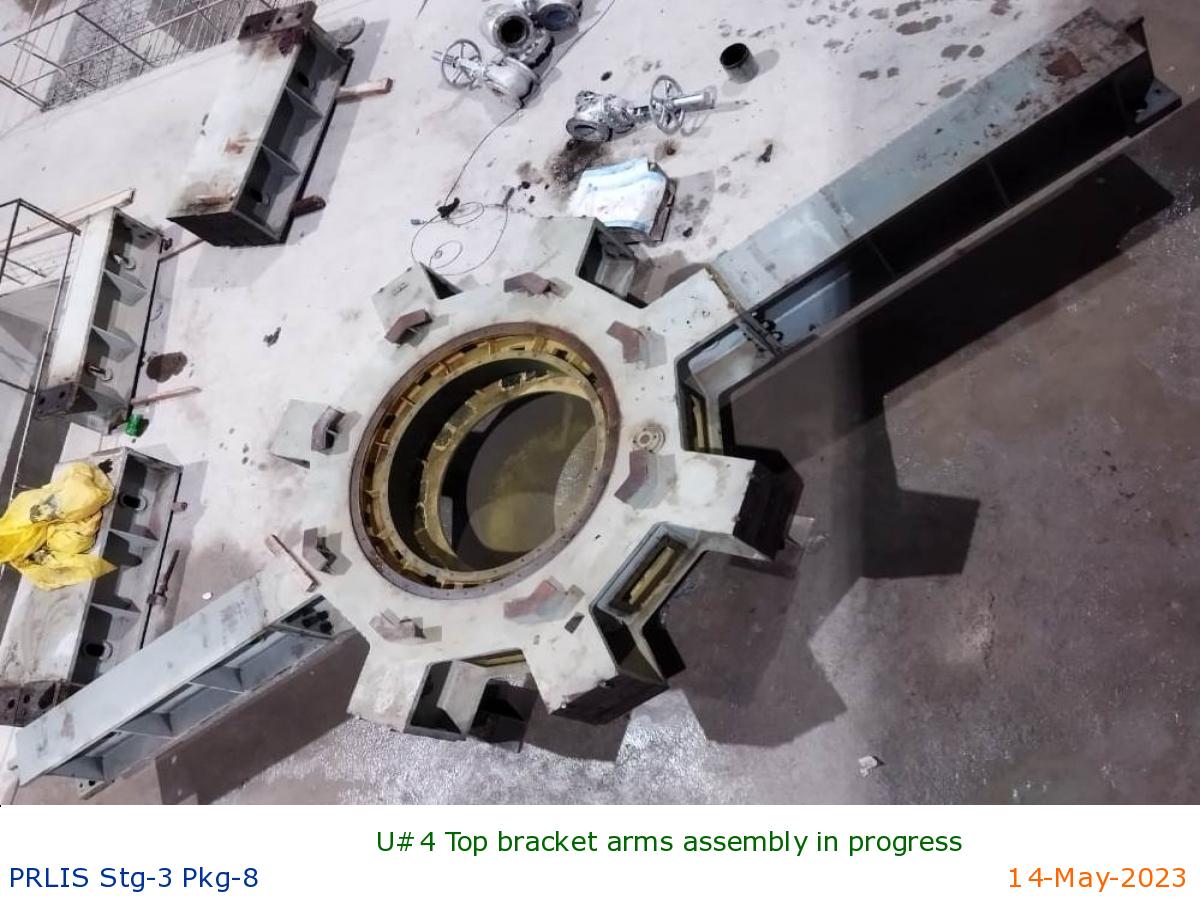

U#4 Top bracket arms assembly completed

|

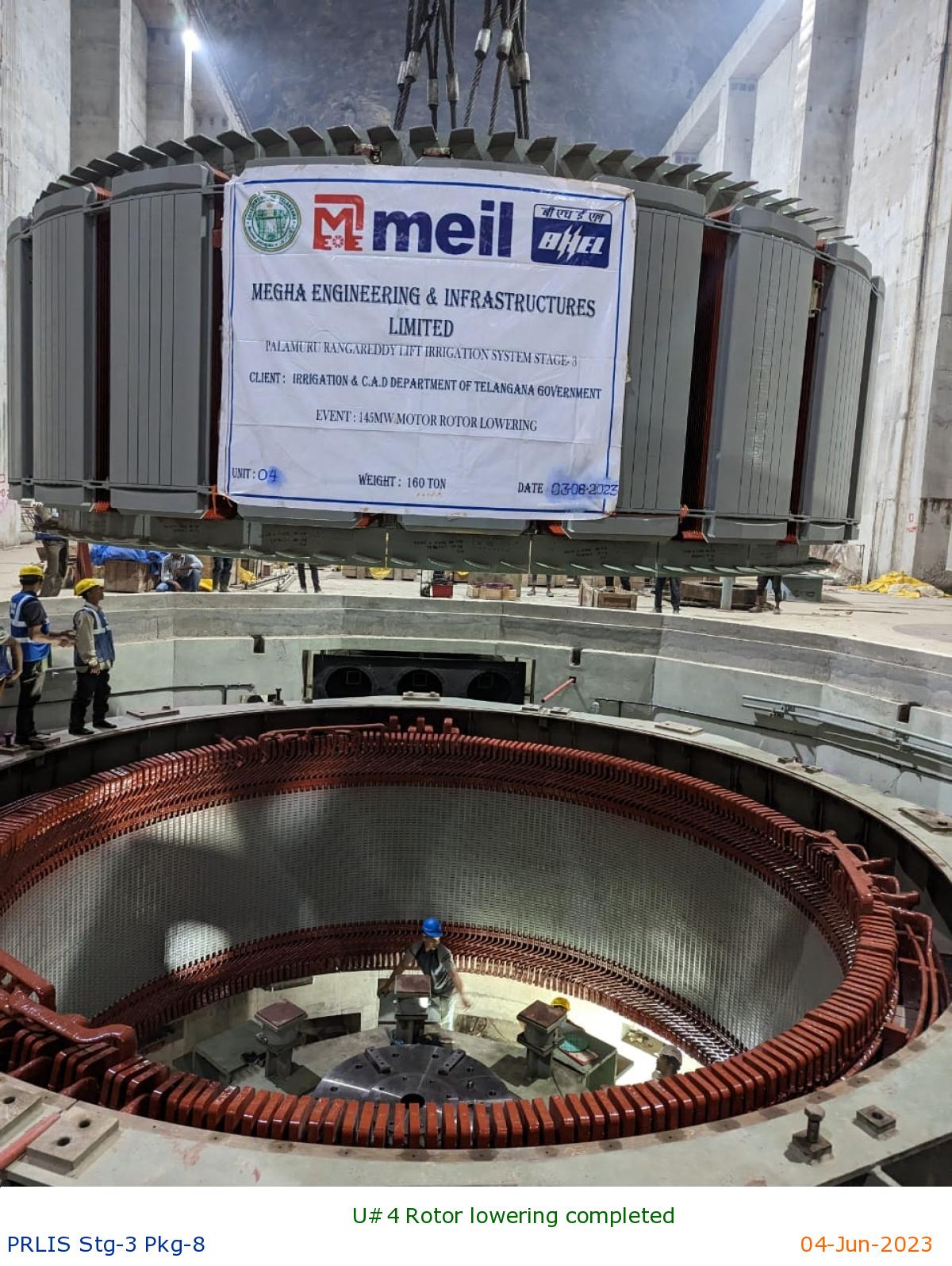

U#4 Rotor lowering completed

|

U#4 Rotor lowering completed

|

U#2 Spiral edge preparation is in progress

|

U#1 shaft seal installation in progress

|

U#4 Motor CW pipeline outside barell routing i/p

|

U#4 motor cw pipeline routing inside barell comple

|

U#4 Rotor final HV completed

|

U#4 bottom shaft lowering completed

|

U#1 shaft seal wfs shifting in progress

|

U#1 oil pipelines routing in progress

|

U#1 shaft seal installation in progress

|

Dewatering sump 2 pump erection completed

|

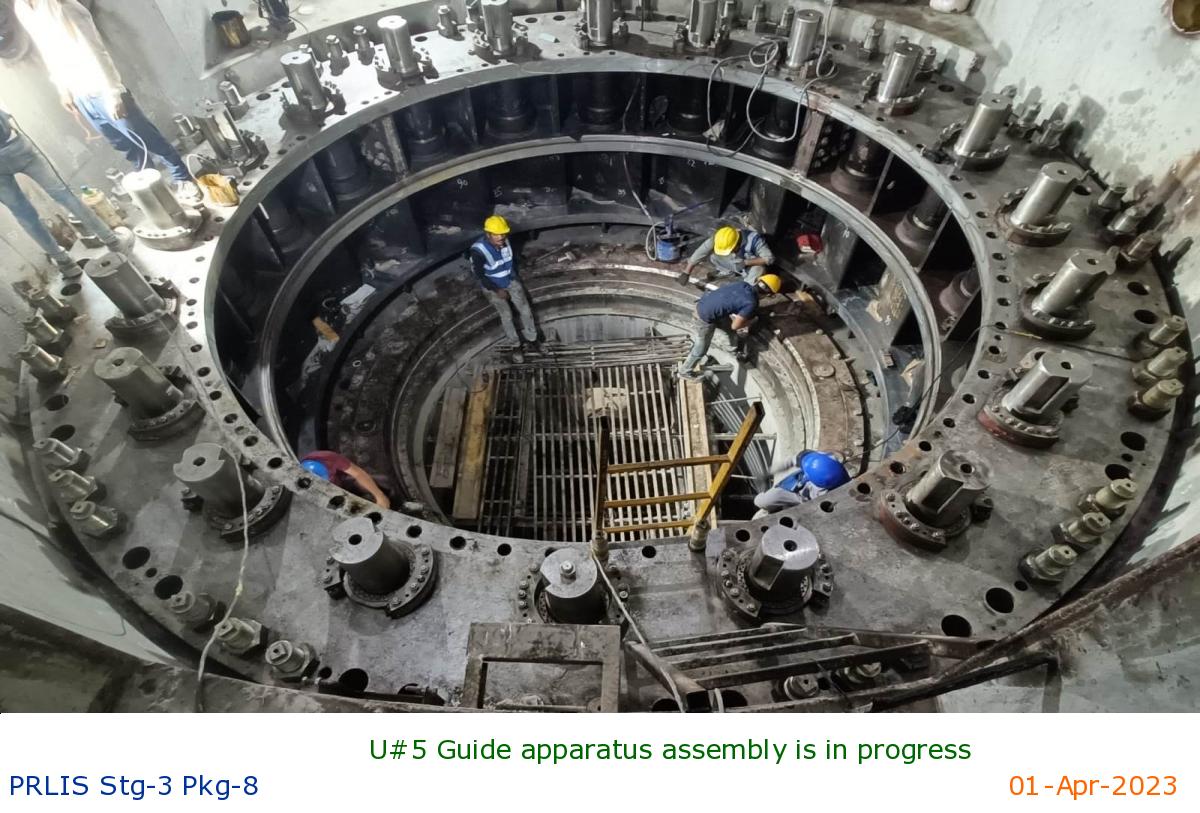

U#5 Guide apparatus assembly is in progress

|

U#4 Top bracket arms assembly in progress

|

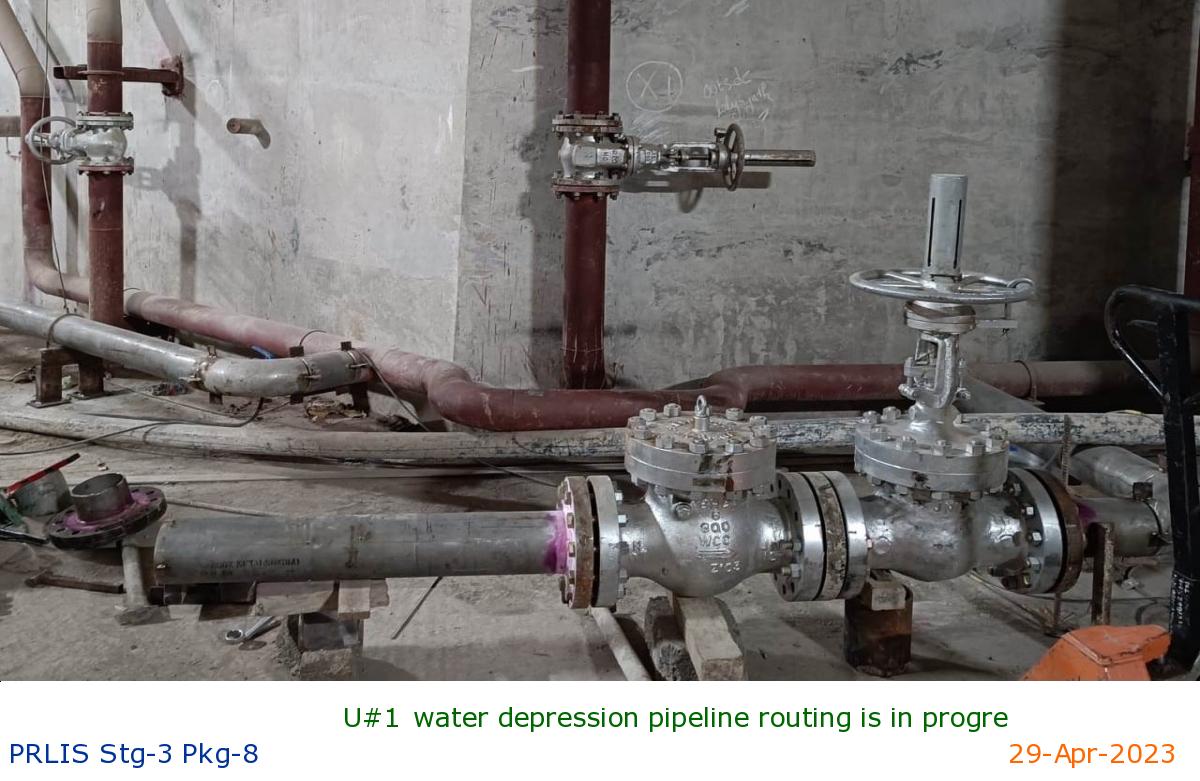

U#1 water depression pipeline routing is in progre

|

U#2 Brake jack pipeline routing completed

|

U#1 Impeller coupling nutguard joint welding compl

|

U#5 Inner top cover lowering completed

|

U#3 CW 350>300nb pipeline routing completed

|

U#4 Rotor pole mounting completed

|

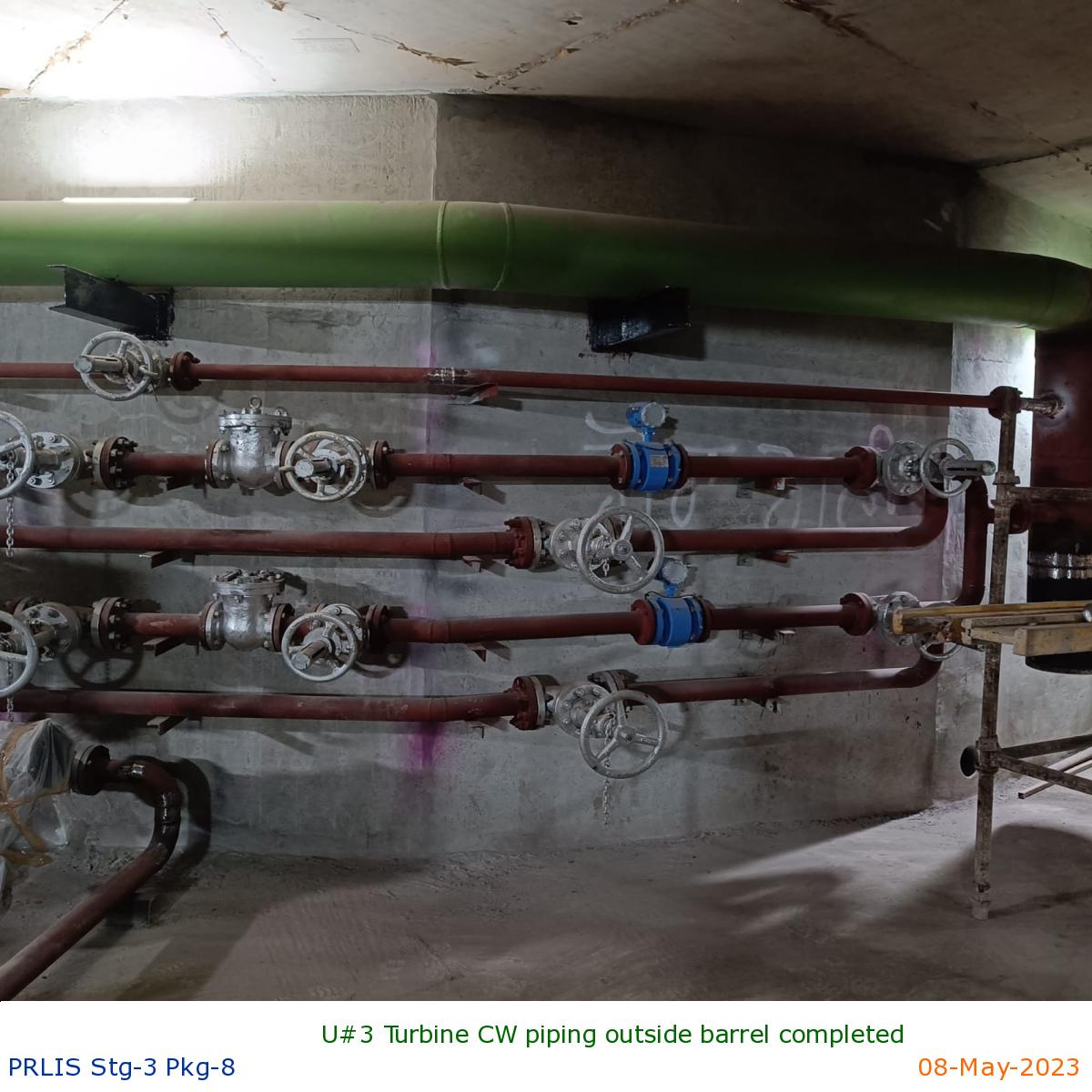

U#3 Turbine CW piping outside barrel completed

|

U#1 Top vapour piping routing is completed

|

U#2 Cooler support pads welding is in progress

|

U#1 Waterdepression pipeline routing in progress

|

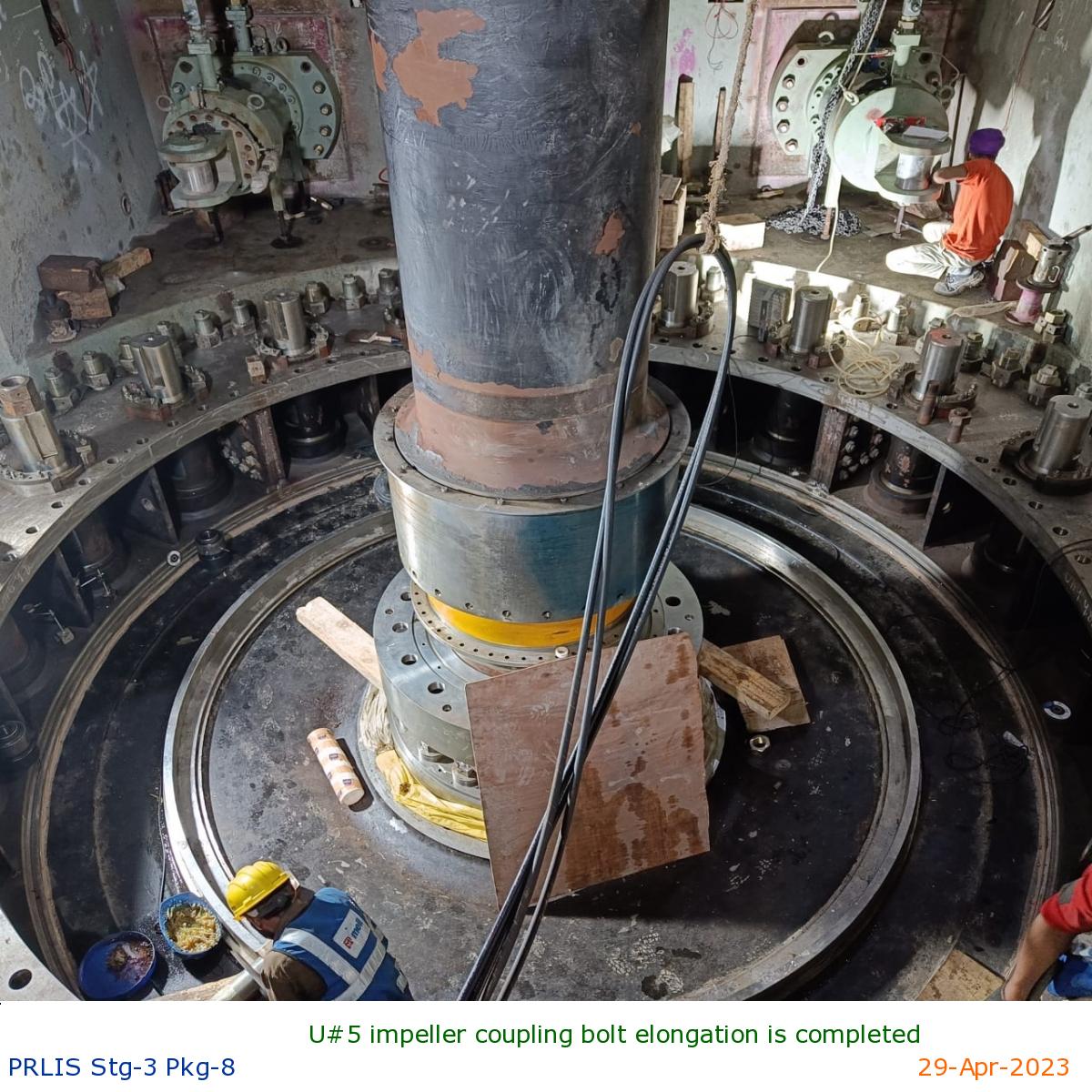

U#5 impeller coupling bolt elongation is completed

|

U#4 rotor rim building is completed

|

U#4 stator cw pipeline routing is in progress

|

U#1 water depression pipeline routing is in progre

|

U#1 Impeller coupling nut guard joint is completed

|

U#1 Top vapour piping routing is completed

|

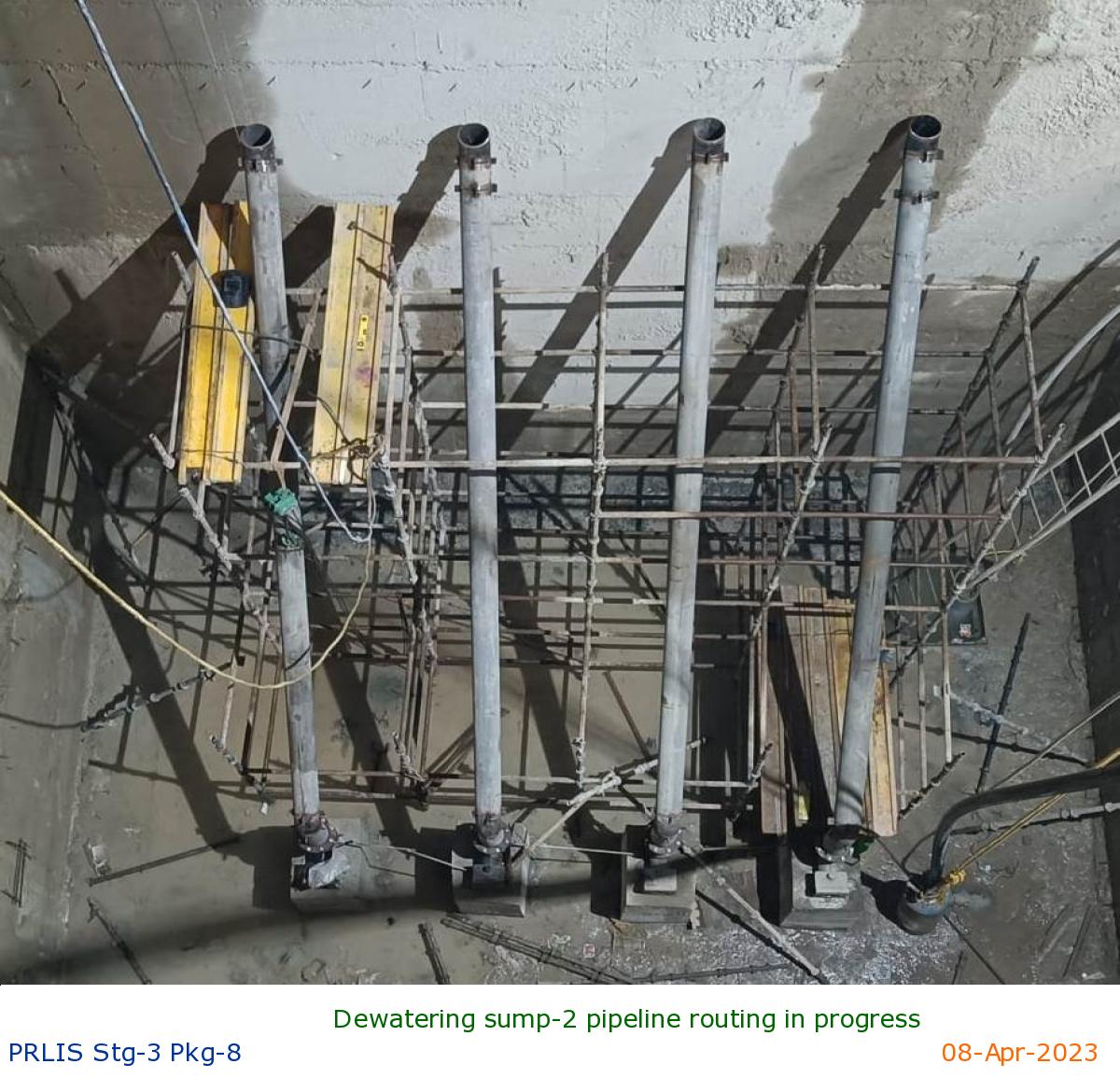

Dewatering sump-2 pipeline routing in progress

|

U#5 TGB pads blue matching is in progress

|

U#4 Rotor rim building is in progress

|

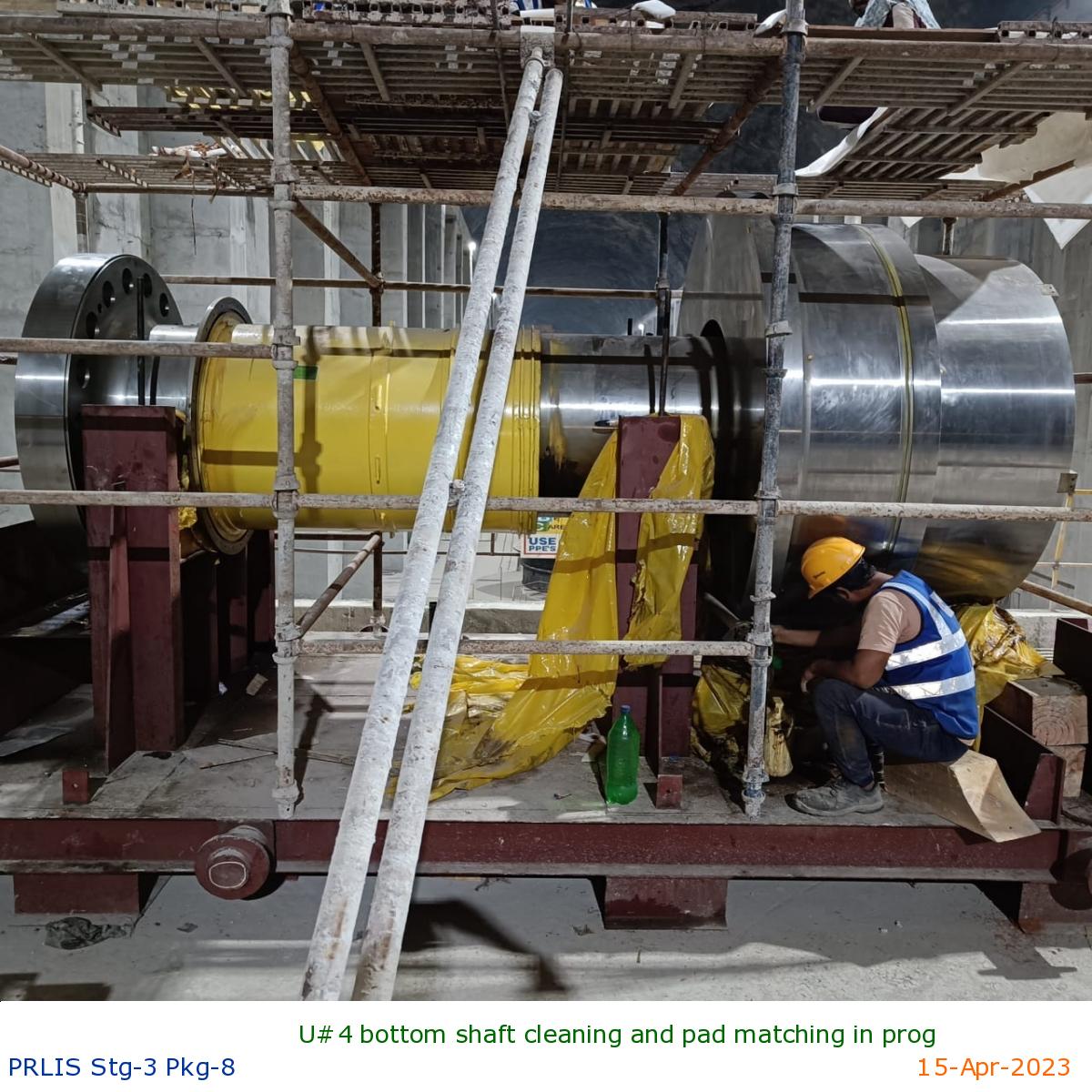

U#4 bottom shaft cleaning and pad matching in prog

|

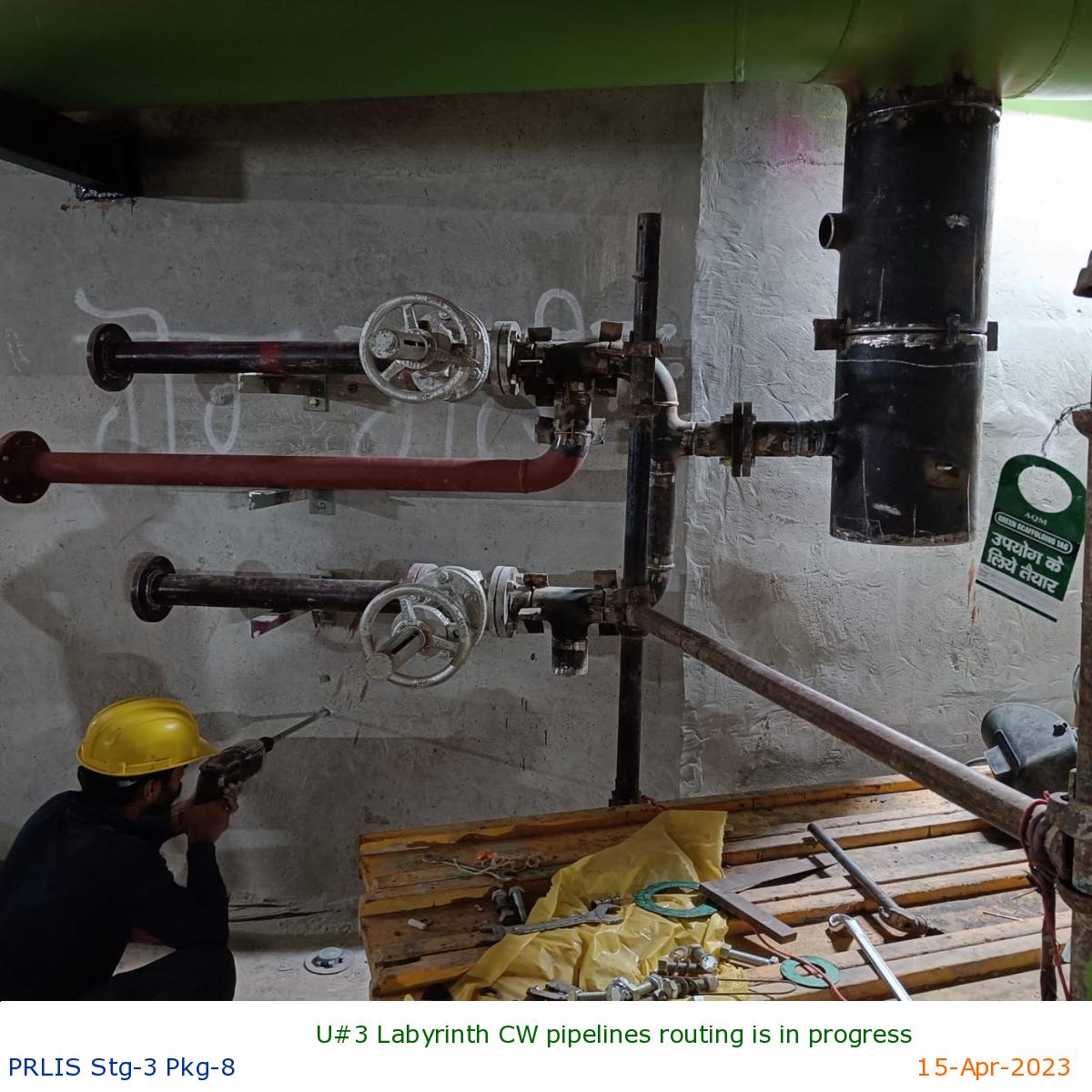

U#3 Labyrinth CW pipelines routing is in progress

|

U#2 top oil vapour piping routing is in progress

|

U#2 CW main headers near DT routing is in progress

|

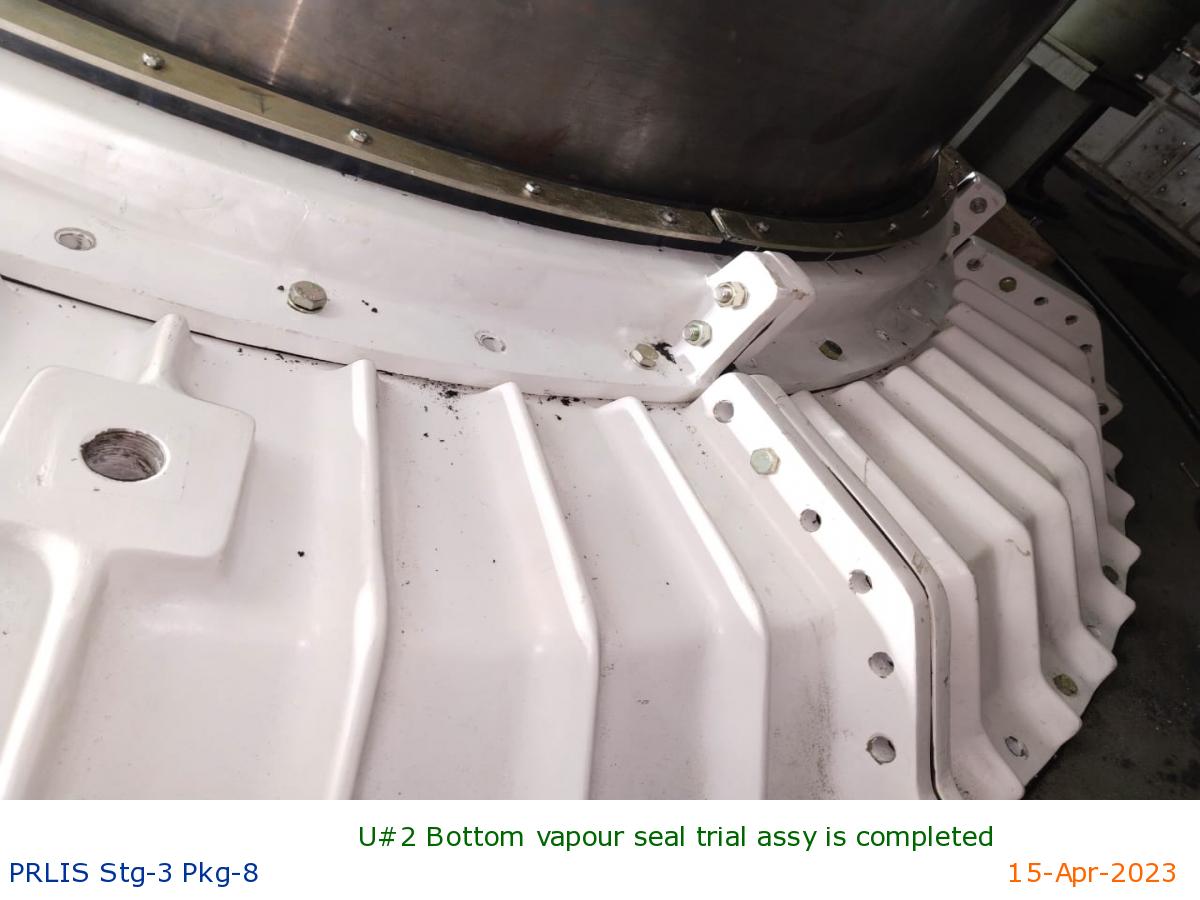

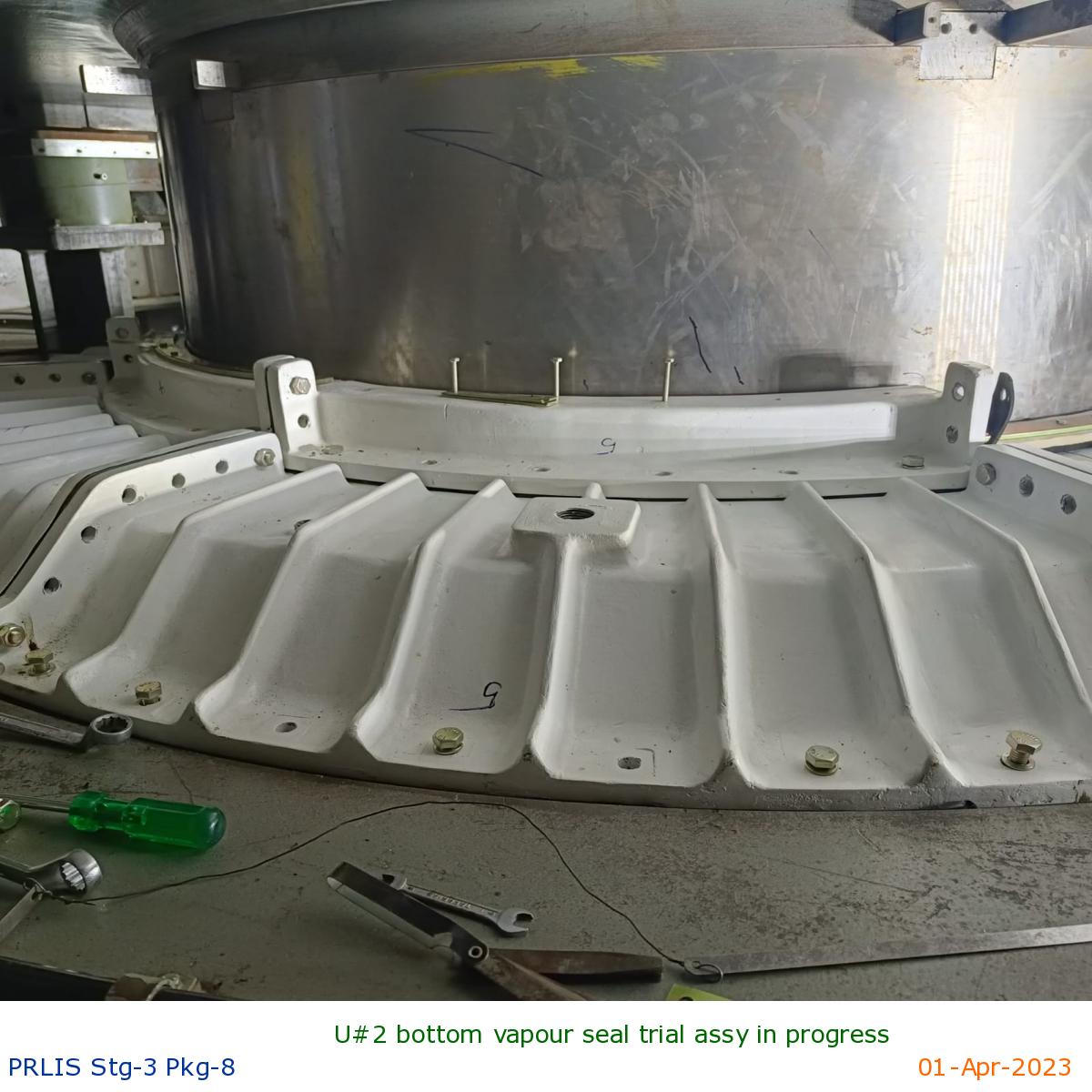

U#2 Bottom vapour seal trial assy is completed

|

U#1 gauge panel positioning is in progress

|

U#1 CW main headers near dt routing completed

|

U#1 top vapour seal trial assy is in progress

|

Dewatering sump-2 pipeline routing in progress

|

U#8 spiral pedestals casting is in progress

|

U#5 TGB pads blue matching is in progress

|

U#5 Guide apparatus assembly is in progress

|

U#5 Impeller lowering completed

|

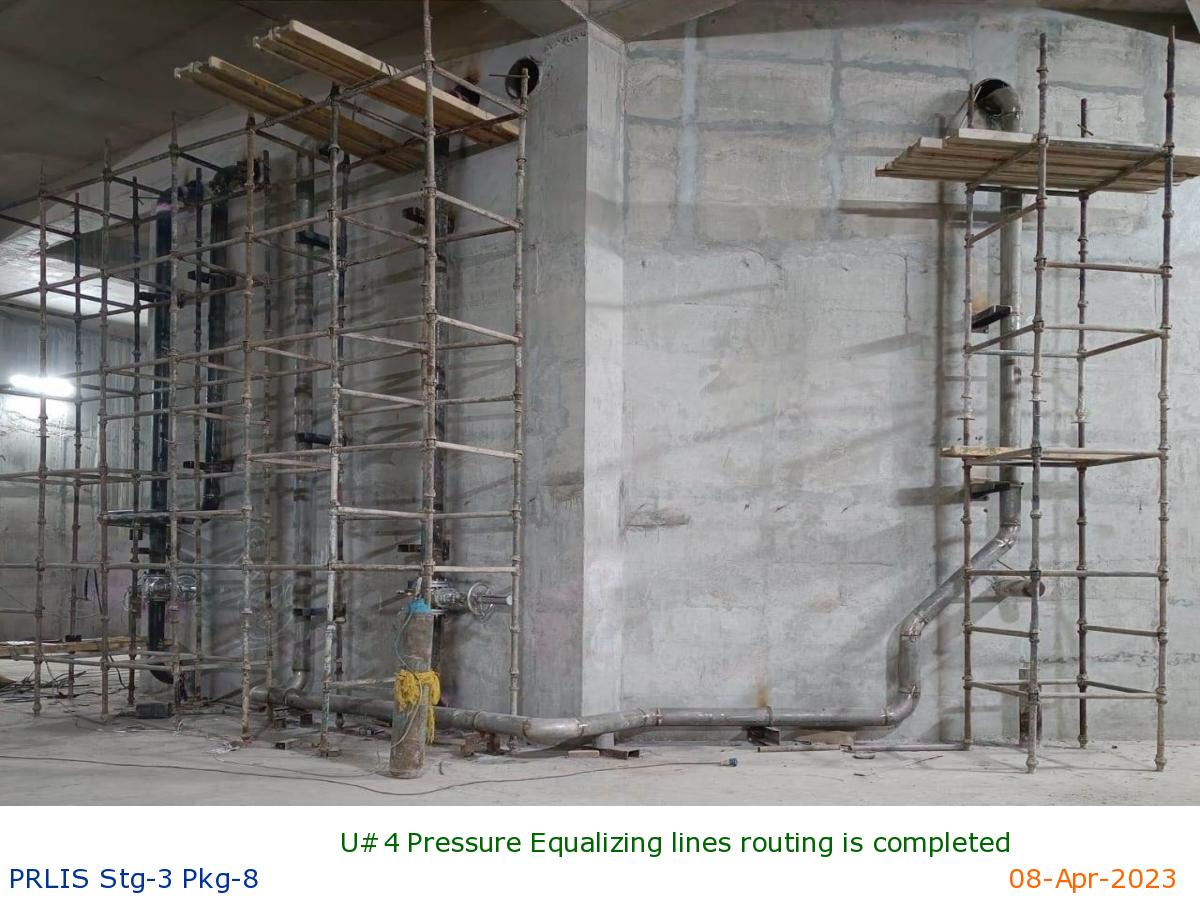

U#4 Pressure Equalizing lines routing is completed

|

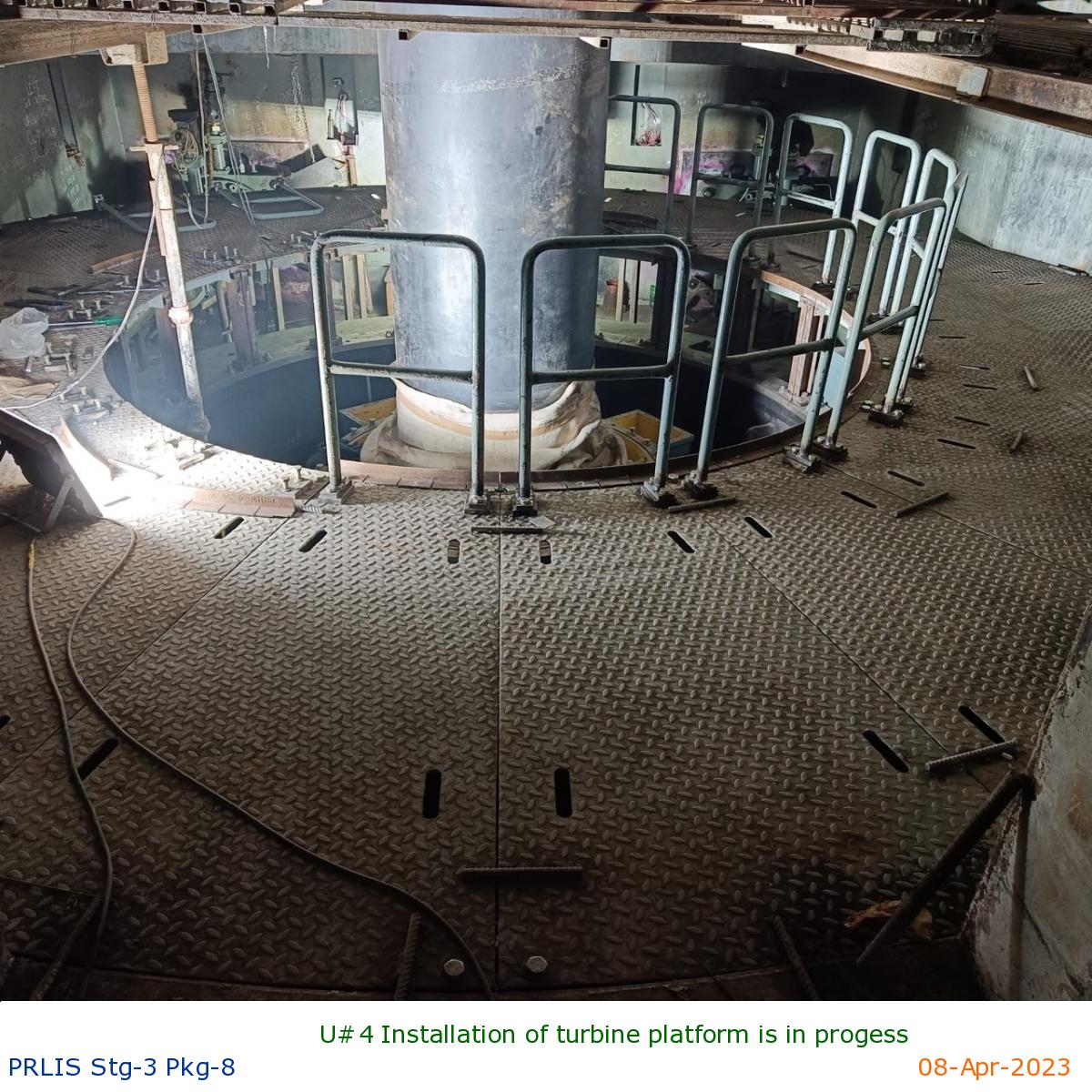

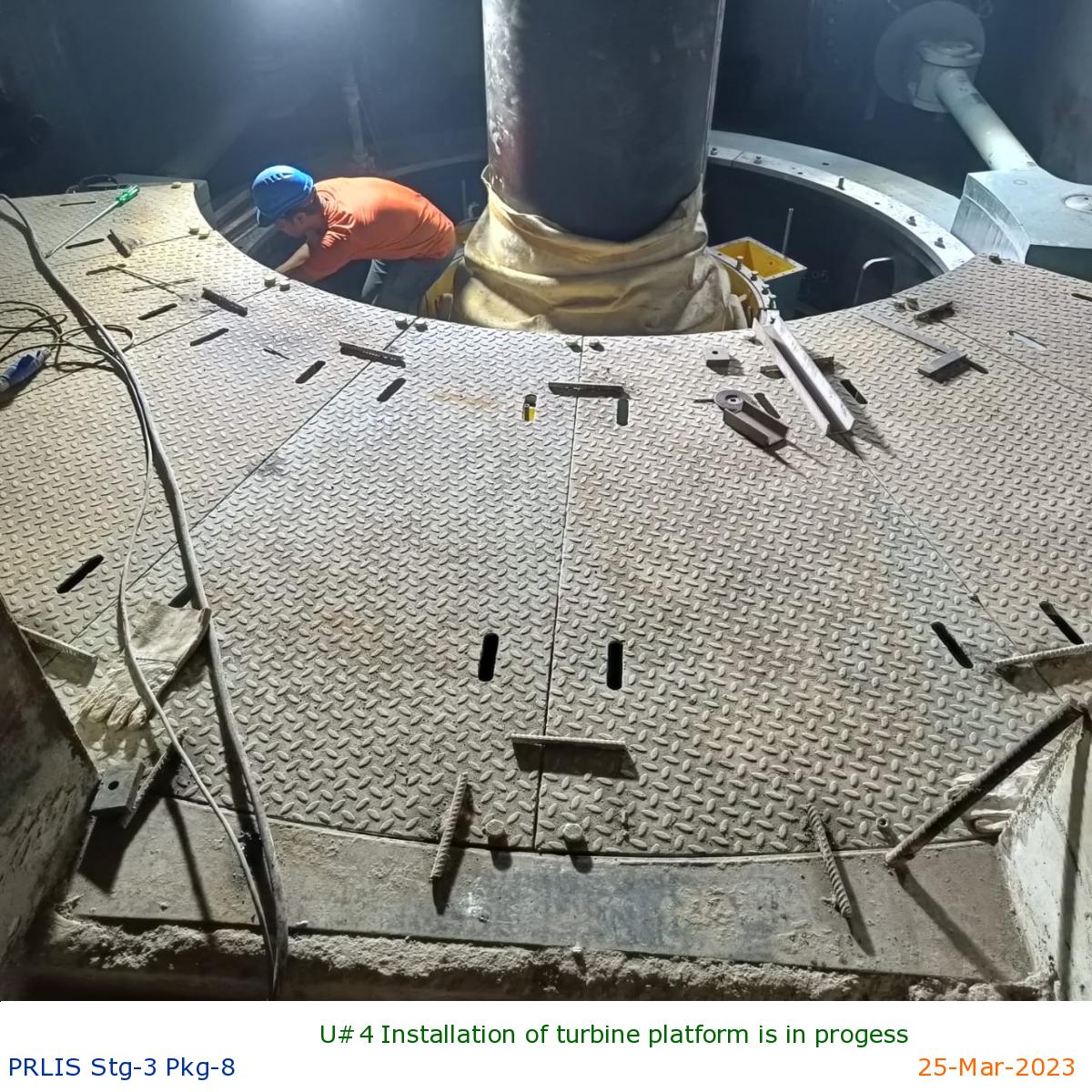

U#4 Installation of turbine platform is in progess

|

U#2 bottom vapour seal trial assy in progress

|

U#2 CW pipeline routing is in progress

|

U#1 CW pipeline routing is in progress

|

U#8 spiral pedestals casting is in progress

|

U#7 Spiral casing pedestals casting is completed

|

U#5 Guide apparatus assembly is in progress

|

U#4 pump pit platform installation in progress

|

U#4 pipeline routing at discharge valve floor i/p

|

U#4 Rotor rim building is in progress

|

U#2 bottom vapour seal trial assy in progress

|

U#1 Motor transformer lv turrets installed

|

U#1 Motor Transformer hv bushing installed

|

Dewatering pump erection is in progress

|

U#8 dt liner concreting is in progress

|

U#7 Spiral casing pedestals casting is in progress

|

U#5 Guide Apparatus trial assy in progress

|

U#4 Rotor rim building is in progress

|

U#4 Installation of turbine platform is in progess

|

U#3 MDV base plates positioning is completed

|

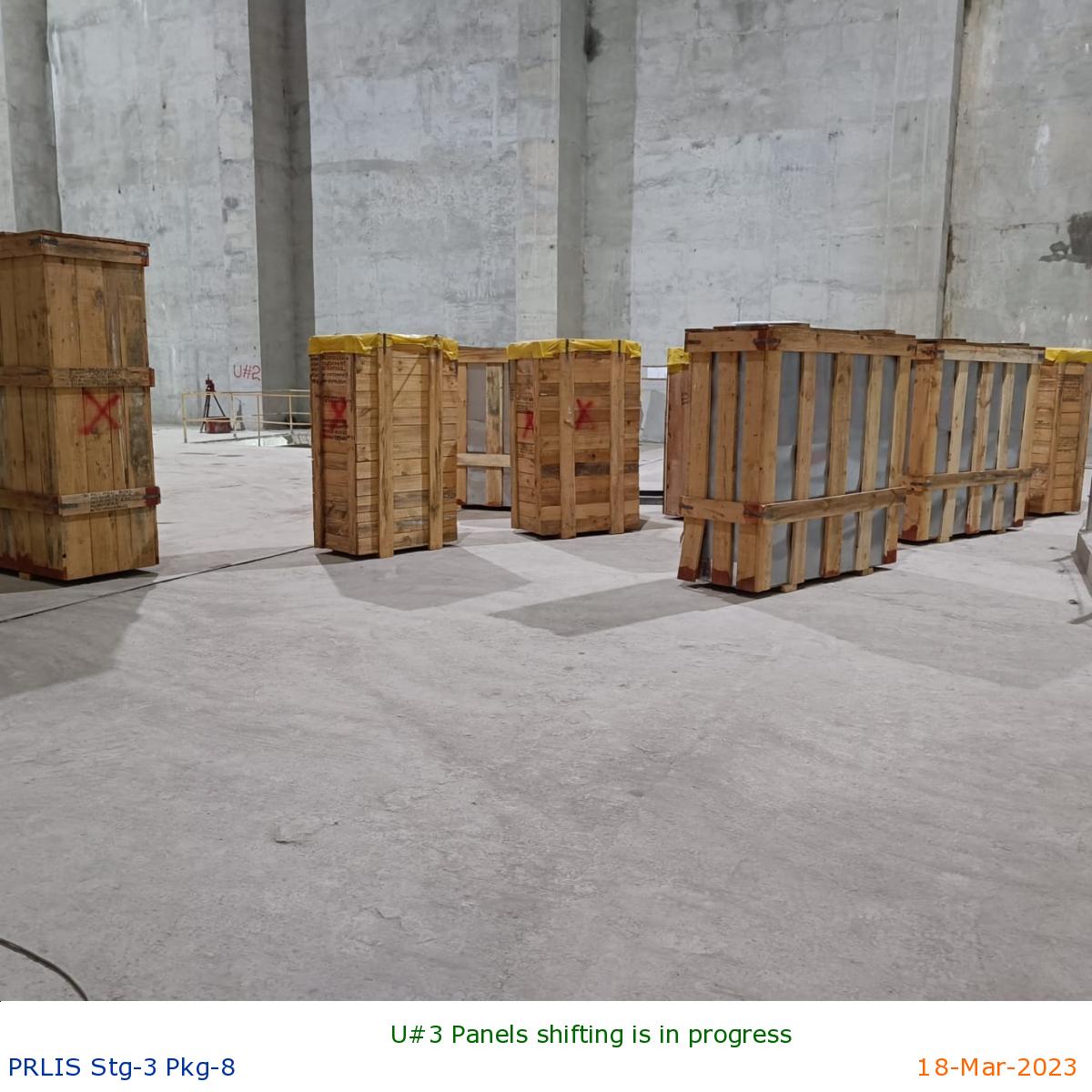

U#3 panels positioning is in progress

|

U#2 Top vapour seal trial assy completed

|

U#1 Transformer HV turrets mounting is in progress

|

U#9 DT elbow liner alignment is in progress

|

U#8 Positioning ofhooks for dt cone is in progress

|

U#7 Spiral casing pedestals casting is in progress

|

U#5 Guide apparatus assembly is in progress

|

U#5 Preparation of inner top cover for lowering

|

U#3 Panels shifting is in progress

|

U#3 MDV base plates positioning is in progress

|

U#2 Panels positioning on motor floor completed

|

U#2 Top vapour pipeline routing in progress

|

U#2 Top vapour seal trial assy in progress

|

U#8 Spiral drain pipeline routing in progress

|

U#7 DT Elbow liner concreting in progress

|

U#6 dt elbow liner concreting completed

|

U#2 Top bearing assy is in progress

|

U#5 Guide vanes lowering is in progress

|

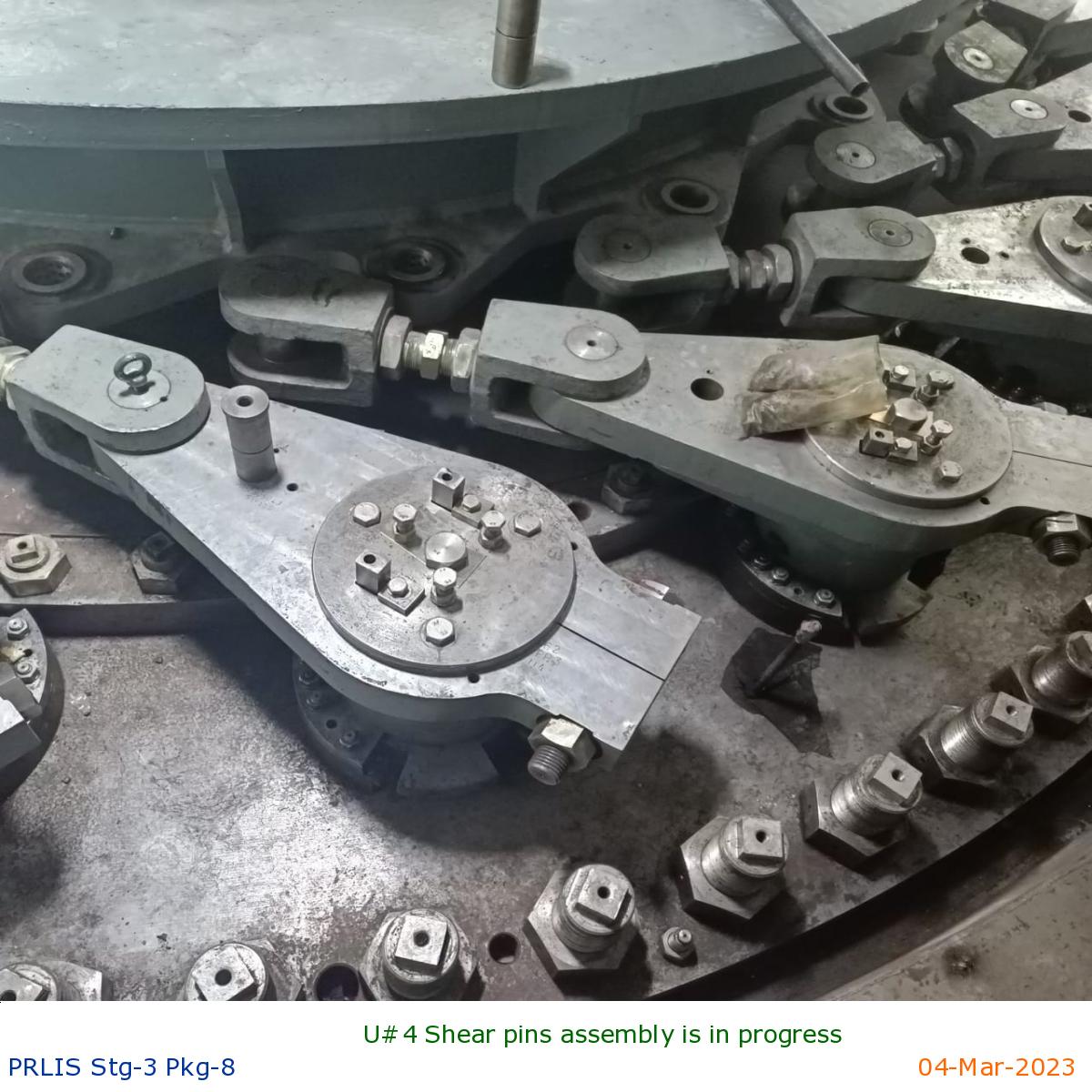

U#4 Shear pins assembly is in progress

|

U#3 MDV base plates positioning is in progress

|

U#2 receivers positioning is in progress

|

U#1 Starter panels positioning in progress

|

U#1 MDV Servomotor positioning completed

|

U#1 Transformer oil conservator&coolers erection

|

U#1 Busduct installation at ground level

|

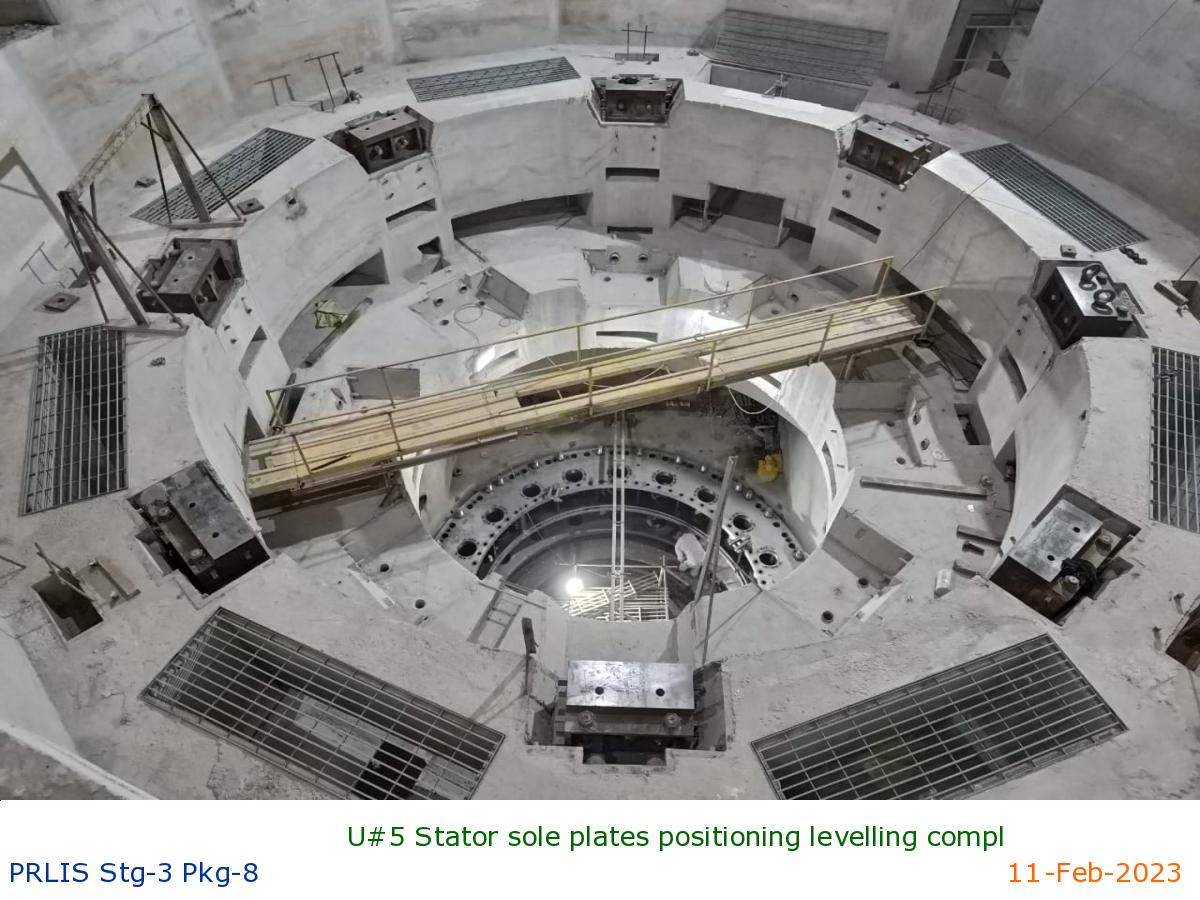

U#5 Stator sole plates positioning levelling compl

|

U#5 LGB Sole plates positioning and levelling i/p

|

U#5 OTC welding completed lowering in progress

|

U#4 Monorail installation is in progress

|

U#4 GV Servomotors reassembly in progress

|

U#4 Bottom bracket jack post welding is in progres

|

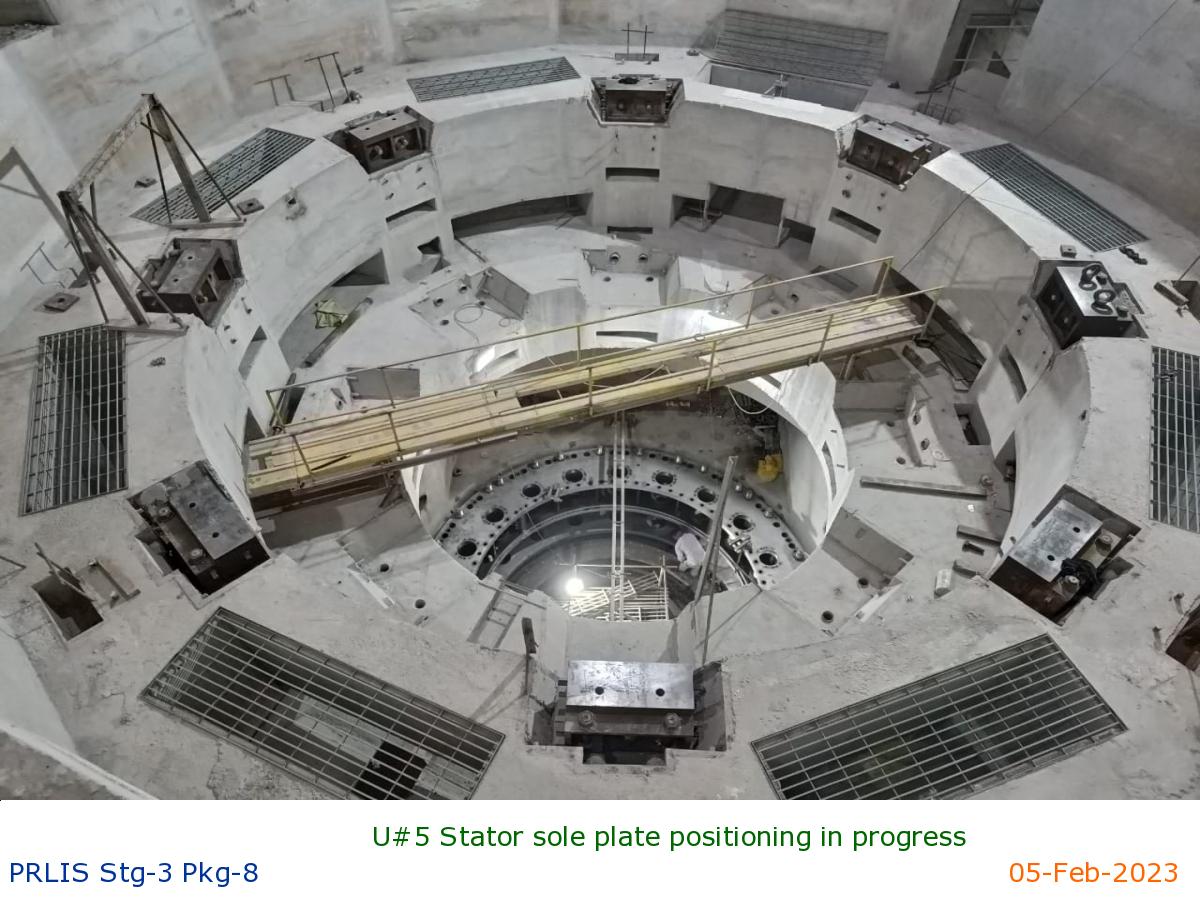

U#5 Stator sole plate positioning in progress

|

U#5 OTC quadrants welding in progress

|

U#4 Monorail installation is in progress

|

U#4 GV Servomotors reassembly in progress

|

U#4 brake jacks positioning completed

|

U#4 brake jacks positioning completed

|

U#4 HS piping inside bottom bracket completed

|

U#1 Governing receivers foundation casting i/p

|

U#1 Transformer oil conservator&coolers erection

|

U#5 stator sole plates hole correction in progress

|

U#7 DT Elbow liner alignment correction in progres

|

U#5 gv cleaning and feather height measurement i/p

|

U#5 OTC quadrants welding in progress

|

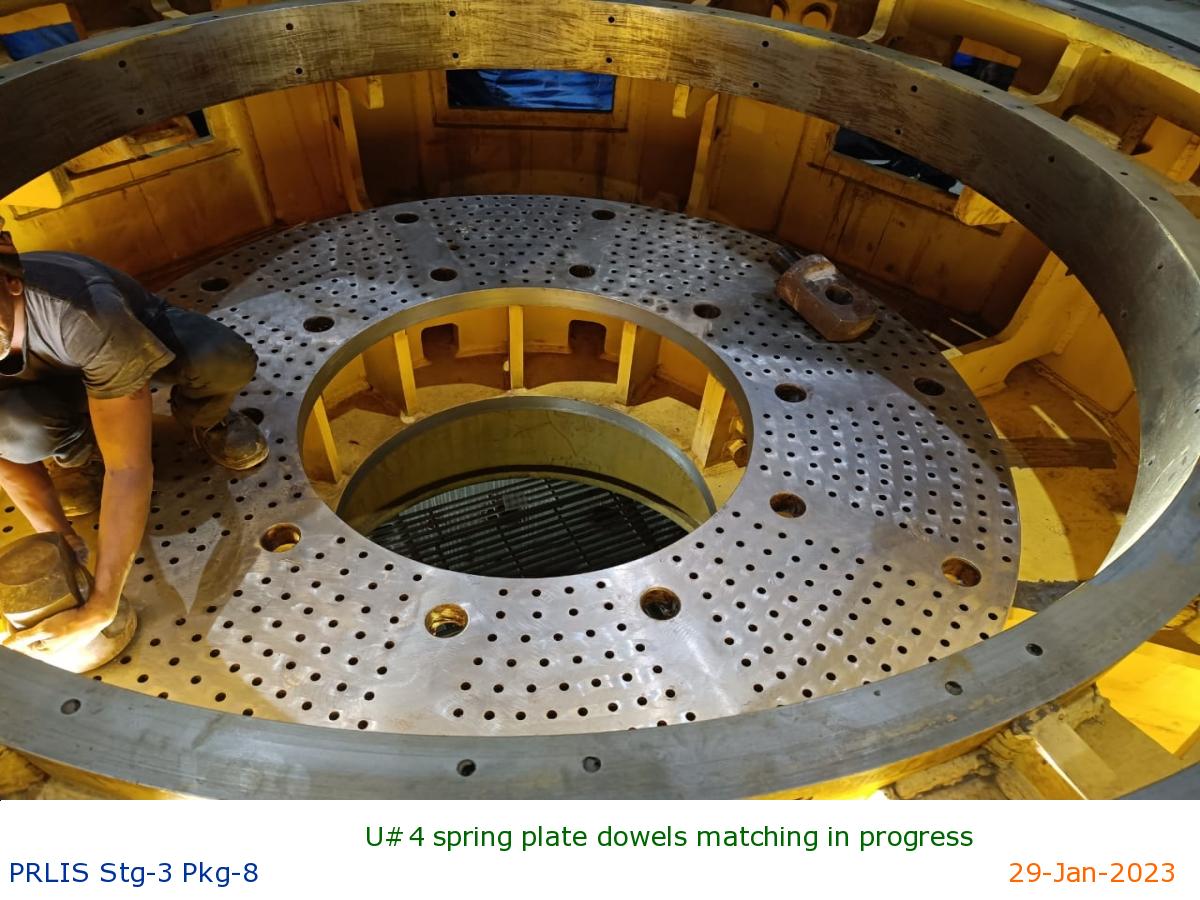

U#4 spring plate dowels matching in progress

|

U#4 Stator air coolers installation in progress

|

U#4 GV Servomotor foundation block welding in prog

|

U#3 MDV OPU CW pipeline welding in progress

|

U#2 Bottom air guide final assy completed

|

U#5 Guide Apparatus trial assy in progress

|

U#10 dt liner segments welding is in progress

|

U#5 Stator sole plate positioning in progress

|

U#4 GV Servomotor welding in progress

|

U#4 HS Skid positioning completed piping in progre

|

U#4 LGB Lowering completed

|

U#4 Stator air cooler hydraulic testing in progres

|

U#3 GV OPU CW pipeline routing in progress

|

U#3 MDV OPU CW pipeline routing in progress

|

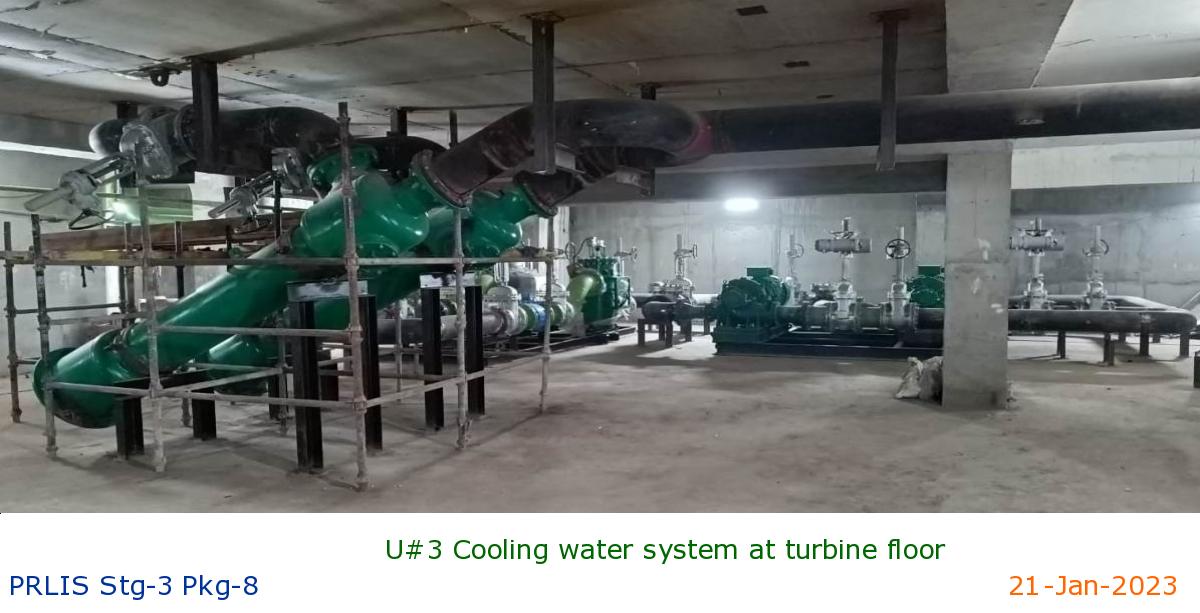

U#3 Cooling water system at turbine floor

|

U#3 Firefighting panel positioning in progress

|

U#1 GV DV Receivers and panels positioning i/p

|

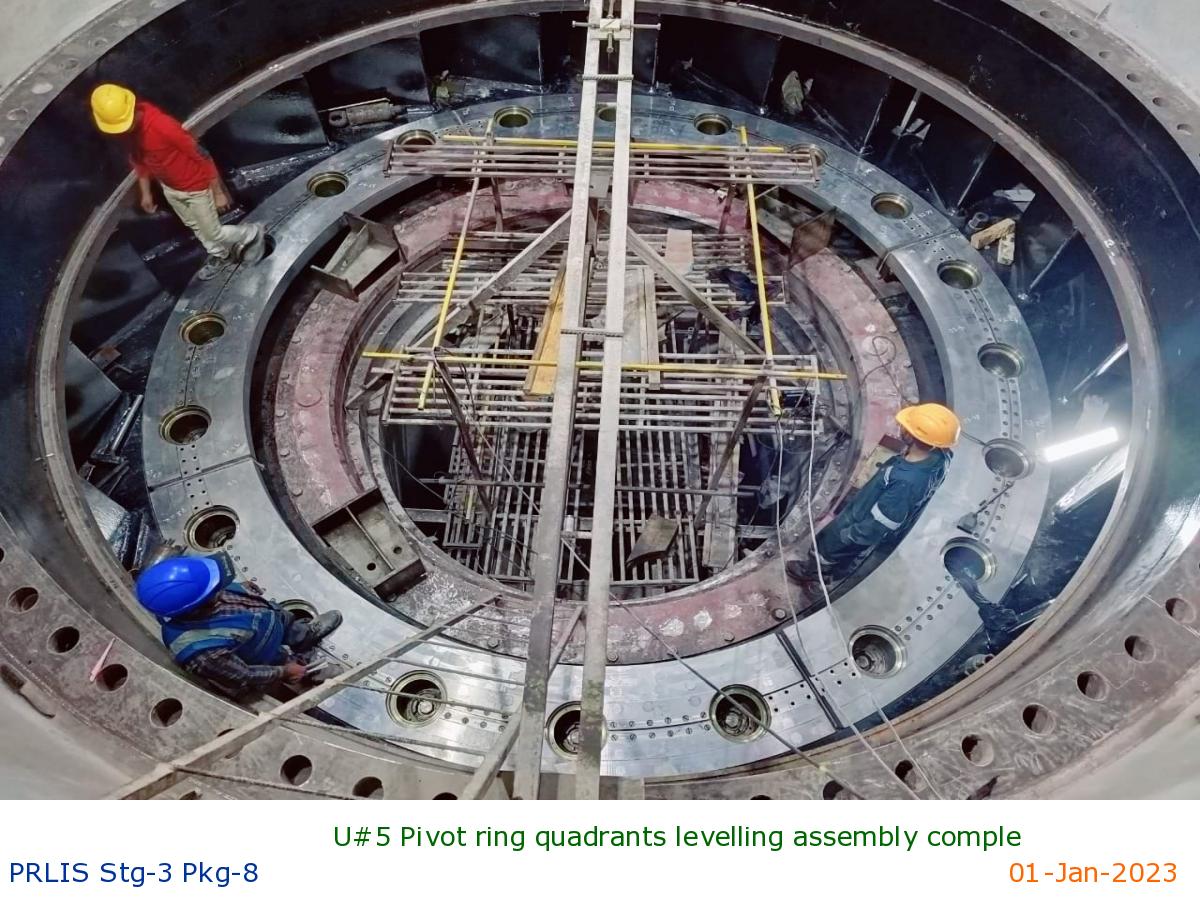

U#5 Pivot ring quadrants levelling assembly comple

|

U#4 Stator instrumentation completed

|

U#4 LGB Sole plates levelling in progress

|

U#4 GV Servo motors testing is in progress

|

U#3 cyclone seperator outlet piping completed

|

U#3 CW System skids positioned

|

U#10 DT Elbow liner all segments positioning compl

|

U#9 DT Elbow liner

|

U#8 DT Drain box installation in progress

|

U#7 DT ELbow liner

|

U#5 Foundation ring grouting plugs welding in prog

|

U#5 Pivot ring quadrants cleaning in progress

|

U#4 ITC & GV Servomotors lowering completed

|

U#2 MDV OPU CW piping routing completed

|

U#3 CW strainer skid positioning in progress

|

U#3 cyclone seperator outlet piping in progress

|

U#3 CW pump motor skid fabrication in progress

|

U#1 MDV and inlet pipe dismantling gap adjustment

|

U#5 Stay ring spiral grouting completed

|

U#4 LGB Sole plates positioning inprogress

|

U#4 Impeller lowering completed

|

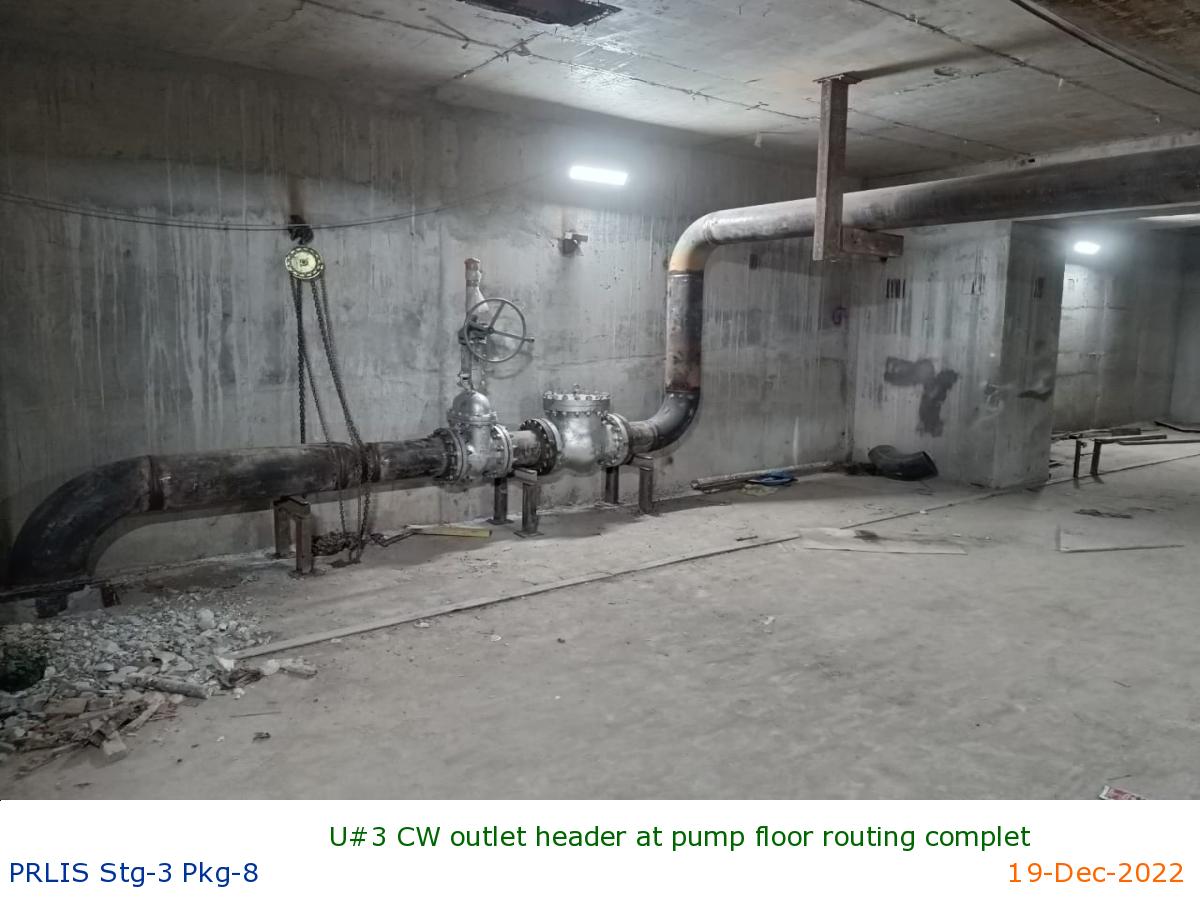

U#3 CW outlet header at pump floor routing complet

|

U#3 Air duct covers installation in progress

|

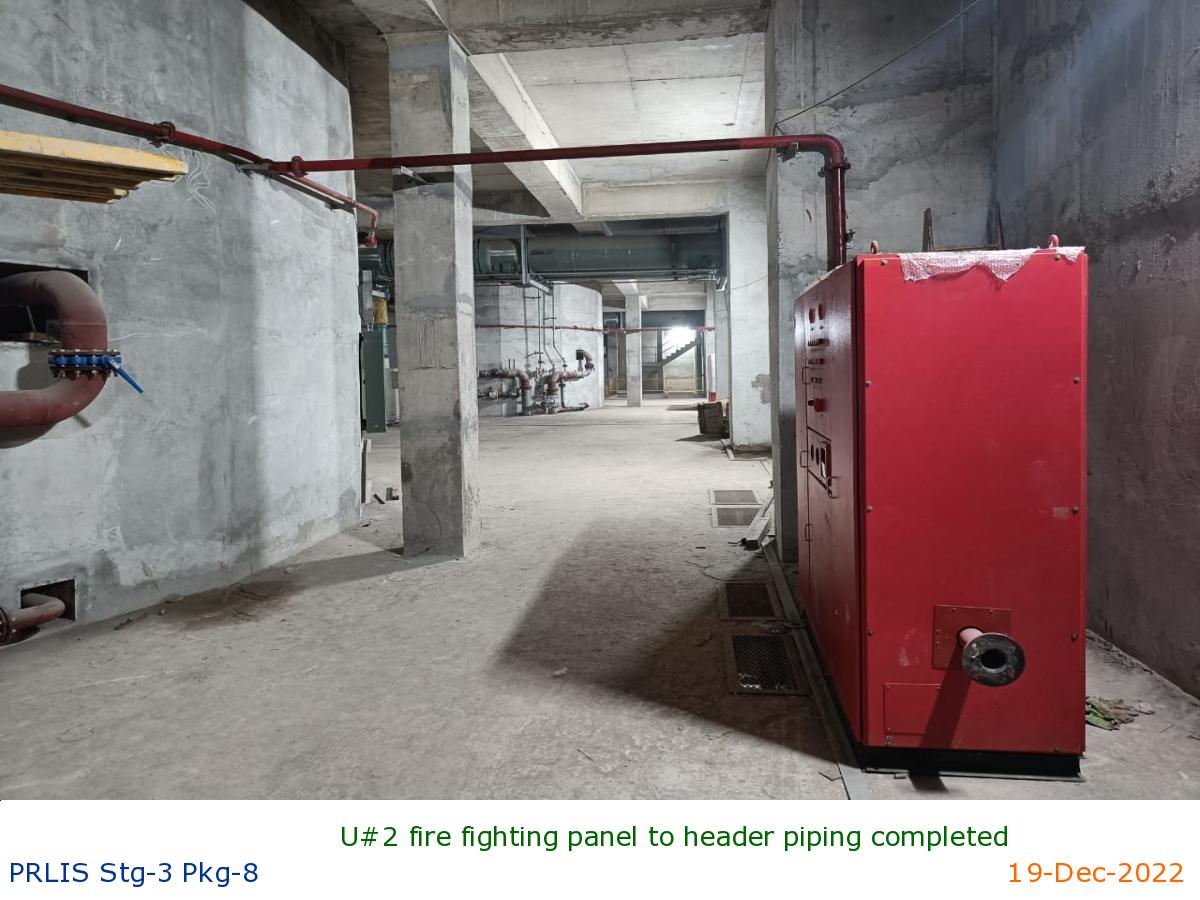

U#2 fire fighting panel to header piping completed

|

U#3 CW strainer skids fabrication in progress

|

U#3 cyclone seperators installation completed

|

U#2 MDV OPU CW piping in progress

|

U#2 GV OPU CW piping inside progress

|

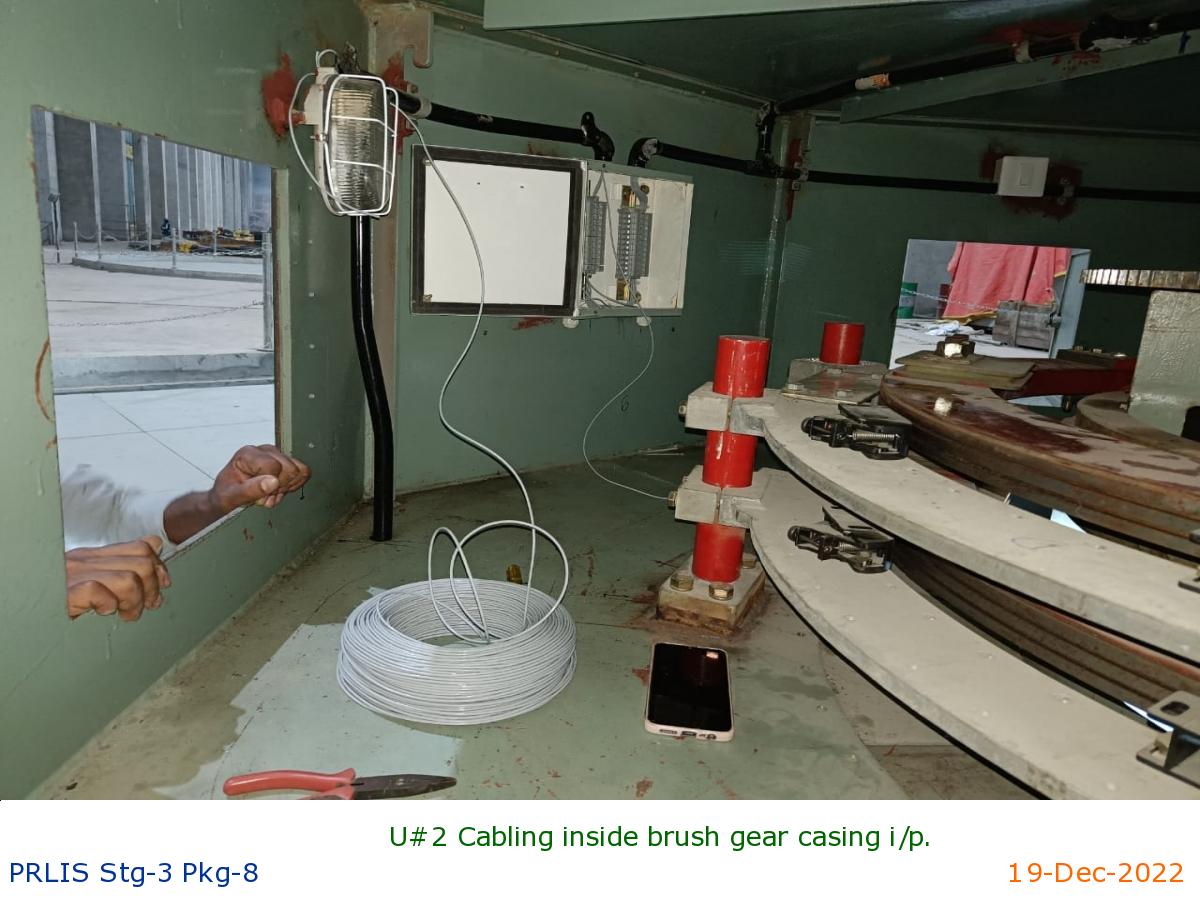

U#2 Cabling inside brush gear casing i/p.

|

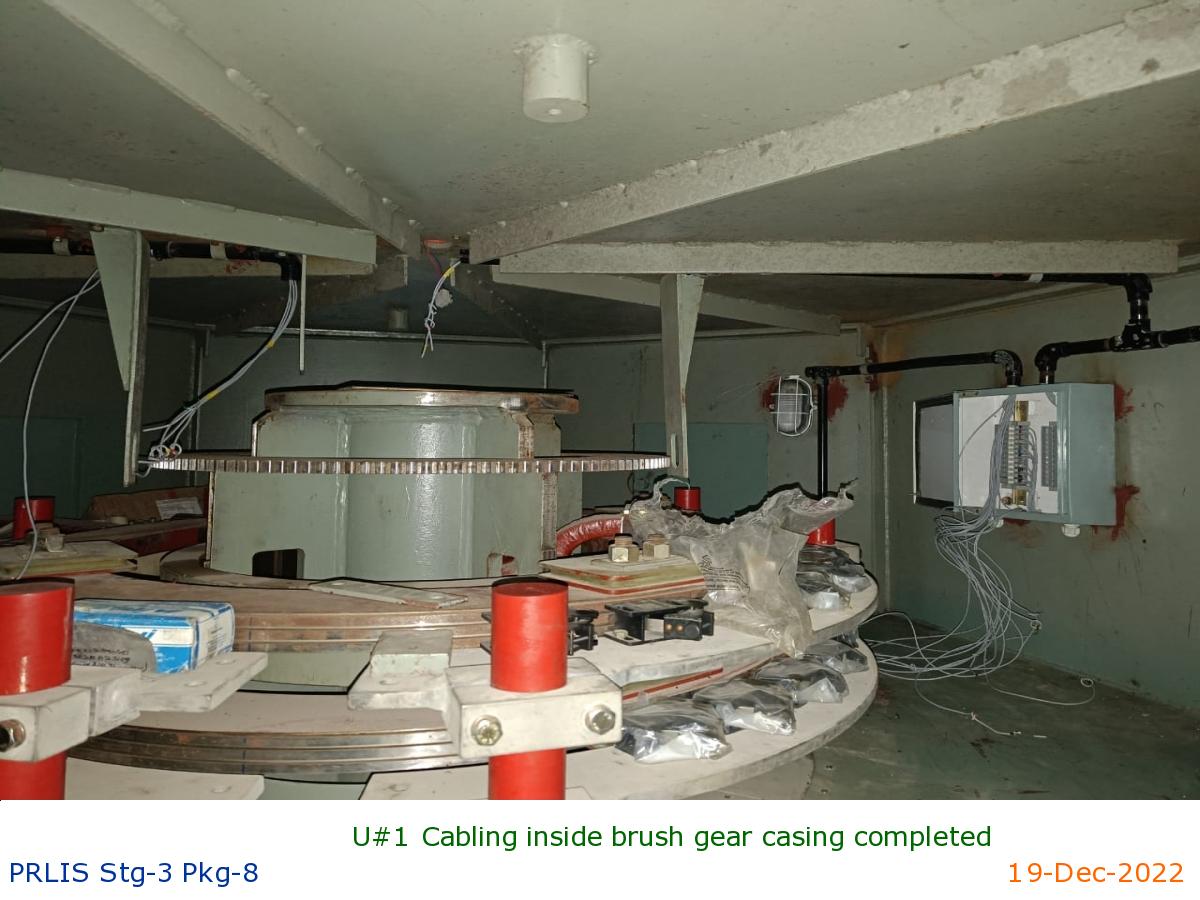

U#1 Cabling inside brush gear casing completed

|

U#5 Staircase concreting outside barrel in progre

|

U#4 LGB sole plates cleaning is in progress

|

U#4 Installation of barell door completed

|

U#4 ITC centering completed dowelling in progress

|

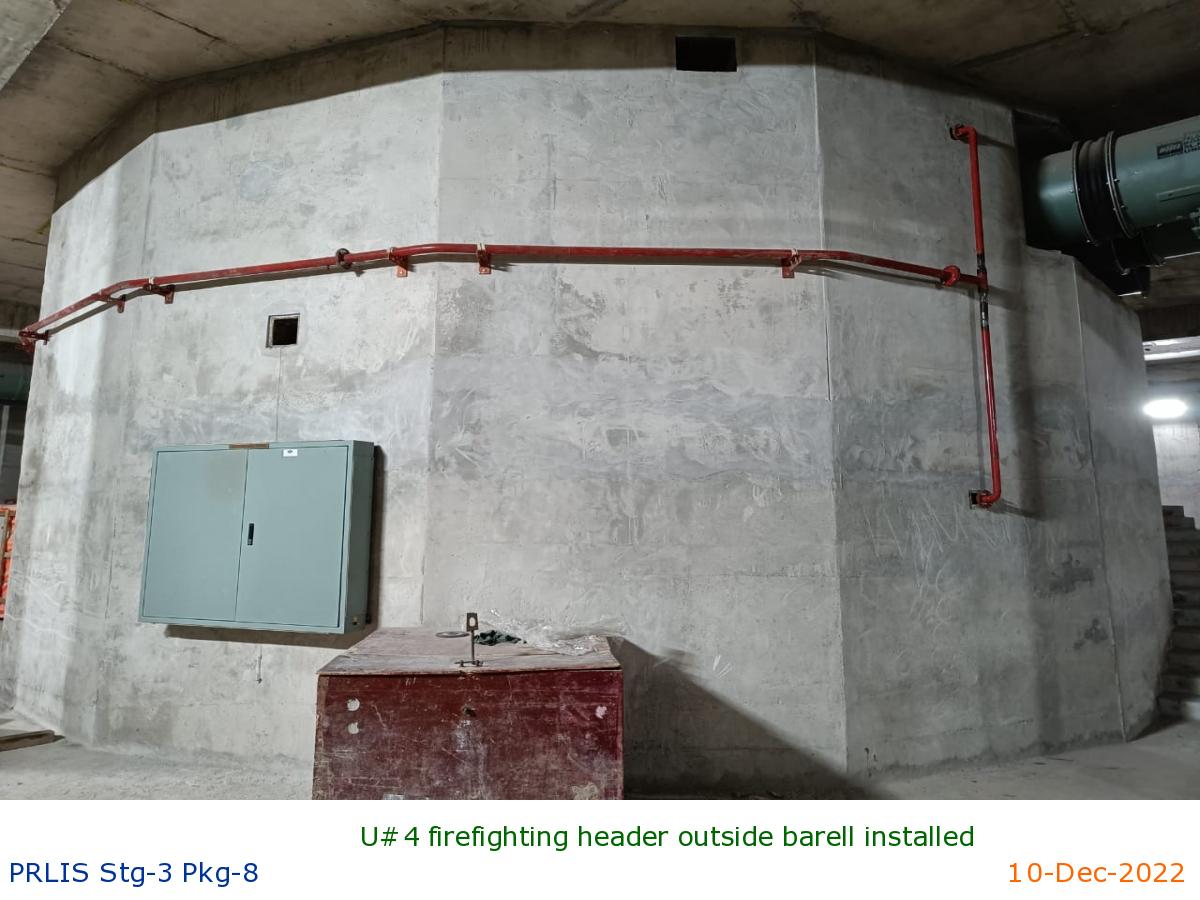

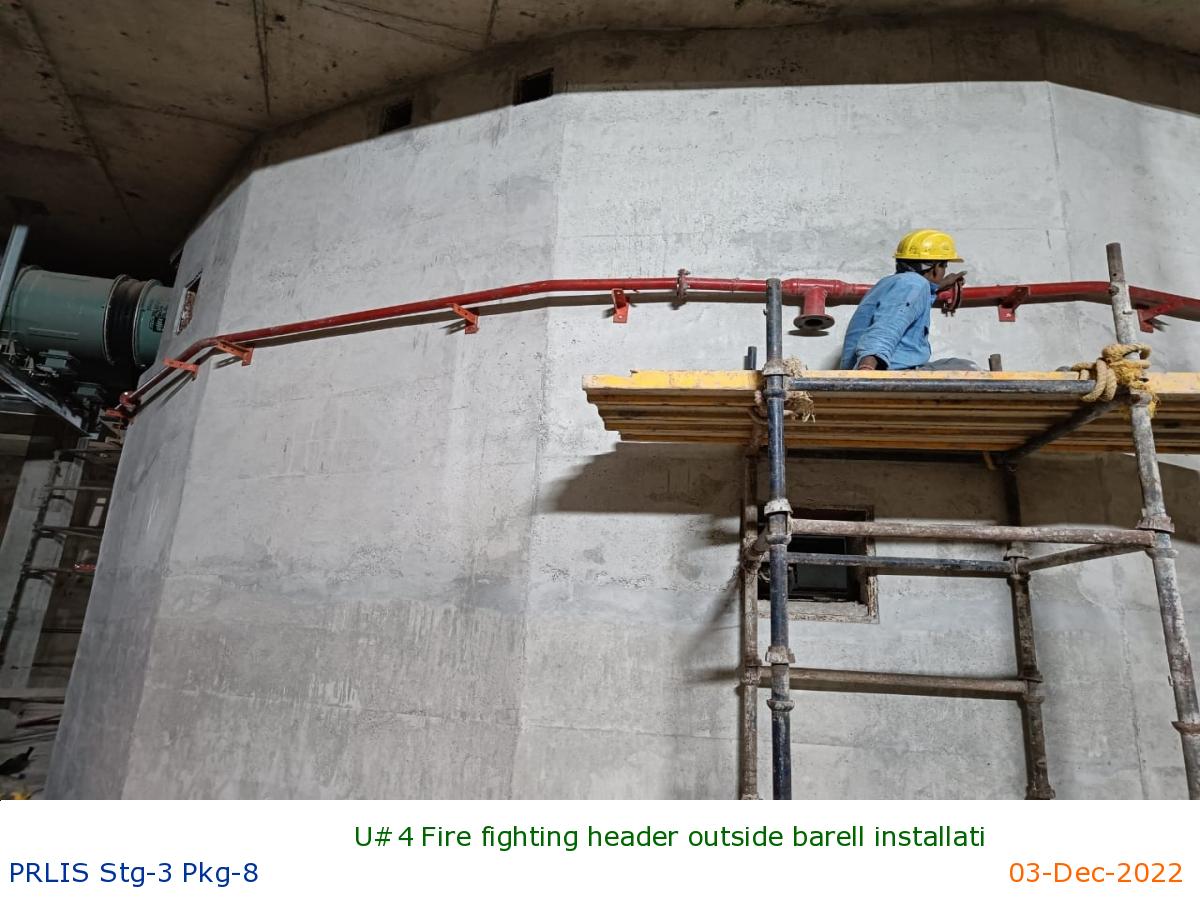

U#4 firefighting header outside barell installed

|

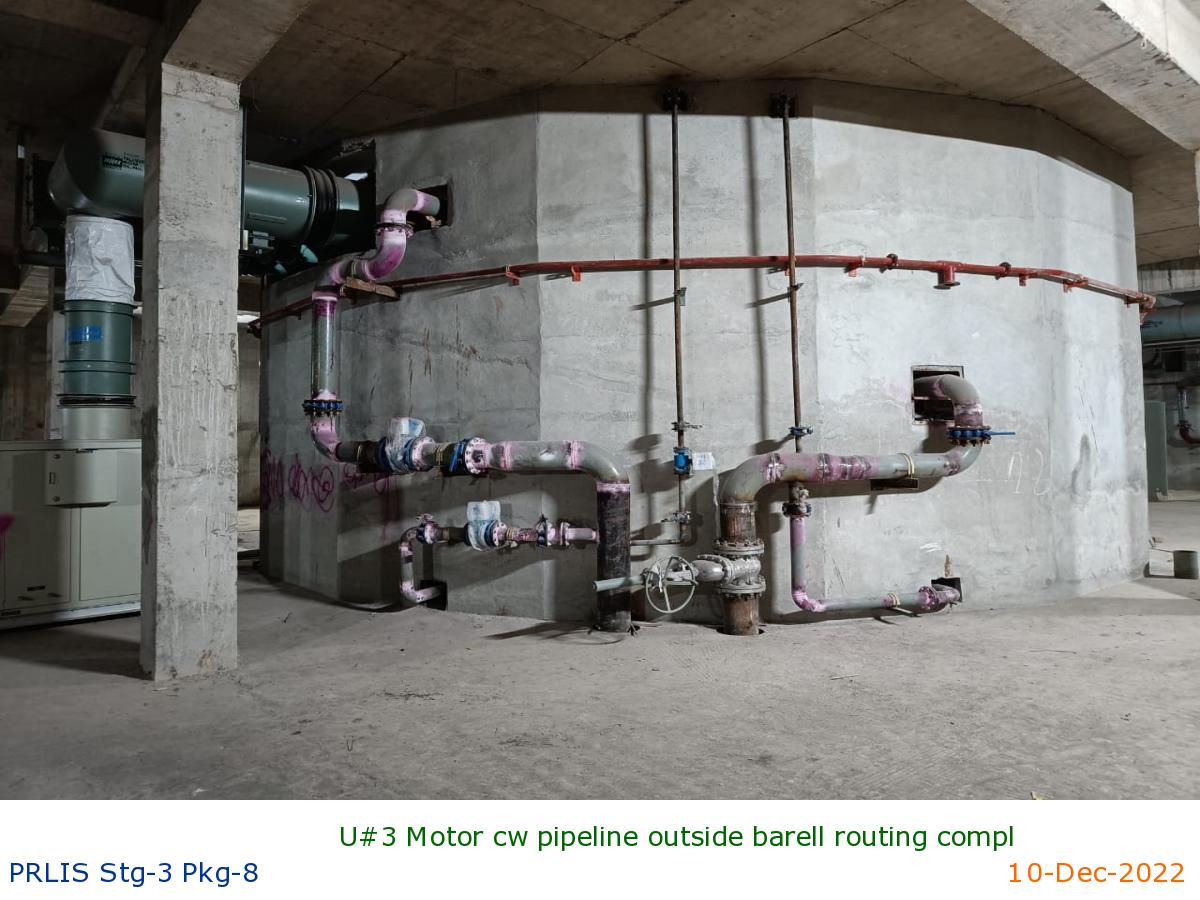

U#3 Motor cw pipeline outside barell routing compl

|

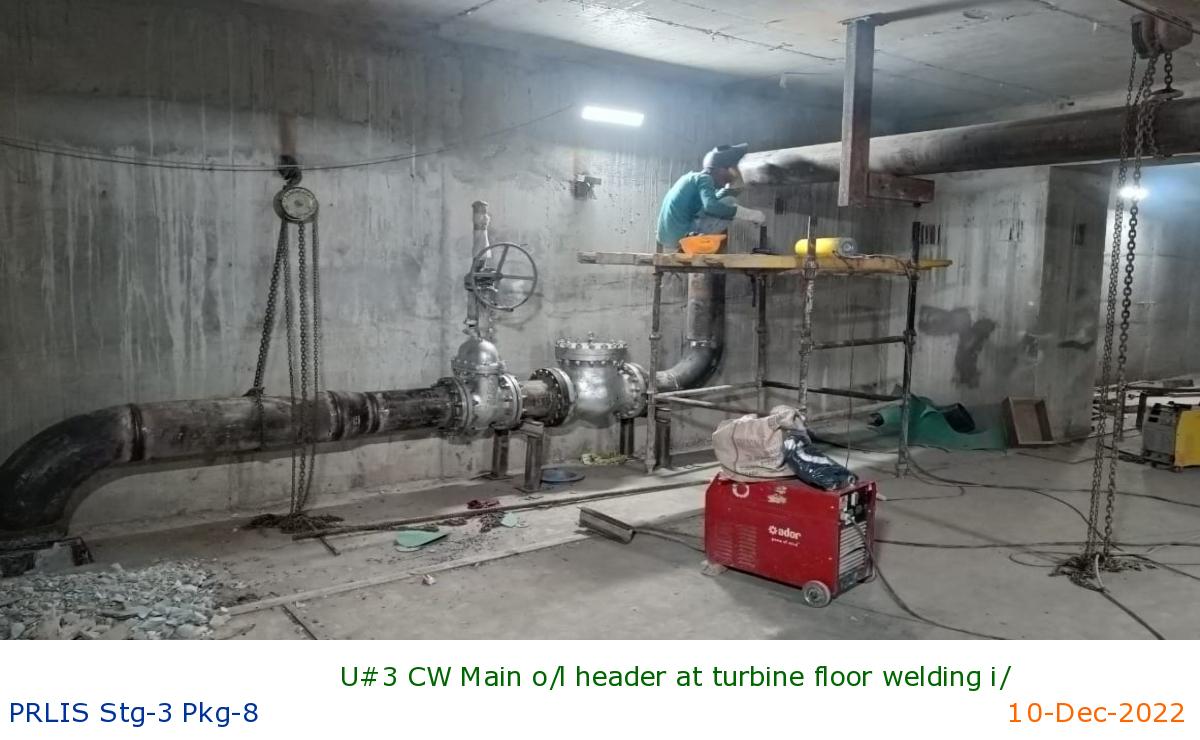

U#3 CW Main o/l header at turbine floor welding i/

|

U#3 Pit air seal final assy completed

|

U#3 Pit air seal final assy completed

|

U#2 Firefighting panel positioned piping in progre

|

U#2 Stator sole plates grouting completed

|

U#2 GV MDV OPU positioning completed

|

U#1 Firefighting panel positioning and piping comp

|

U#1 MDV OPU CW piping completed

|

U#1 GV OPU CW piping completed

|

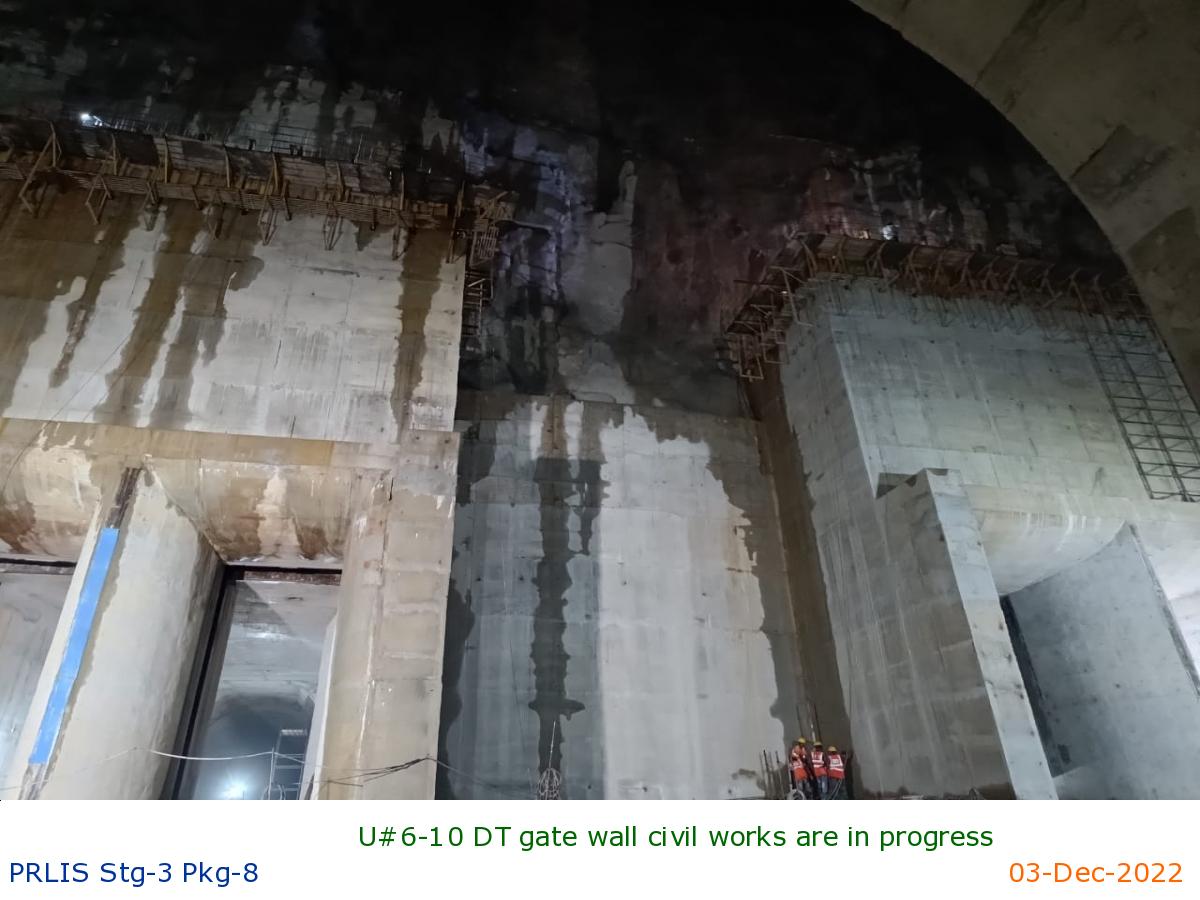

U#6-10 DT gate wall civil works are in progress

|

U#1-5 Surge pool concreting completed upto gantry

|

U#1 DT Gates installed seal assy in progress

|

U#4 Turbine bearing pads blue matching in progress

|

U#4 Fire fighting header outside barell installati

|

U#4 Guide apparatus final assy in progress

|

U#3 LGB Cooler hydraulic testing completed

|

U#3 CW header at turbine floor routing i/p

|

U#3 Barell door installation completed

|

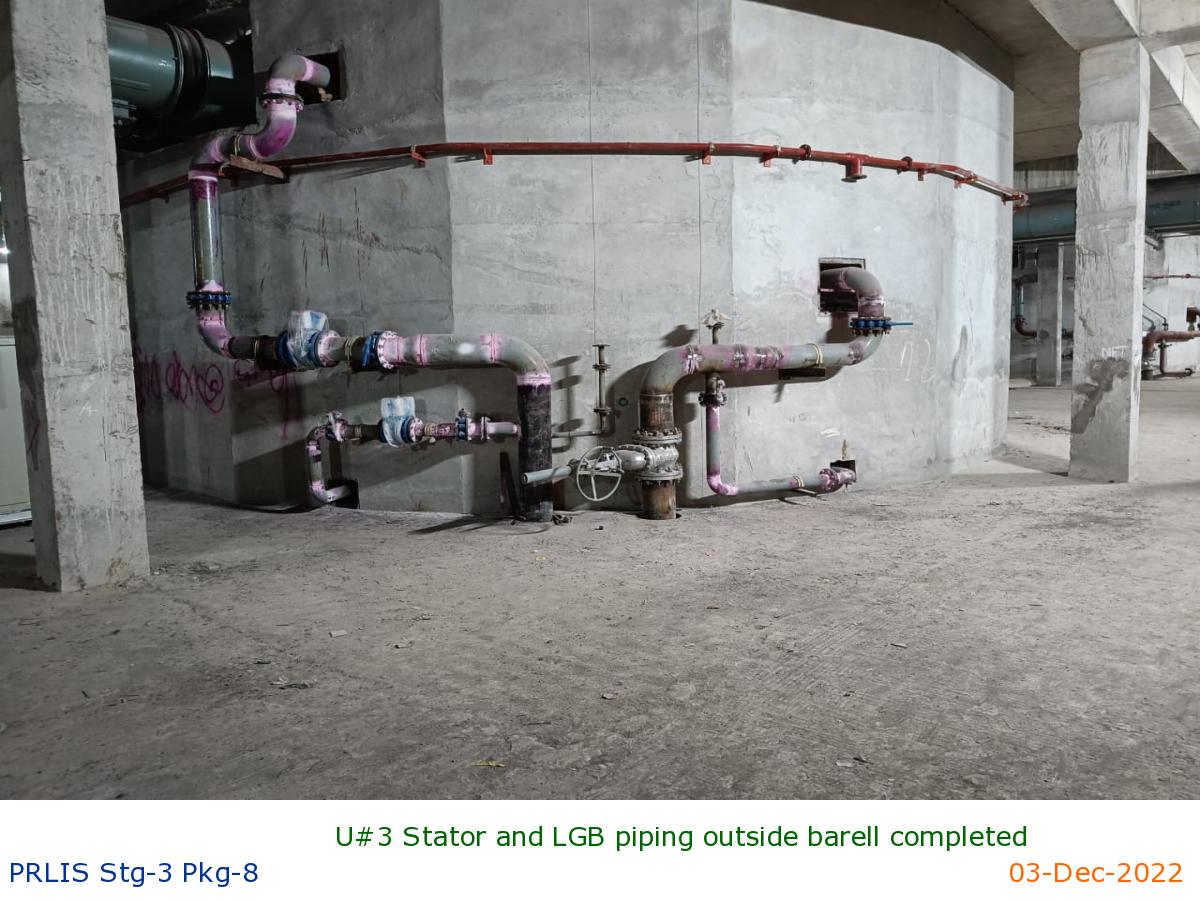

U#3 Stator and LGB piping outside barell completed

|

U#3 UGB CW piping final assembly is in progress

|

U#3 Fire fighting piping inside stator i/p

|

U#2 MDV & GV OPU Positioning completed

|

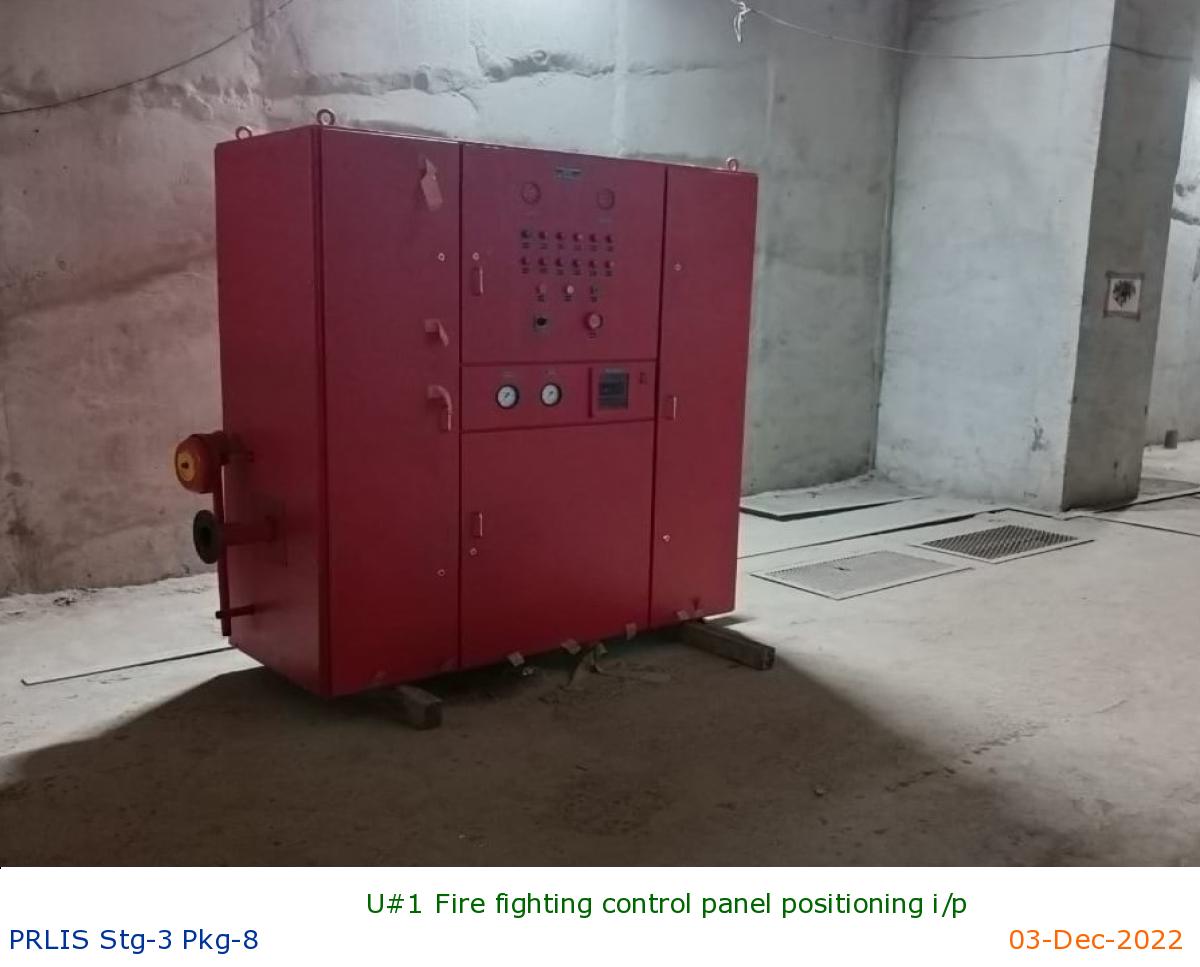

U#1 Fire fighting control panel positioning i/p

|

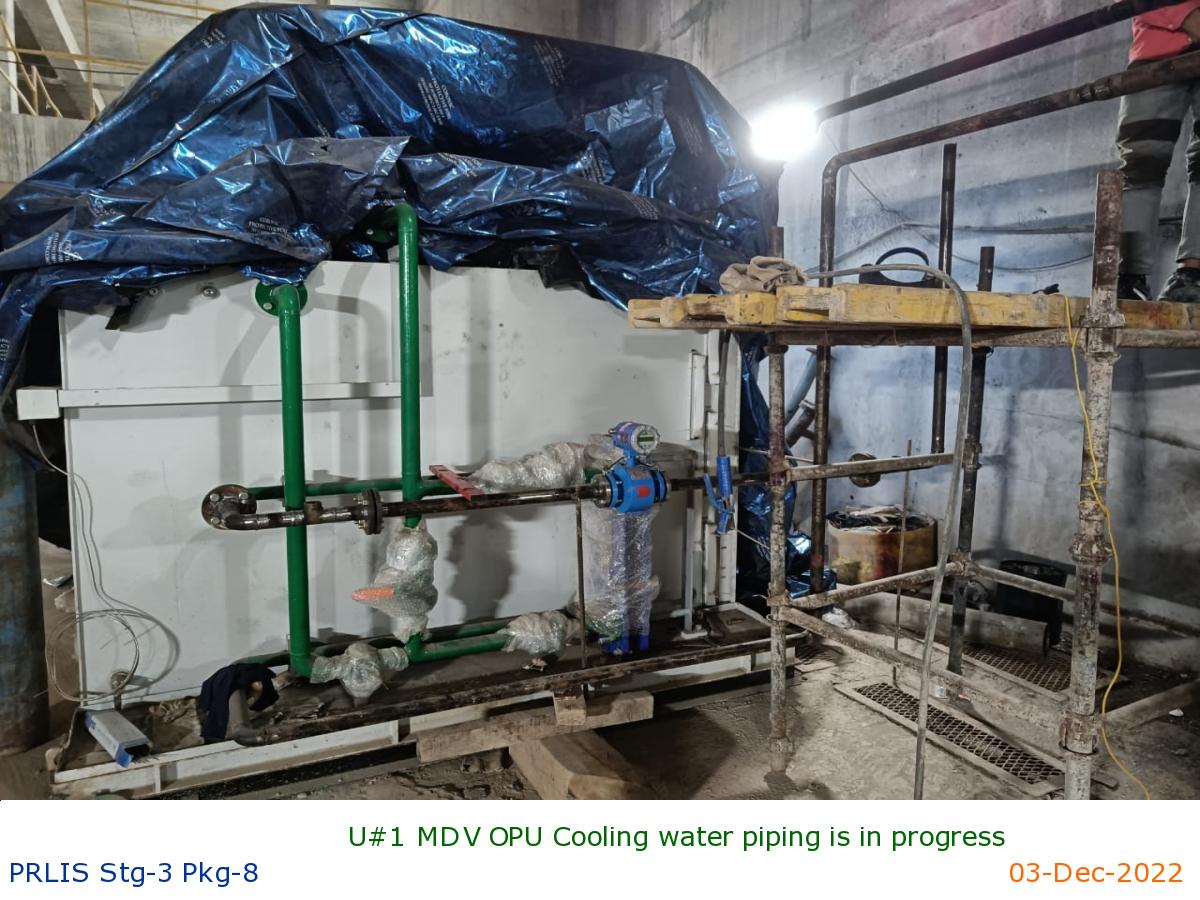

U#1 MDV OPU Cooling water piping is in progress

|

U#1 MDV & GV OPU Positioning completed

|

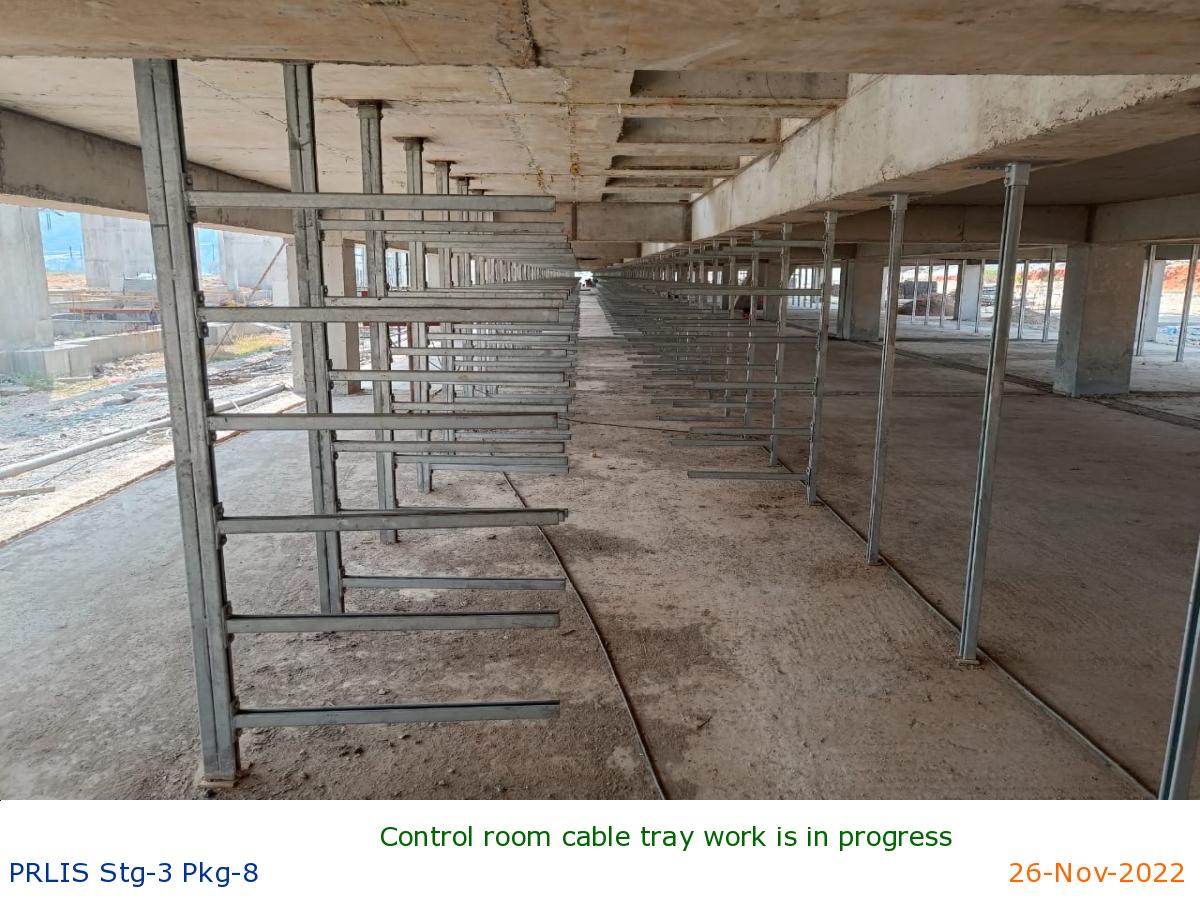

Control room cable tray work is in progress

|

U#4 gv lever fork and fork pin drilling i/p

|

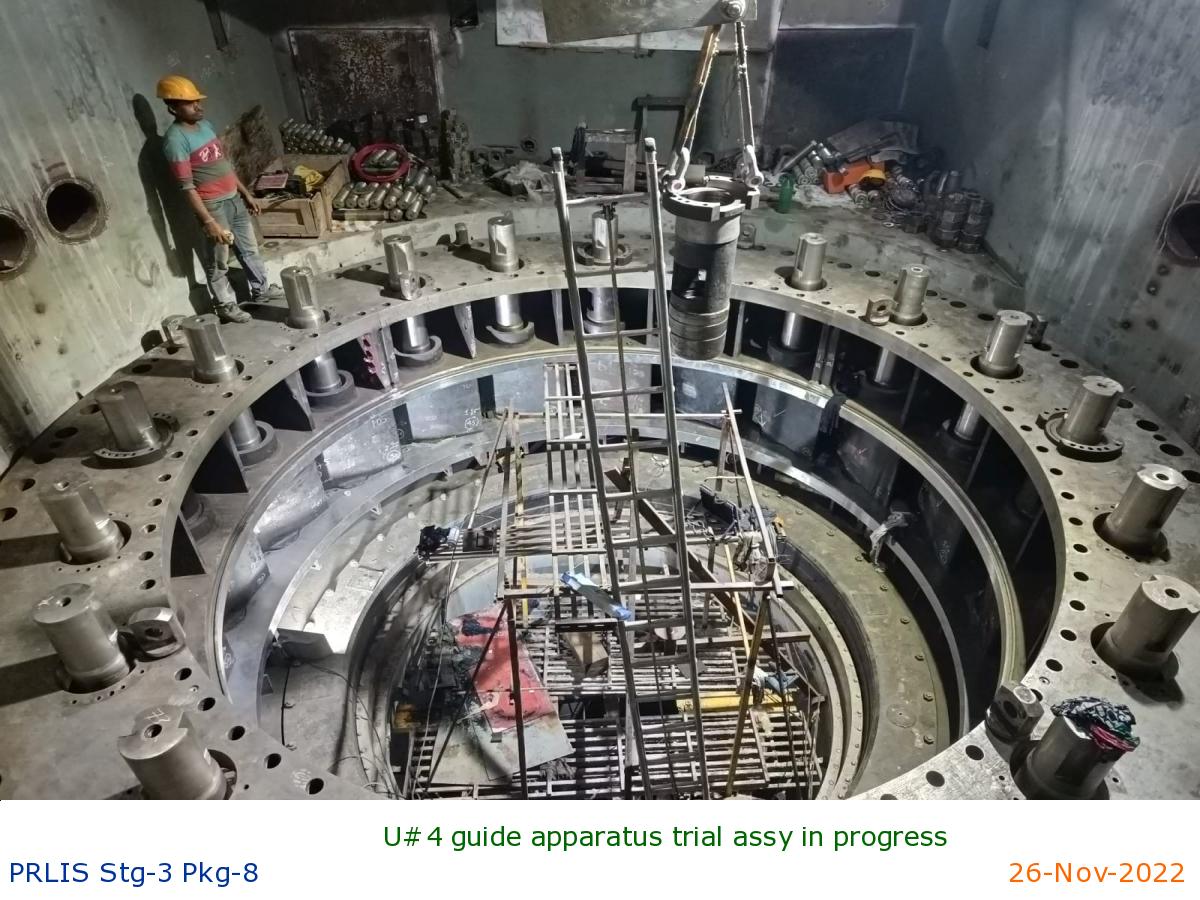

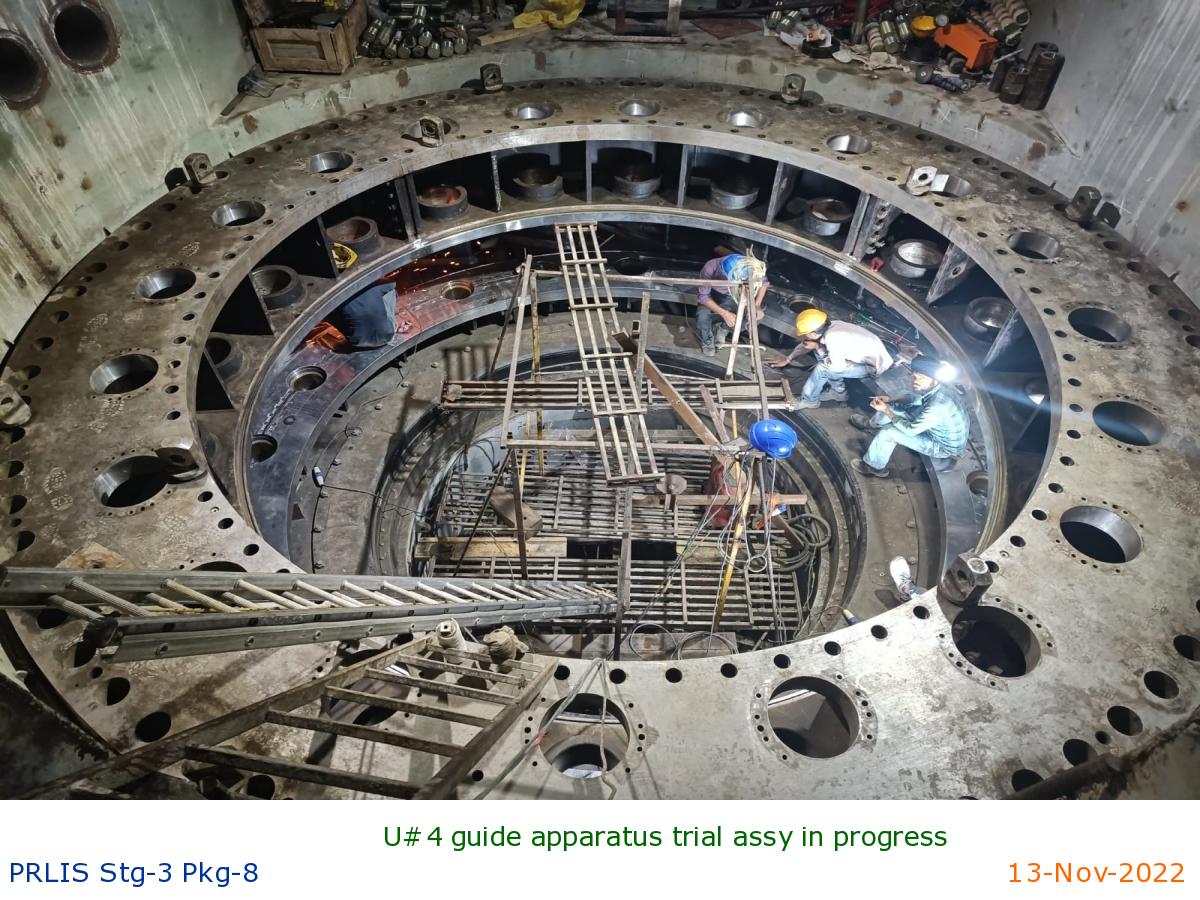

U#4 guide apparatus trial assy in progress

|

U#4 Turbine bearing pad blue matching in progress

|

U#3 Motor floor plate support beamassy in progress

|

U#3 stator cooler to header connection piping i/p

|

U#3 Stator cw piping outside barell routing comple

|

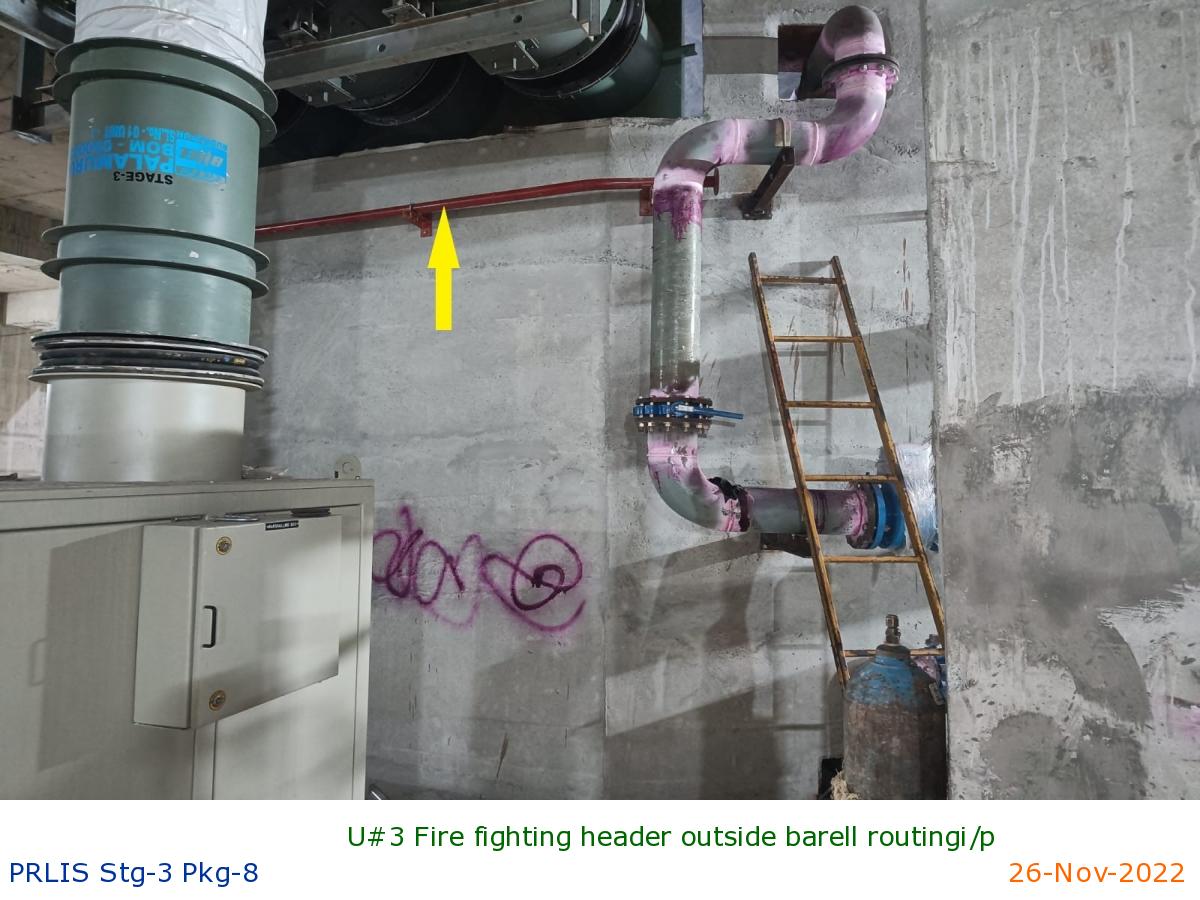

U#3 Fire fighting header outside barell routingi/p

|

U#2 Stator sole plate grouting is in progress

|

U#1 MDV OPU positioning is in progress

|

U#1 Brake dust collector positioning completed

|

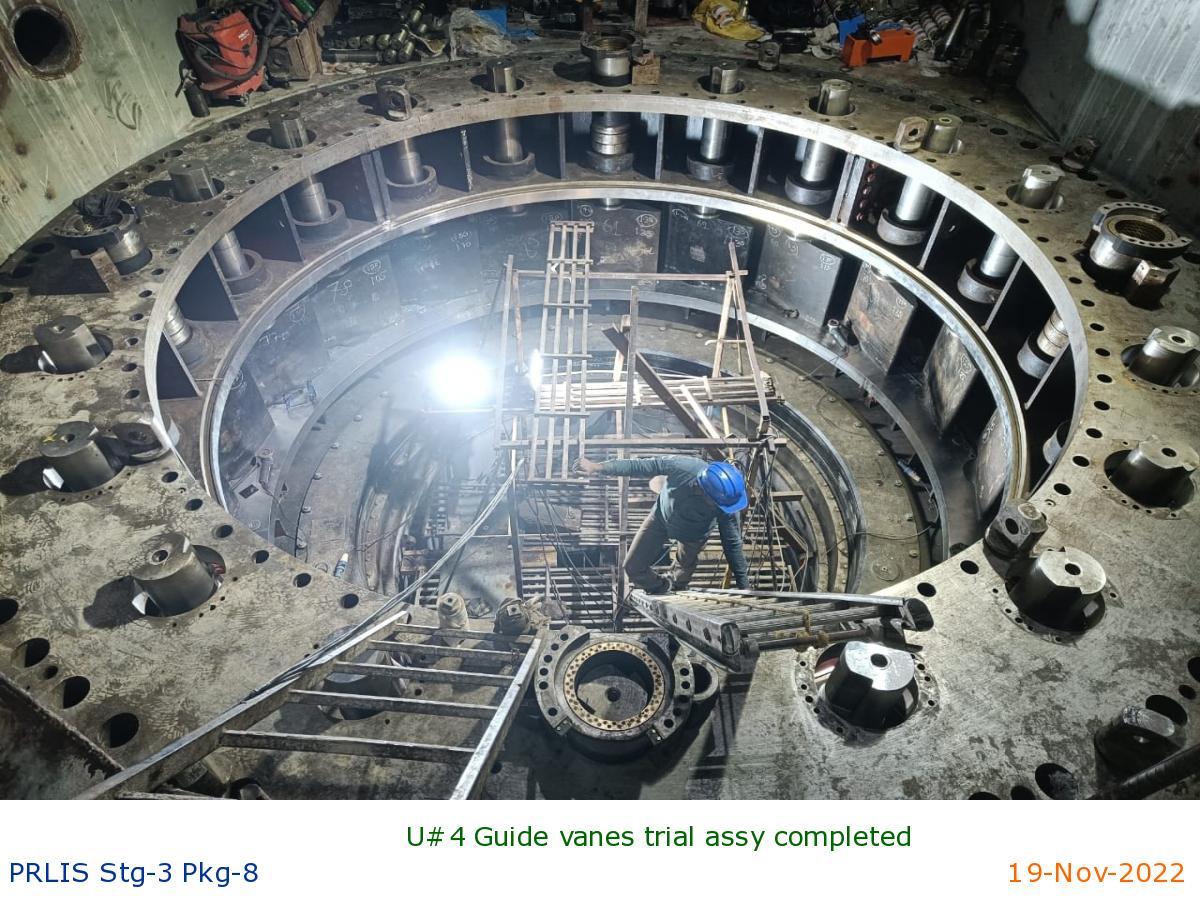

U#4 Guide vanes trial assy completed

|

U#3 Installation of stator air coolers i/p

|

U#3 Pit air seal final assy in progress

|

U#3 UGB CW pipeline inside barell routing i/p

|

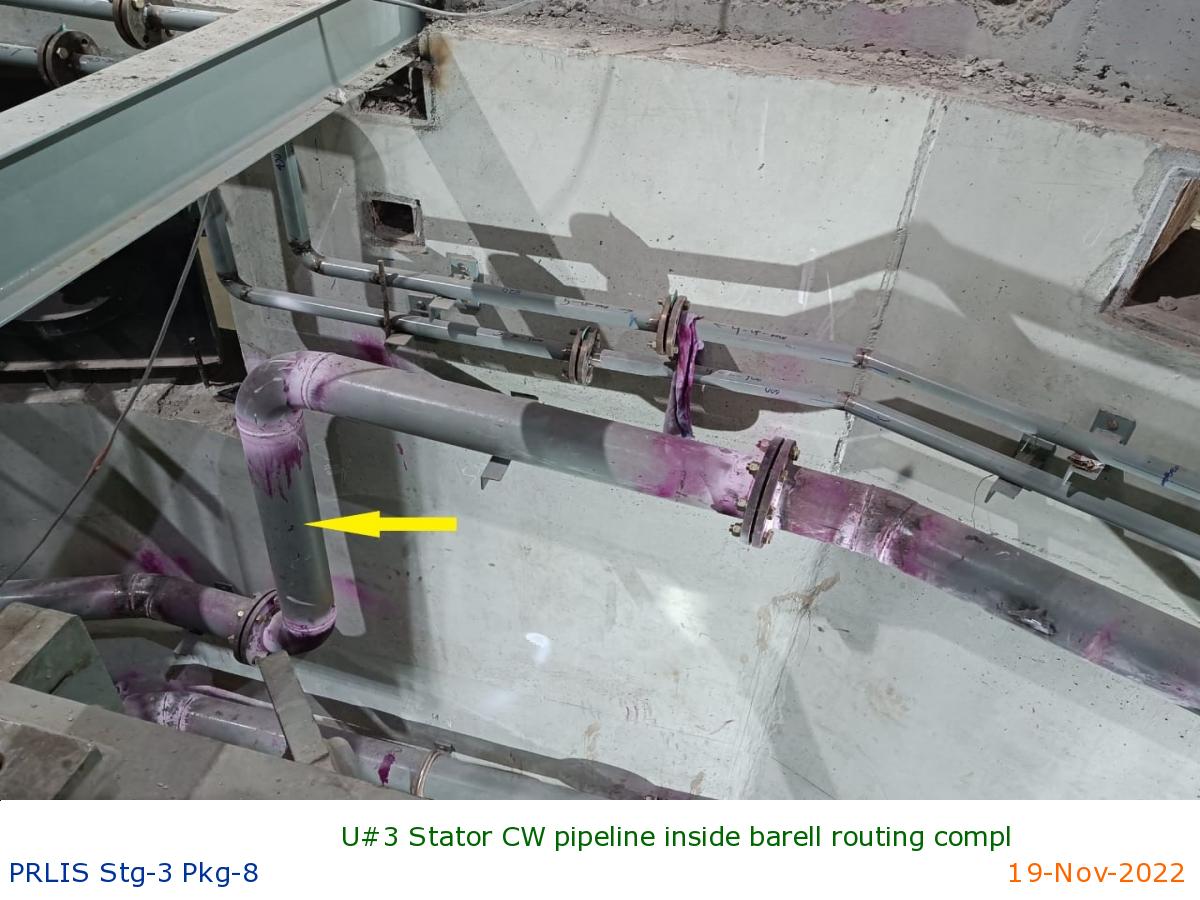

U#3 Stator CW pipeline inside barell routing compl

|

U#3 Stator CW pipeline outside barell routing i/p

|

U#1 Installation of motor space heaters in progres

|

U#1 Installation of air duct covers in progress

|

Dewatering sump2 header pipeline routing in progre

|

U#4 guide apparatus trial assy in progress

|

U#3 stator air cooler hydraulic testing in progres

|

U#3 pit air seal rings welding in progress

|

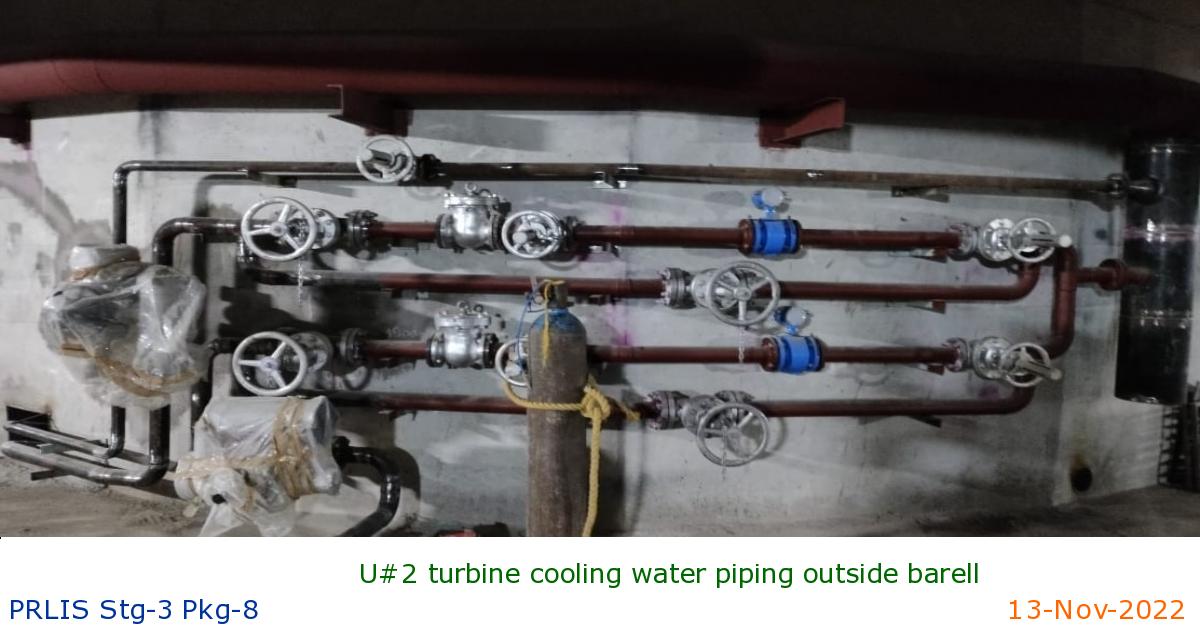

U#2 turbine cooling water piping outside barell

|

U#2 cyclone seperators installation completed

|

U#1 MDV inlet pipe welding is in progress

|

U#4 OTC lowering and tightening is in progress

|

U#3 coupling nut guard installation completed

|

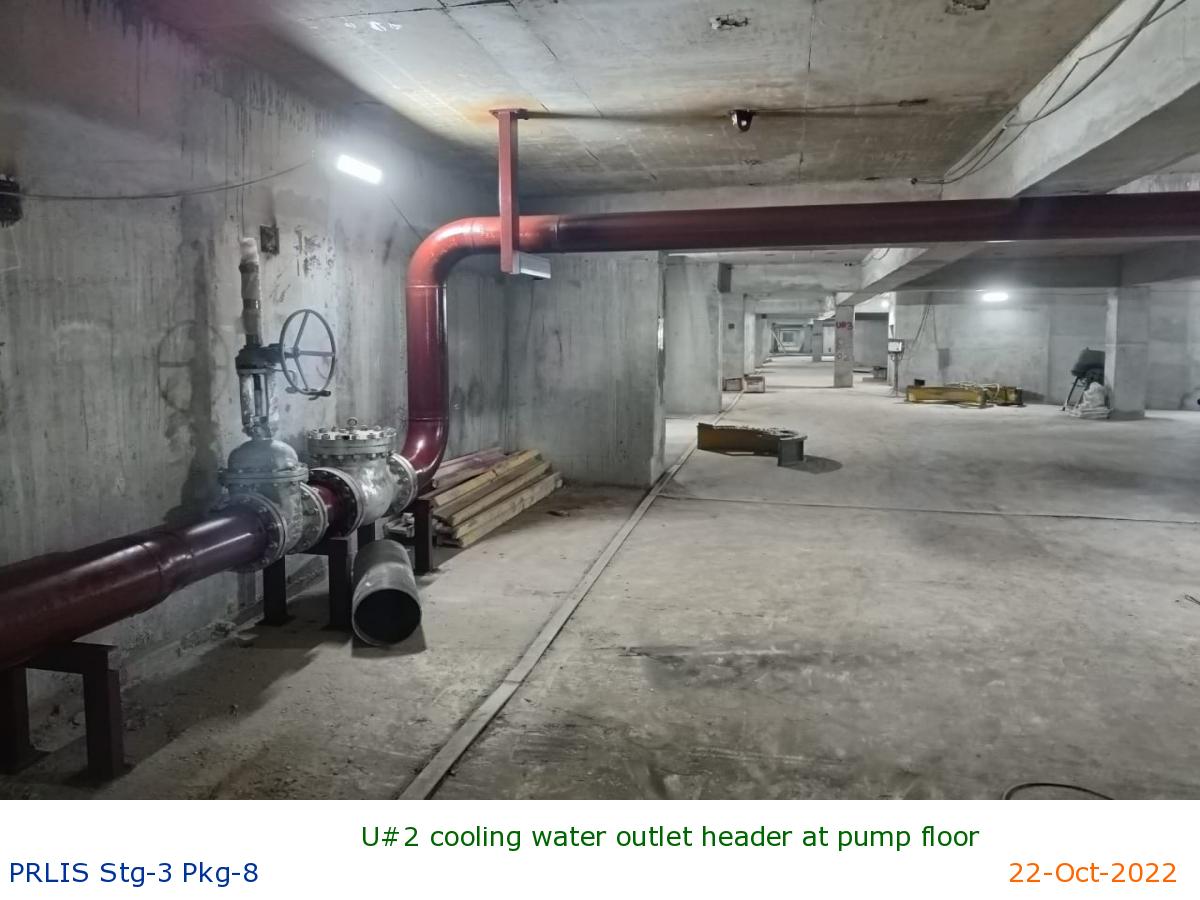

U#2 cooling water outlet header at pump floor

|

U#2 cooling water piping routing and welding i/p.

|

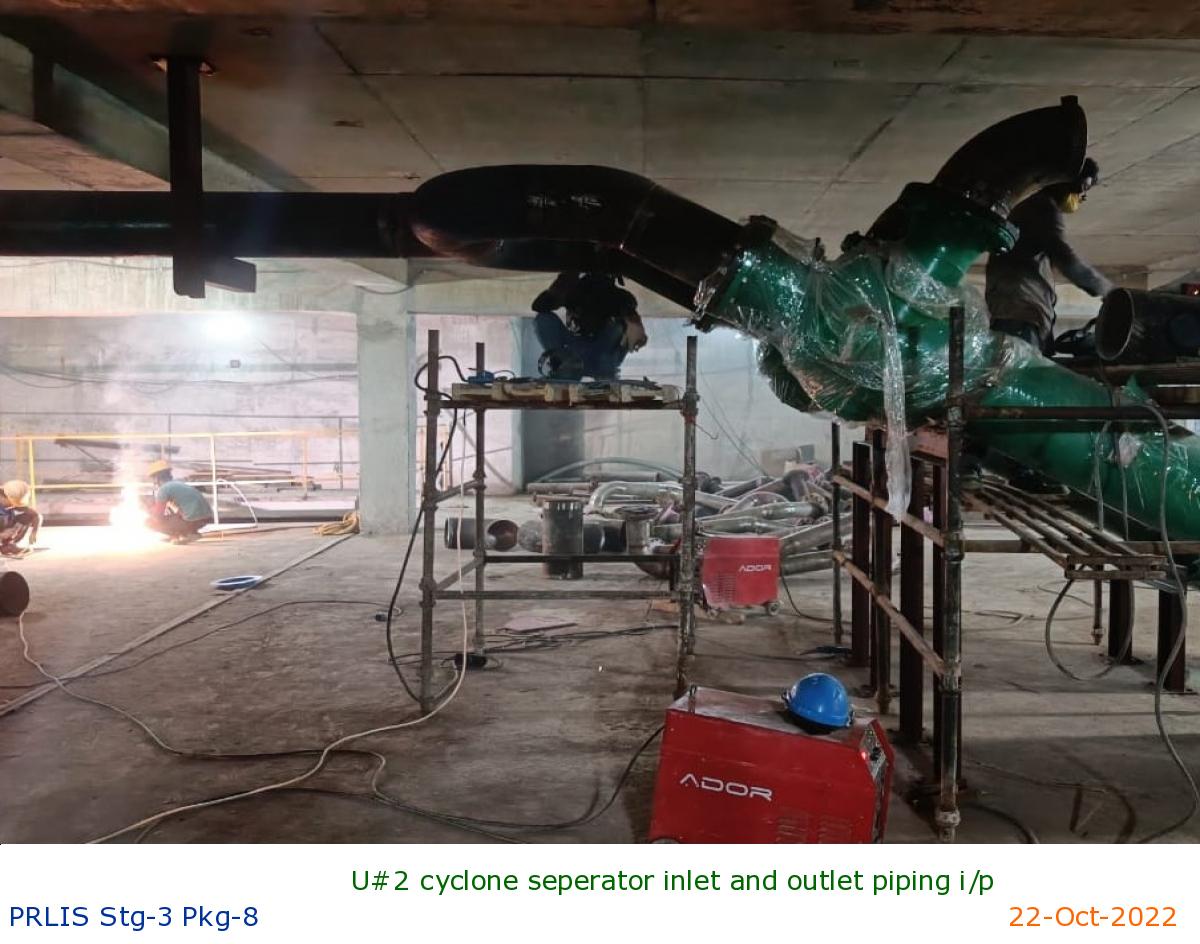

U#2 cyclone seperator inlet and outlet piping i/p

|

U#2 bottom fire fighting piping routing is i/p

|

U#2 Bottom air baffle trial assy in progress

|

Dewatering sump-2 pipeline routing in progress

|

Water depression header routing completed upto ASB

|

U#4 OTC quadrants welding is in progress

|

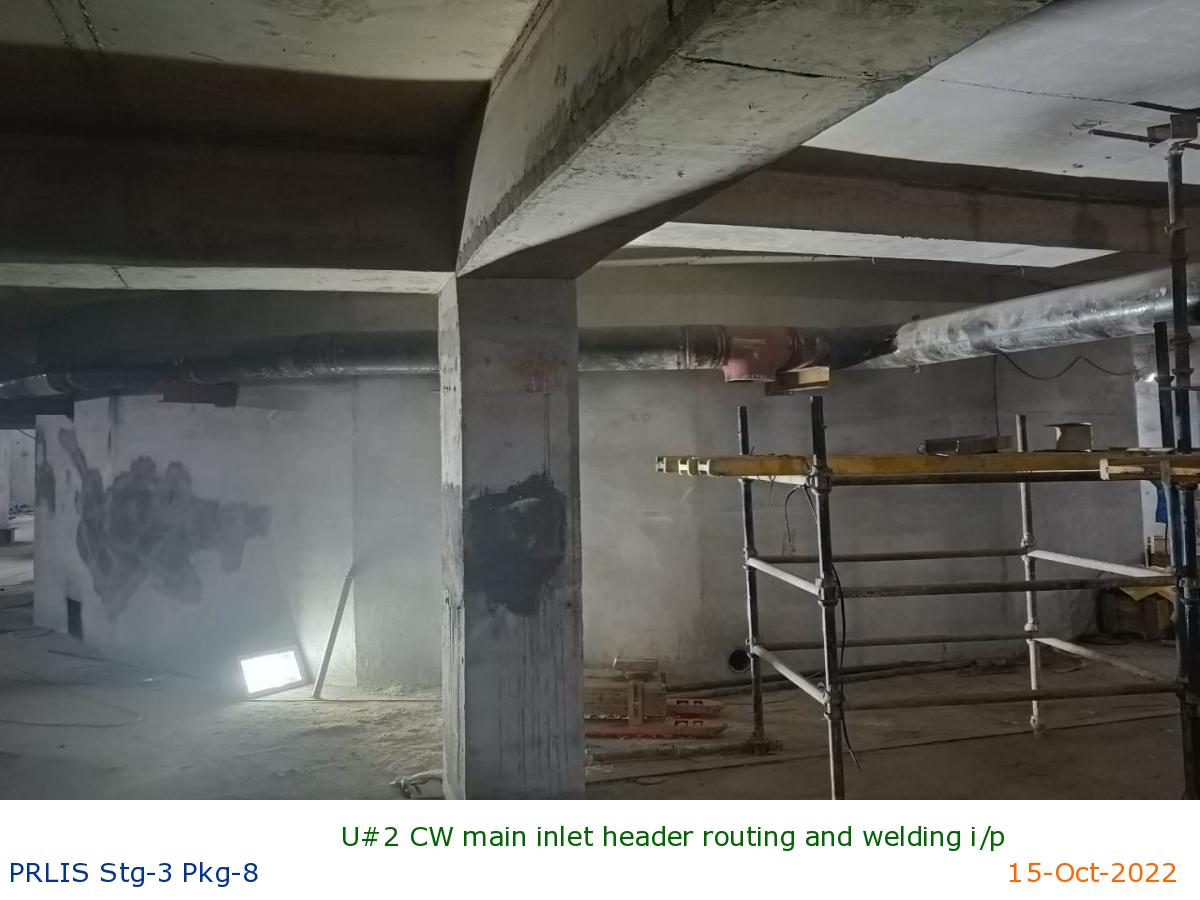

U#2 CW main inlet header routing and welding i/p

|

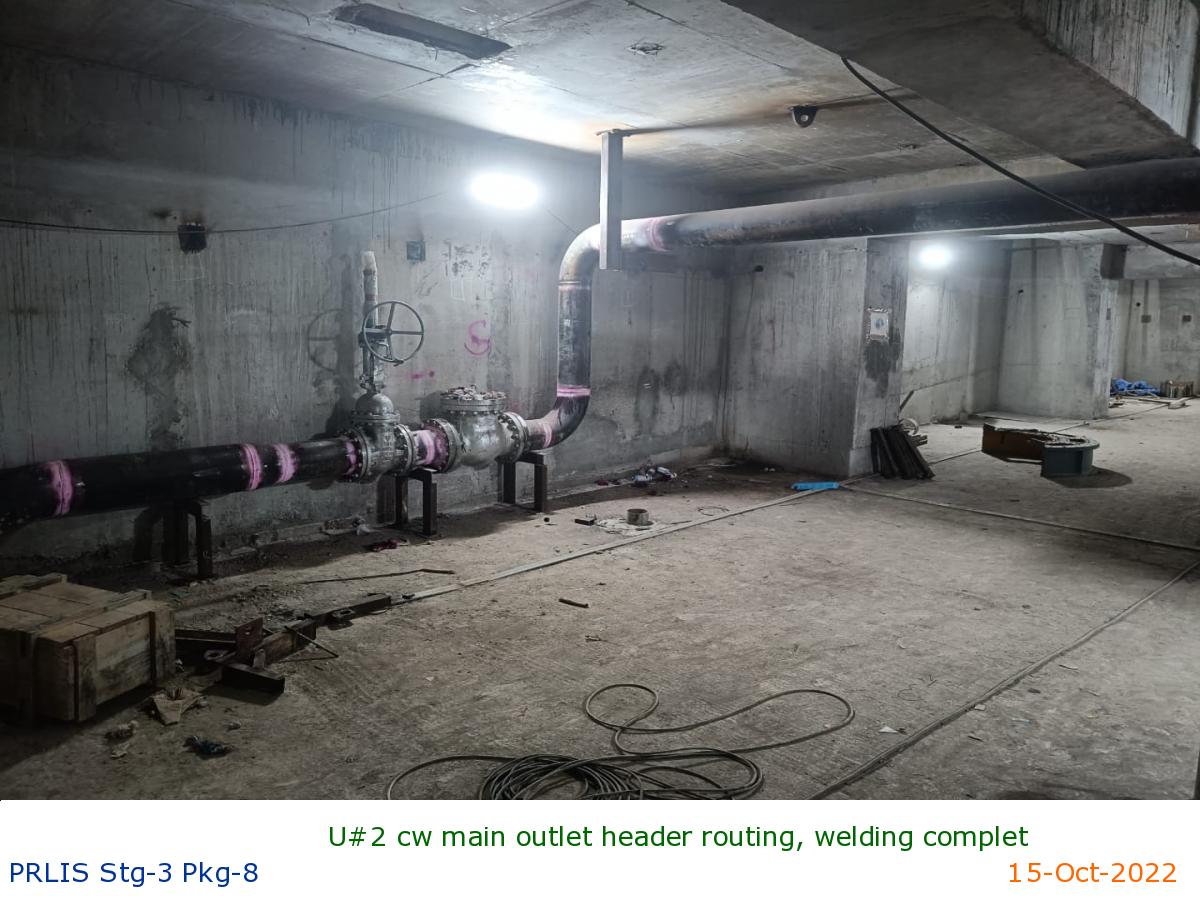

U#2 cw main outlet header routing, welding complet

|

U#2 cyclone seperators installation in progress

|

U#1 MDV erection completed

|

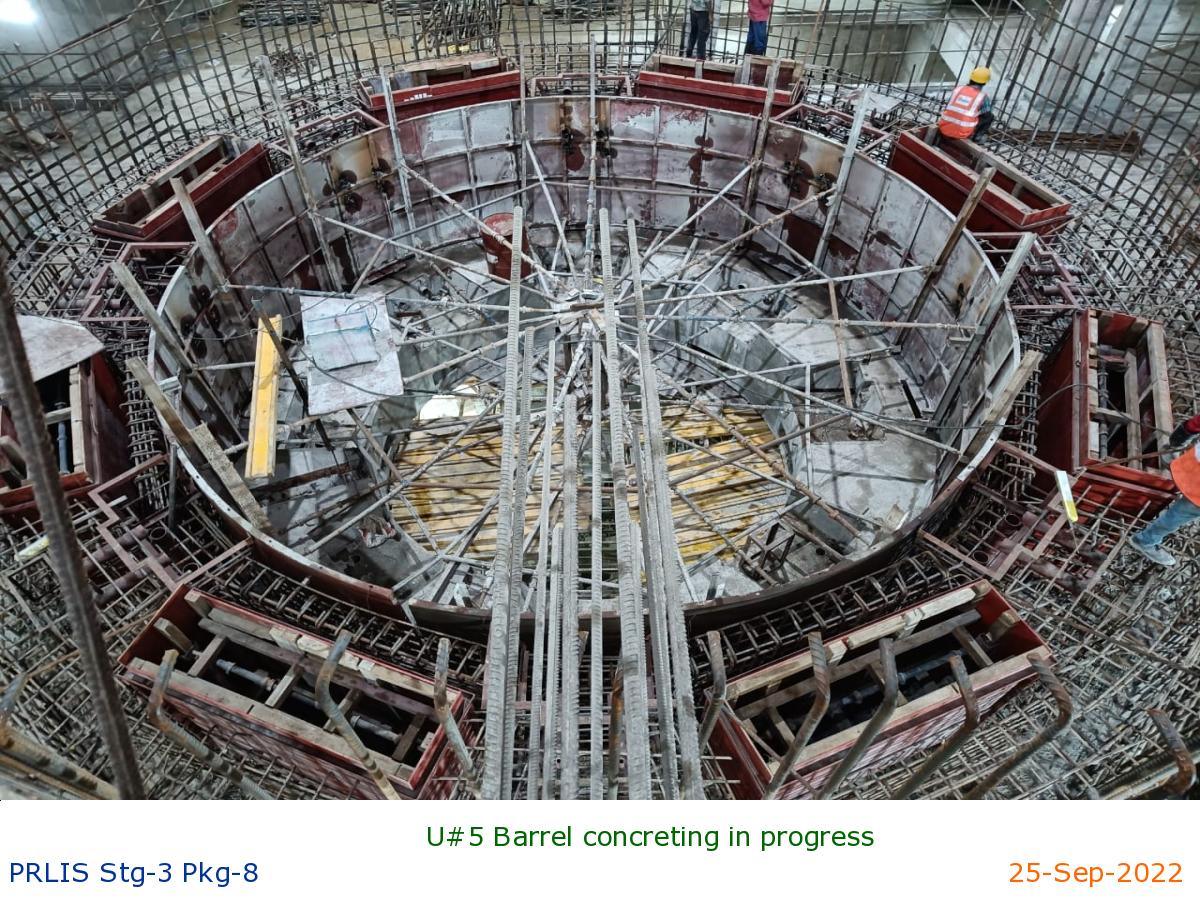

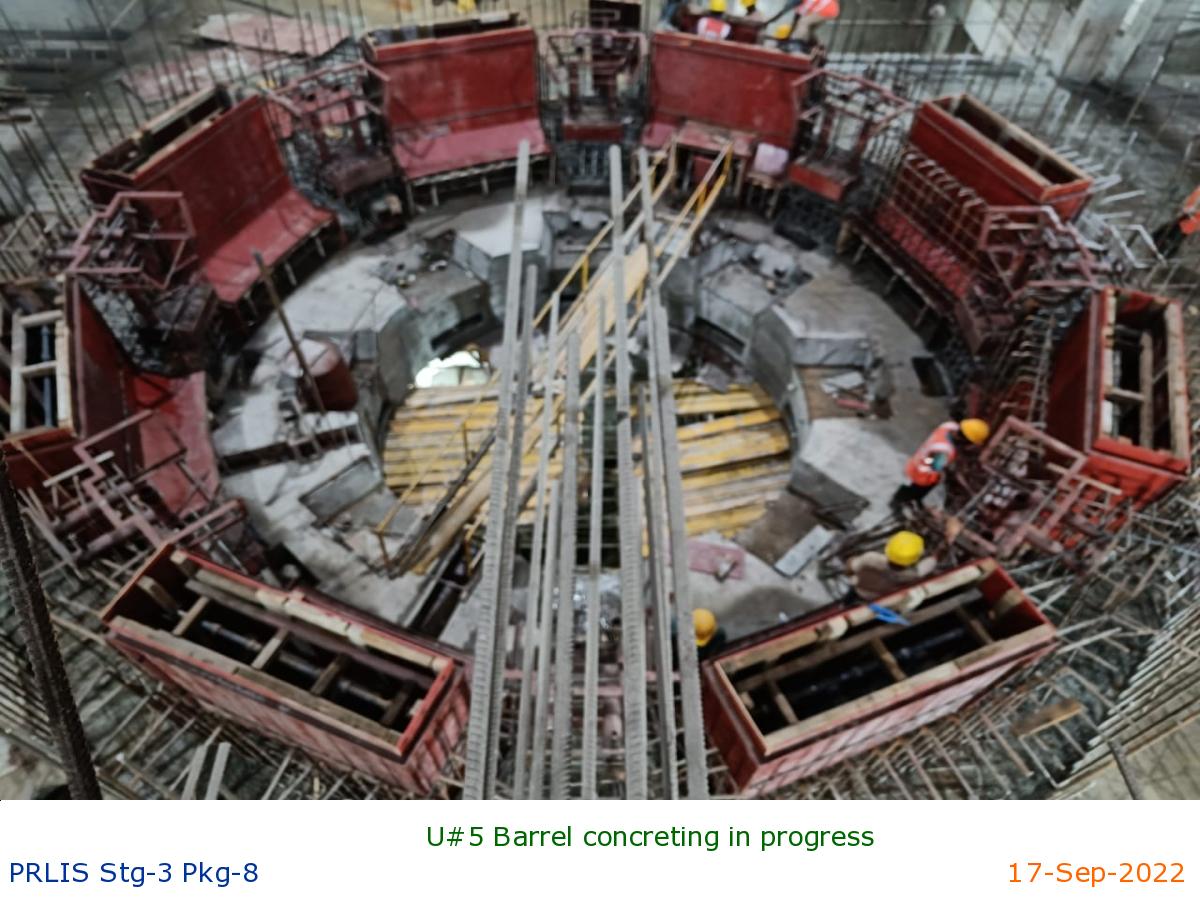

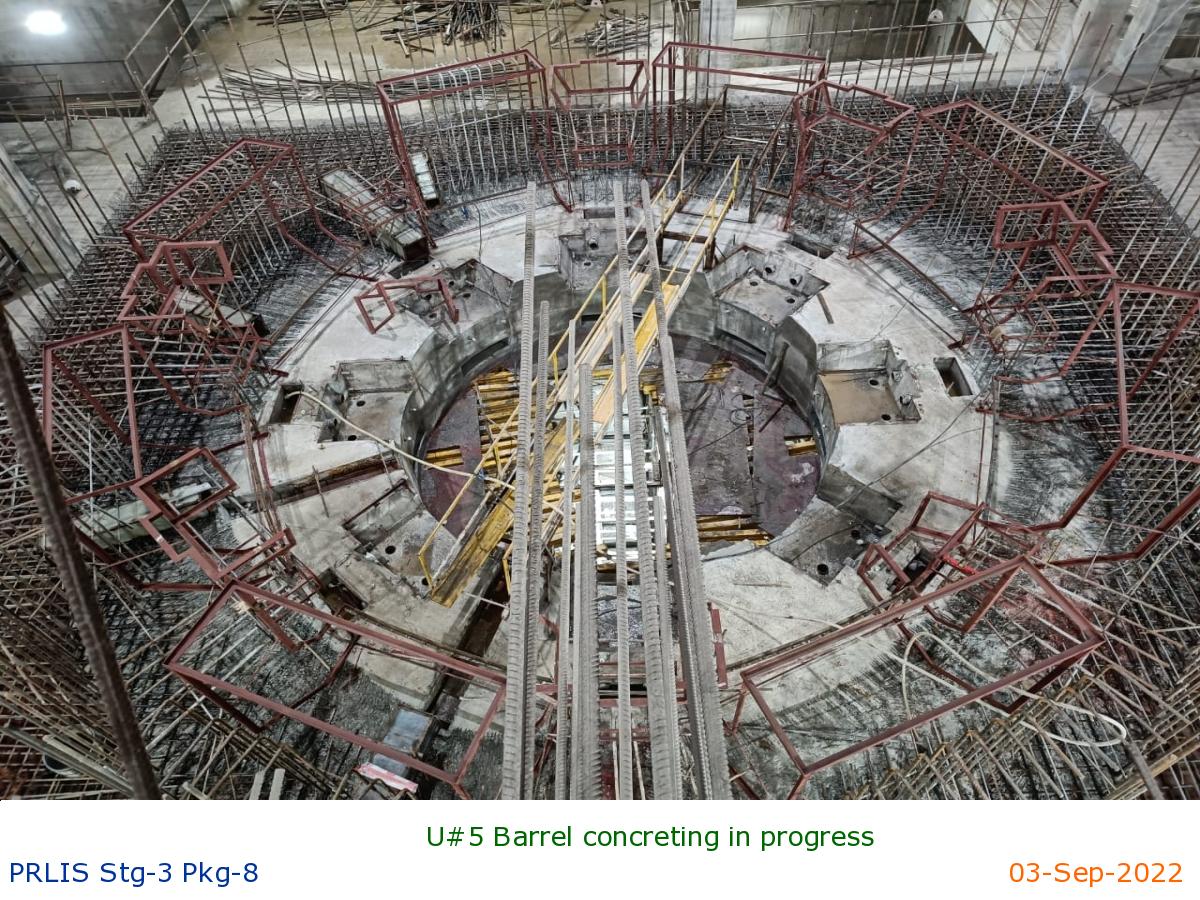

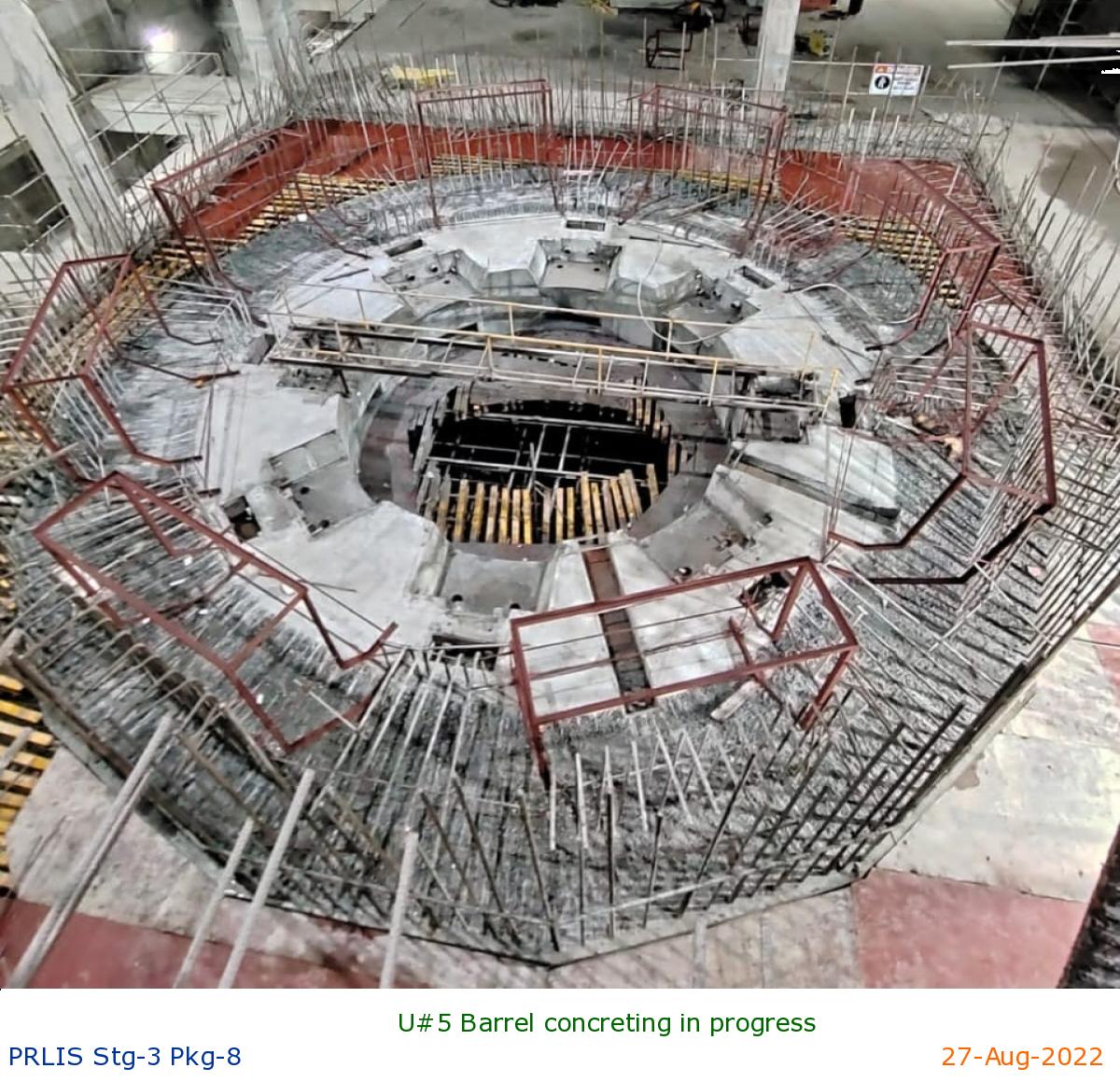

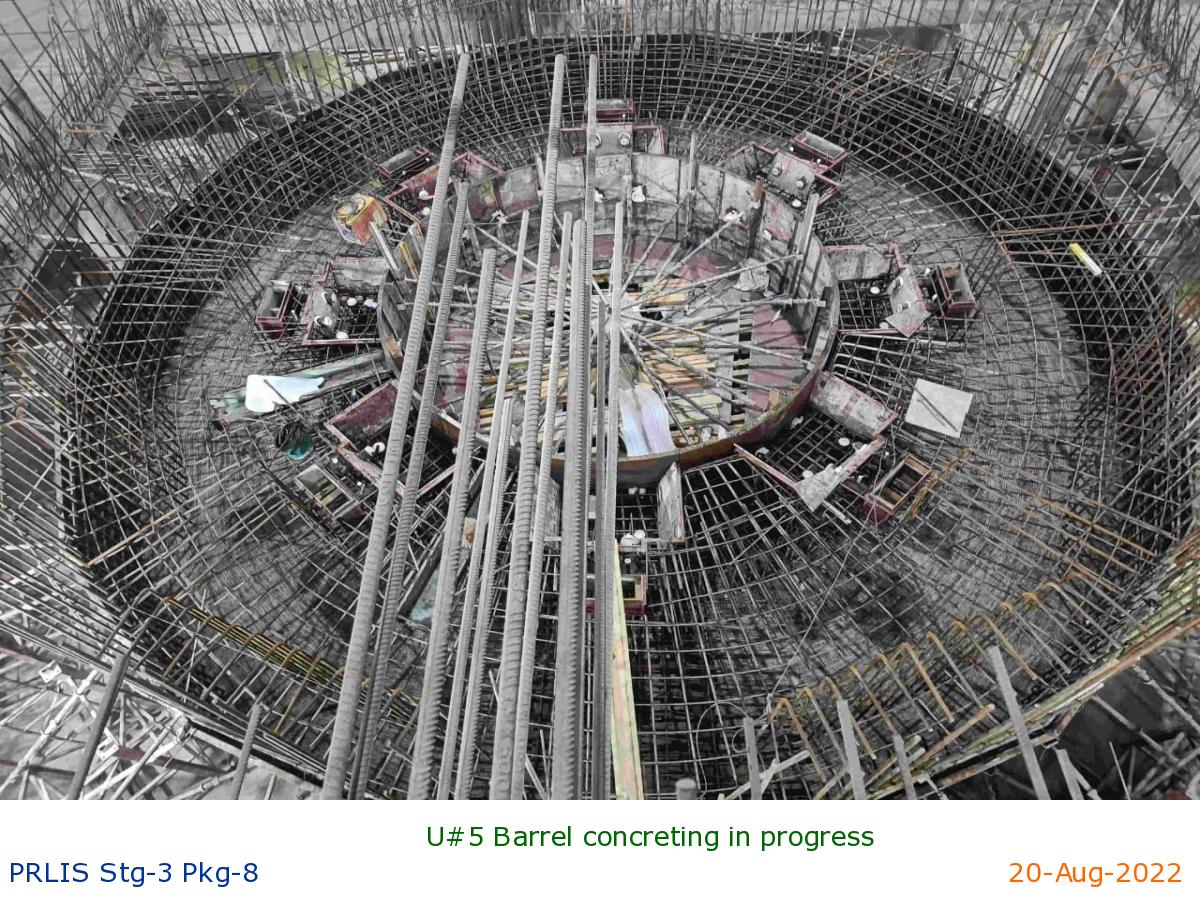

U#5 Barrel concreting in progress

|

U#4 OTC Quadrants lowering in progress

|

U#2 cw skids shifted to pump floor

|

U#2 bottom air guide trial assy i/p

|

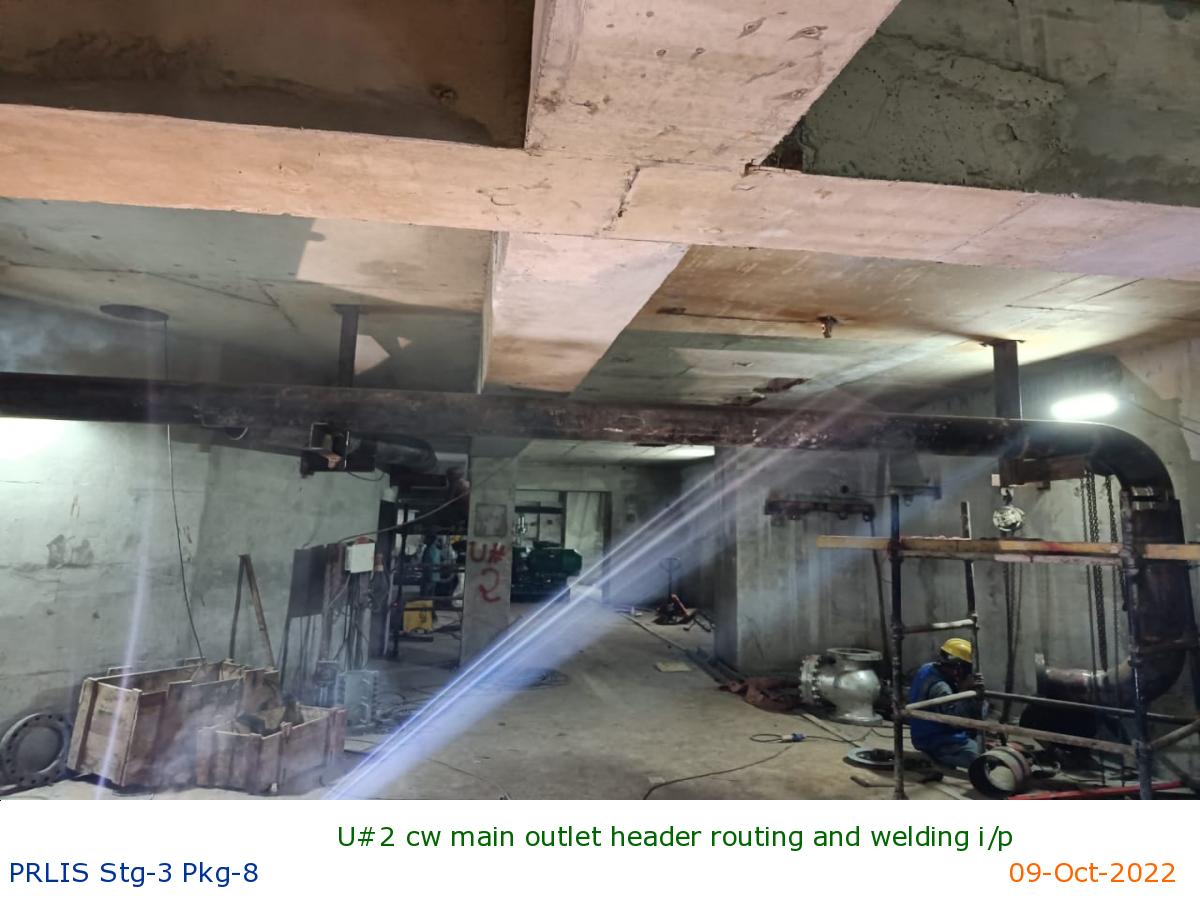

U#2 cw main outlet header routing and welding i/p

|

U#2 CW main inlet header routing and welding i/p

|

U#2 top oil cooler piping routing and welding i/p

|

U#1 MDV inlet and outlet pipe lowering completed

|

U#5 Barrel concreting in progress

|

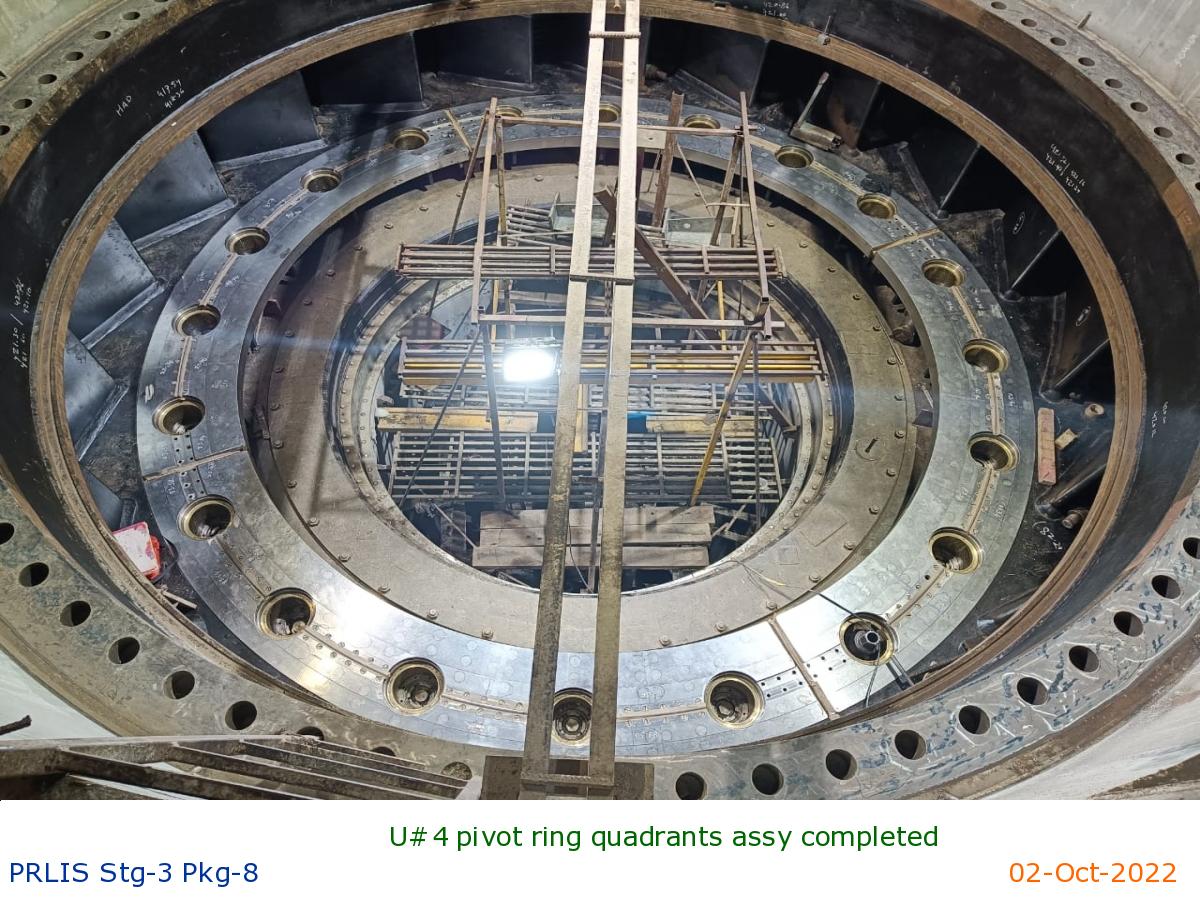

U#4 pivot ring quadrants assy completed

|

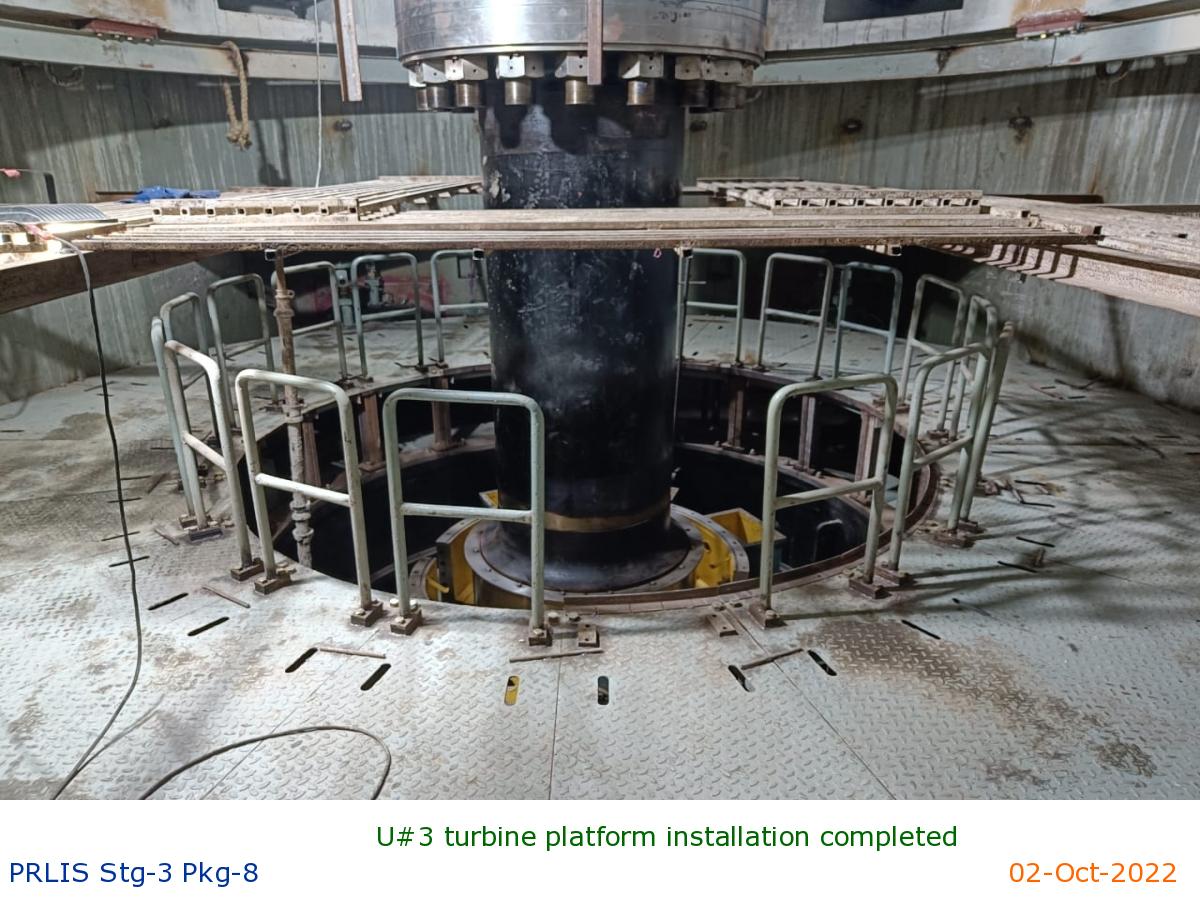

U#3 turbine platform installation completed

|

U#2 bottom air guide trial assy i/p

|

U#2 strainer assy on skid is in progress

|

U#2 cw pump motor skid positioning i/p

|

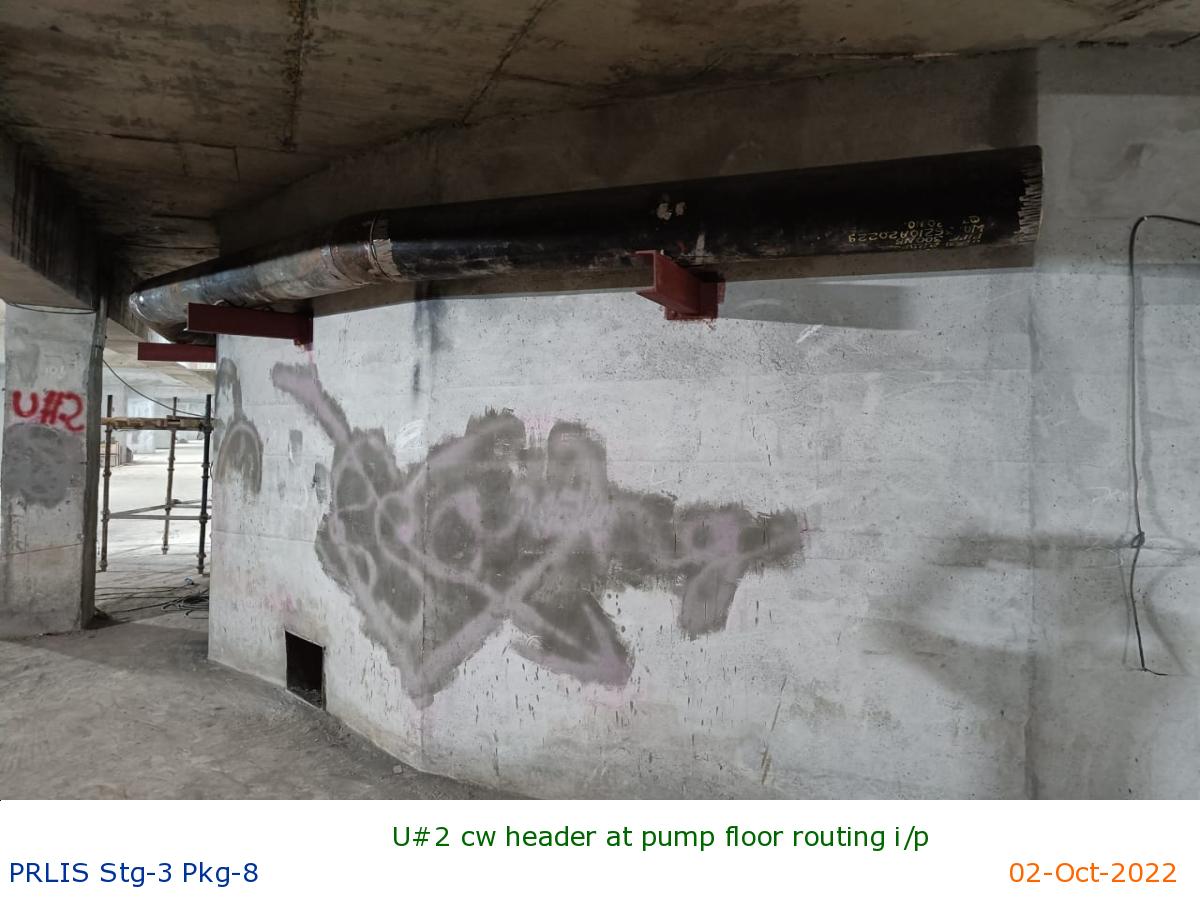

U#2 cw header at pump floor routing i/p

|

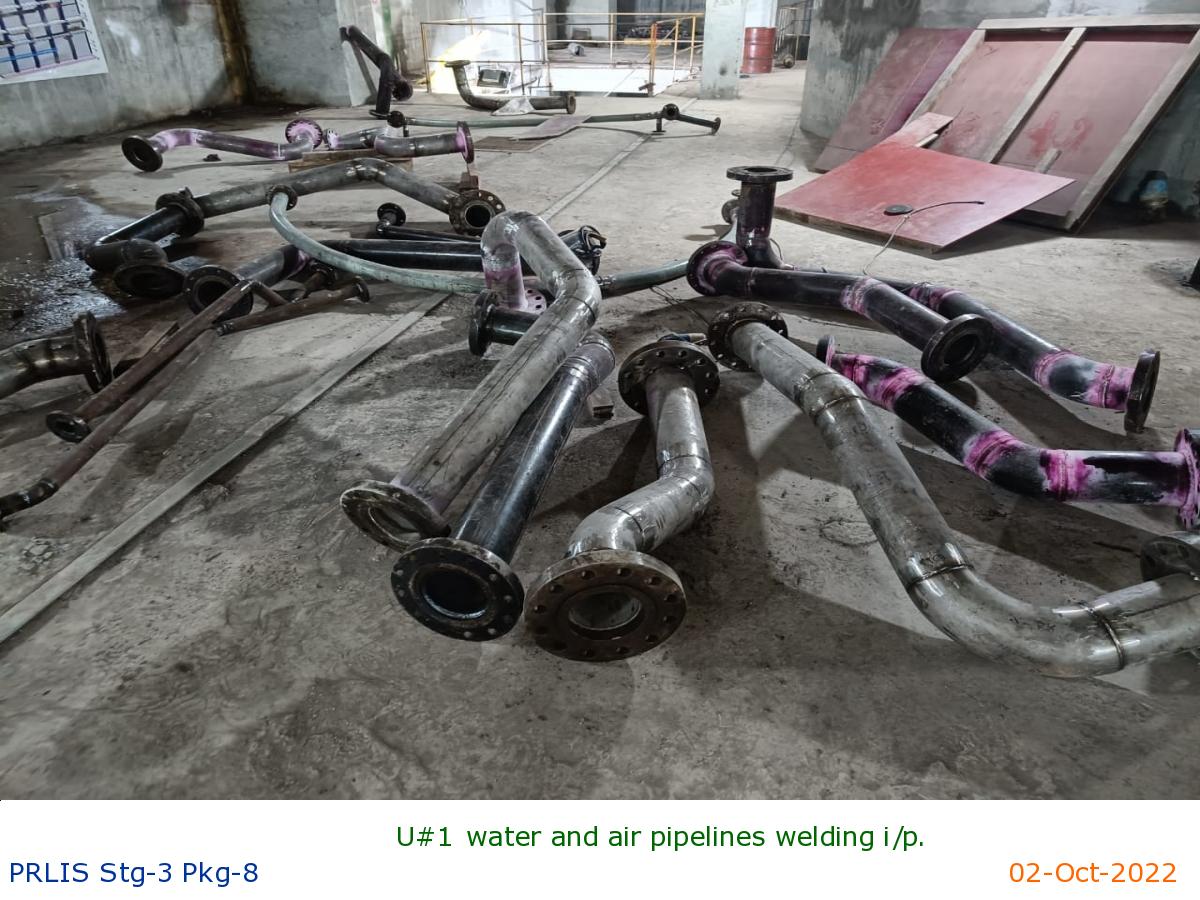

U#1 water and air pipelines welding i/p.

|

U#1&2 busduct installation at ground level

|

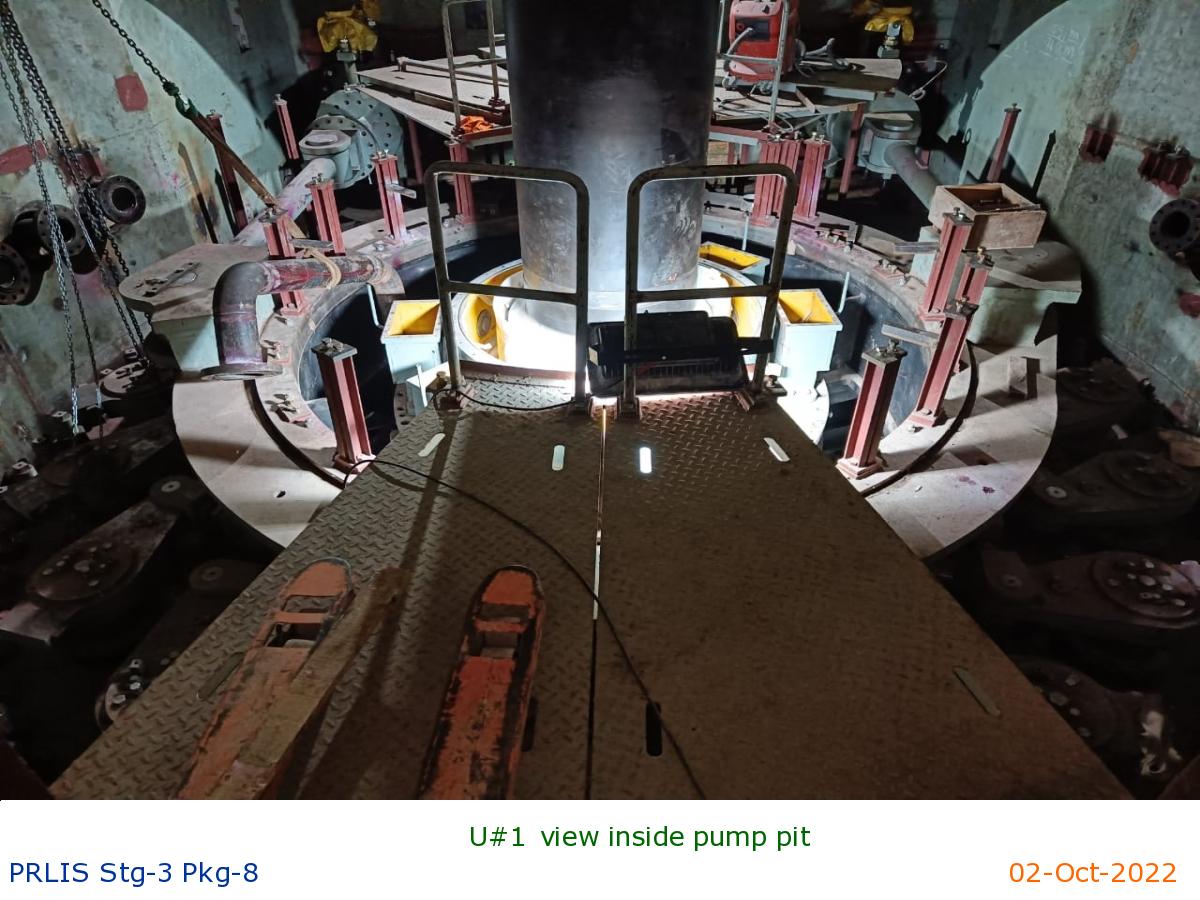

U#1 view inside pump pit

|

U#1 MDV inlet pipe edge preparation in progress

|

U#1 topoilvapour pipingoutside barell is completed

|

Com.aux-Water depression main header routing i/p.

|

U#5 Barrel concreting in progress

|

U#5 Barrel concreting in progress

|

U#4 Pivot ring quadrants assy in progress

|

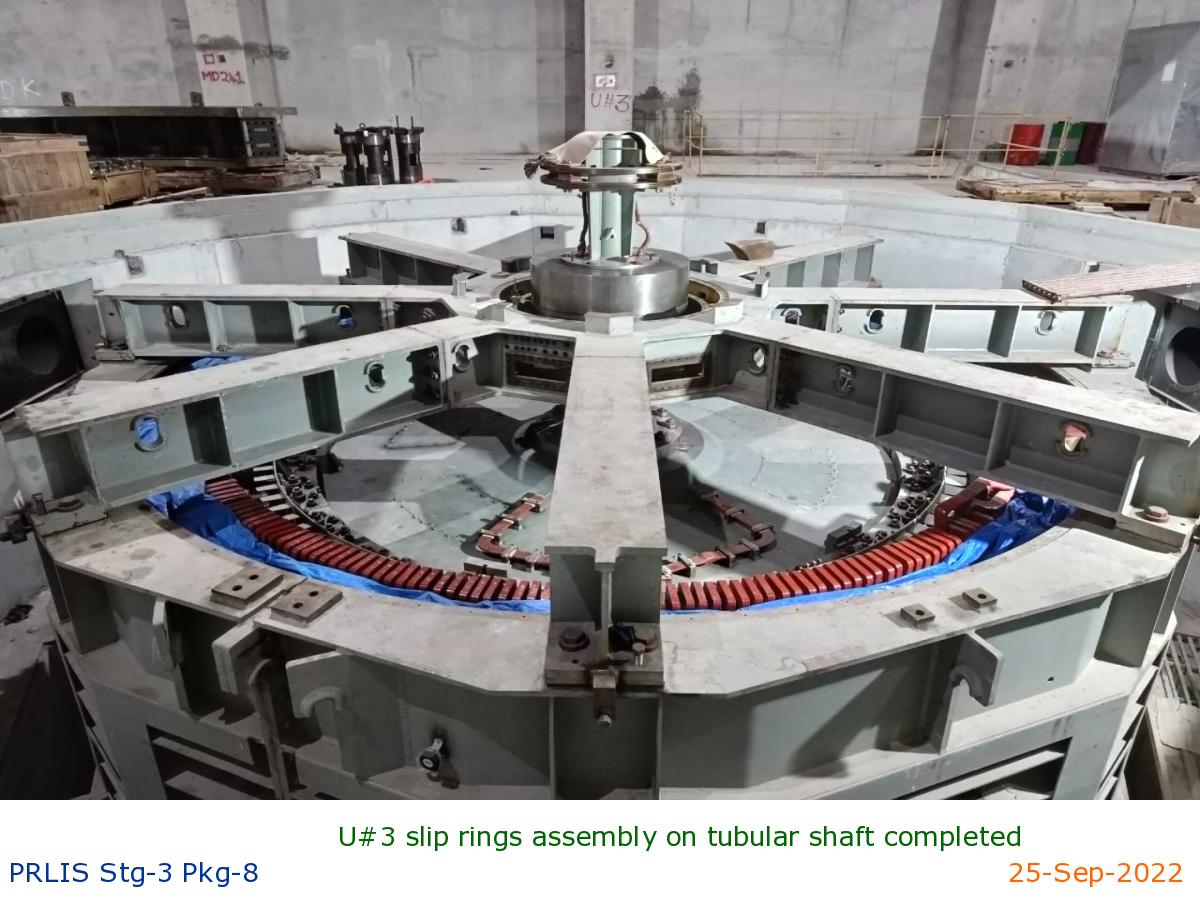

U#3 slip rings assembly on tubular shaft completed

|

U#2 CW pump motor assembly on skid is in progress

|

U#1 CW main inlet header routing in progress

|

U# bottom bracket oil level indicator installed

|

U#1 Top bracket oil level indicator installed

|

U#1 MDV Erection in progress

|

U#1 Top shaft voltage equalizing brush installed

|

U#5 Barrel concreting in progress

|

U#4 Pivot ring face seal assembly is in progress

|

U#3 Turbine platform installation in progress

|

U#3 Pump motor shaft coupling completed

|

U#3 Tubular shaft assembly completed

|

U#2 Turbine platform installation completed

|

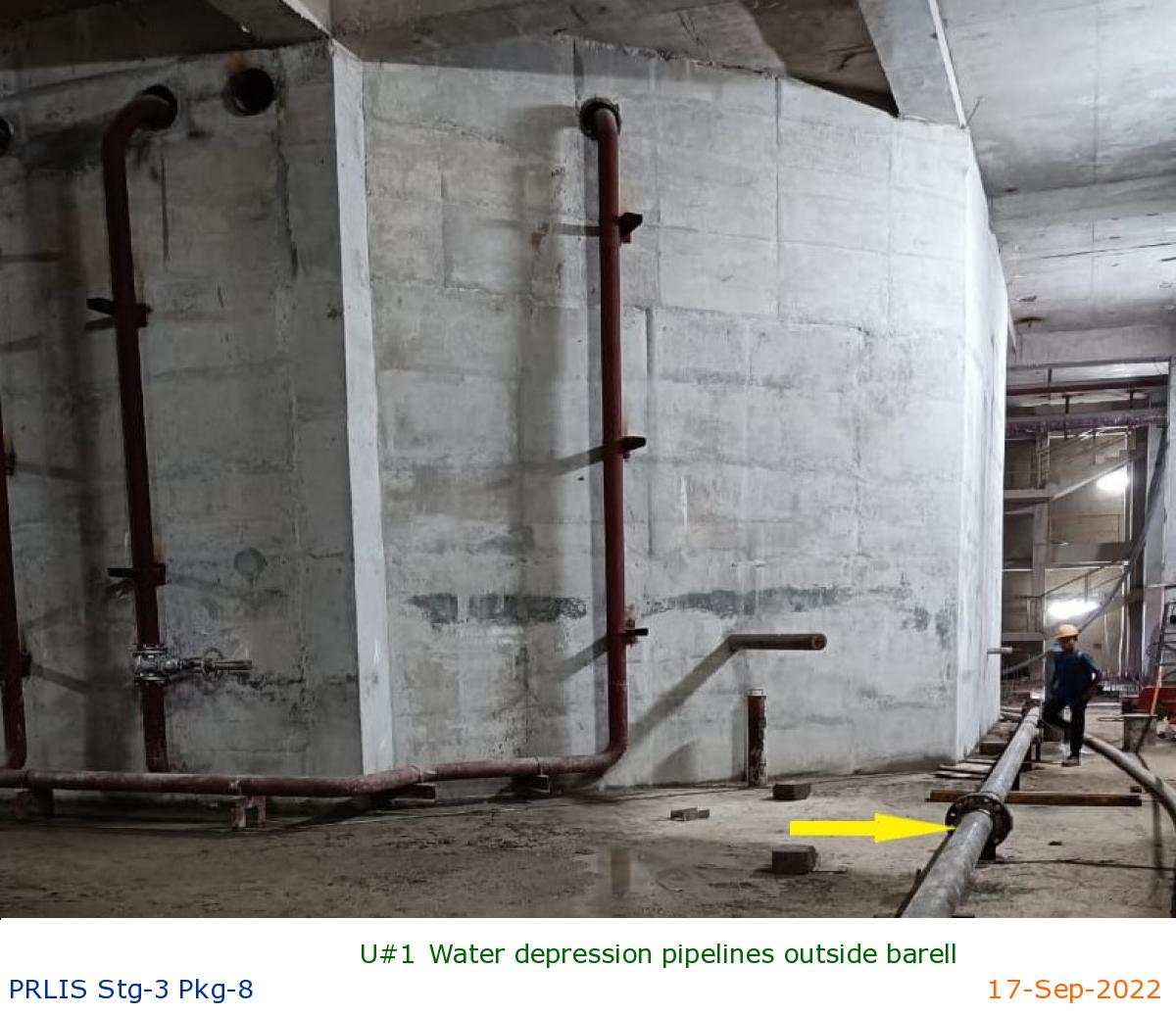

U#1 Water depression pipelines outside barell

|

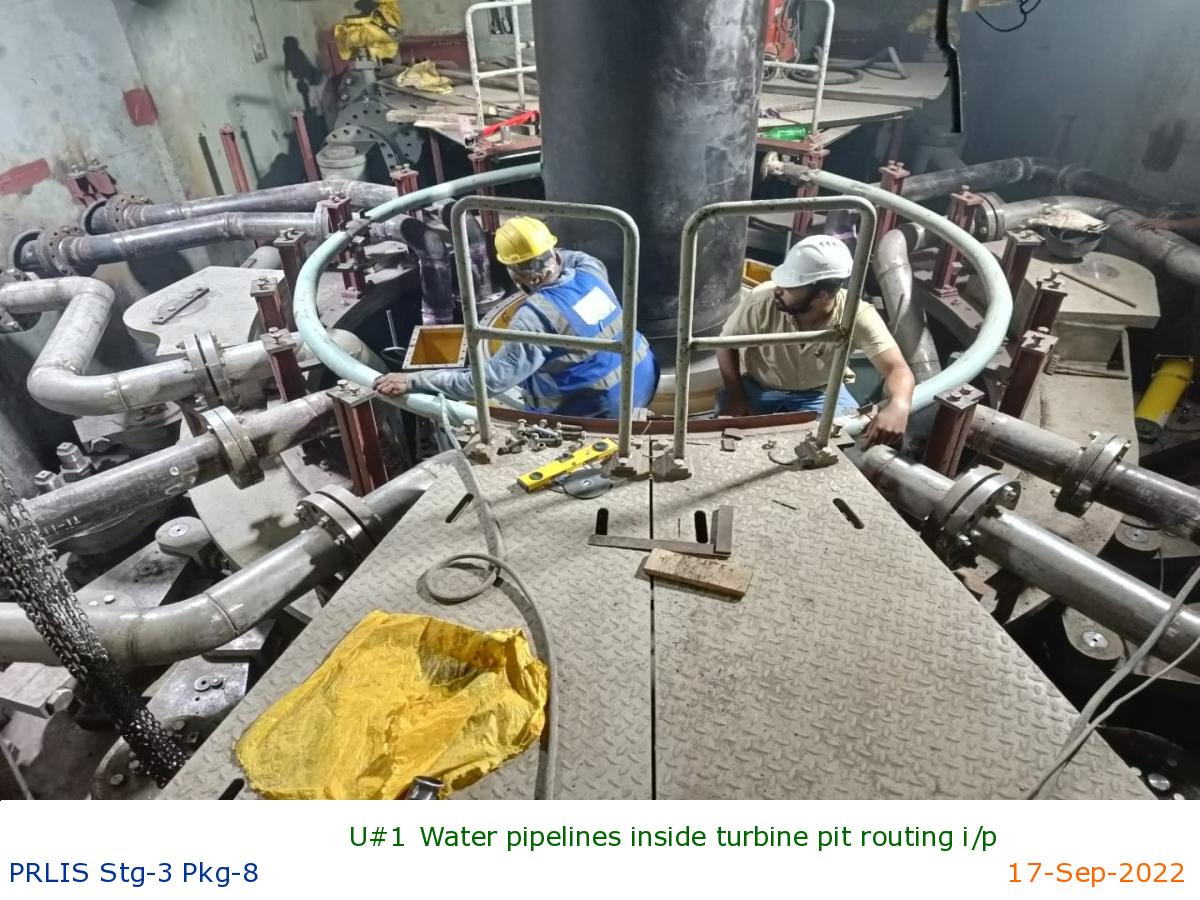

U#1 Water pipelines inside turbine pit routing i/p

|

U#1 Busduct installation at ground level

|

U#1 cable trays fixing outside barell in progress

|

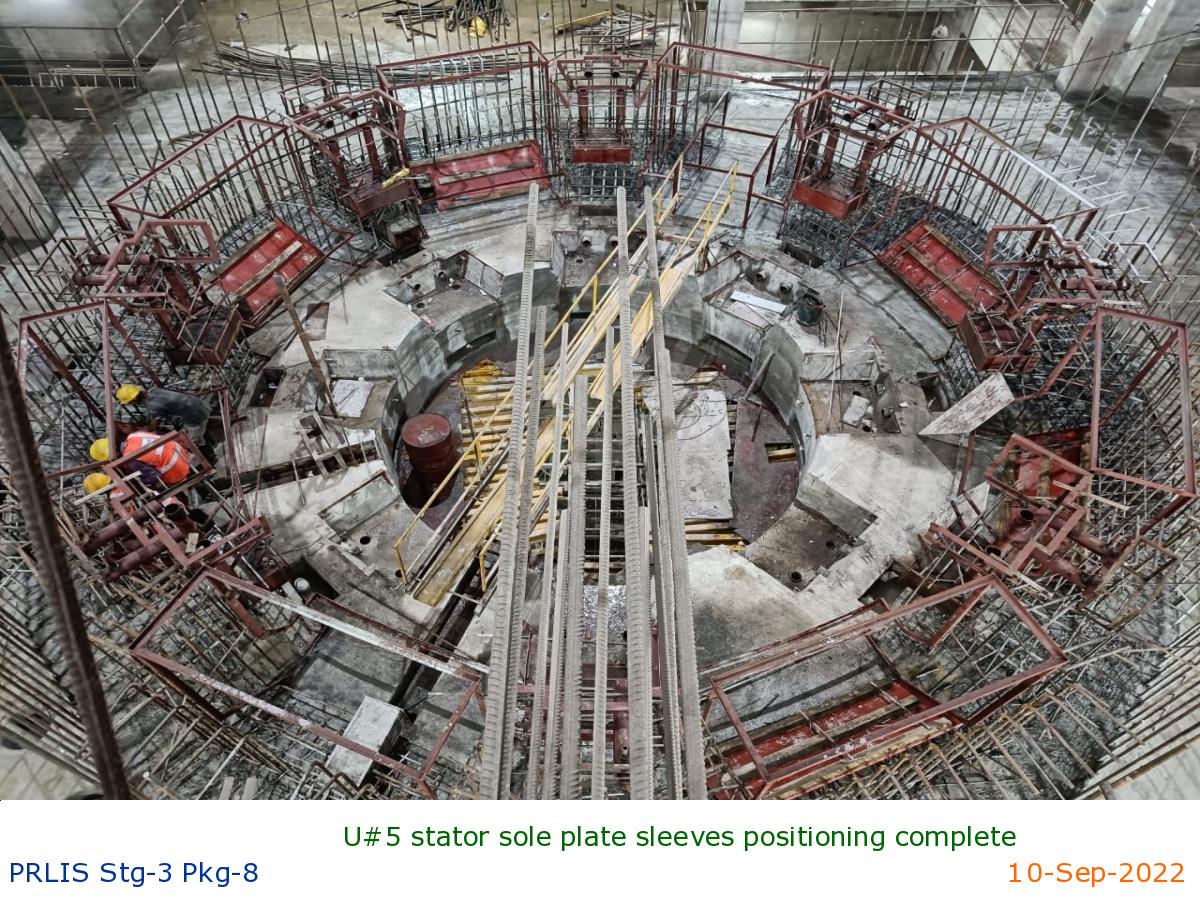

U#5 stator sole plate sleeves positioning complete

|

U#4 Pivot ring quadrants cleaning in progress

|

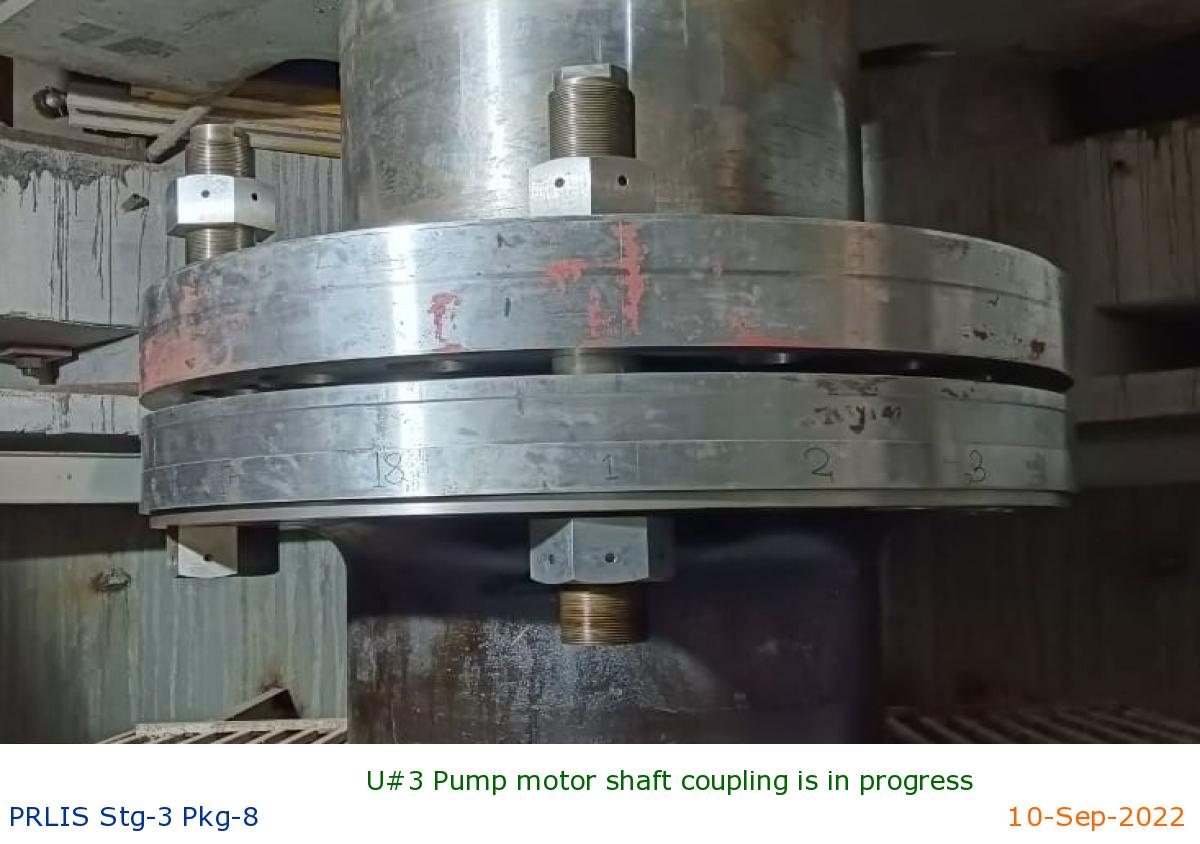

U#3 Pump motor shaft coupling is in progress

|

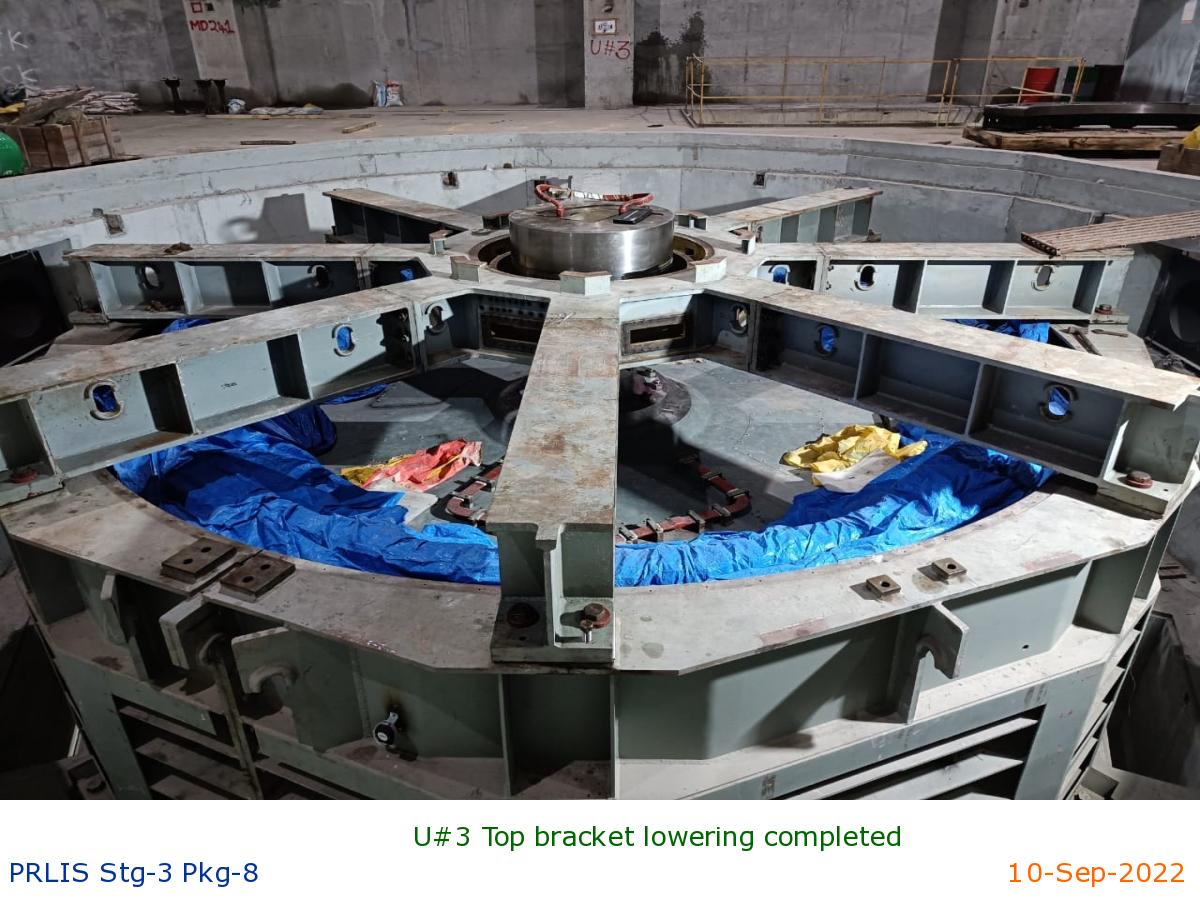

U#3 Top bracket lowering completed

|

U#2 Preparation for MDV Testing is in progress

|

U#1 TGB clearance adjustment in progress

|

U#1 LGB Clearance adjustment in progress

|

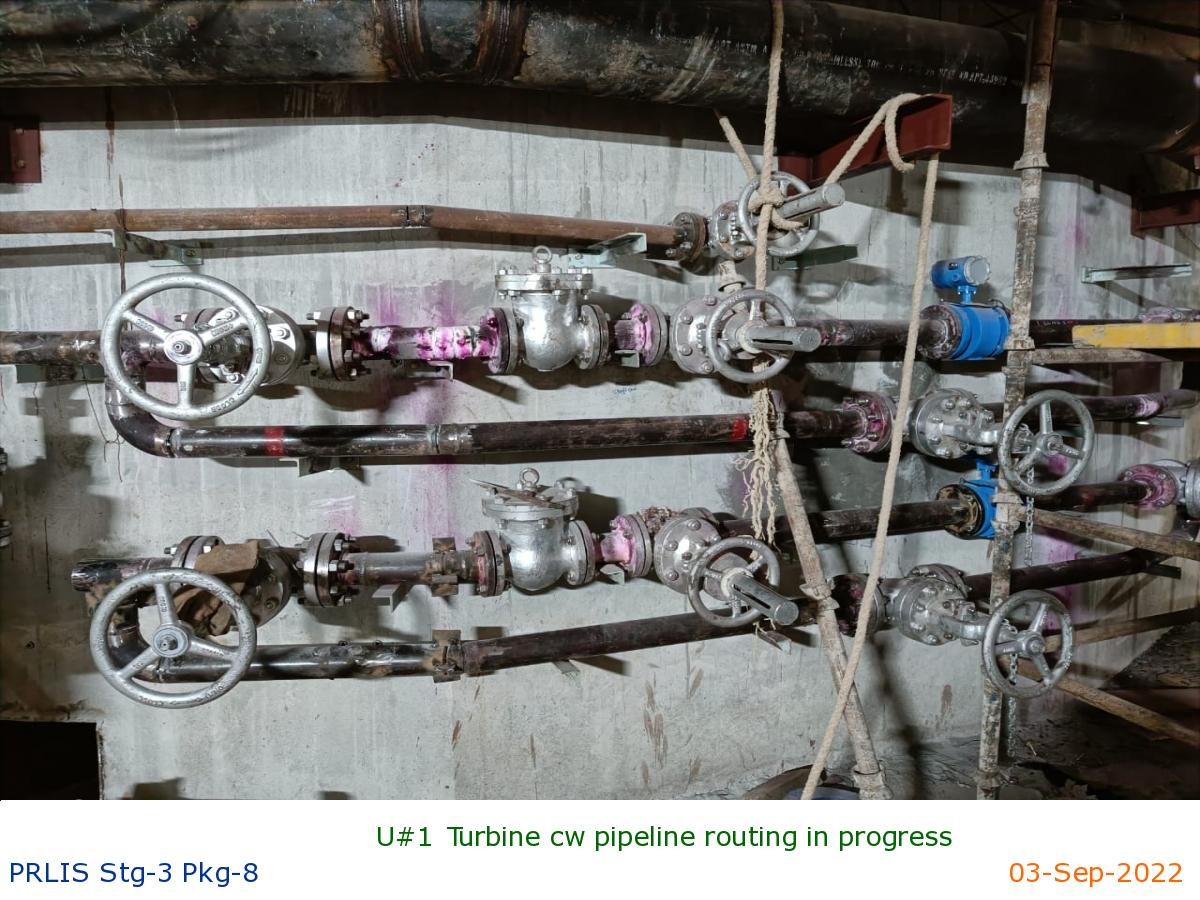

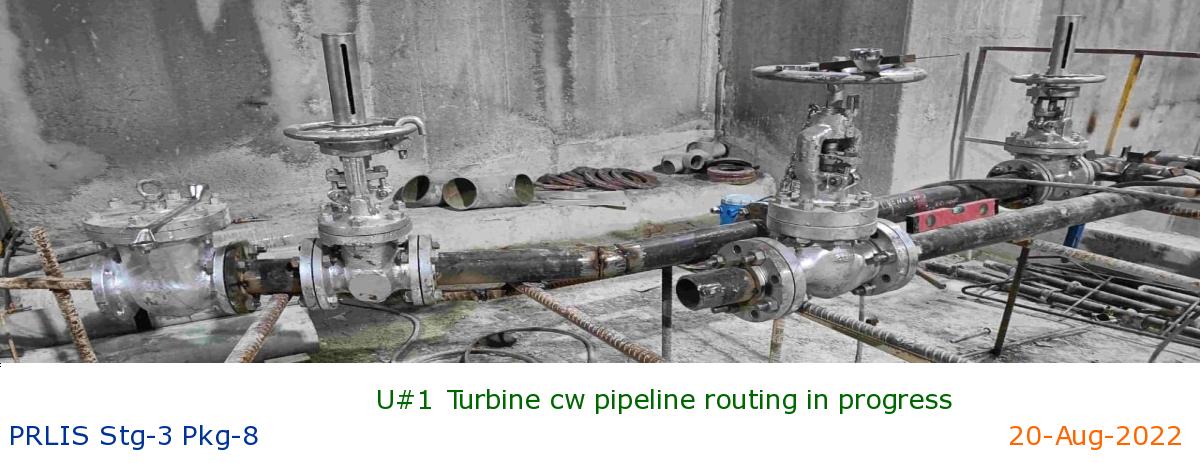

U#1 Turbine cw pipeline routing in progress

|

U#1 Water pipelines inside turbine pit routing i/p

|

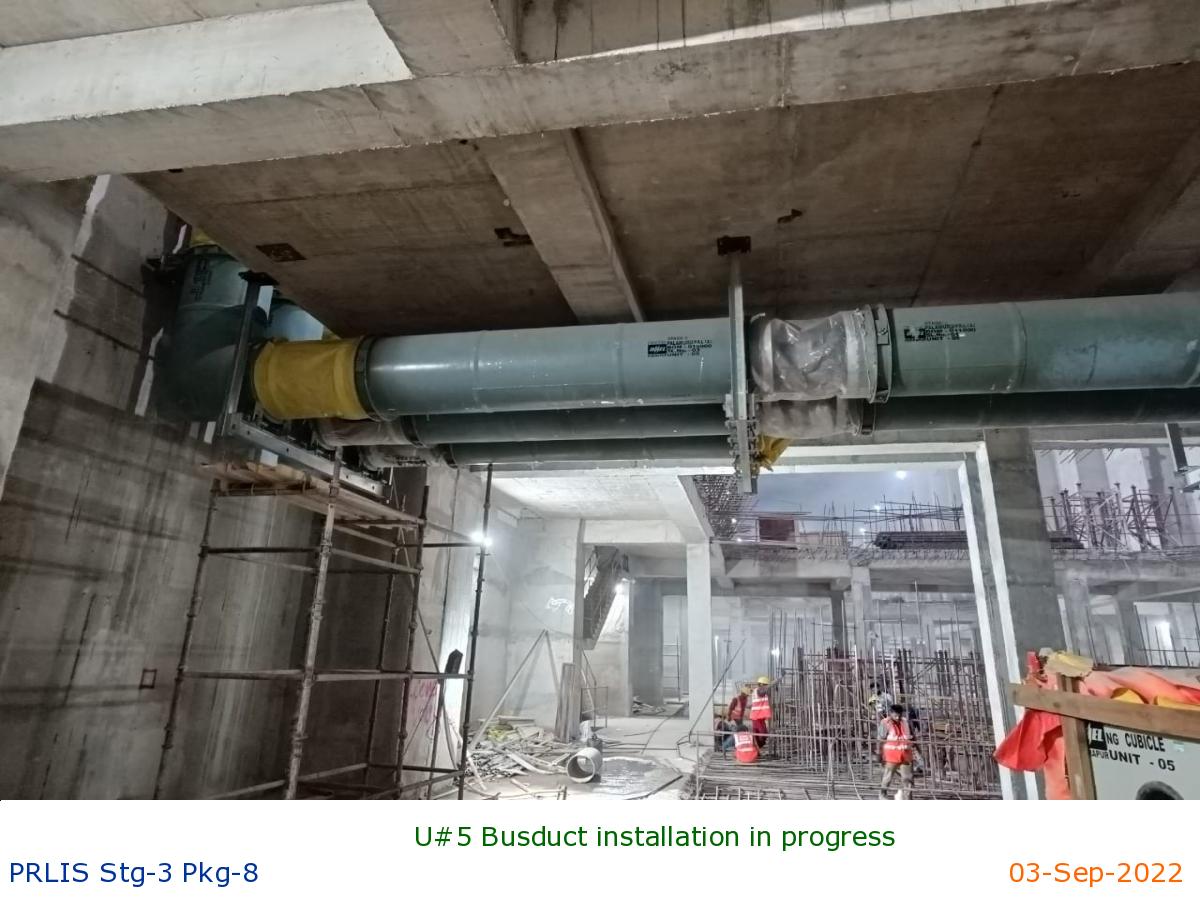

U#5 Busduct installation in progress

|

U#5 Barrel concreting in progress

|

U#4 Stay ring levelling in progress

|

U#3 Top shaft lowered into barell

|

U#3 Rotor lowered into barell

|

U#2 CW skid works in progress

|

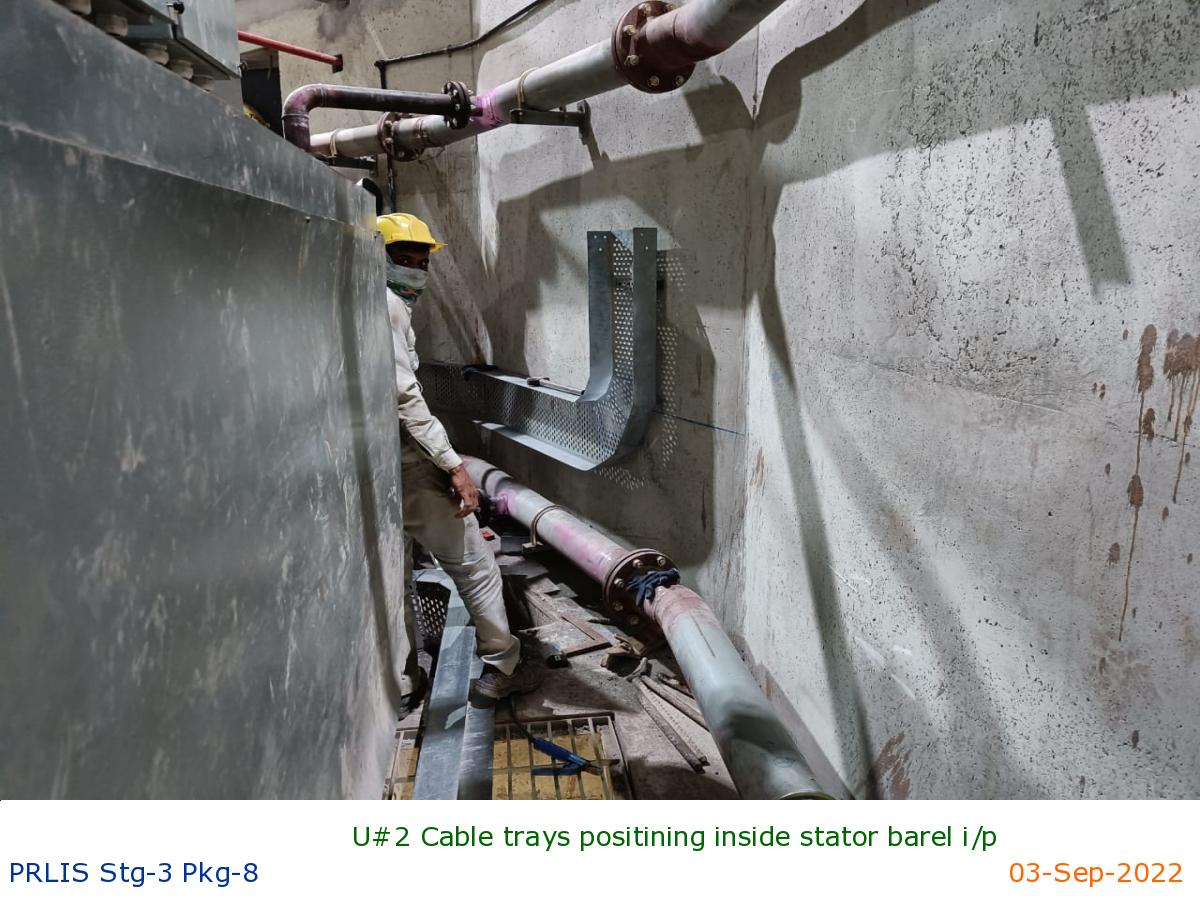

U#2 Cable trays positining inside stator barel i/p

|

U#1 Stator sole plates grouting is in progress

|

U#1 LGB CW pipeline routing is in progress

|

U#1 Cable trays positioned inside stator barell

|

U#1 Bottom bearing clearance setting in progress

|

U#1 Top bearing clearance setting in progress

|

U#1 Turbine cw pipeline routing in progress

|

U#1 Water pipelines inside turbine pit routing i/p

|

PRLIS Stage-III Motor Transformers in position

|

PRLIS Stage-III Control room works in progress

|

U#10 DT Ebow liner segments positioning in progres

|

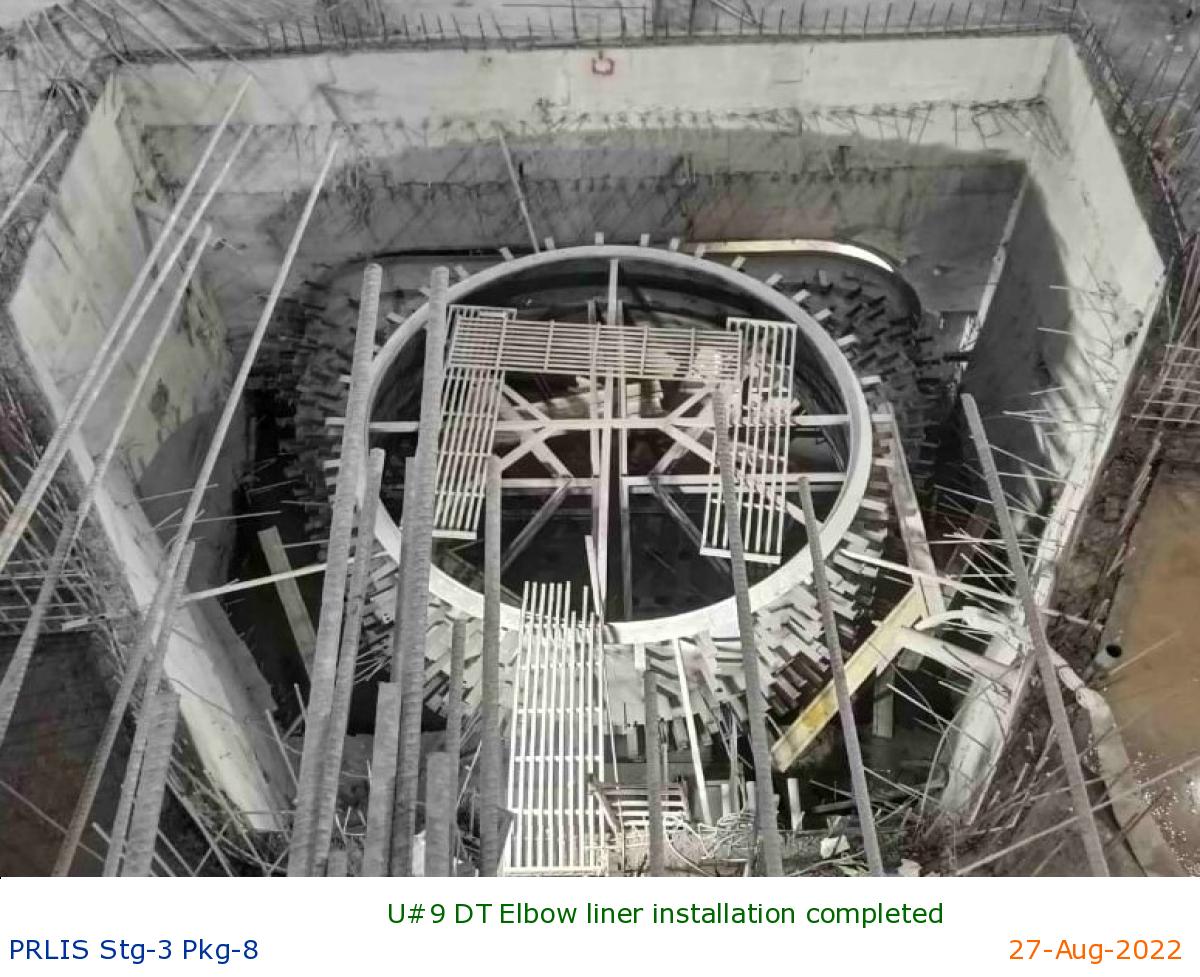

U#9 DT Elbow liner installation completed

|

U#8 DT Elbow liner installation completed

|

U#7 DT Elbow liner installation completed

|

U#5 Busduct installation in progress

|

U#5 Barrel concreting in progress

|

U#4 Turbine shaft cleaning in progress

|

U#3 Turbine platform installation in progress

|

U#1 Water pipelines inside turbine pit routing i/p

|

U#3 UGB Bracket and arms cleaning in progress

|

U#3 HS Pipeline routing and testing completed

|

U#3 HS Skid positioned in turbine floor

|

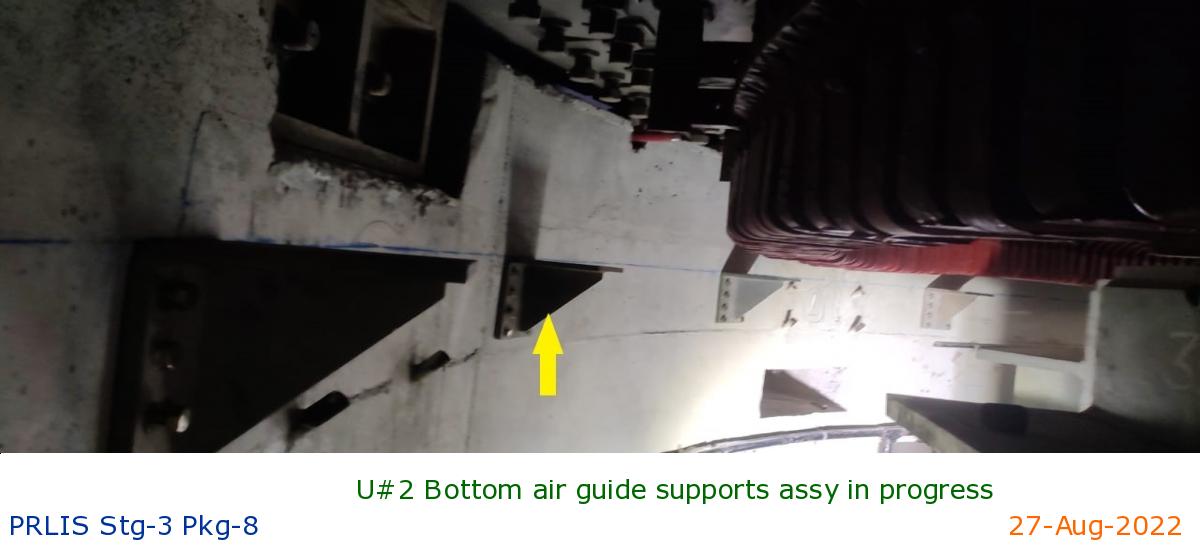

U#2 Bottom air guide supports assy in progress

|

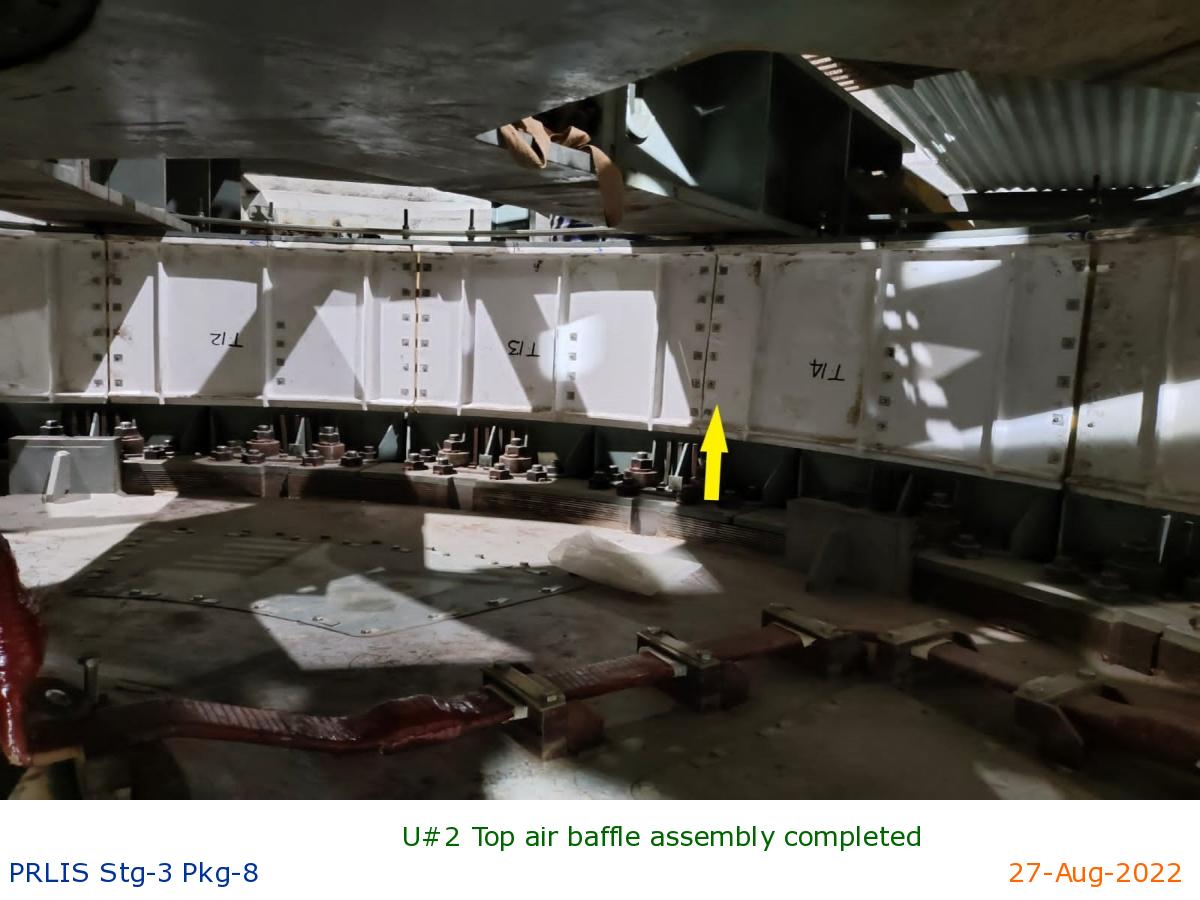

U#2 Top air baffle assembly completed

|

U#1 LGB cooler trial assy in progress

|

U#1 LGB cooler supports fixing in progress

|

U#1 UGB oil retainer assembly completed

|

U#2 Top air baffle trial assy

|

U#3 Top shaft bearing pad matching in progress

|

U#5 Barrel concreting in progress

|

U#5 Barrel concreting in progress

|

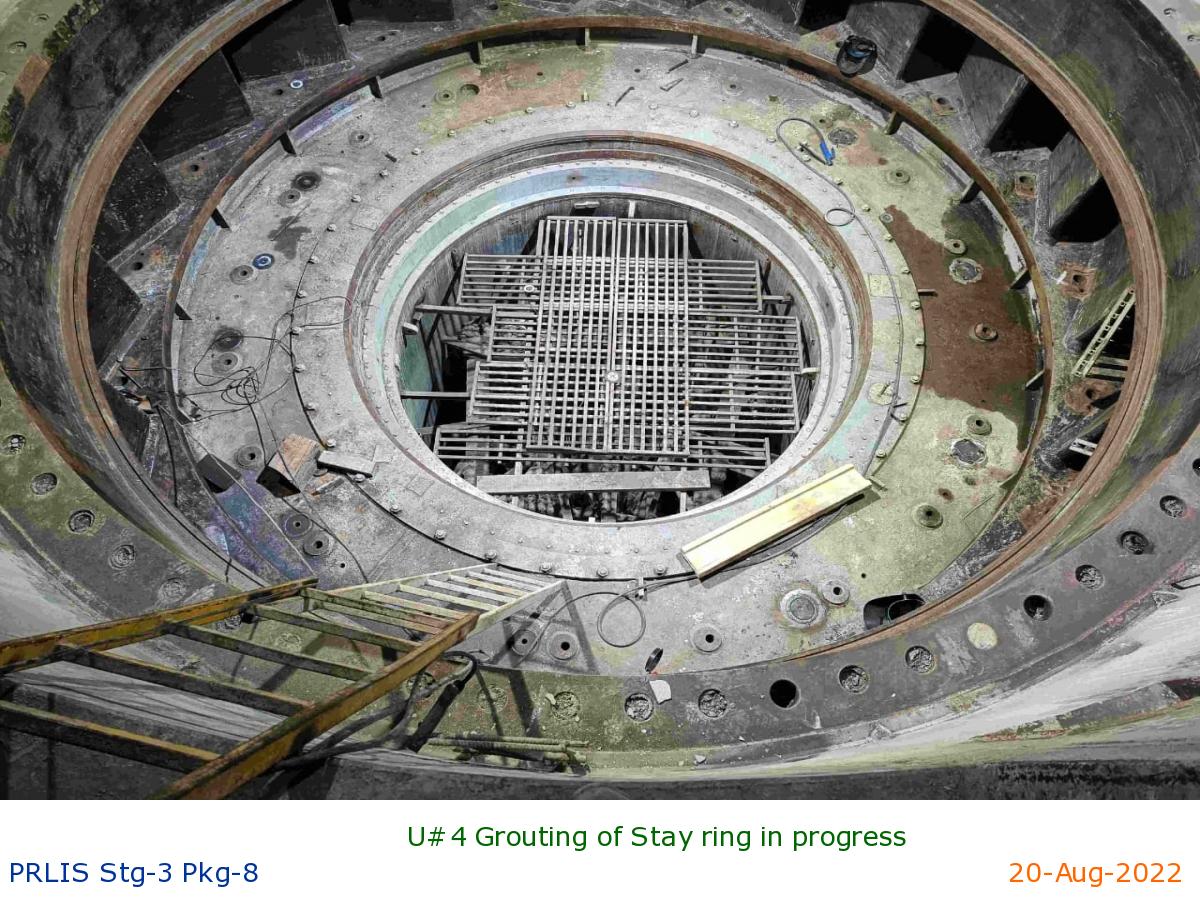

U#4 Grouting of Stay ring in progress

|

U#3 GV Servomotors final assembly alignment comple

|

U#3 guide apparatus final assy in progress

|

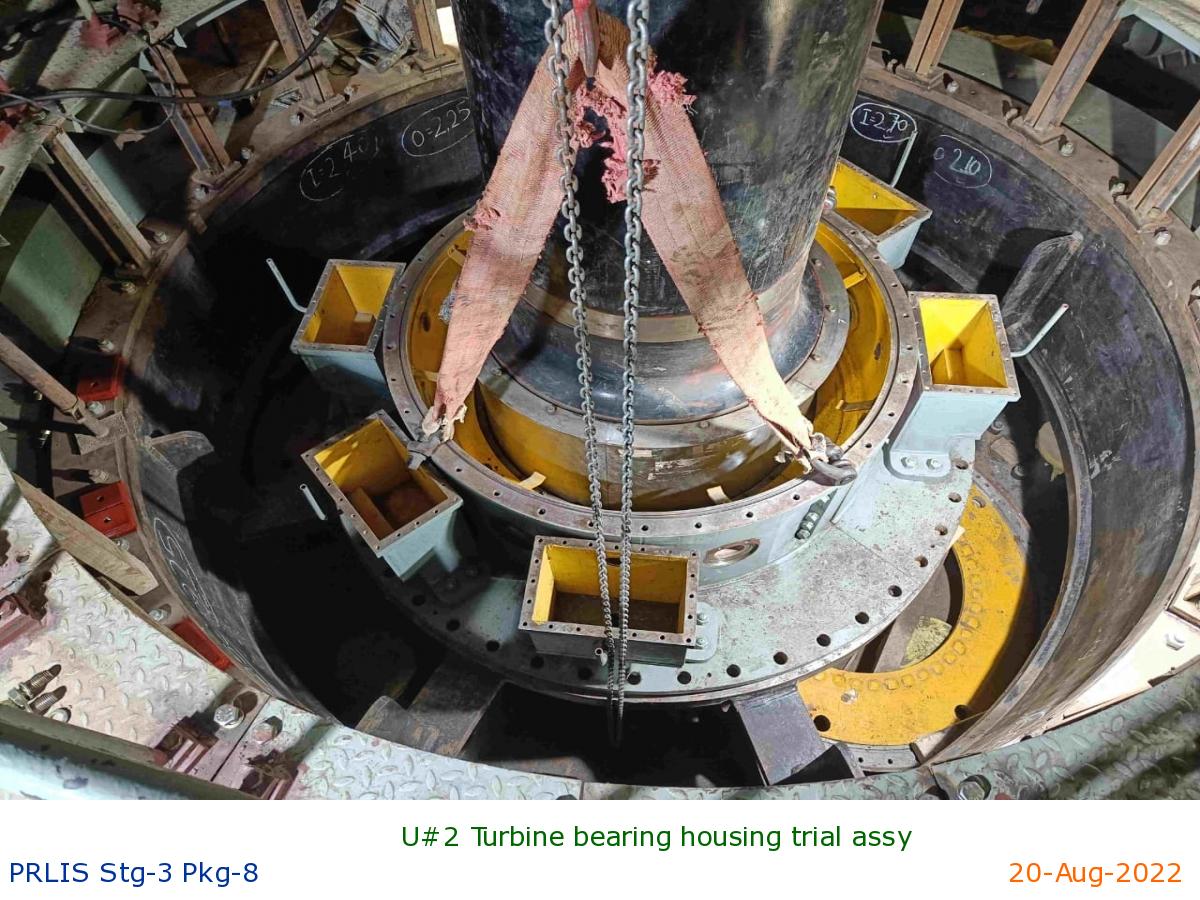

U#2 Turbine bearing housing trial assy

|

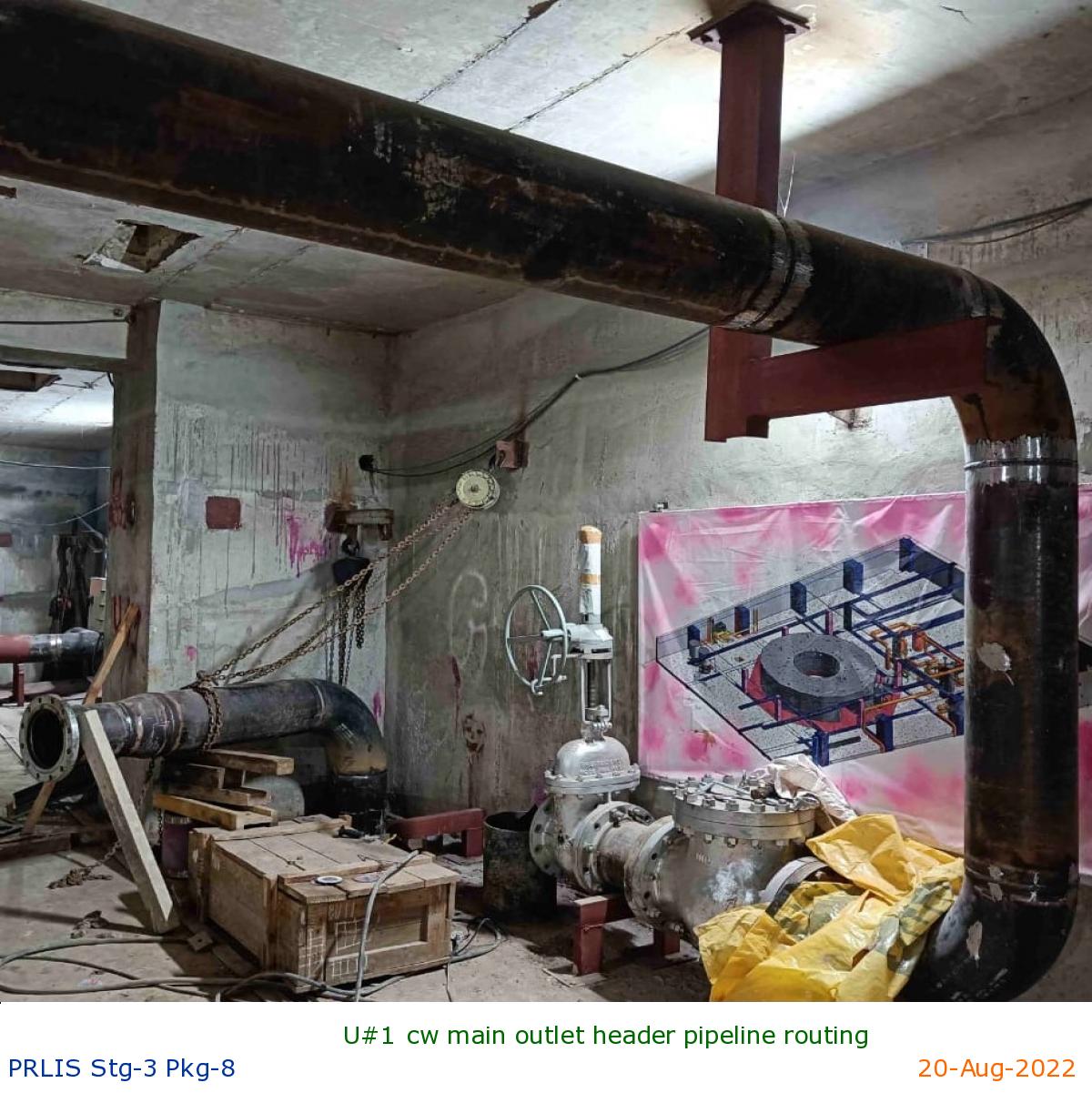

U#1 cw main outlet header pipeline routing

|

U#1 Turbine cw pipeline routing in progress

|

U#2 Bottom shaft and spring plate assembled in LGB

|

U#2 busduct to stator connection arrangement

|

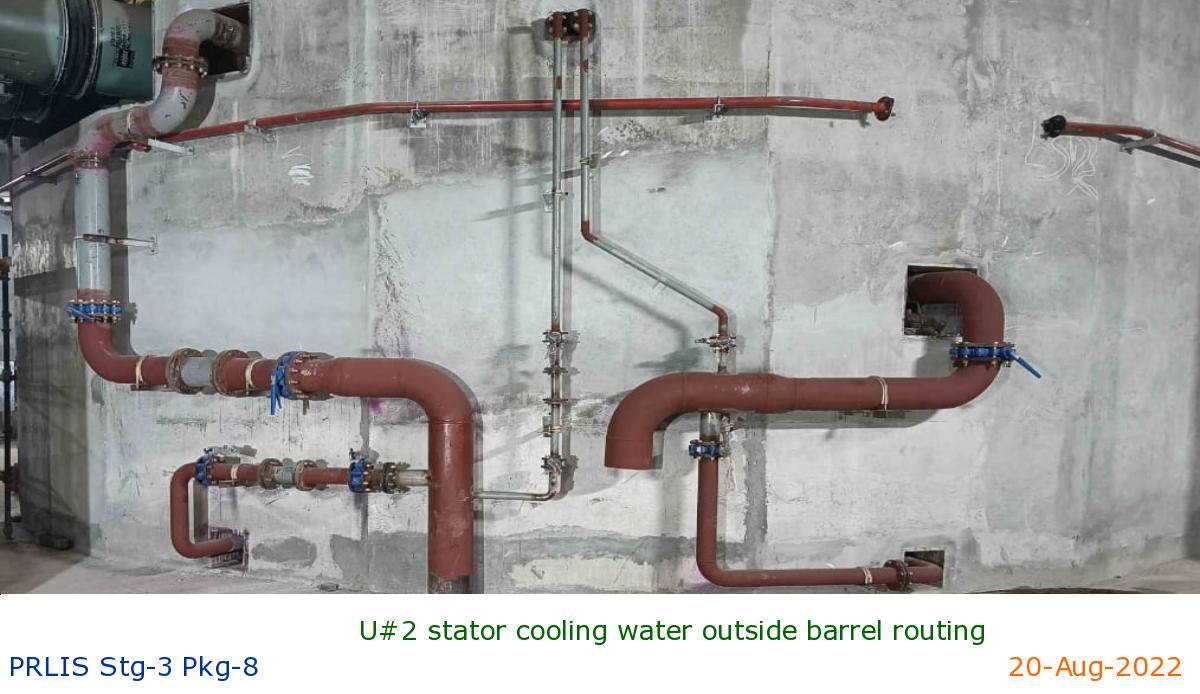

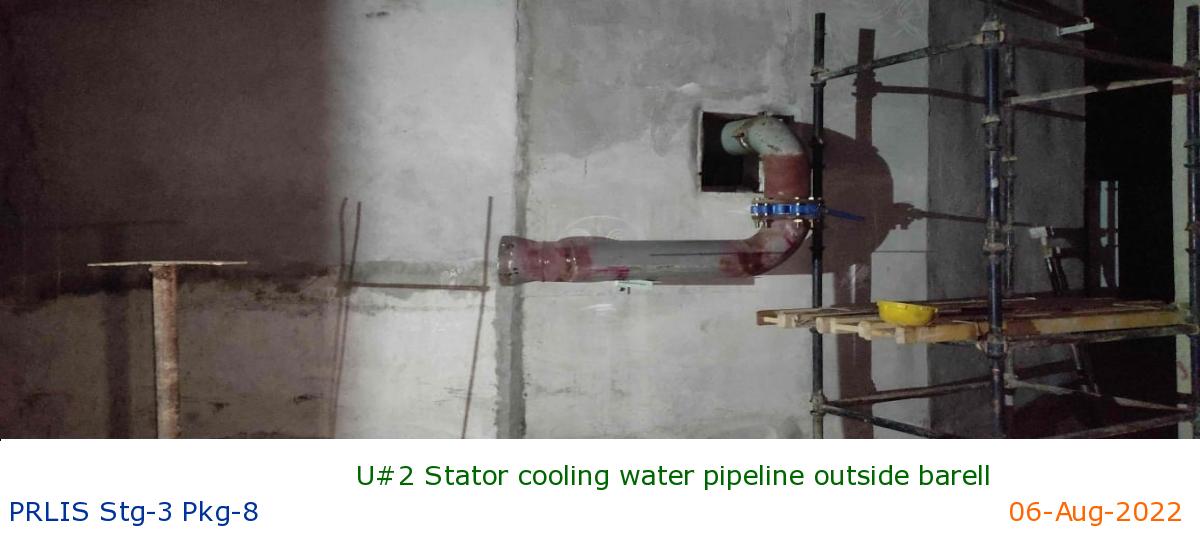

U#2 stator cooling water outside barrel routing

|

U#2 view from motor floor

|

U#1 view from motor floor

|

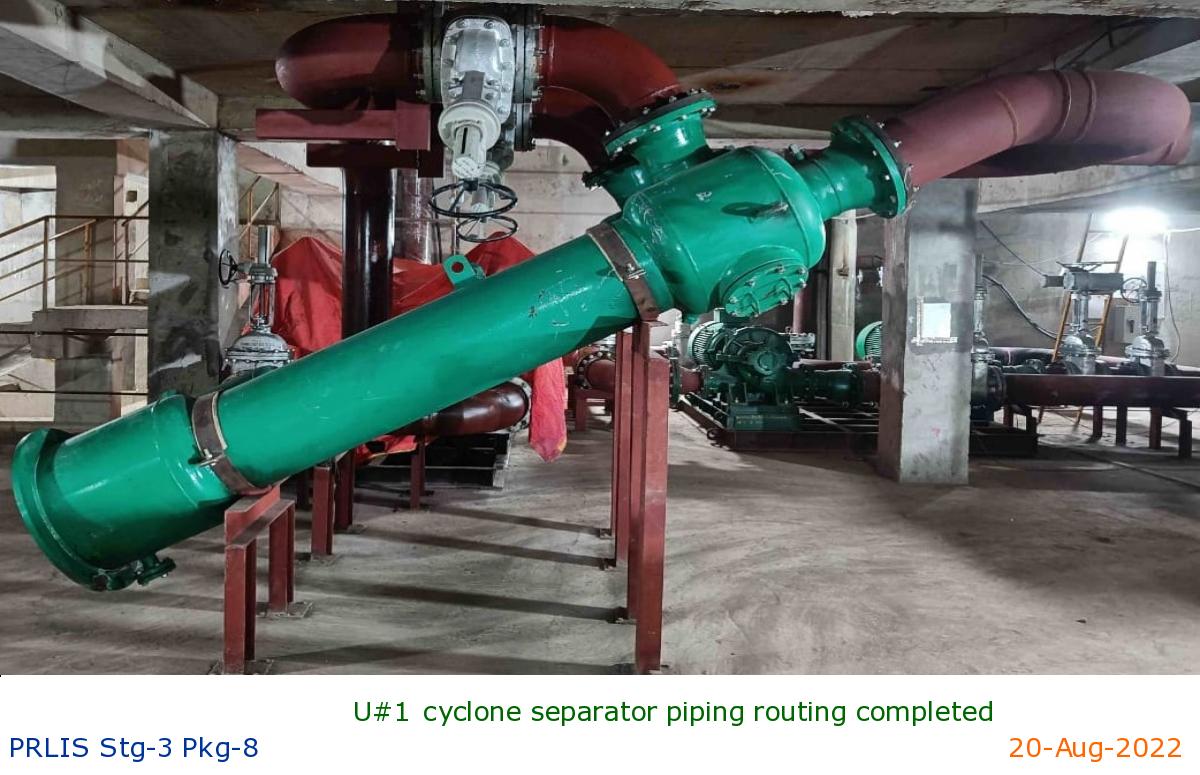

U#1 cyclone separator piping routing completed

|

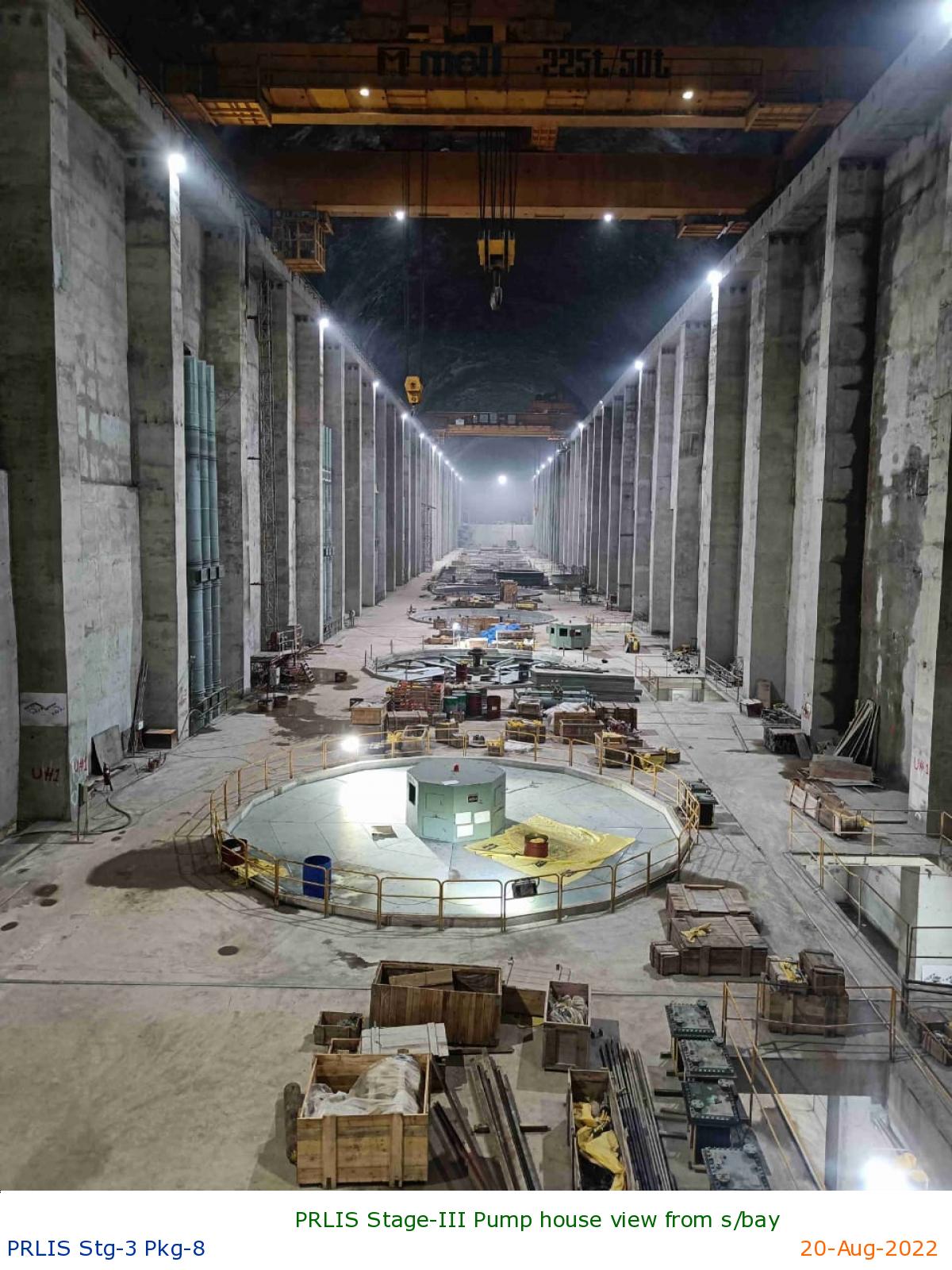

PRLIS Stage-III Pump house view from s/bay

|

U#1 Shaft current monitor installation completed

|

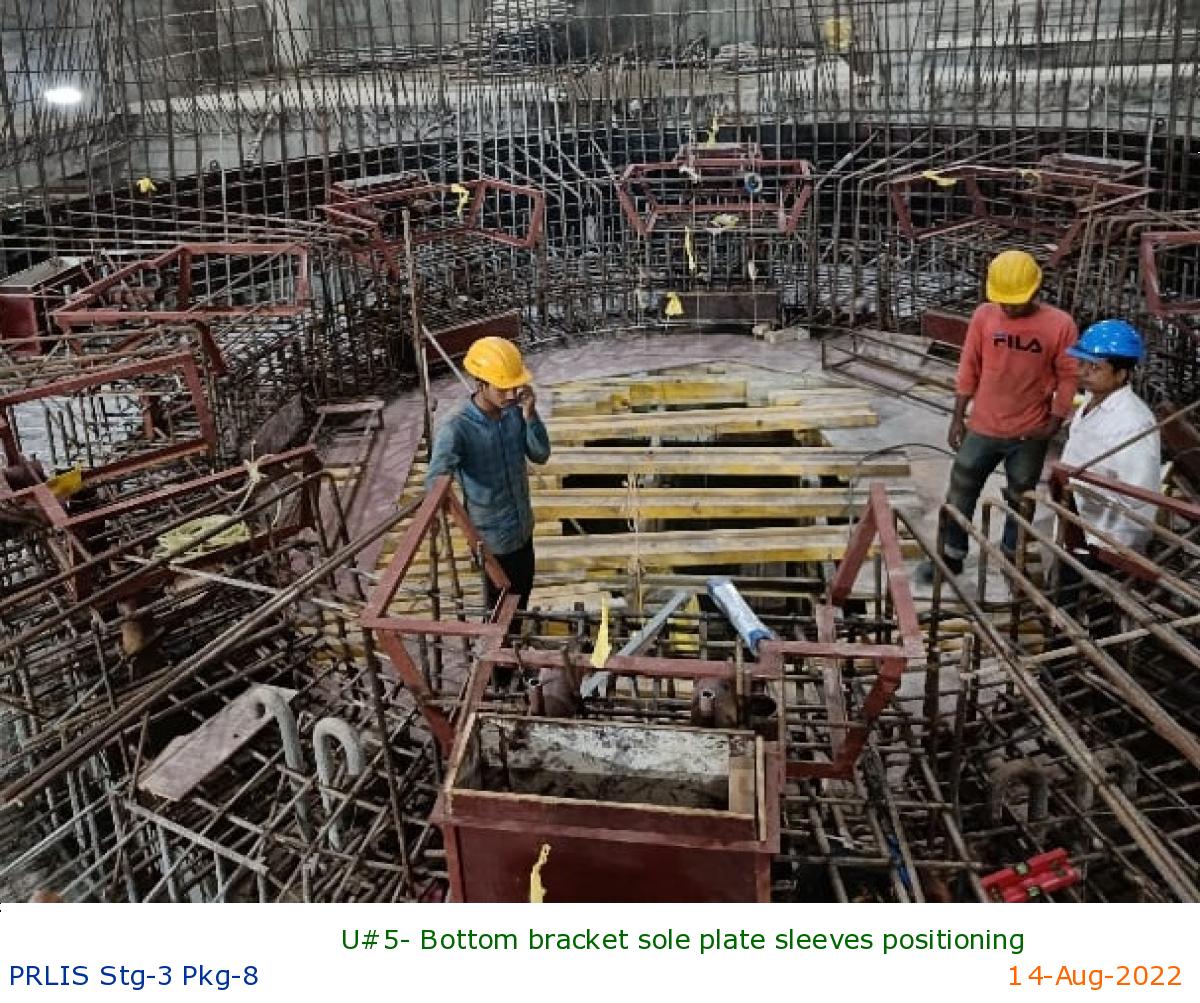

U#5- Bottom bracket sole plate sleeves positioning

|

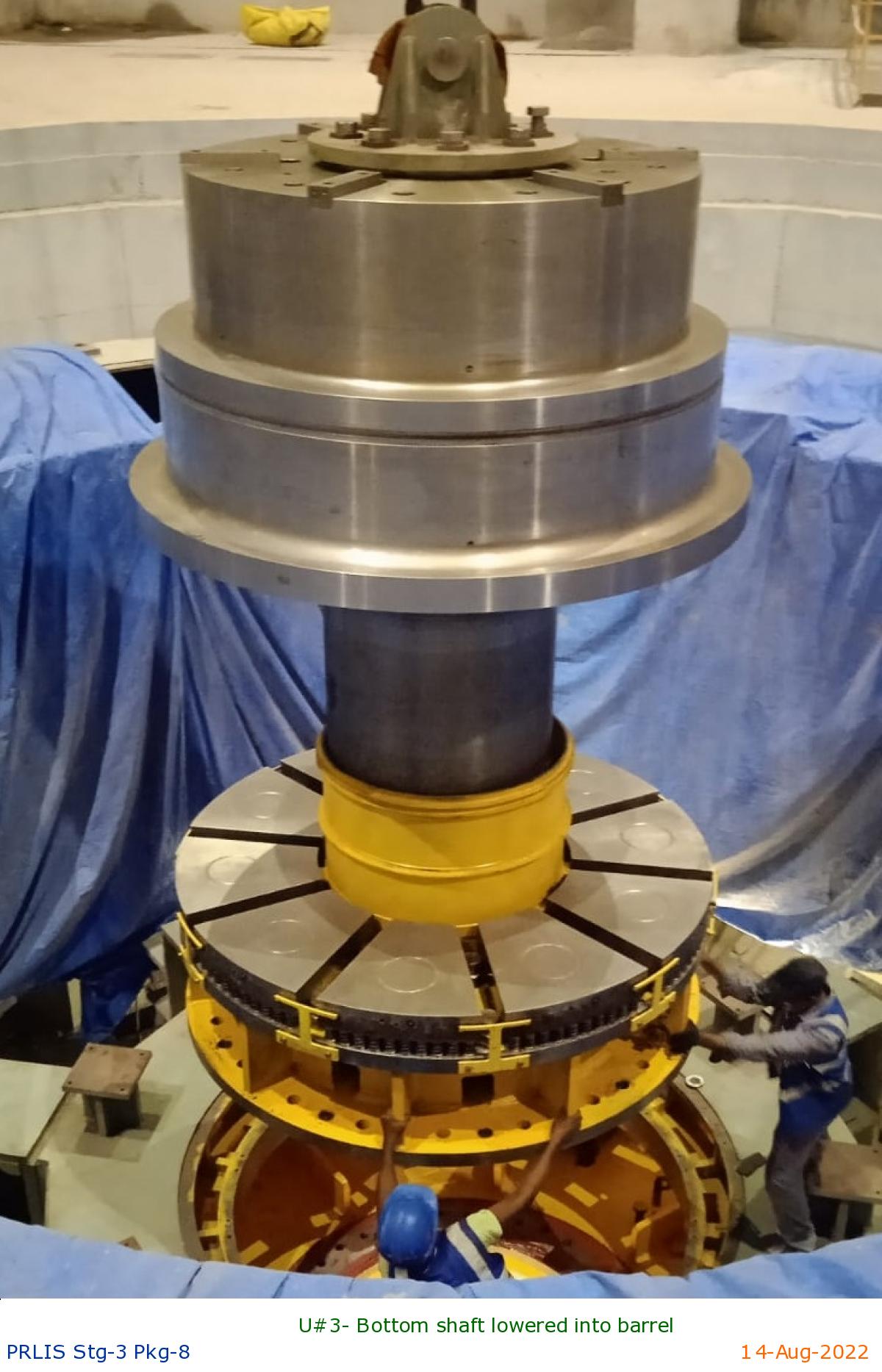

U#3- Bottom shaft lowered into barrel

|

U#3- Spring plate assy around bottom shaft

|

U#2- Busduct seal off bushing assembly in progress

|

U#2-Stator cooler inlet and outlet connections

|

U#2- Stator cw pipelines outside barrel

|

U#2- Fire fighting top ring assembly completed

|

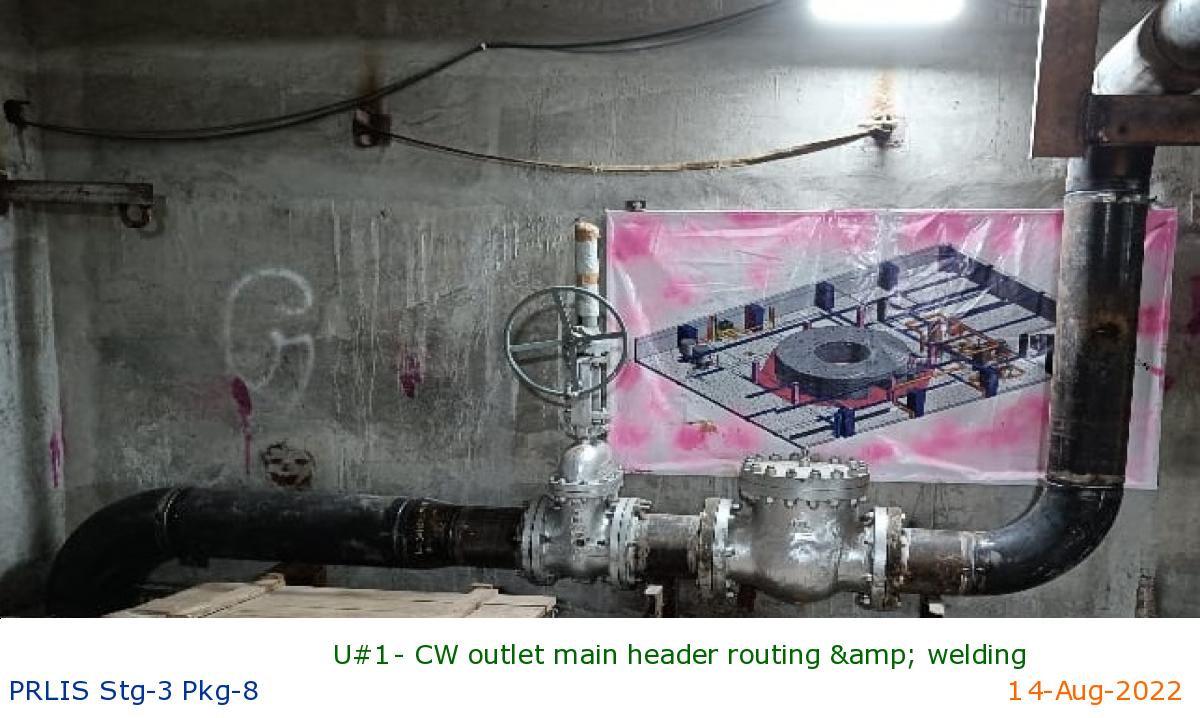

U#1- CW outlet main header routing & welding

|

U#1- Cyclone separator pipeline welding in progre

|

U#2- Turbine platform installation in progress

|

U#1- Busduct seal off bushing assembly

|

U#5 Barrel concreting in progress

|

U#5 Busduct installation in progress

|

U#4 Busduct installation in progress

|

U#4 Preparation for Pit liner grouting

|

U#3 Bottom shaft cleaning and bearing pads matchin

|

U#3 Rotor poles mounting completed

|

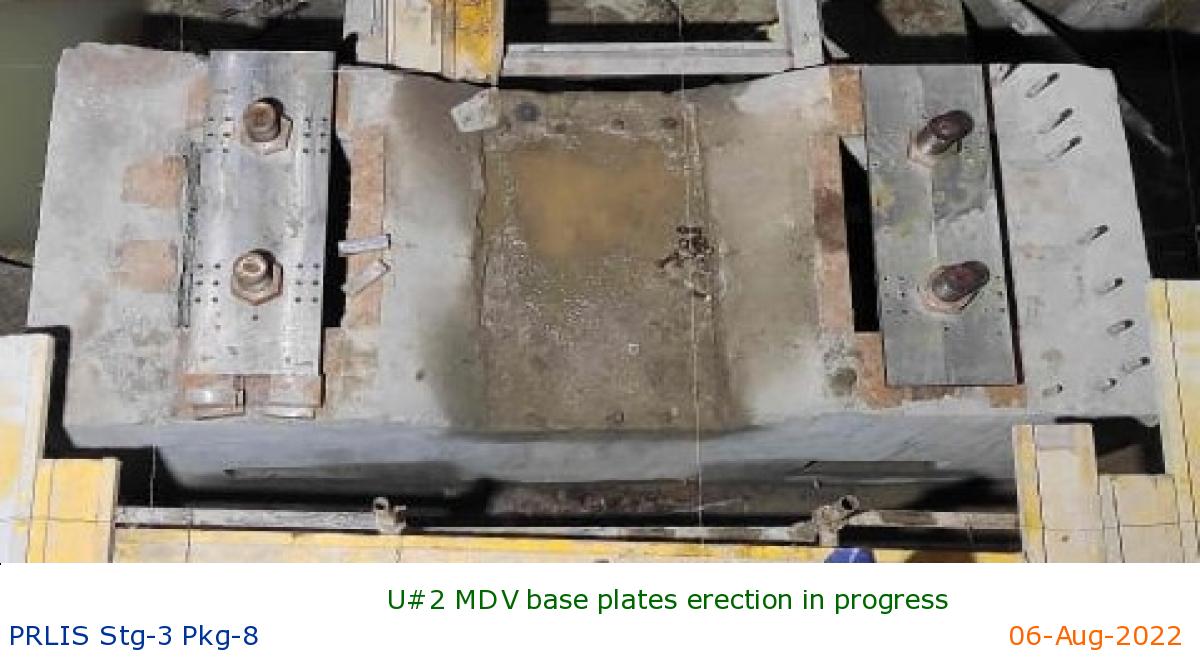

U#2 MDV base plates erection in progress

|

U#2 GV Servomotors after final assy

|

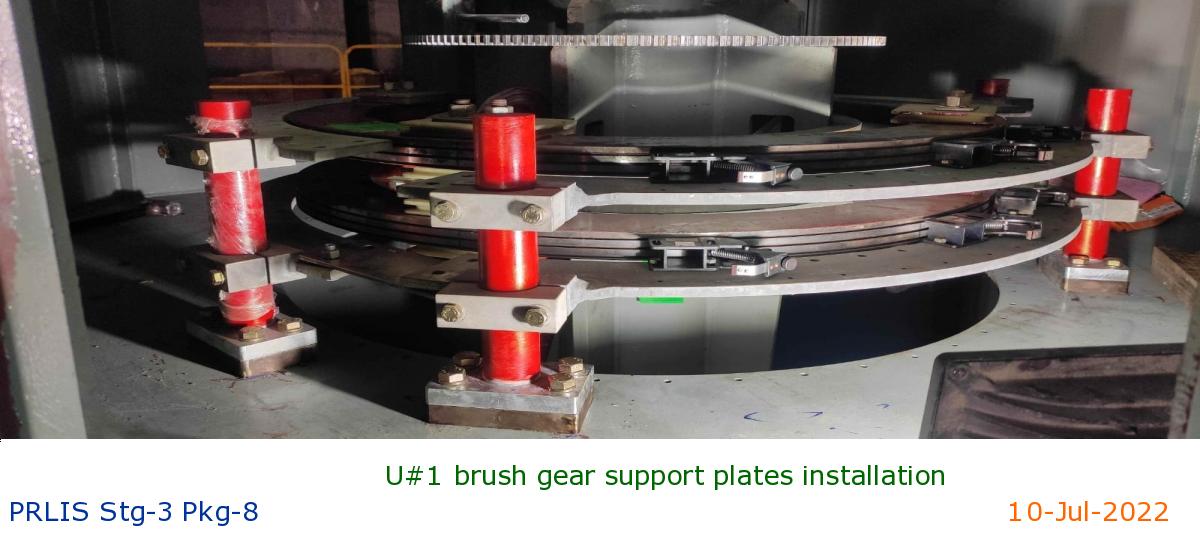

U#2 Brush gear plates installation complete

|

U#2 Stator cooling water pipeline outside barell

|

U#2 Pit air seal installation completed

|

U#1 Turbine platform assy

|

U#1 Motor flooring completed

|

U#1 cyclone separator erection

|

U#1 Turbine platform trial assy in progress

|

U#1Collector to spider connections comlpeted

|

U#1 Rotor DC Connections assy in progress

|

U#1 cooling water skids assembly

|

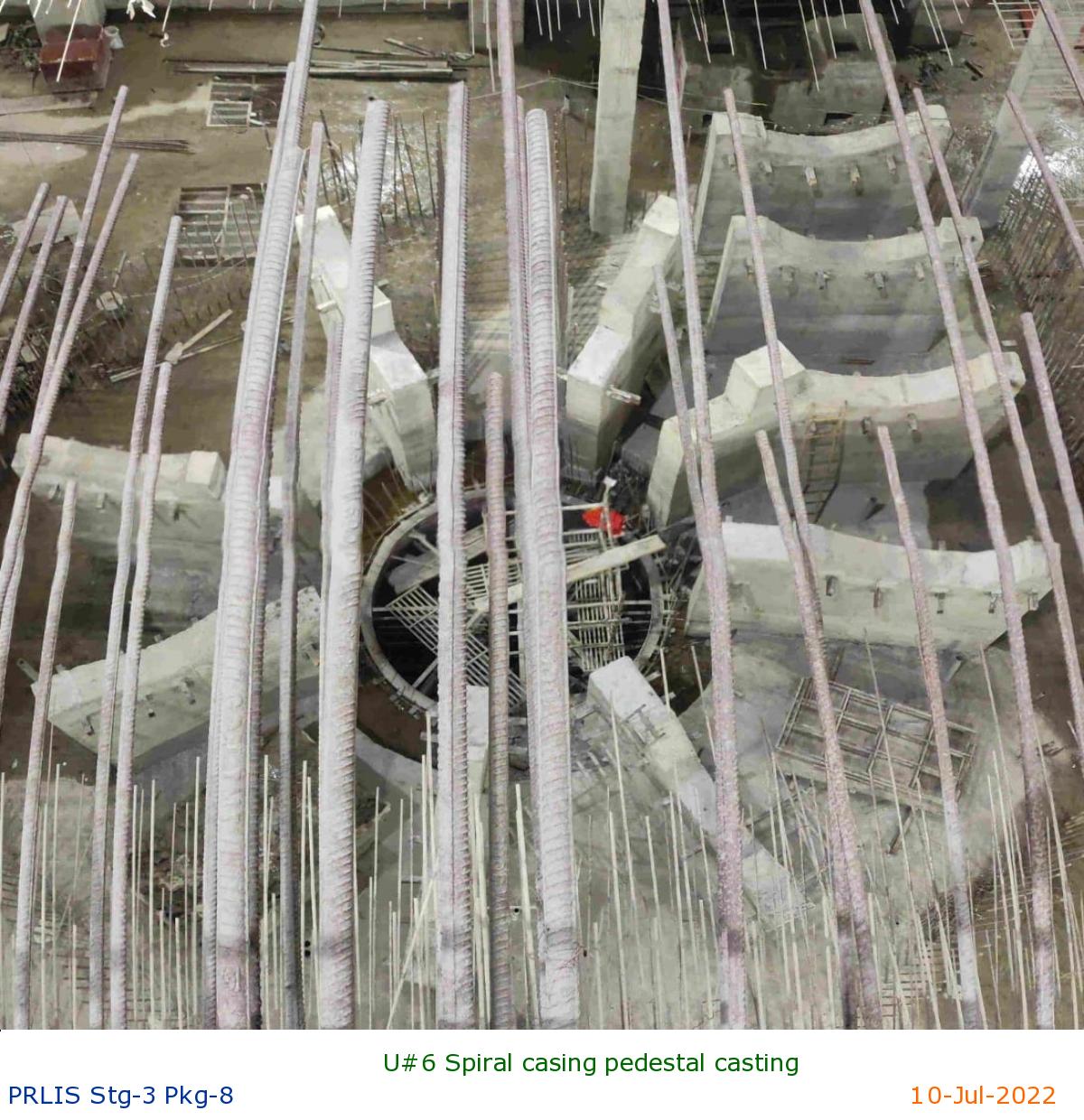

U#6 Spiral casing pedestal casting

|

U#3 Water and air piping outside barrell

|

U#5 Busduct installation

|

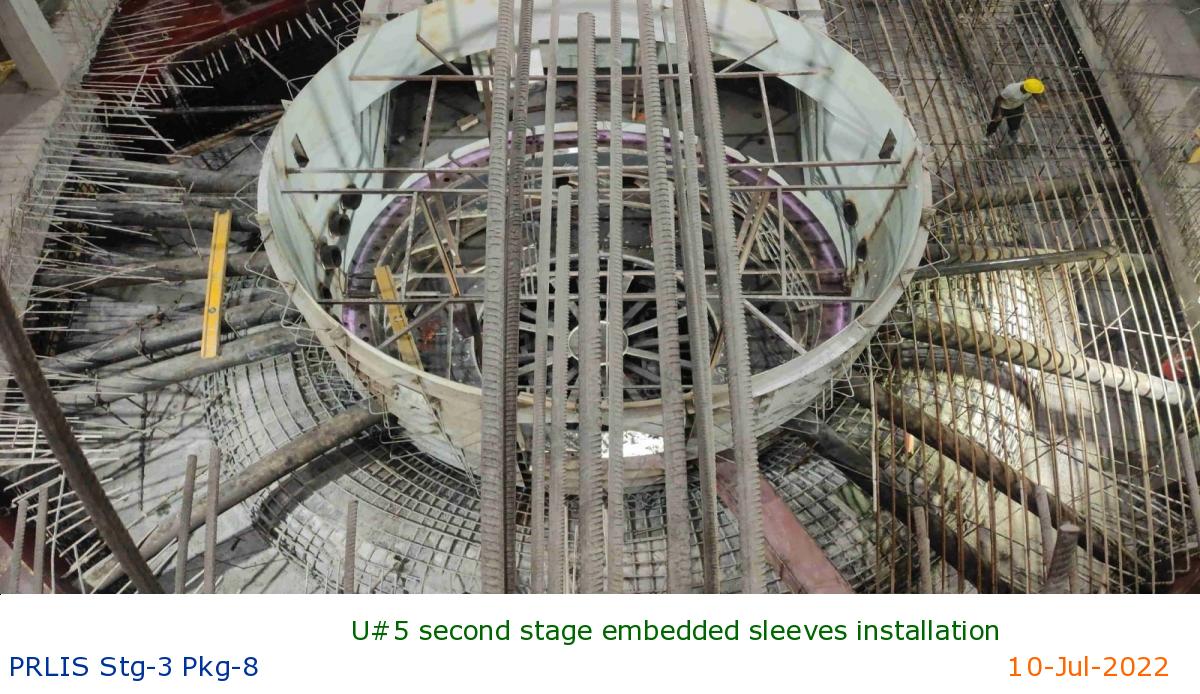

U#5 second stage embedded sleeves installation

|

U#3LGB Bracket and arms assy

|

U#3 LGB Sole plates leveling completed

|

U#2 pit air seal trial assy

|

U#1 Bottom air baffle trial assy

|

U#1 CW Strainer piping routing

|

U#1 GV lever link assy

|

U#1 brush gear support plates installation

|

U#1 Brush gear casing installation completed

|

U#1 Testing of Discharge valve

|

U#5 Second stage embedments installation i/p.

|

U#3 LGB Sole plates levelling is in progress

|

U#2 slip ring alignment is in progress

|

U#2 stator cooling water header routing in progres

|

U#2 Pump motor shaft nutgaurd assy in progress

|

U#1 CW pump motor assy on skid in progress

|

U#1 GV Servomotor final alignment completed

|

U#1 Bottom fire fighting header routing completed

|

U#1 Bottom shaft keys assy completed

|

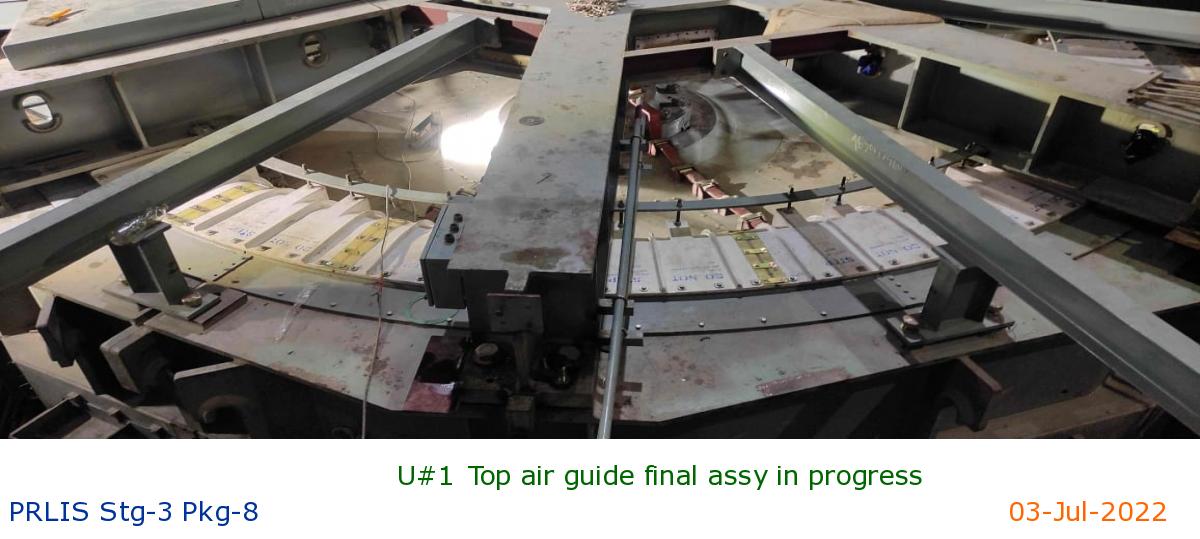

U#1 Top air guide final assy in progress

|

U#1 MDV Testing preparation in progress

|

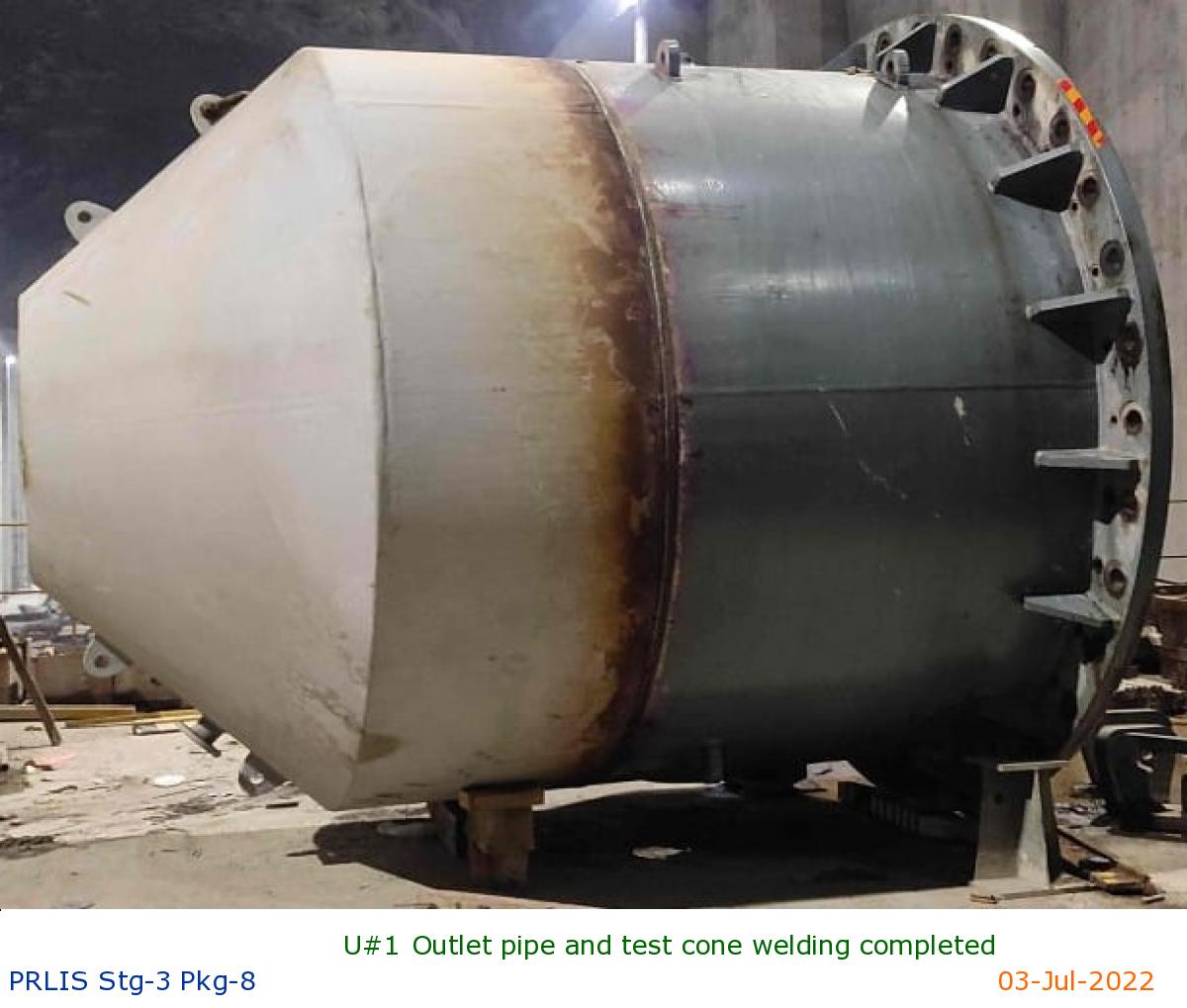

U#1 Outlet pipe and test cone welding completed

|

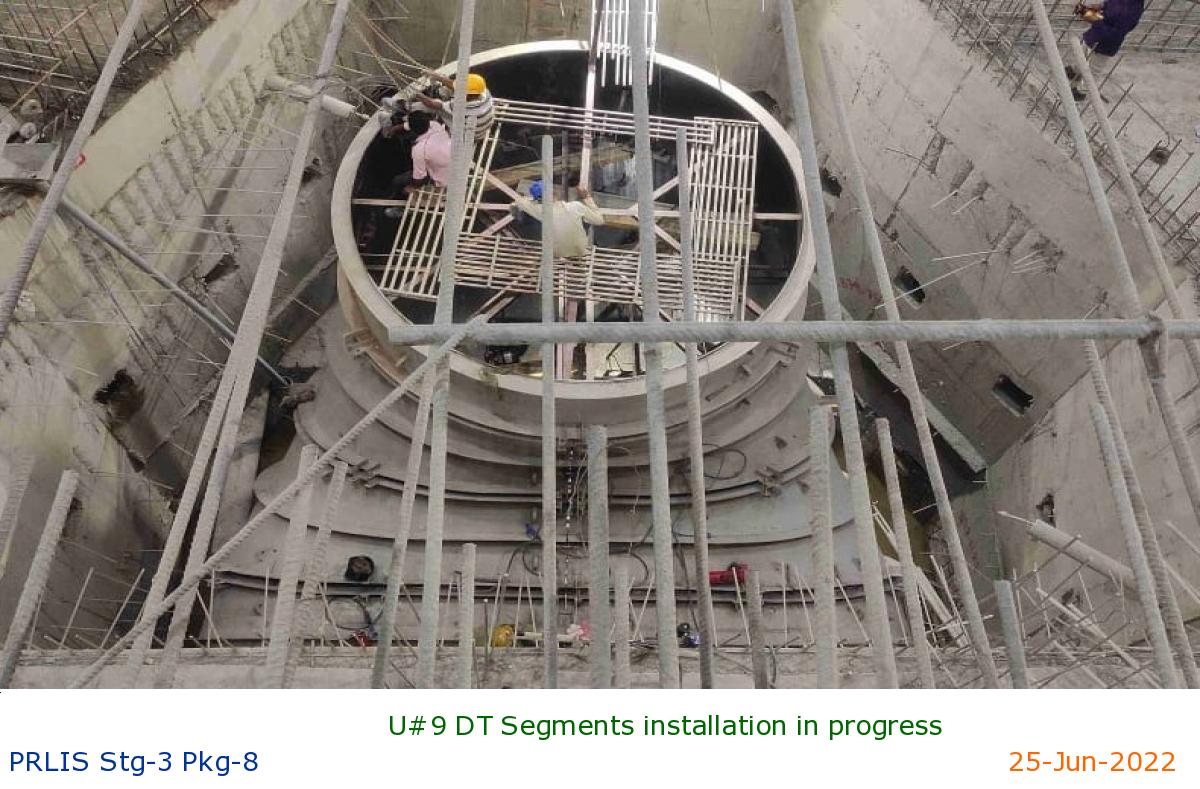

U#9 DT Segments installation in progress

|

U#8 First stage piping in progress

|

U#7 DT Anchor hooks welding completed

|

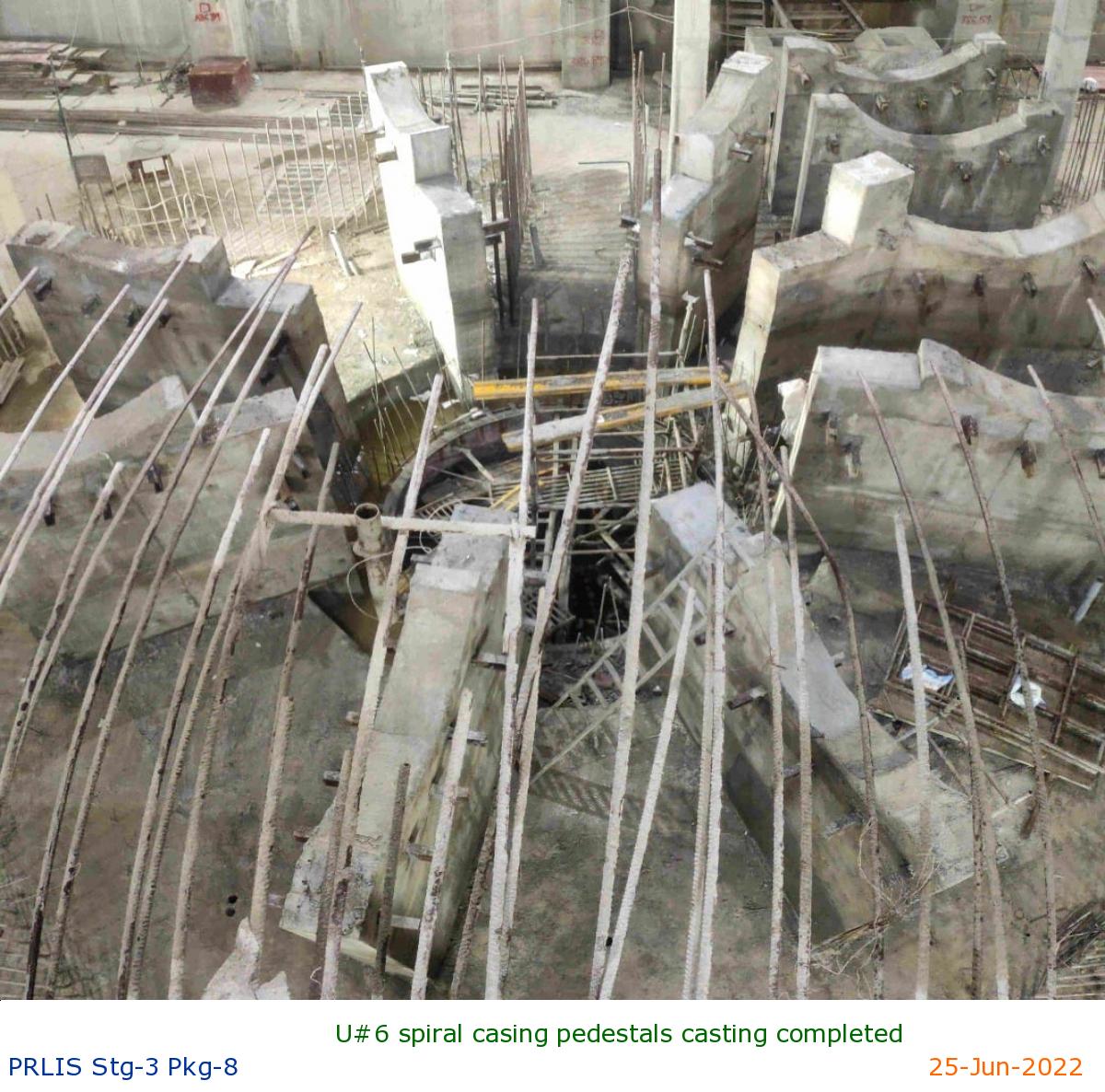

U#6 spiral casing pedestals casting completed

|

U#5 pit liner installation completed

|

U#3 rotor rim building is in progress

|

U#3 Motor Transformer positioning completed

|

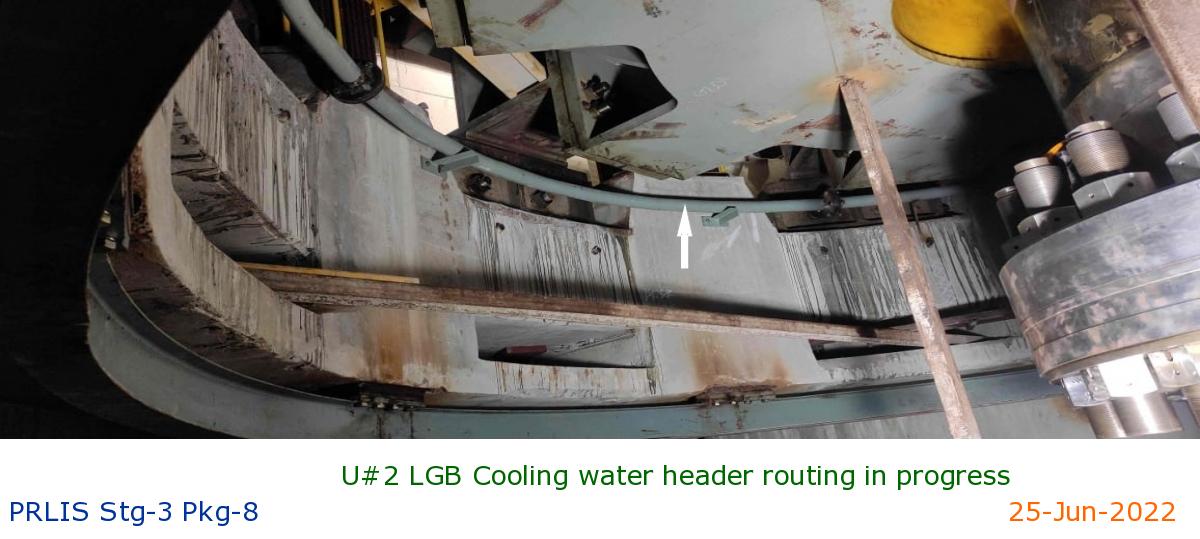

U#2 LGB Cooling water header routing in progress

|

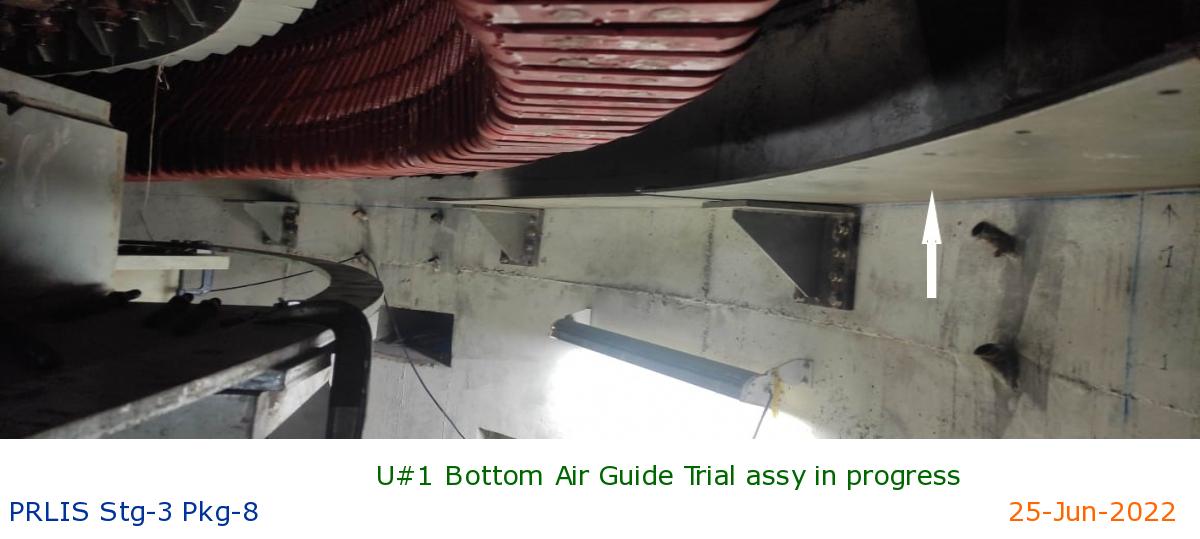

U#1 Bottom Air Guide Trial assy in progress

|

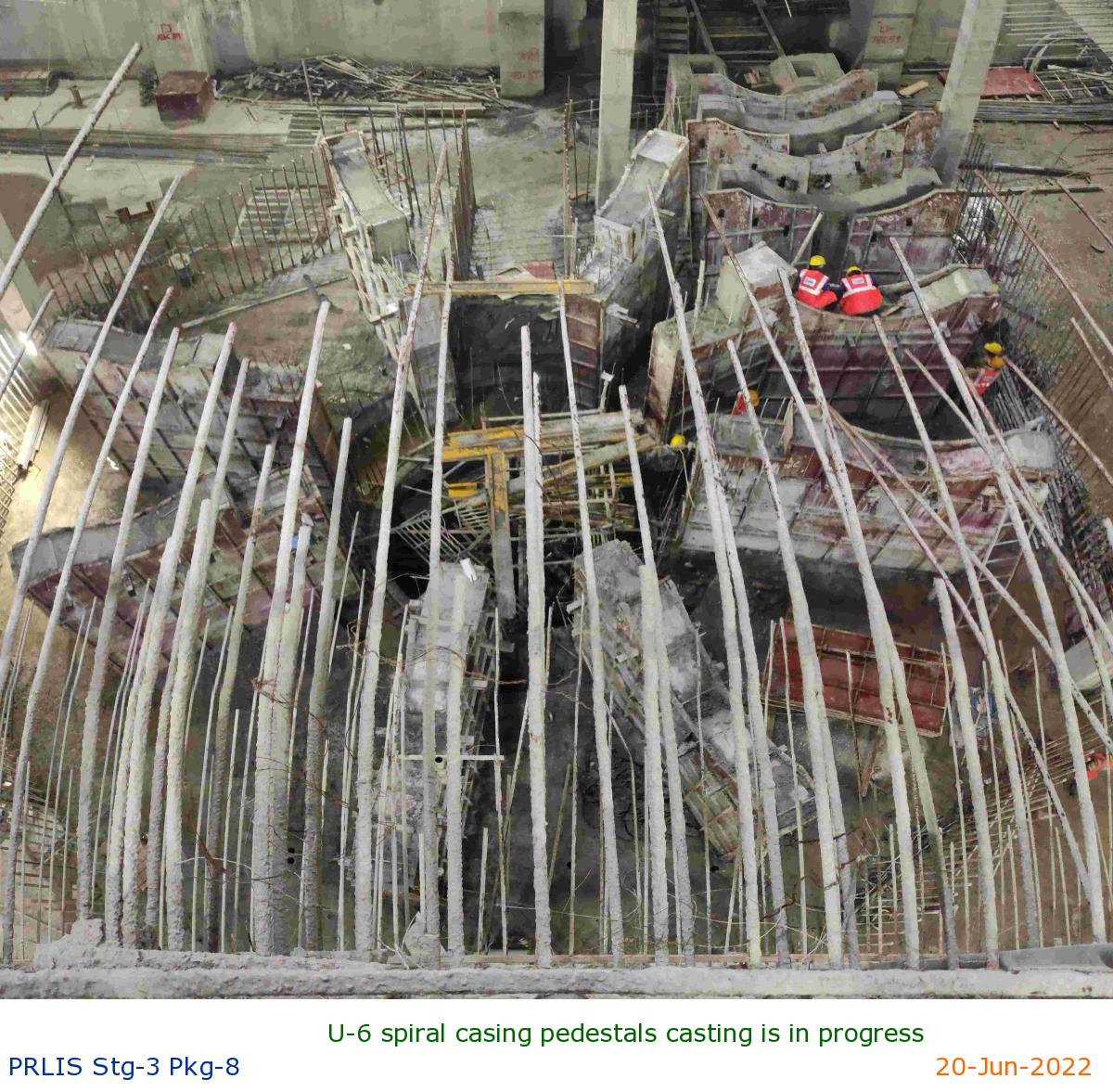

U-6 spiral casing pedestals casting is in progress

|

U-5 concreting is in progress

|

U-5 pit liner segments assy is in progress

|

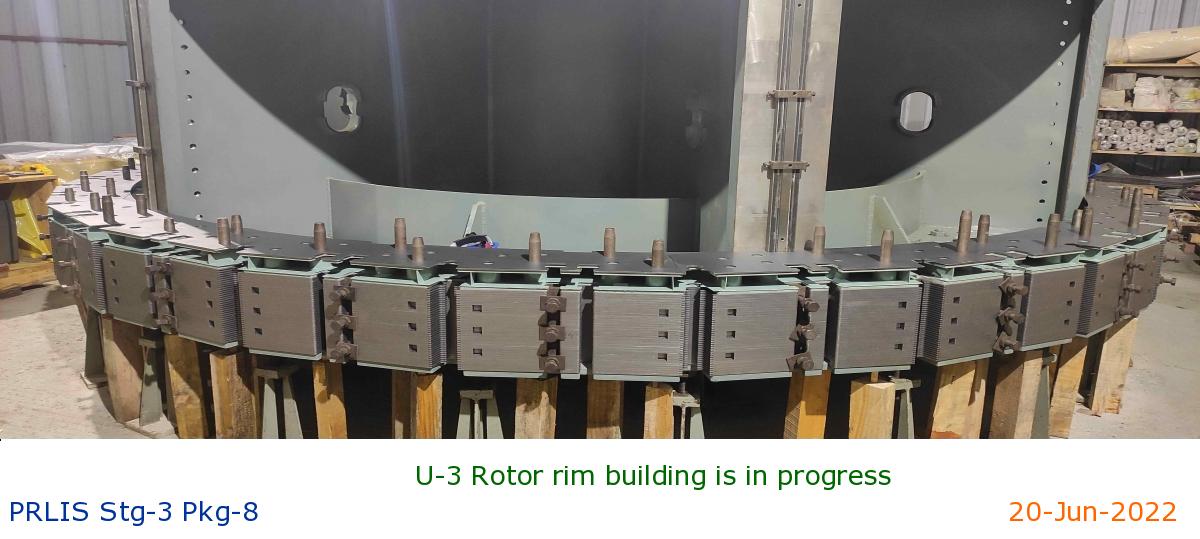

U-3 Rotor rim building is in progress

|

U-3 GV Servomotor lowering completed

|

Unit-2

|

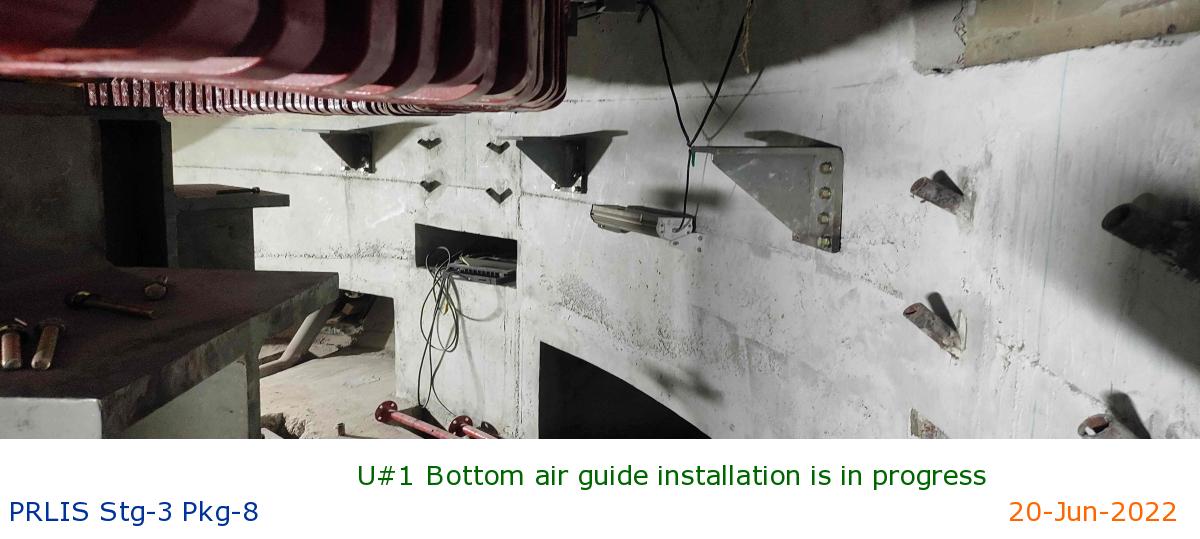

U#1 Bottom air guide installation is in progress

|

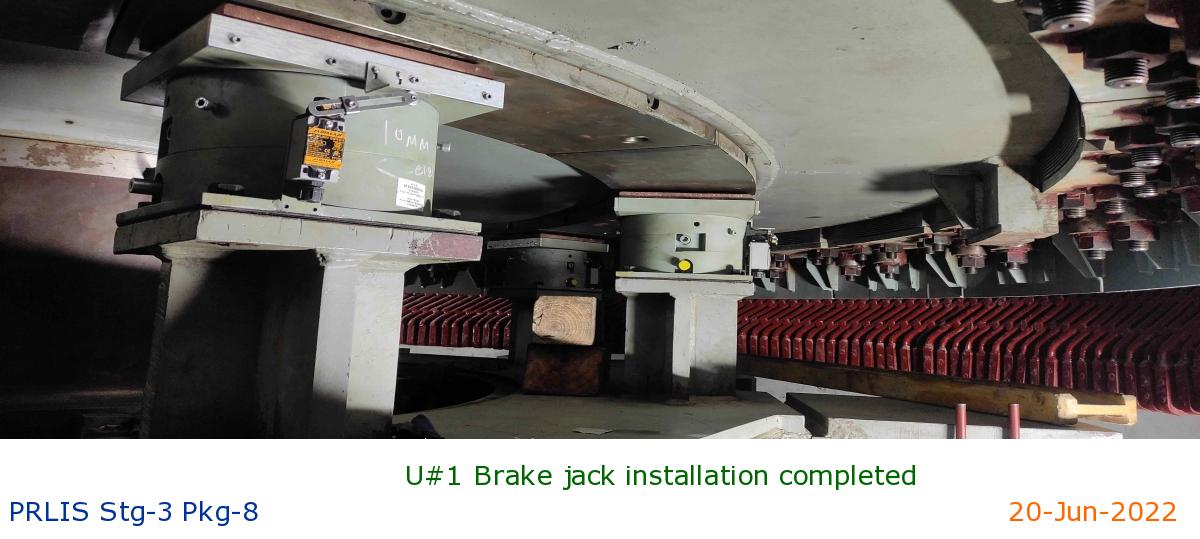

U#1 Brake jack installation completed

|

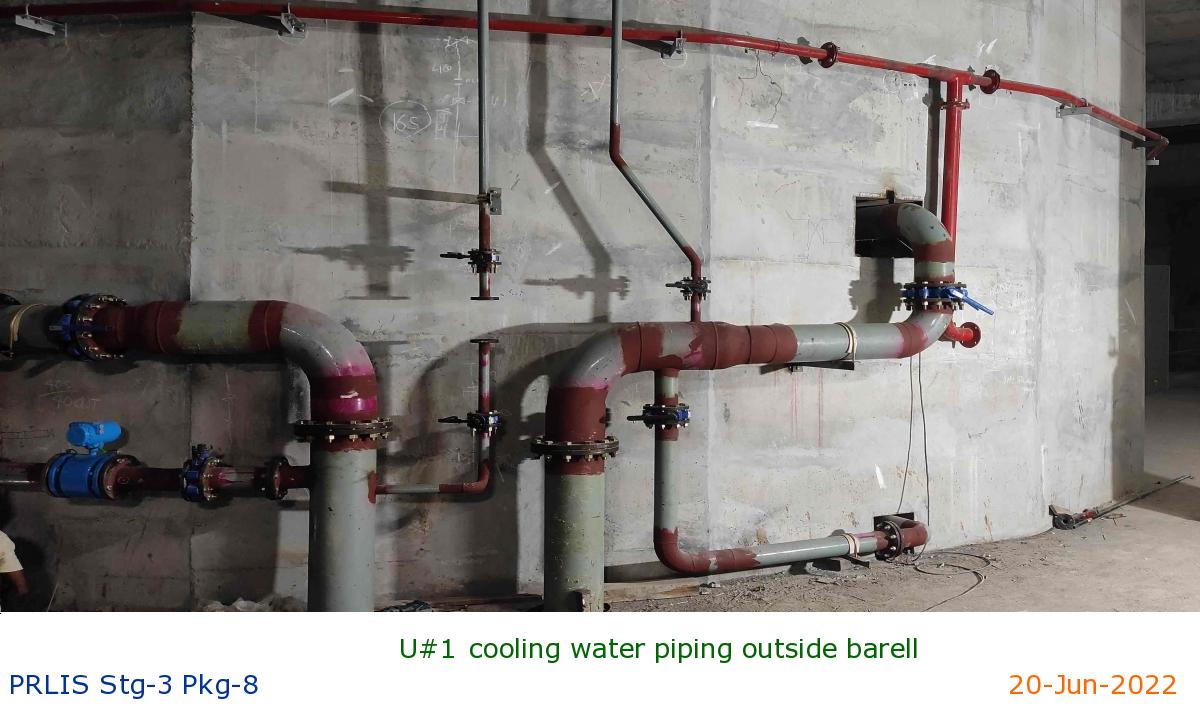

U#1 cooling water piping outside barell

|

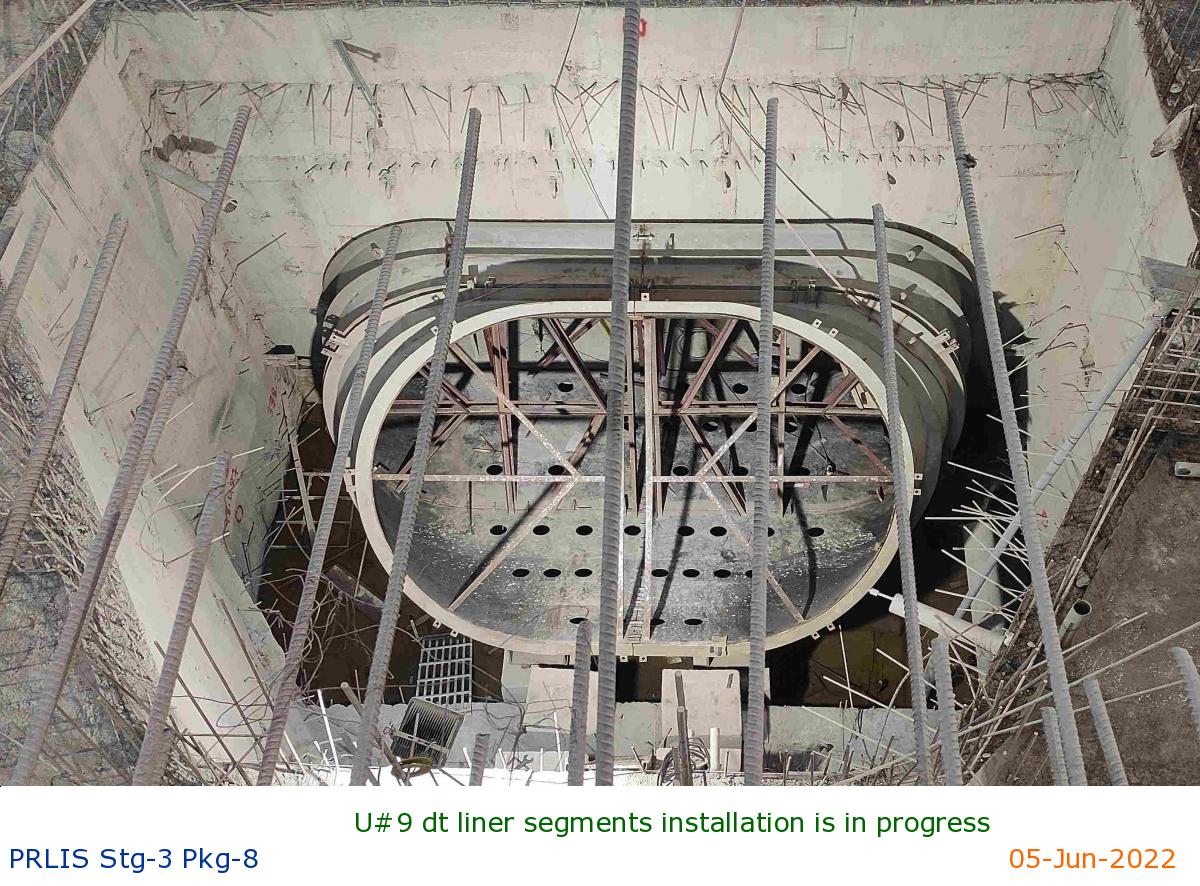

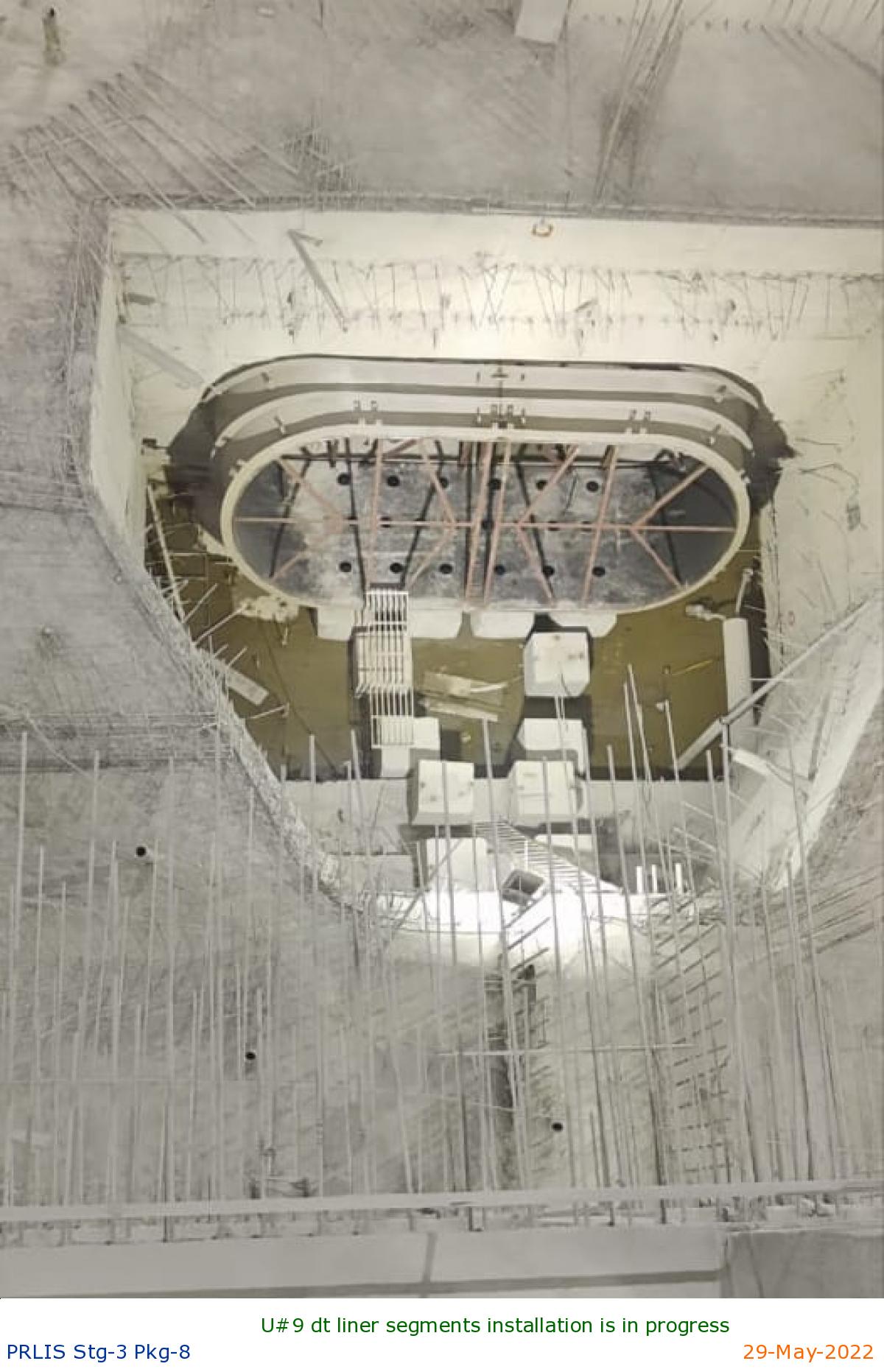

U#9 dt liner segments installation is in progress

|

U#8 first stage piping is in progress

|

U#6 spiral pedestals casting is in progress

|

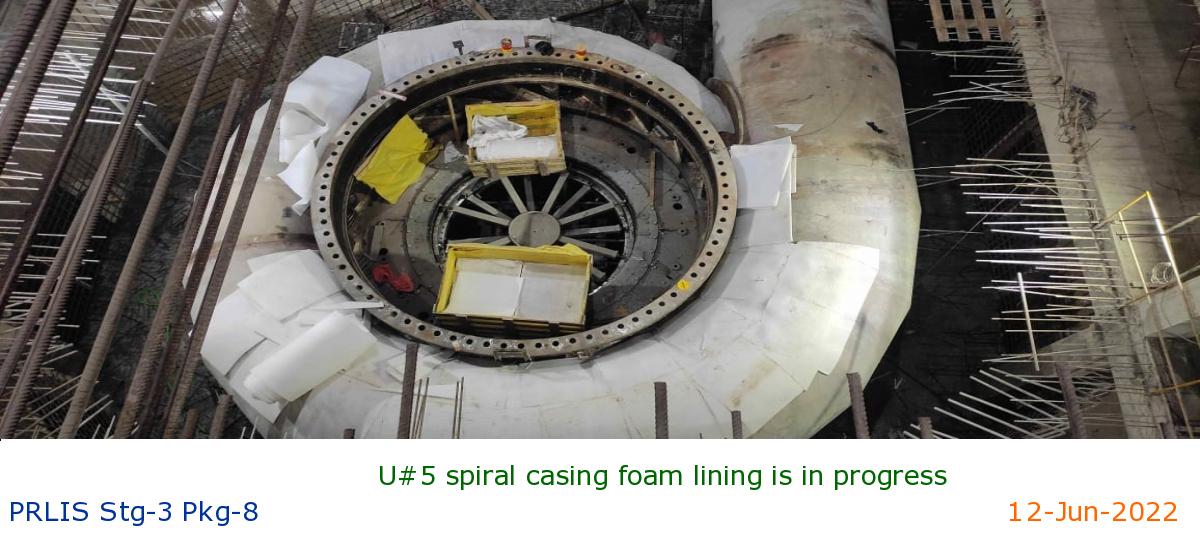

U#5 spiral casing foam lining is in progress

|

U#3 pump shaft, itc, regulating ring lowering comp

|

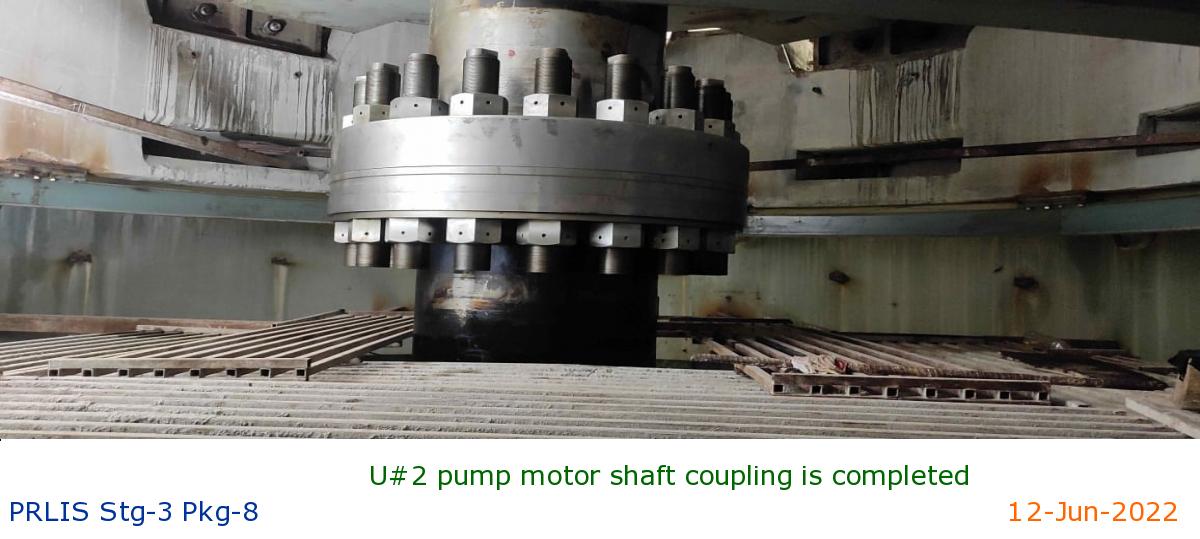

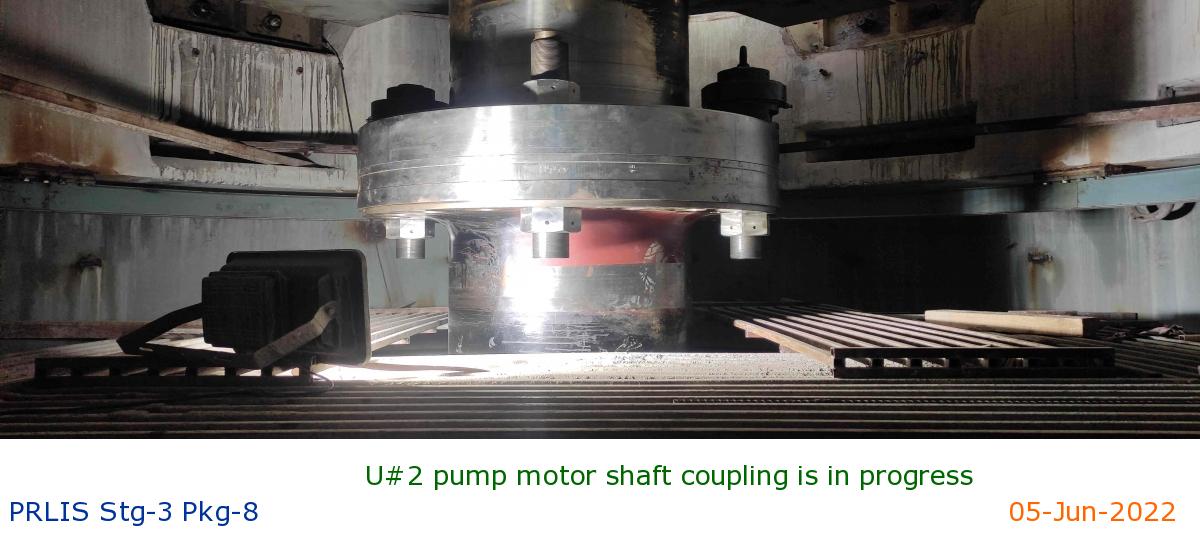

U#2 pump motor shaft coupling is completed

|

U#1 GV Servomotor alignment is in progress

|

U#2 Top shaft and bracket assy completed

|

U#1 Top air guide trial assy is in progress

|

U#9 dt liner segments installation is in progress

|

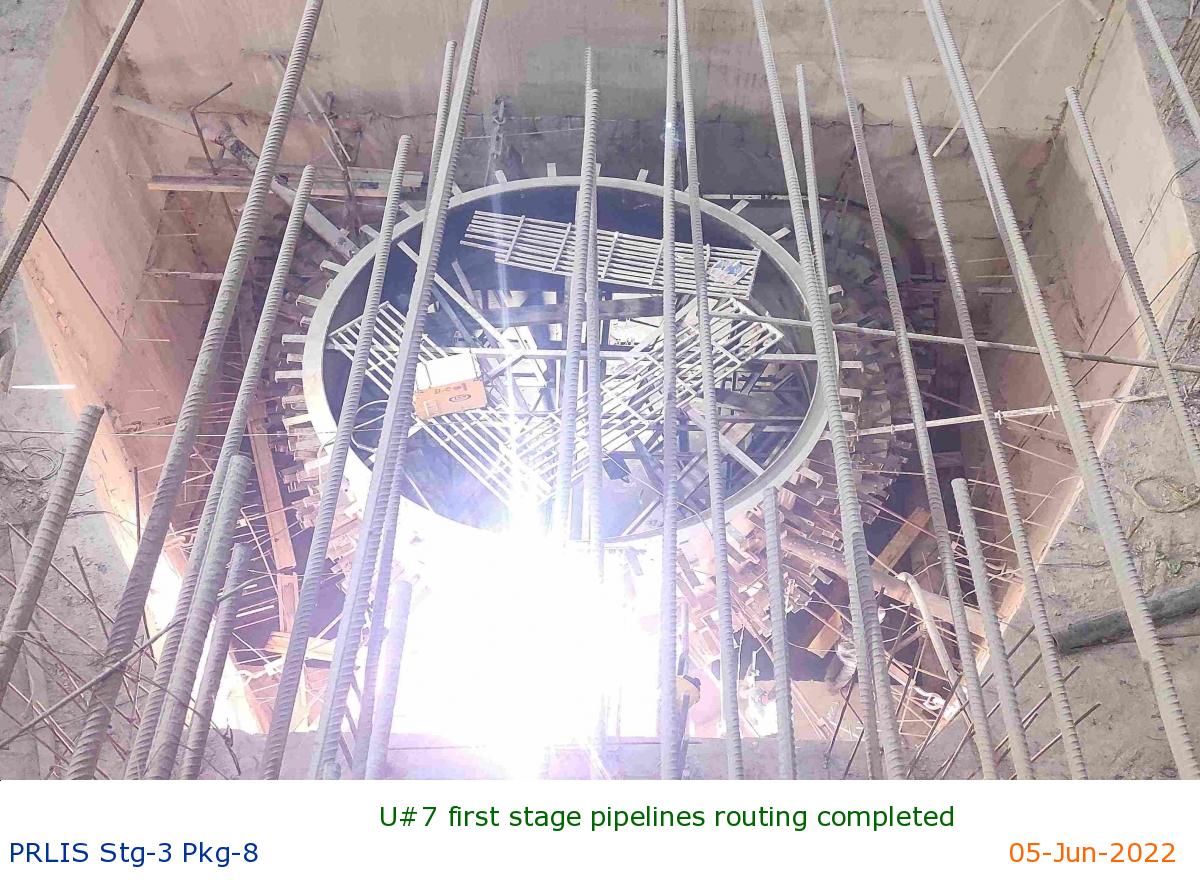

U#7 first stage pipelines routing completed

|

U#6 spiral pedestals casting is in progress

|

U#5 concreting of barell is in progress

|

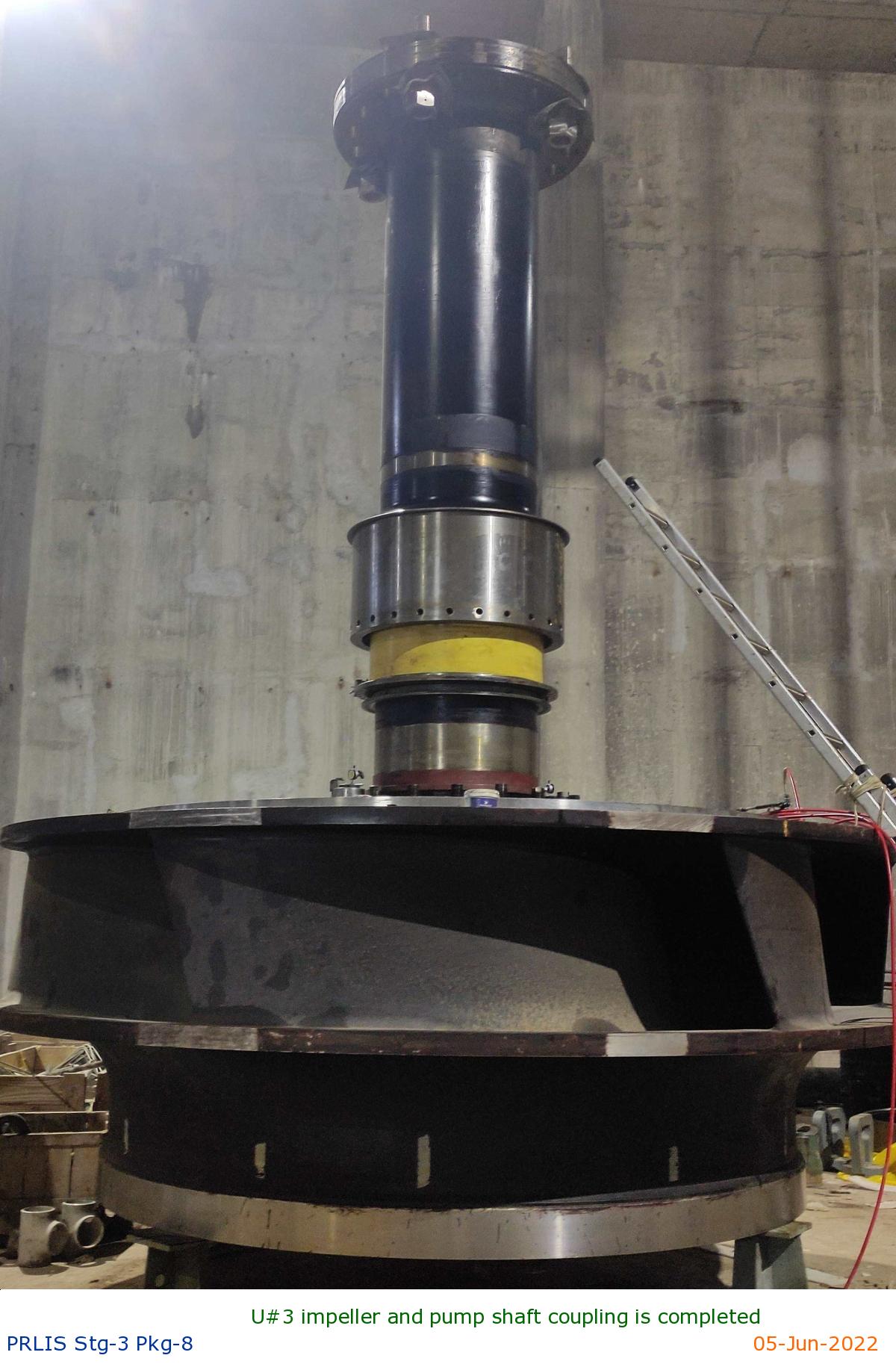

U#3 impeller and pump shaft coupling is completed

|

U#2 pump motor shaft coupling is in progress

|

U#1 GV SErvomotors shifted inside turbine pit

|

U#9 dt liner segments installation is in progress

|

U#8 dt liner segments installationcompleted

|

U#7 first stage piping is in progress

|

U#6 dt liner concreting is completed

|

U#5 Spiral concreting is in progress

|

U#4 Stator lowering completed

|

U#3 Guide Apparatus assy in progress

|

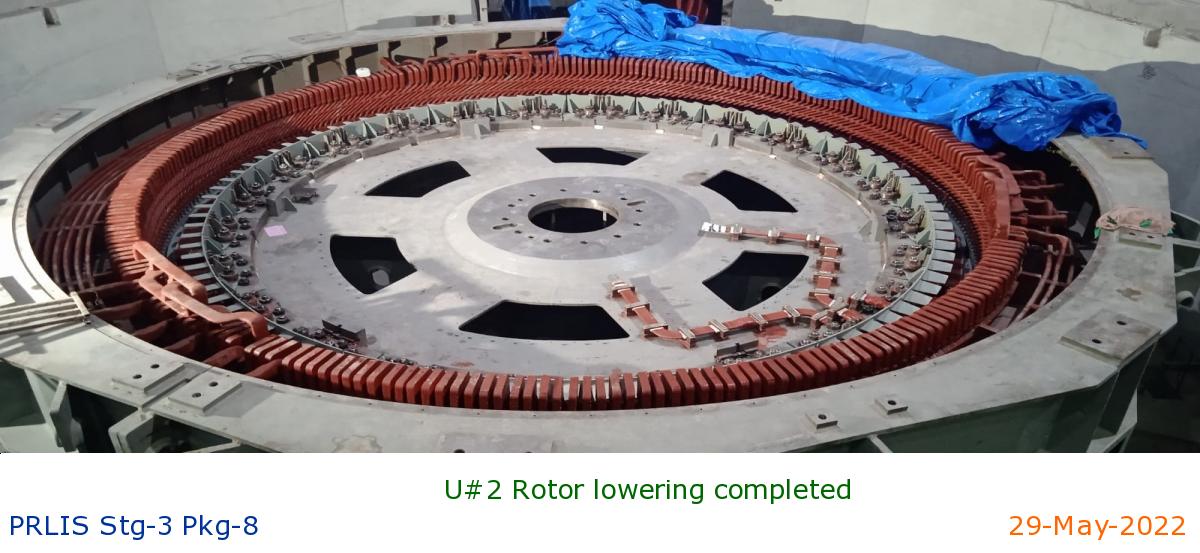

U#2 Rotor lowering completed

|

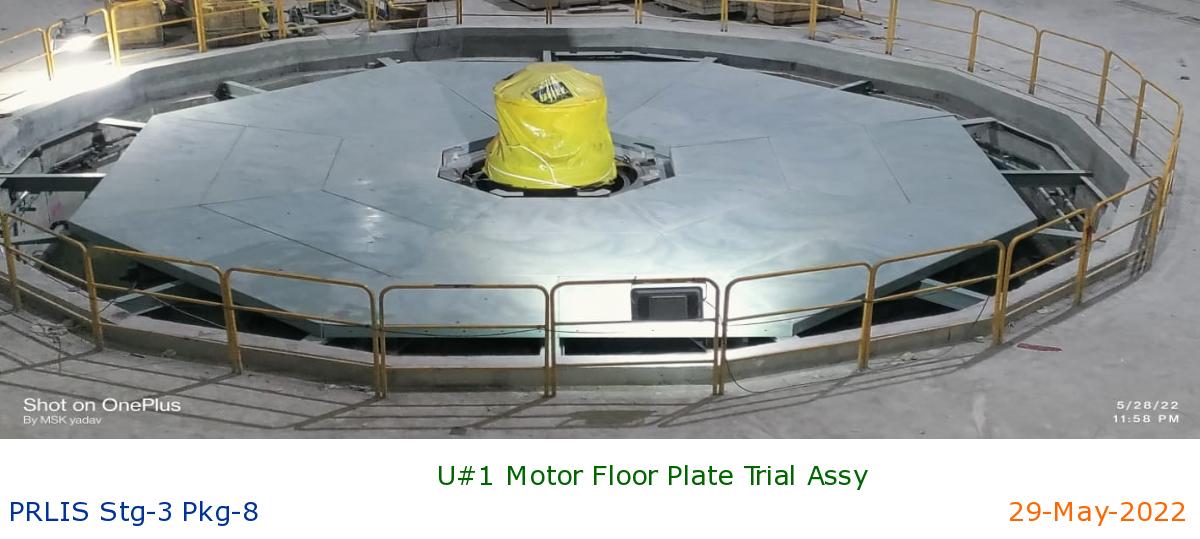

U#1 Motor Floor Plate Trial Assy

|

U#8 dt liner segments installationcompleted

|

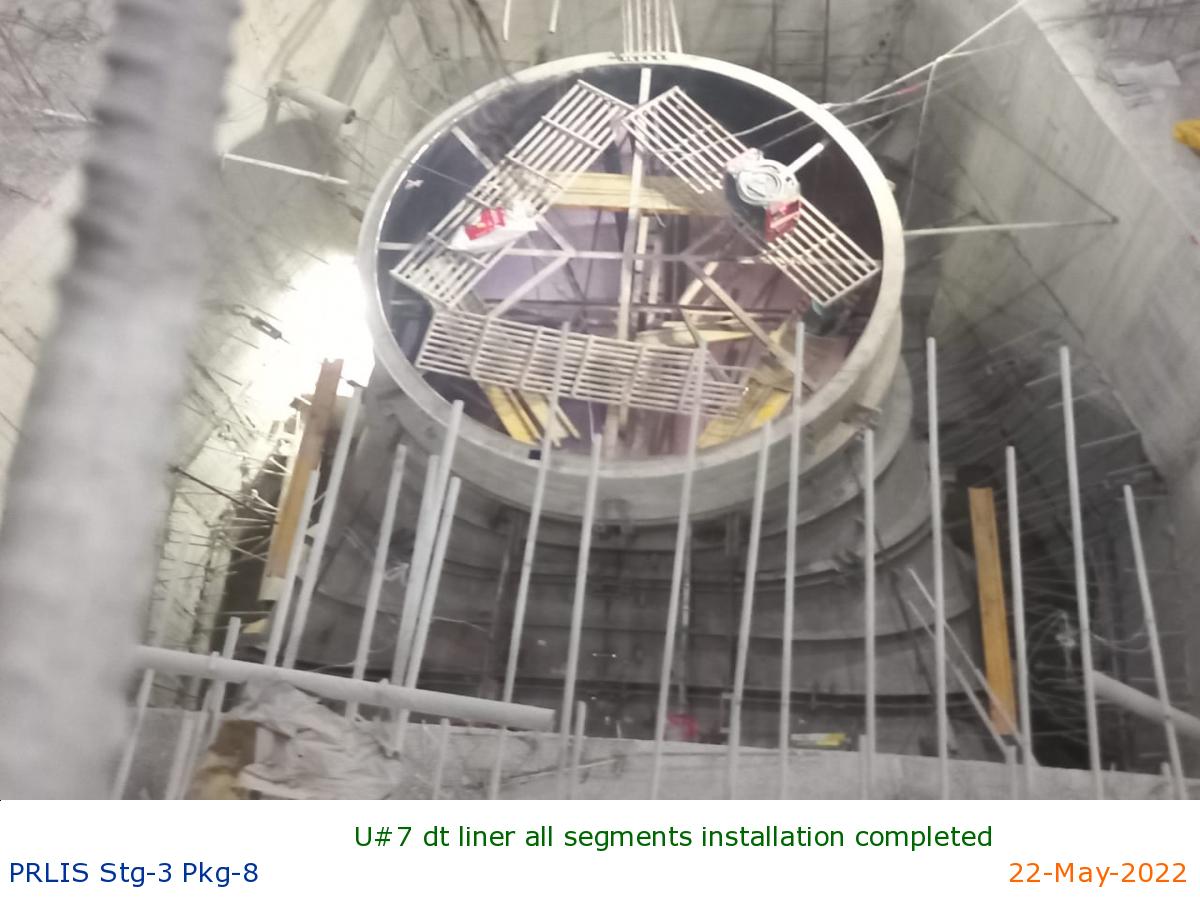

U#7 dt liner all segments installation completed

|

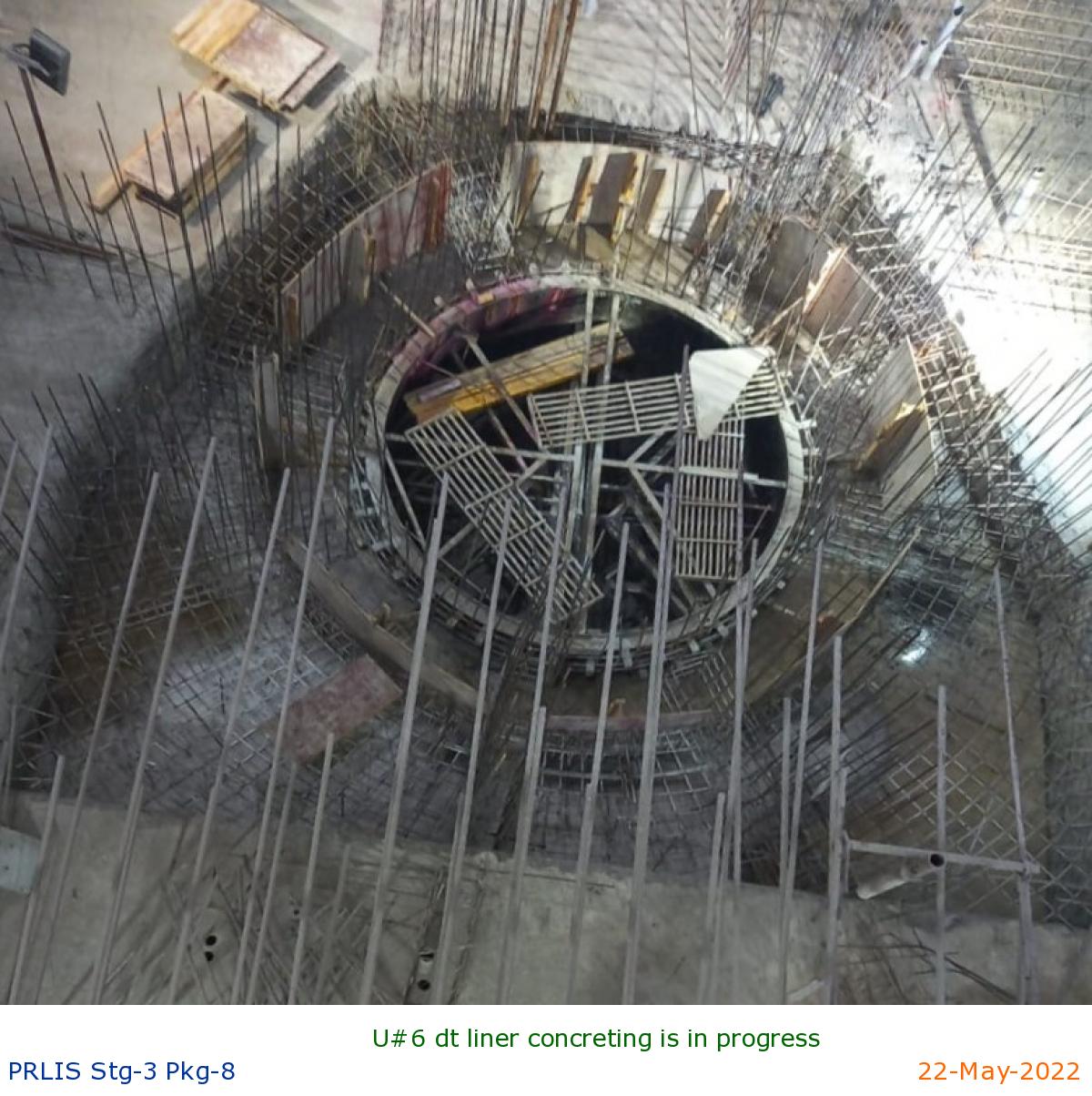

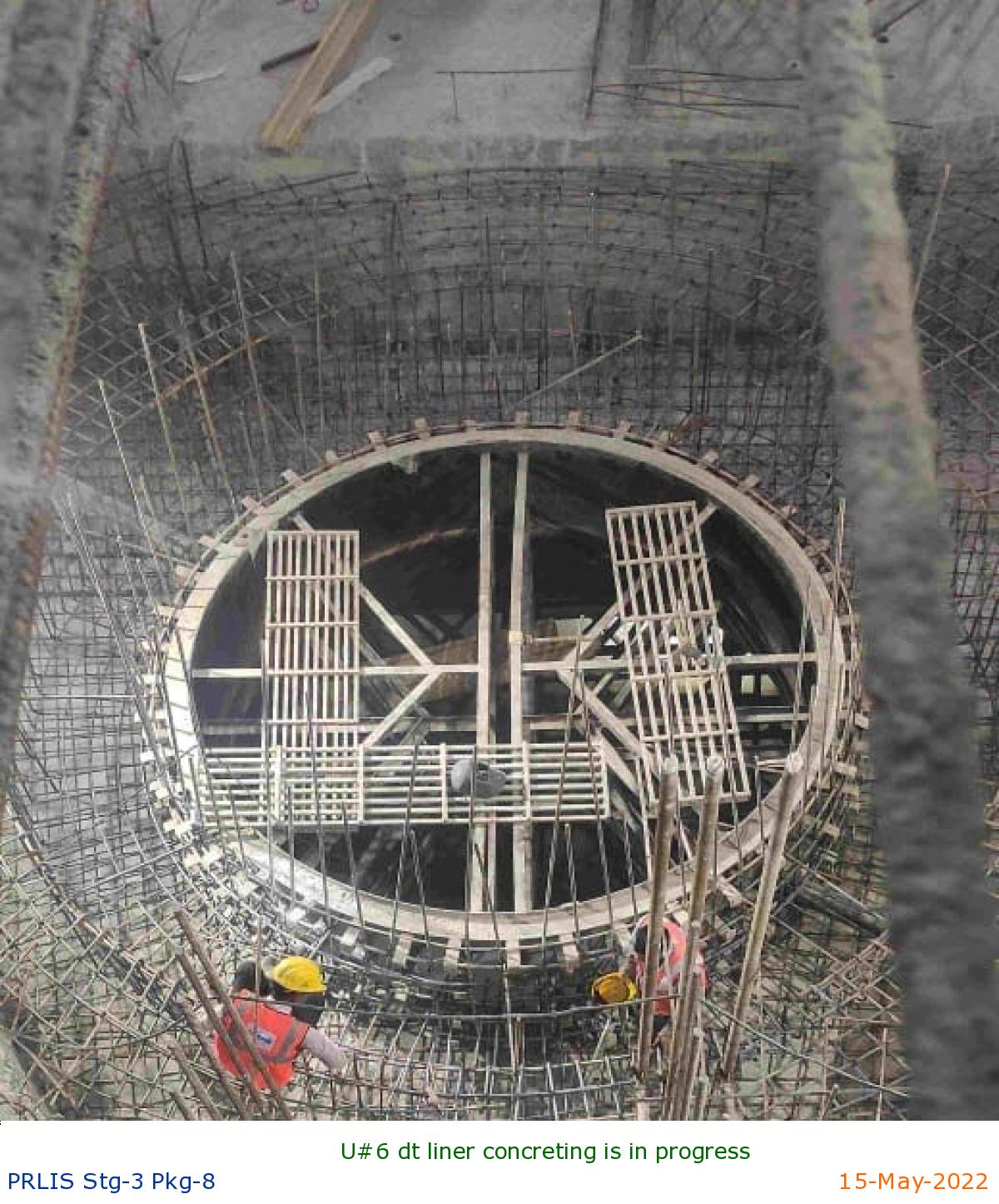

U#6 dt liner concreting is in progress

|

U#2

|

U#5

|

U#4 Stator sole plates levelling is in progress

|

U#3 ITC Centering and dowelling completed

|

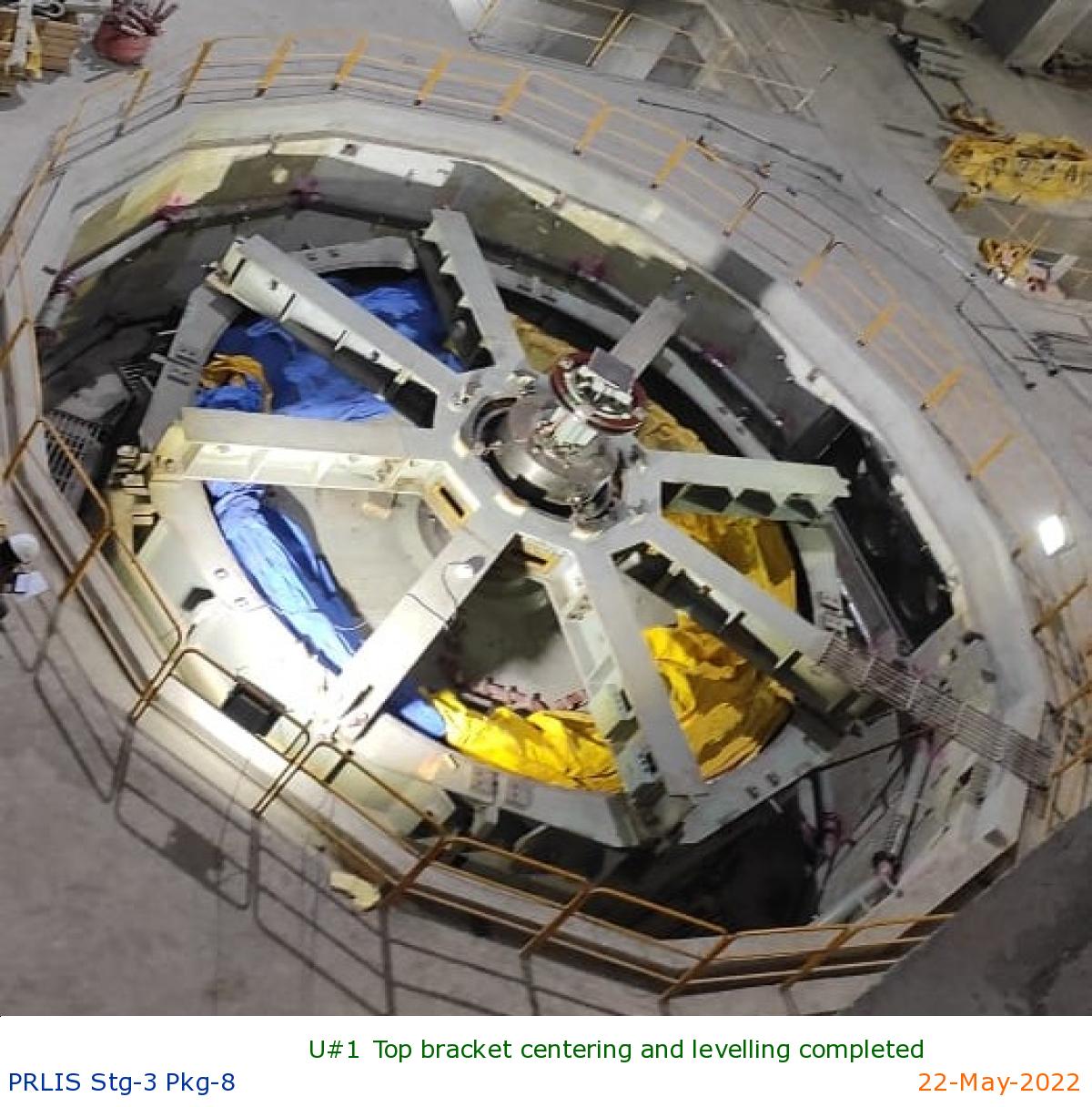

U#1 Top bracket centering and levelling completed

|

U#2 Rotor poles mounting is in progress

|

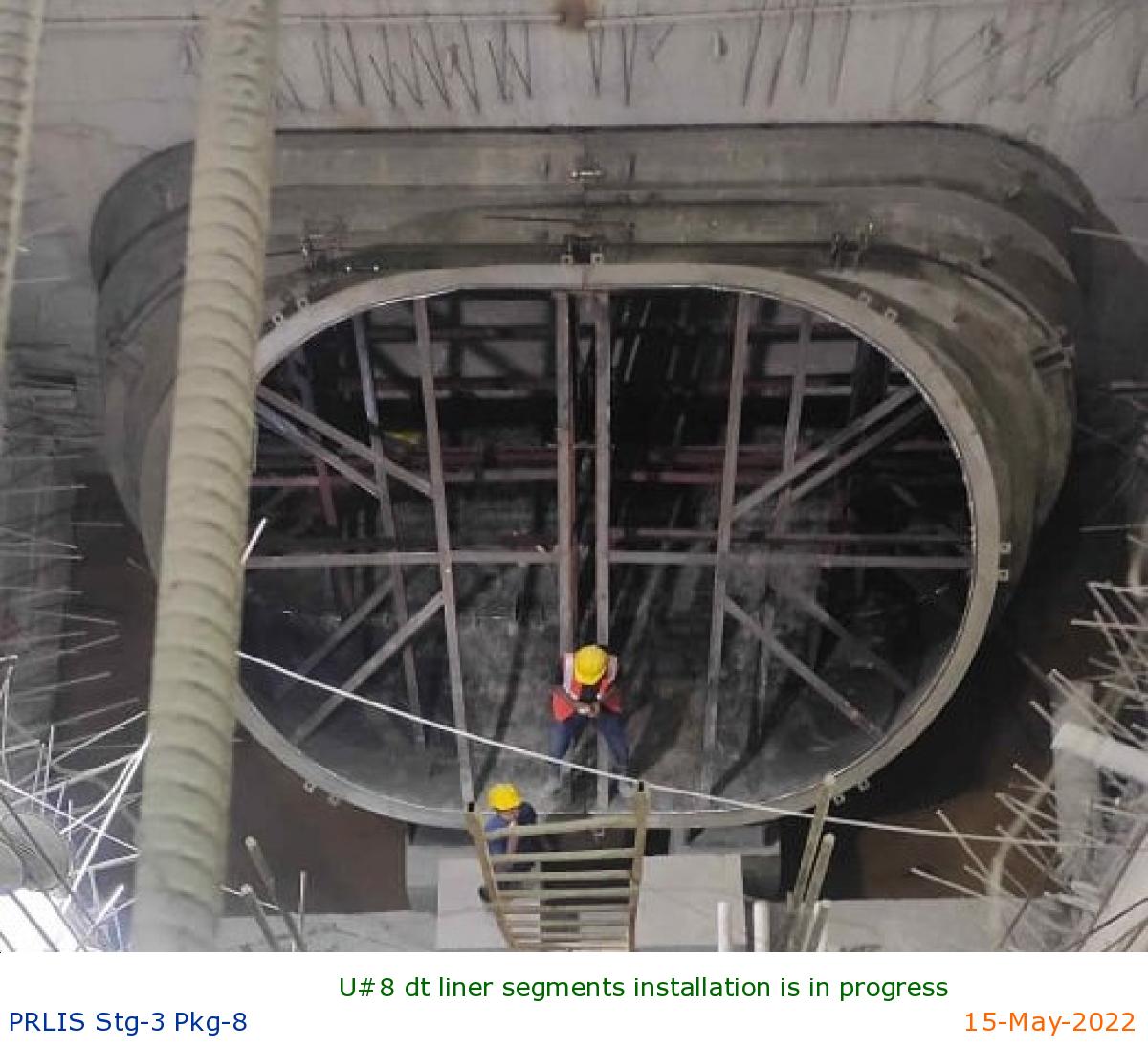

U#8 dt liner segments installation is in progress

|

U#7 dt liner all segments installation completed

|

U#6 dt liner concreting is in progress

|

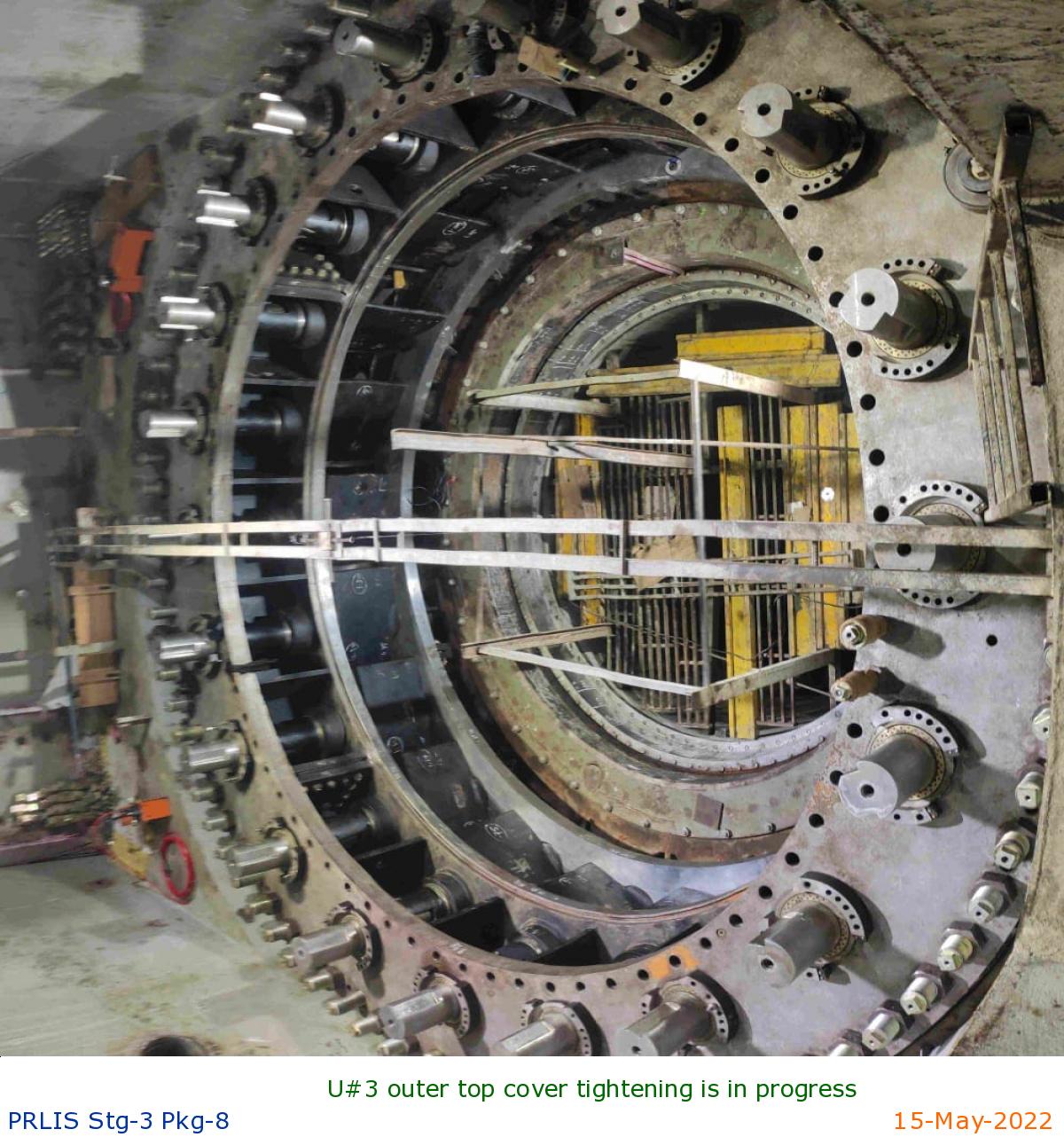

U#3 outer top cover tightening is in progress

|

U#2 bottom shaft lowering completed

|

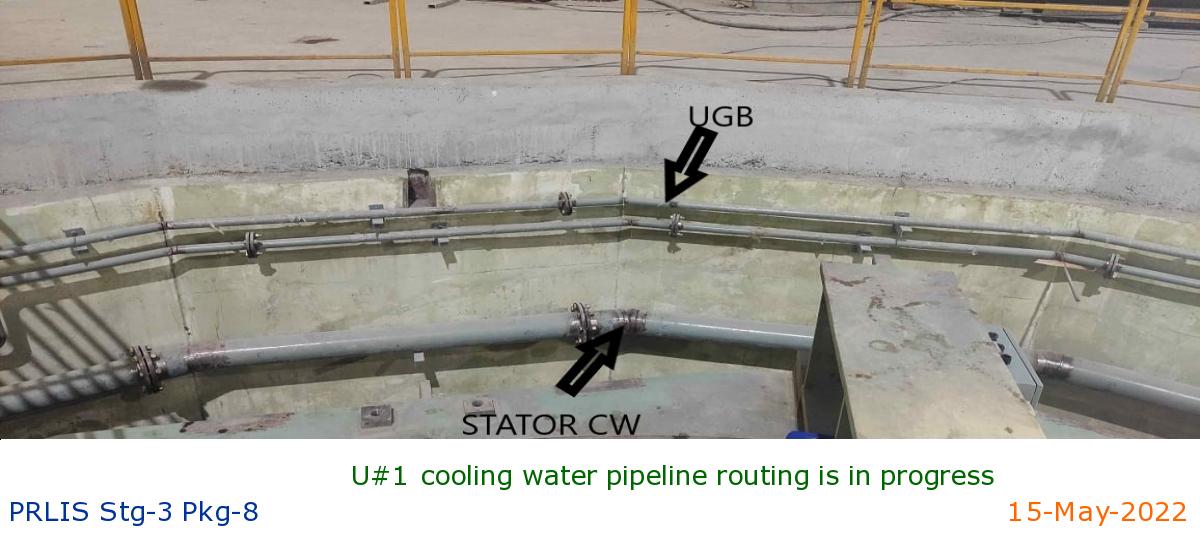

U#1 cooling water pipeline routing is in progress

|

U#1 positioning of ng cubicle completed

|

U#7 dt liner installation is in progress

|

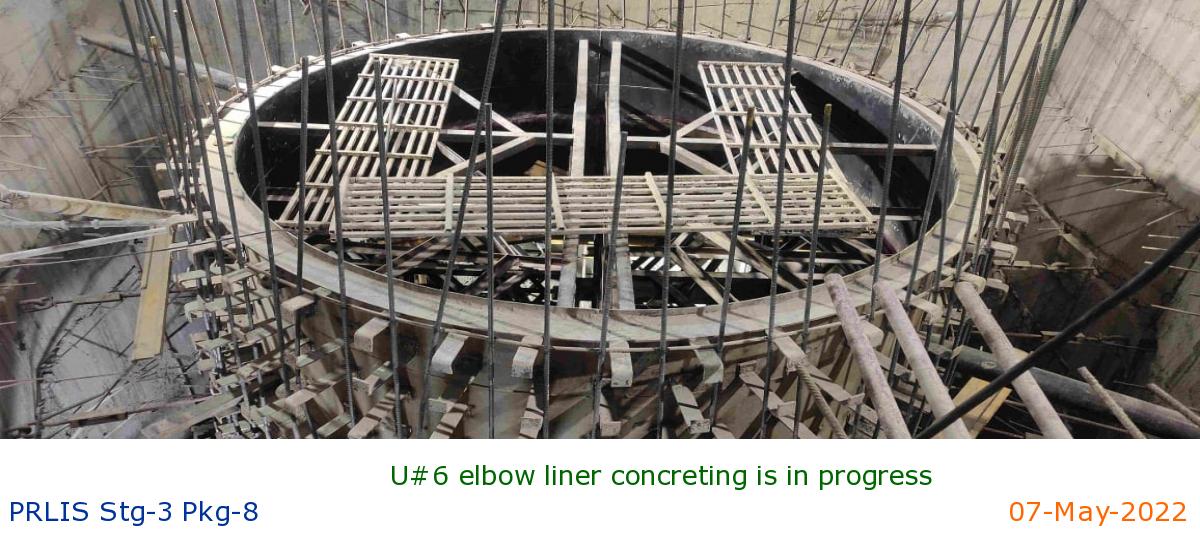

U#6 elbow liner concreting is in progress

|

U#5 second stage pipeline routing u/p.

|

U#4 busduct installation under progress

|

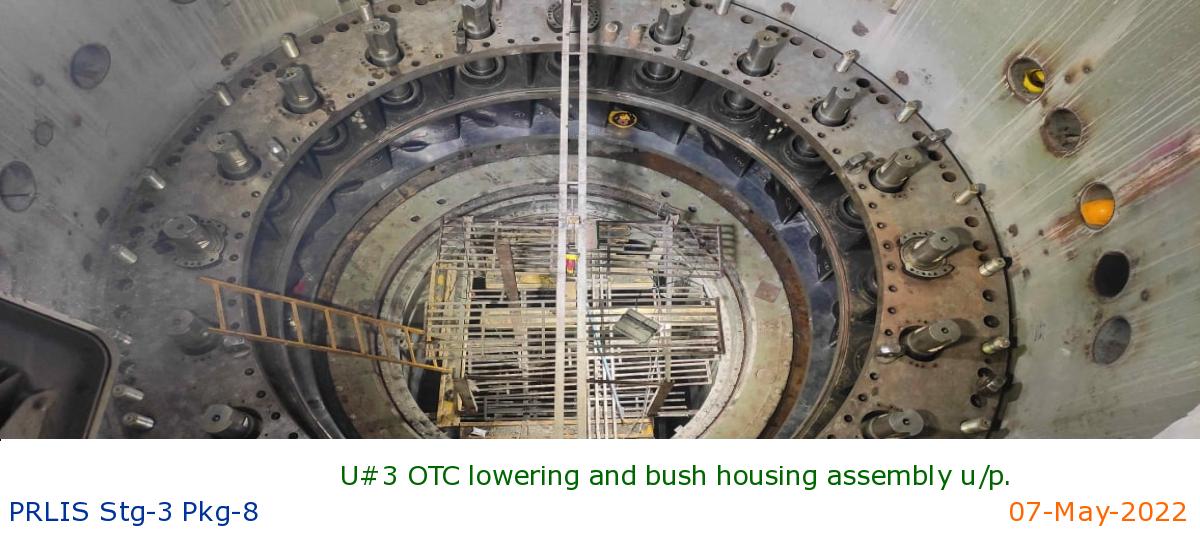

U#3 OTC lowering and bush housing assembly u/p.

|

U#2 LGB bracket lowering completed

|

U#1 shafts alignment completed

|

U#7 installation of dt liner is in progress

|

U#6 dt elbow liner installation completed

|

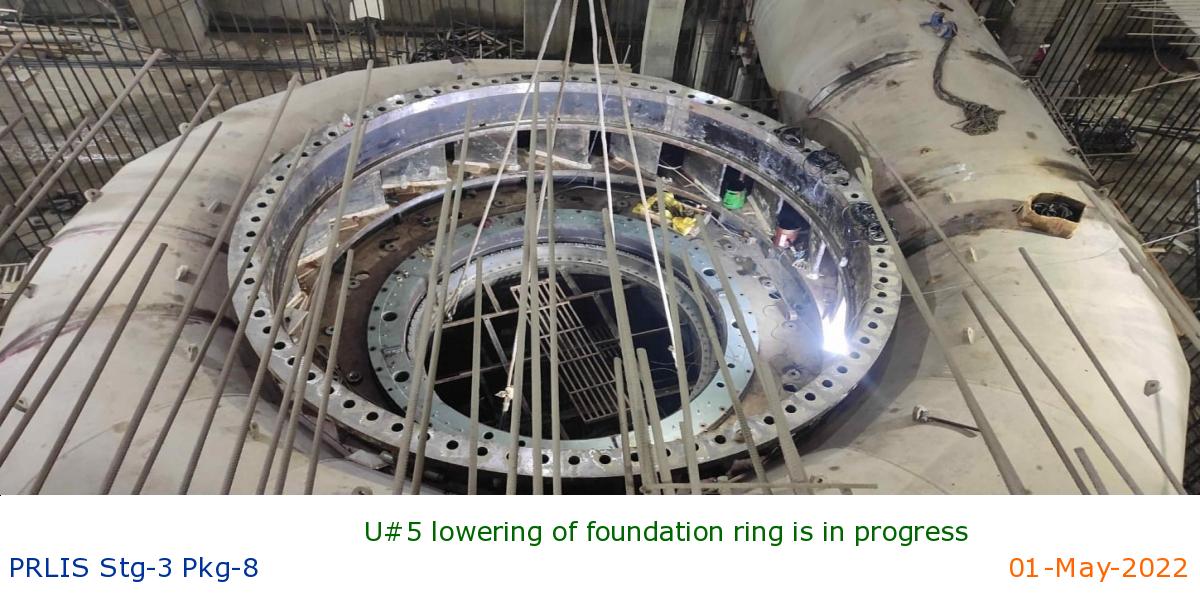

U#5 lowering of foundation ring is in progress

|

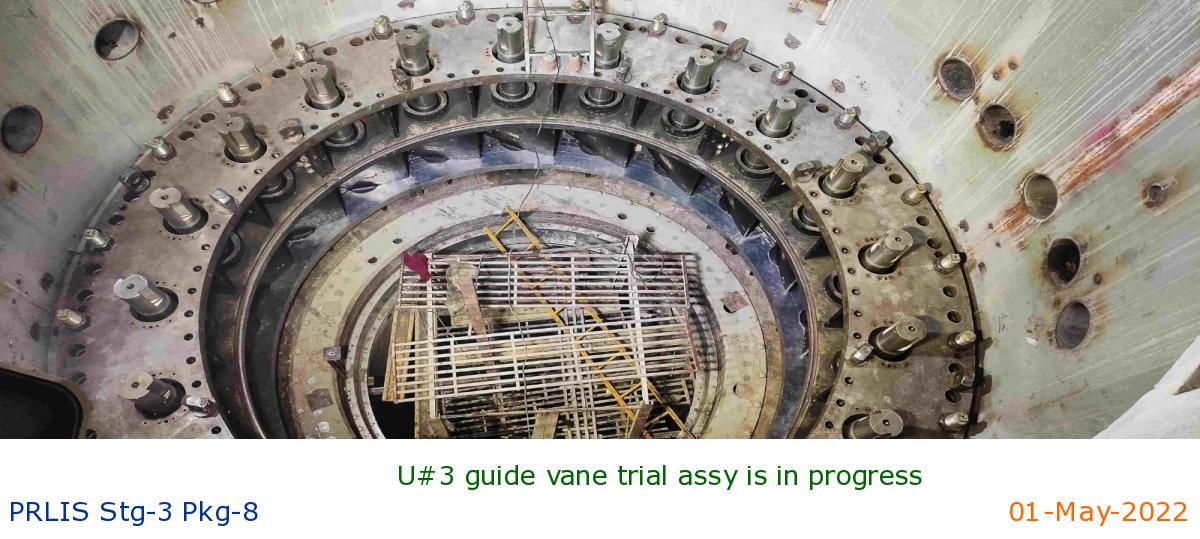

U#3 guide vane trial assy is in progress

|

U#2 lgb spring plate trial assy is in progress

|

U#1 tubular shaft alignment is in progress

|

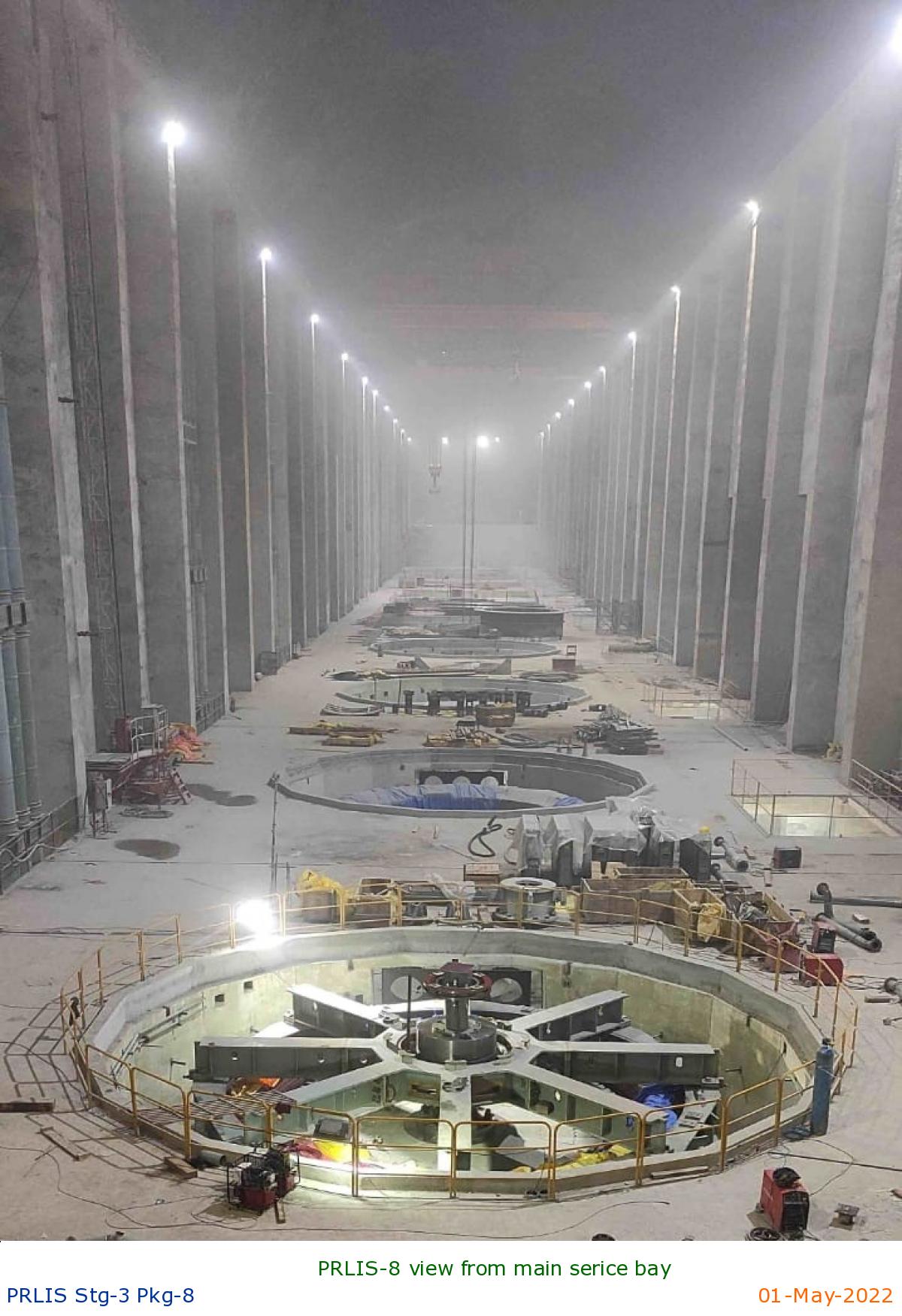

PRLIS-8 view from main serice bay

|

U#1 Motor transformer shifting completed

|

U#4 busduct installation under progress

|

U#5 cleaning of foundation ring for assembly

|

U#2 lgb arms assembly completed

|

U#4 barrell concreting completed, cleaning in prog

|

U#3 otc levelling after welding is in progress

|

U#2 rotor rim building is in progress

|

U#2 rotor rim building is in progress

|

U#5 spiral casing hydraulic testing completed

|

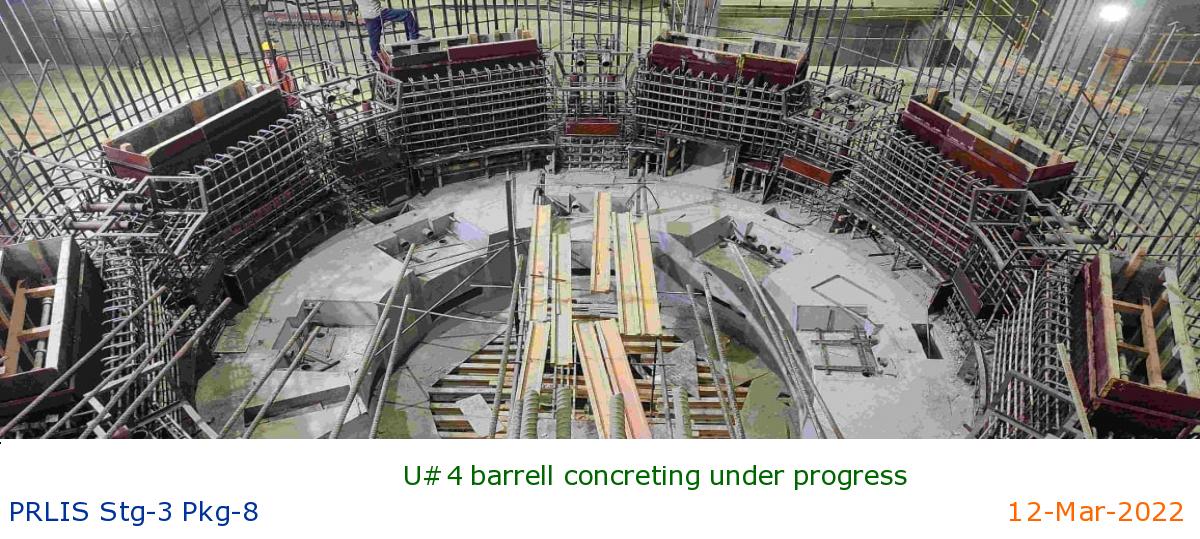

U#4 barrell concreting under progress

|

U#3 guide vane height measurement in progress

|

U#2 Inner top cover, bearing housing lowered

|

U#1 top bracket lowered, tubular shaft assembled

|

U#5 spiral segments welding in progress

|

U#4 busduct installation under progress

|

U#4 barrell concreting under progress

|

U#3 otc quadrants assy completed welding isin prog

|

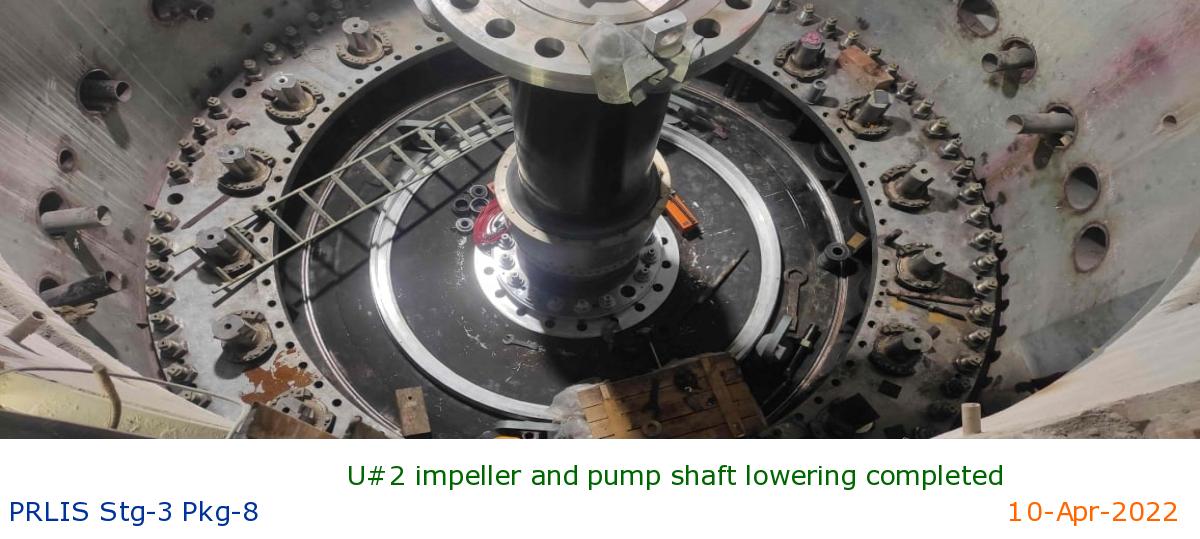

U#2 impeller and pump shaft lowering completed

|

U#1 pump motor shaft coupling is in progress

|

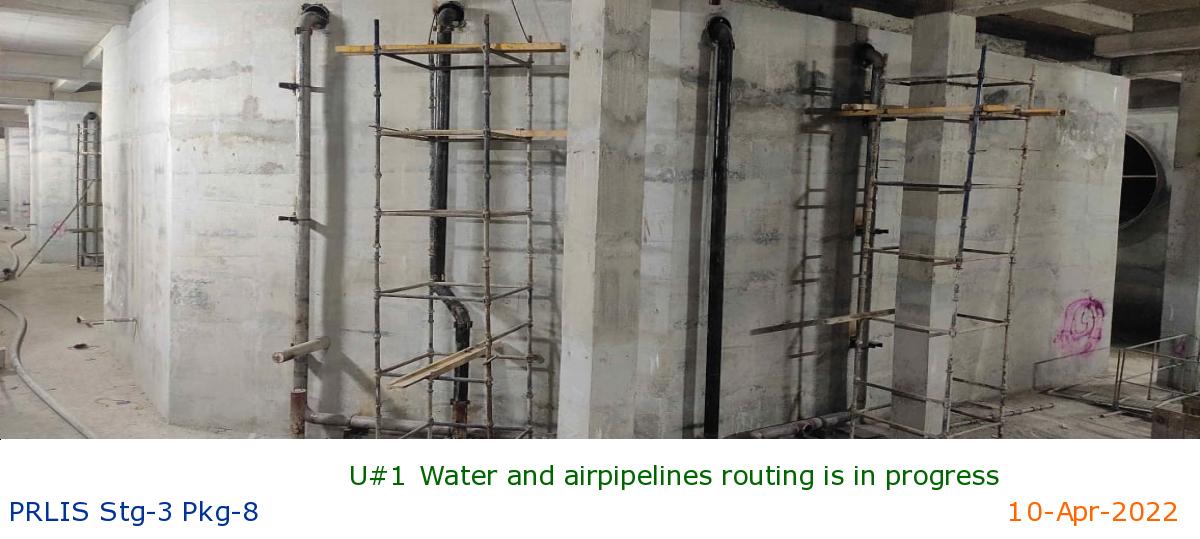

U#1 Water and airpipelines routing is in progress

|

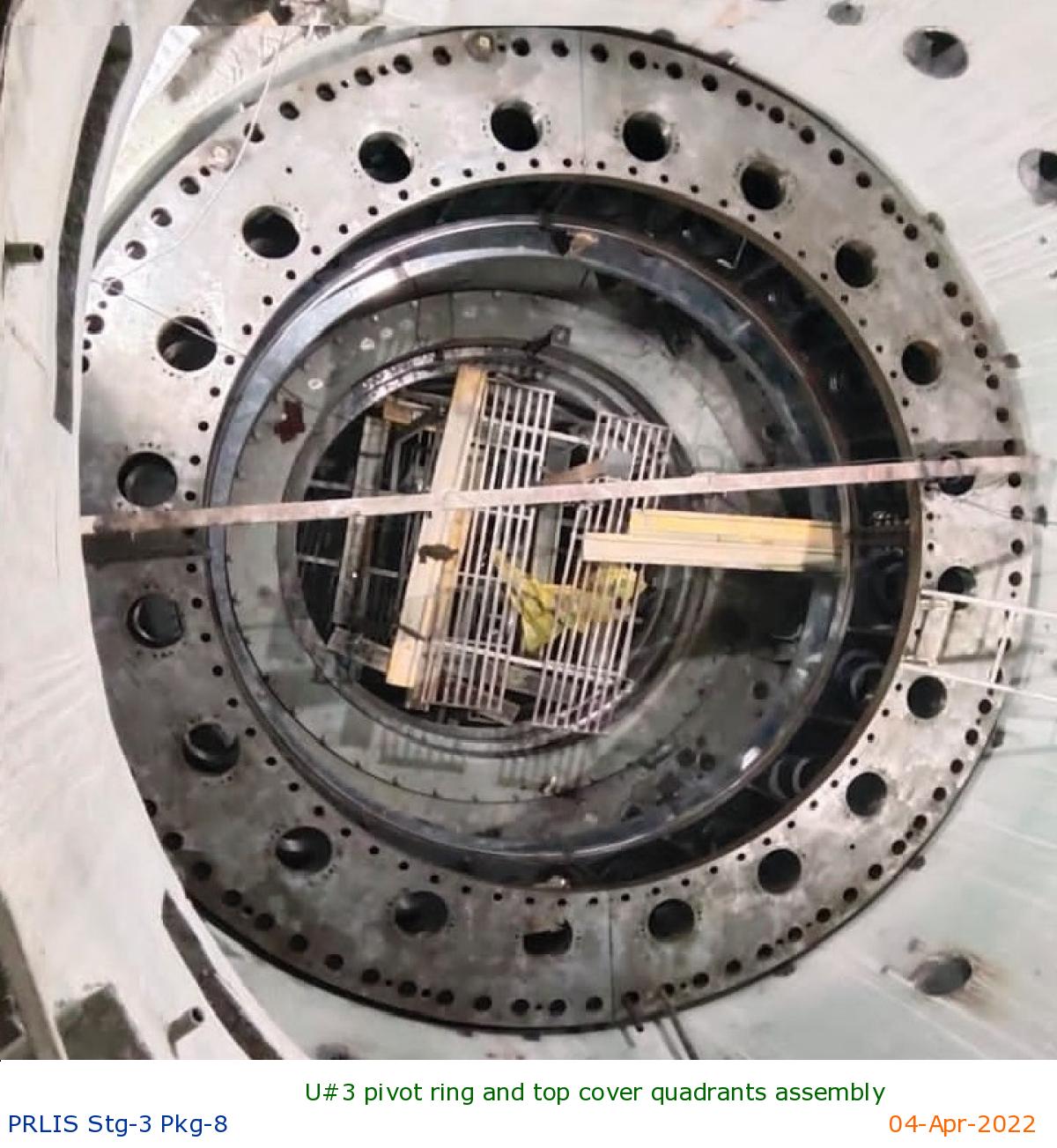

U#3 pivot ring and top cover quadrants assembly

|

U#5 spiral segments welding in progress

|

U#1 Motor Rotor and Top Shaft after lowering

|

U#1 Rotor Lowering into barrel

|

U#5 spiral segments welding in progress

|

U#2 inner top cover centering

|

U#4 barrell concreting under progress

|

U#1 Bottom Bracket arms assembly

|

U#1 Complete Rotor

|

U#4 barrell concreting under progress

|

U#3 busduct installation under progress

|

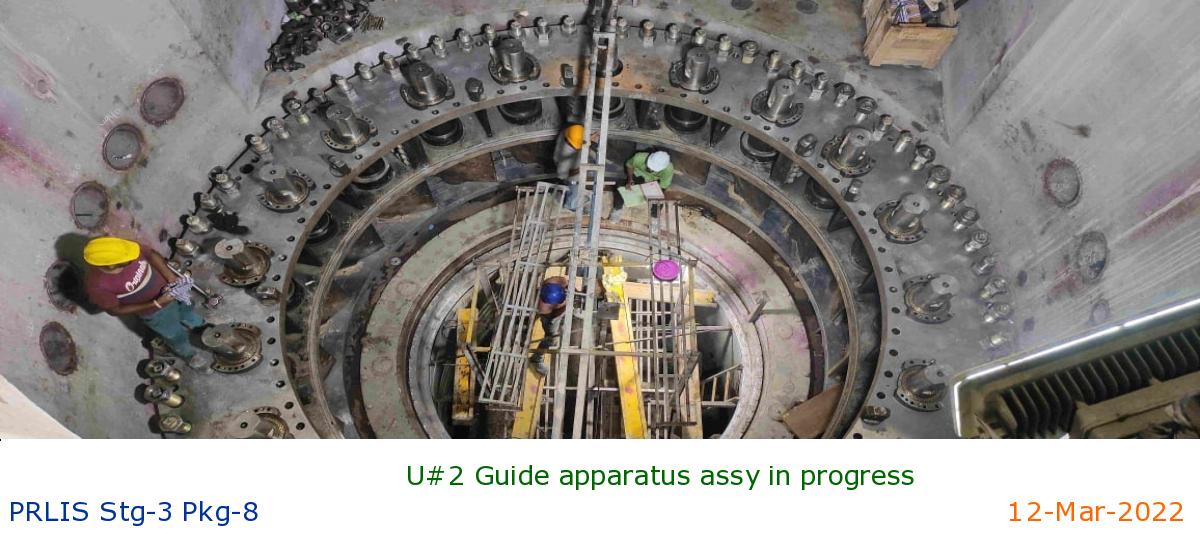

U#2 Guide apparatus assy in progress

|

U#4 stator bar laying under progress

|

U#5 spiral segments erection under progress

|

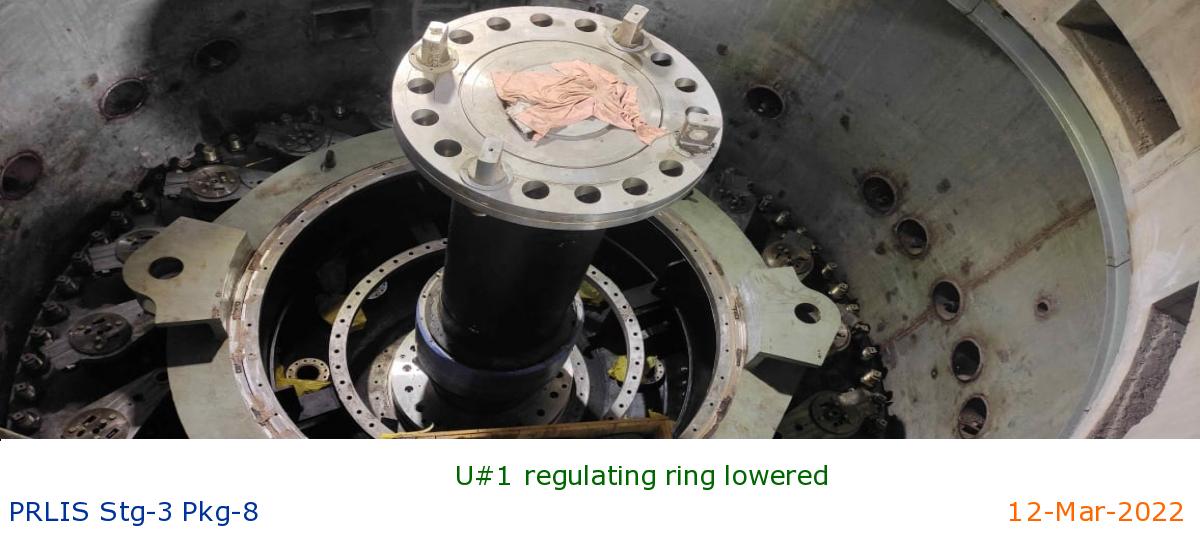

U#1 regulating ring lowered

|

U#1 Rotor poles assembly

|

U#5 spiral segments erection under progress

|

U#2 Guide apparatus assy in progress

|

U#3 Stator lowering completed

|

U#1 Runner Lowering completed

|

U#4 Pit liner installation completed

|

U#2 Stator Lowering completed

|

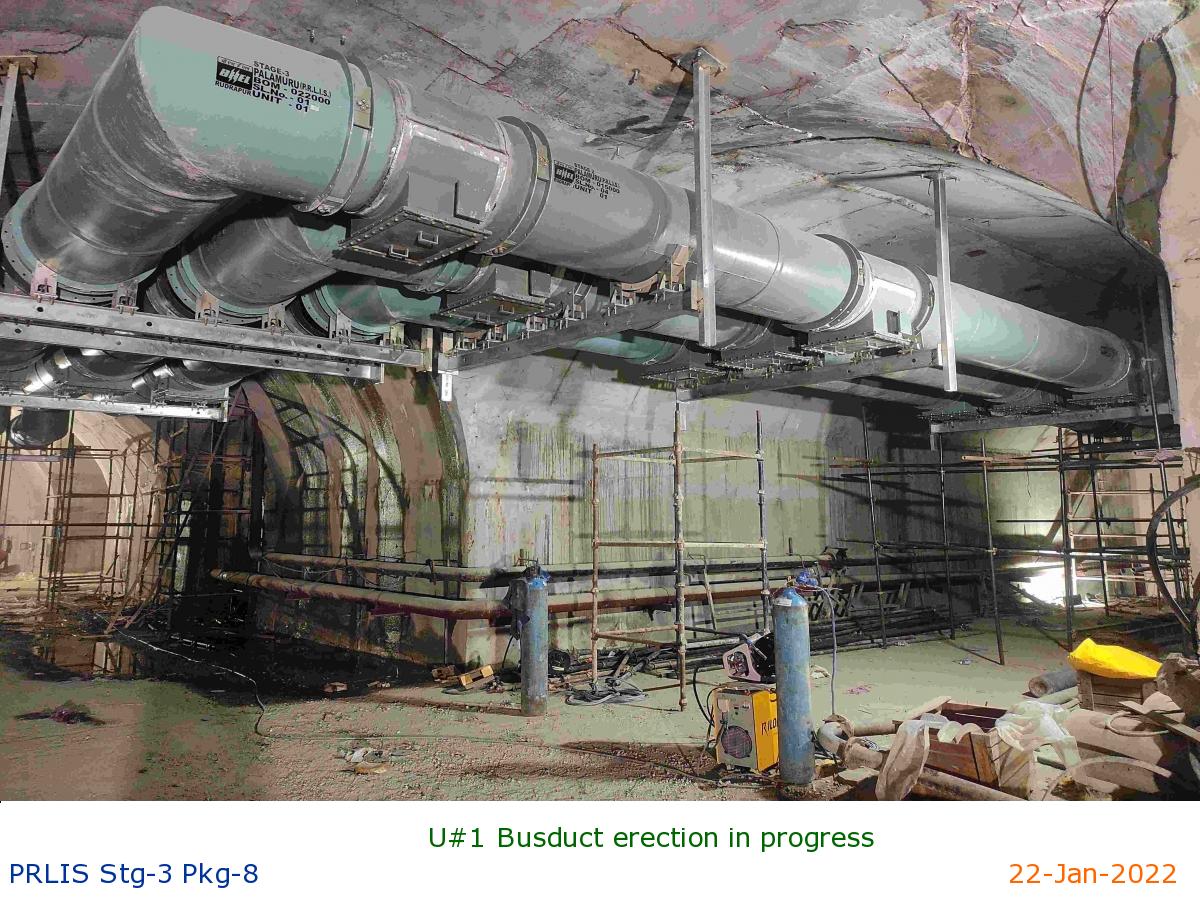

U#1 Busduct erection in progress

|

U#1 Guide Apparatus erection in progress

|

U#2 stator joints brazing completed

|

U#2 Bus duct erection in progress

|

U#1 Rotor Rim building in progress

|

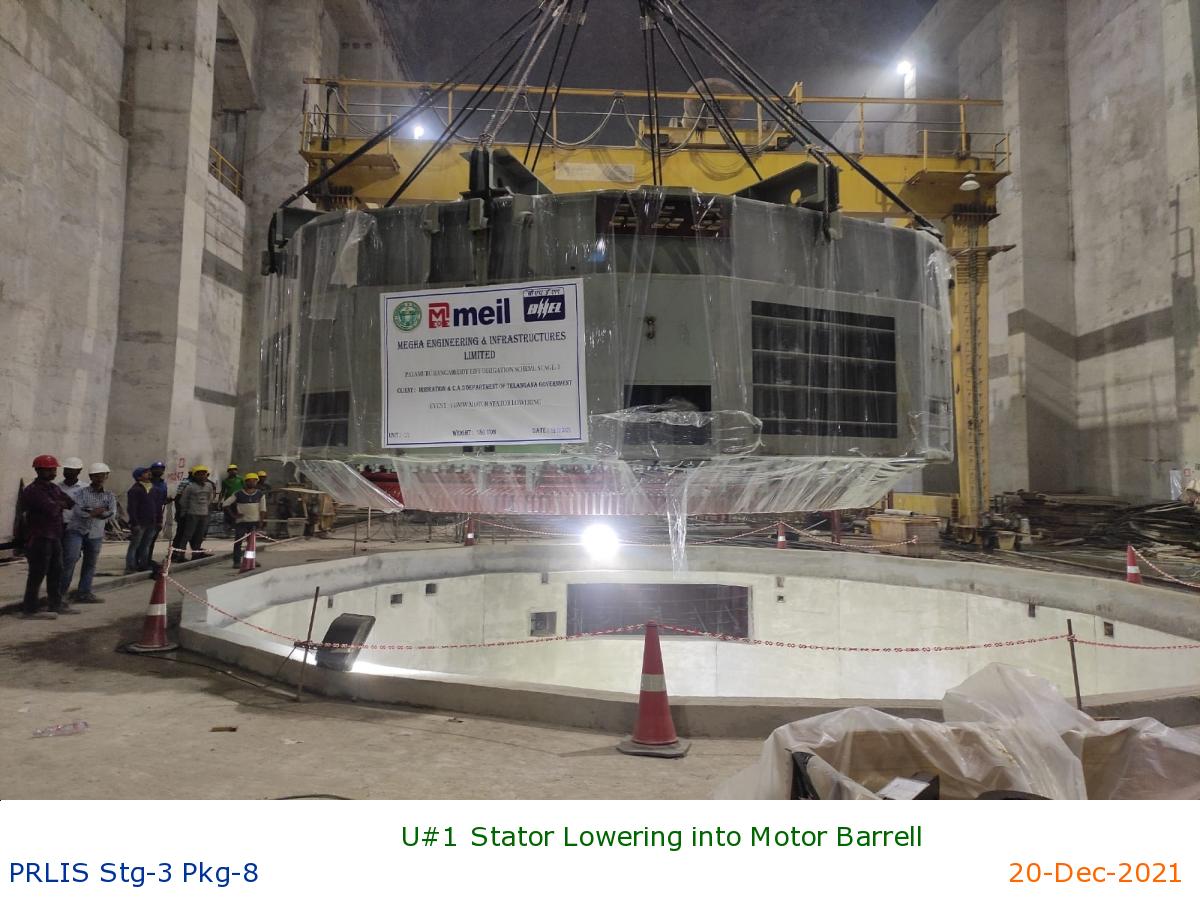

U#1 Stator Lowering completed

|

U#1 Stator Lowering into Motor Barrell

|

U#1 Busduct erection under progress

|

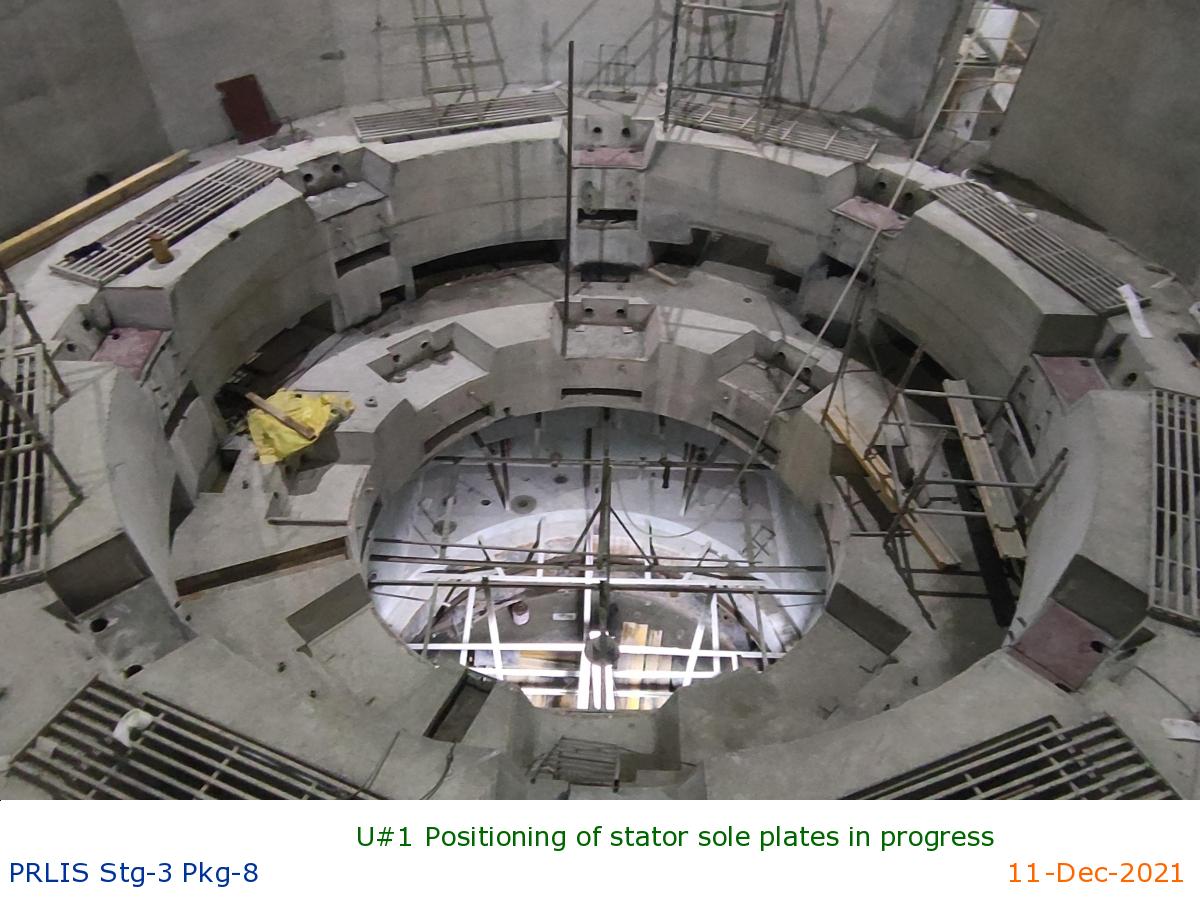

U#1 Positioning of stator sole plates in progress

|

U#4 Pitliner halves welding completed

|

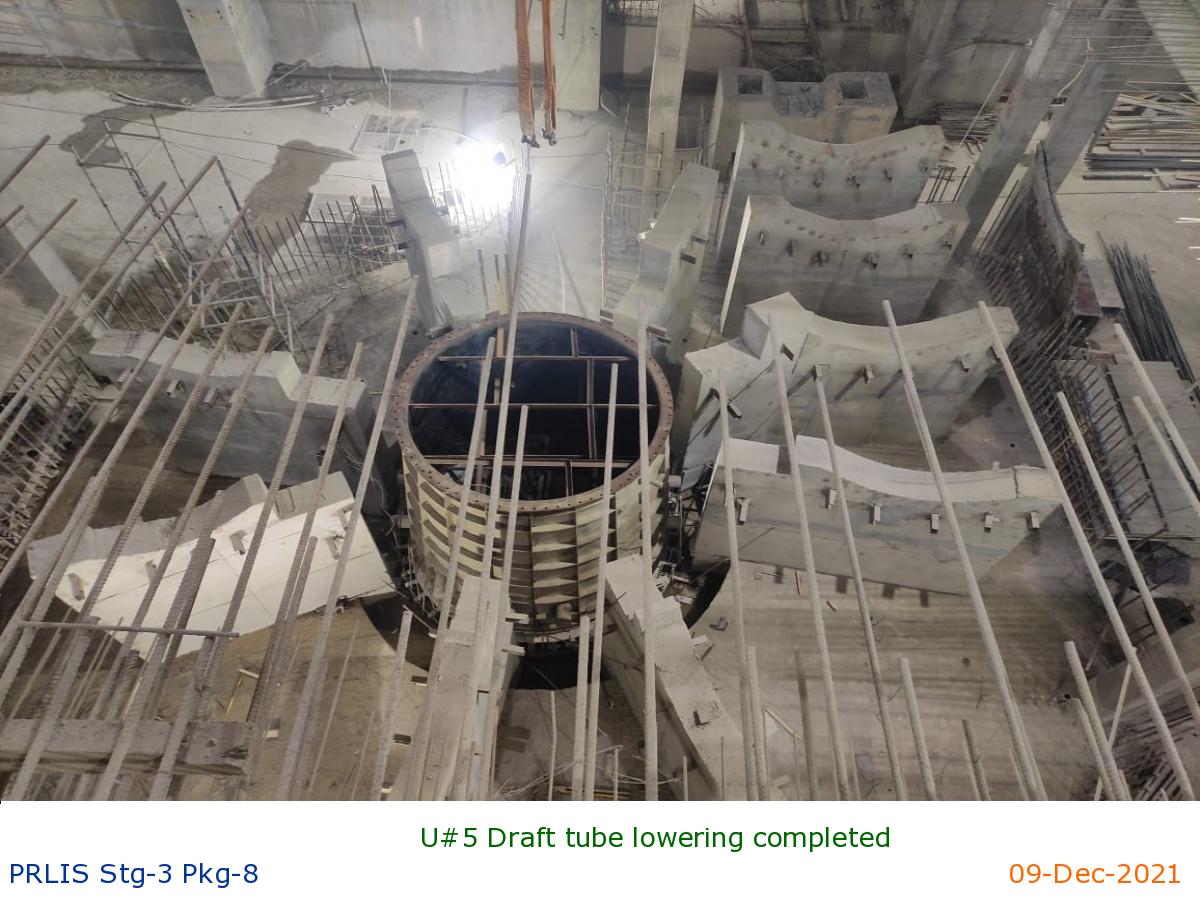

U#5 Draft tube lowering completed

|

U#2 Stator Sole plate sleeves installation

|

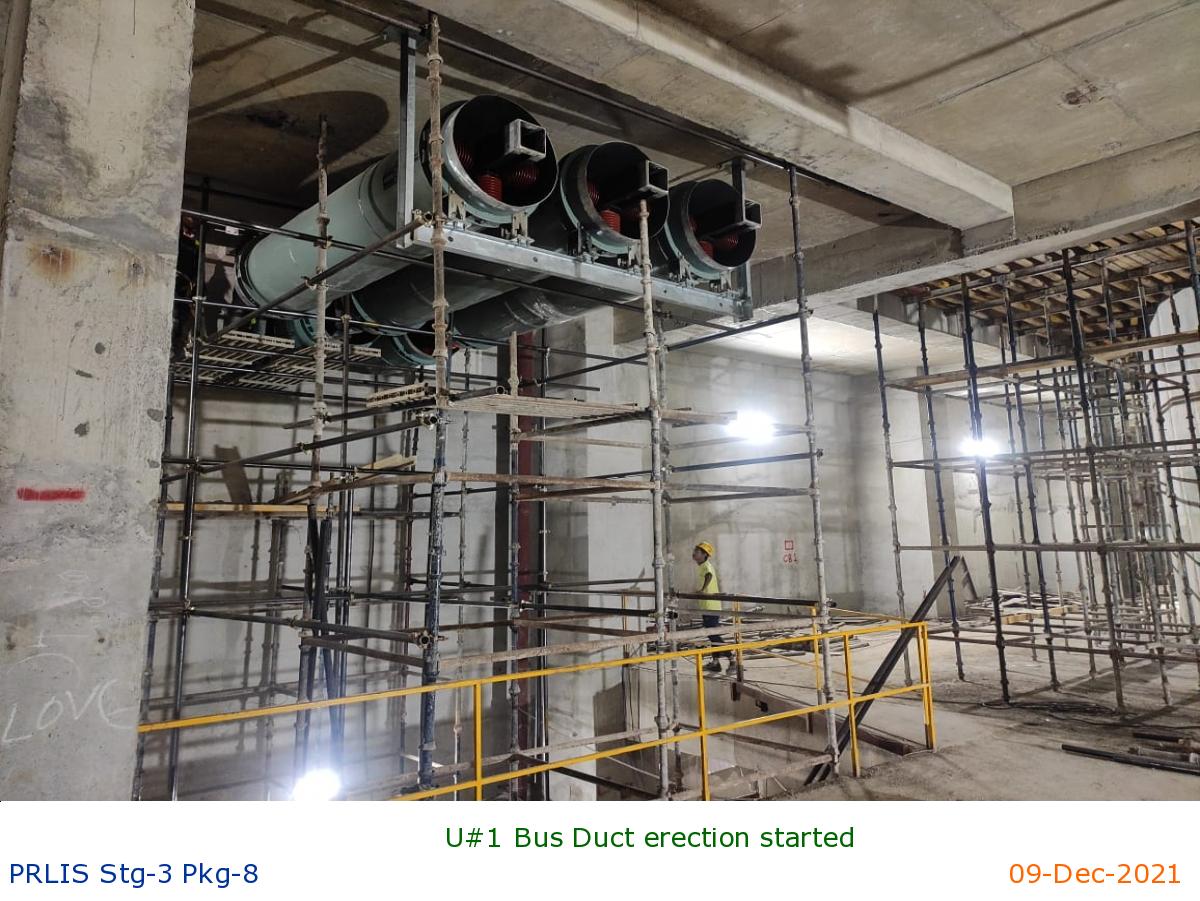

U#1 Bus Duct erection started

|

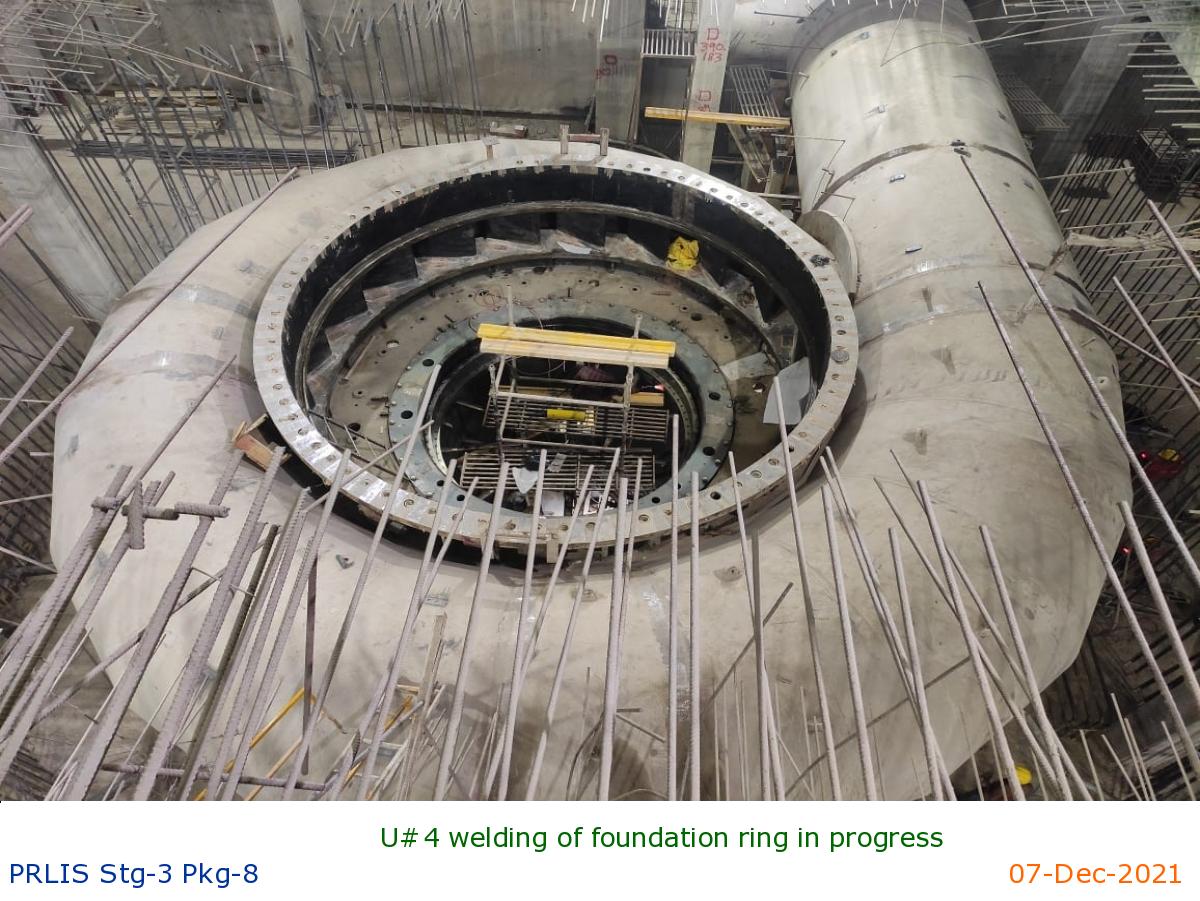

U#4 welding of foundation ring in progress

|

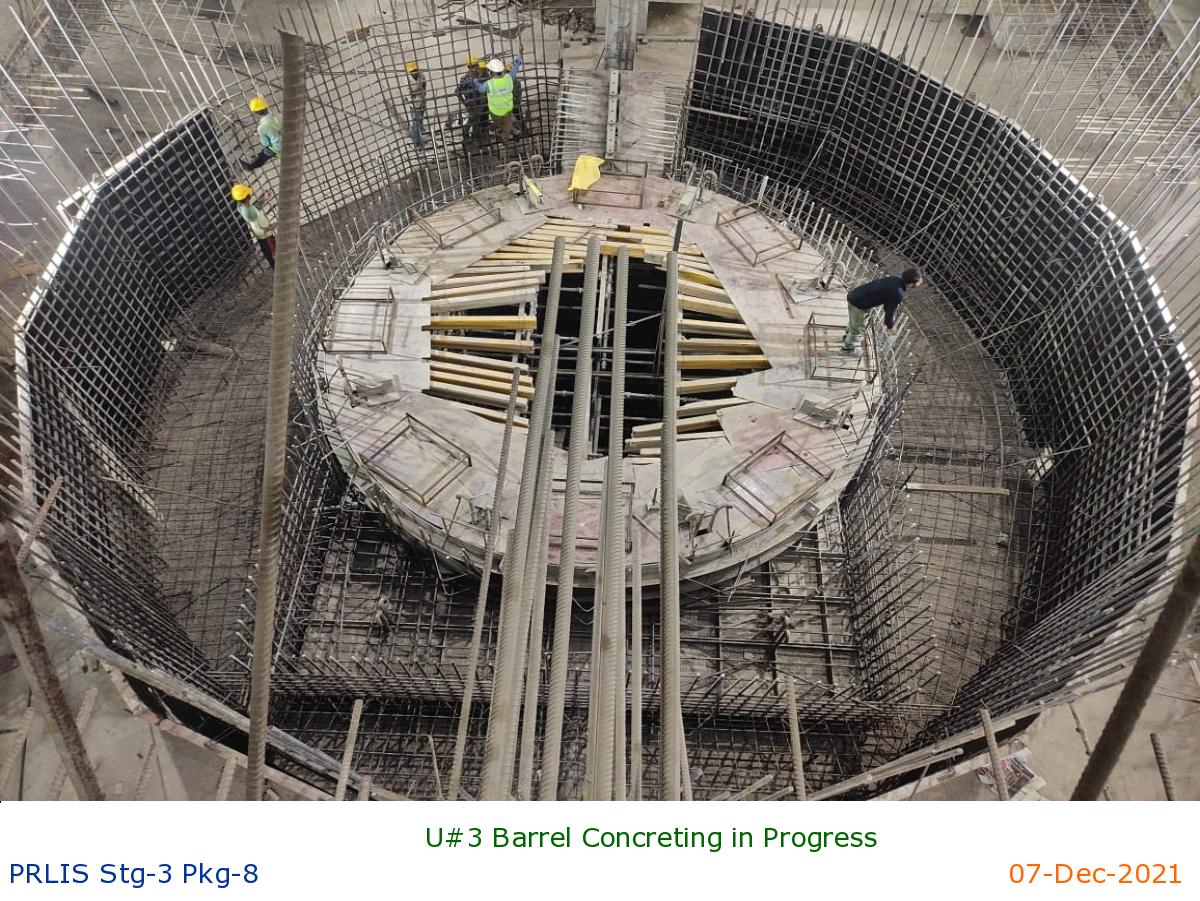

U#3 Barrel Concreting in Progress

|

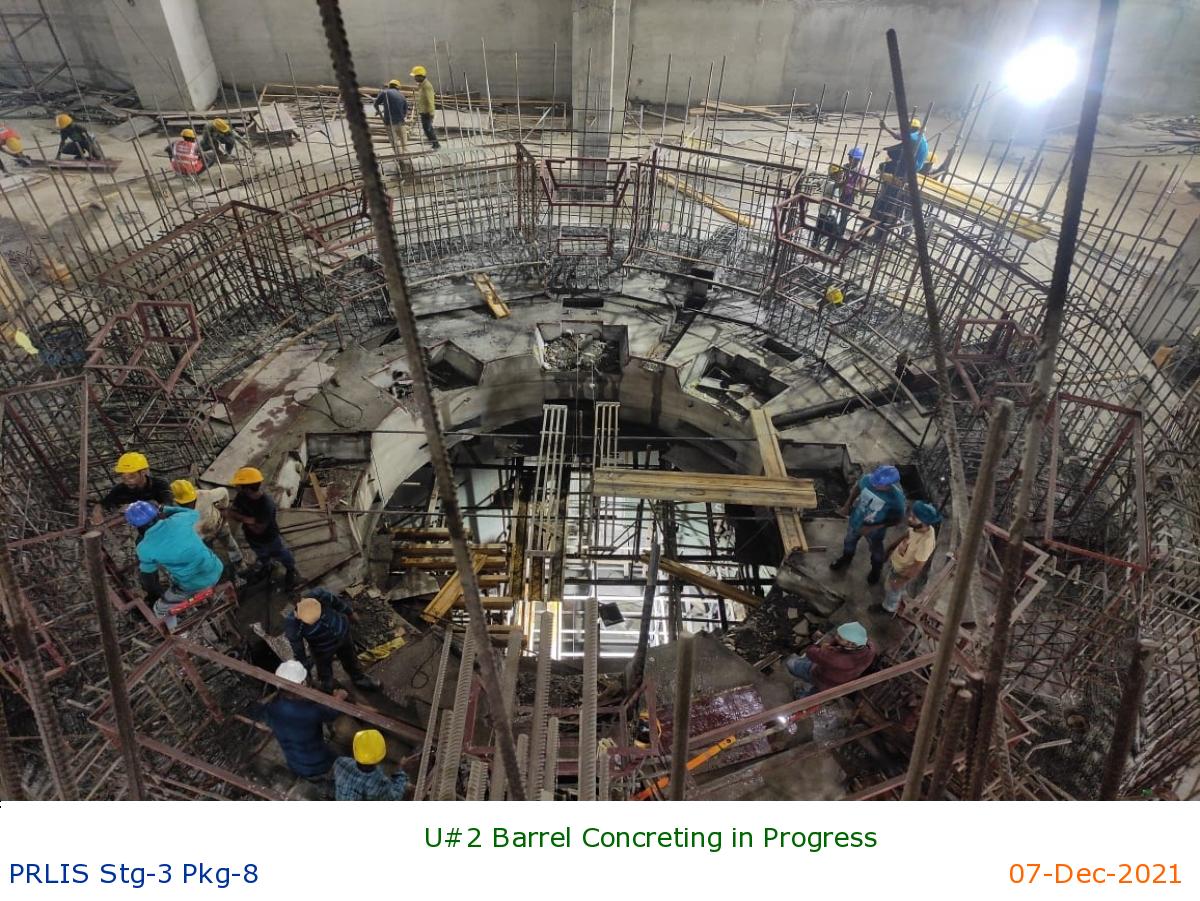

U#2 Barrel Concreting in Progress

|

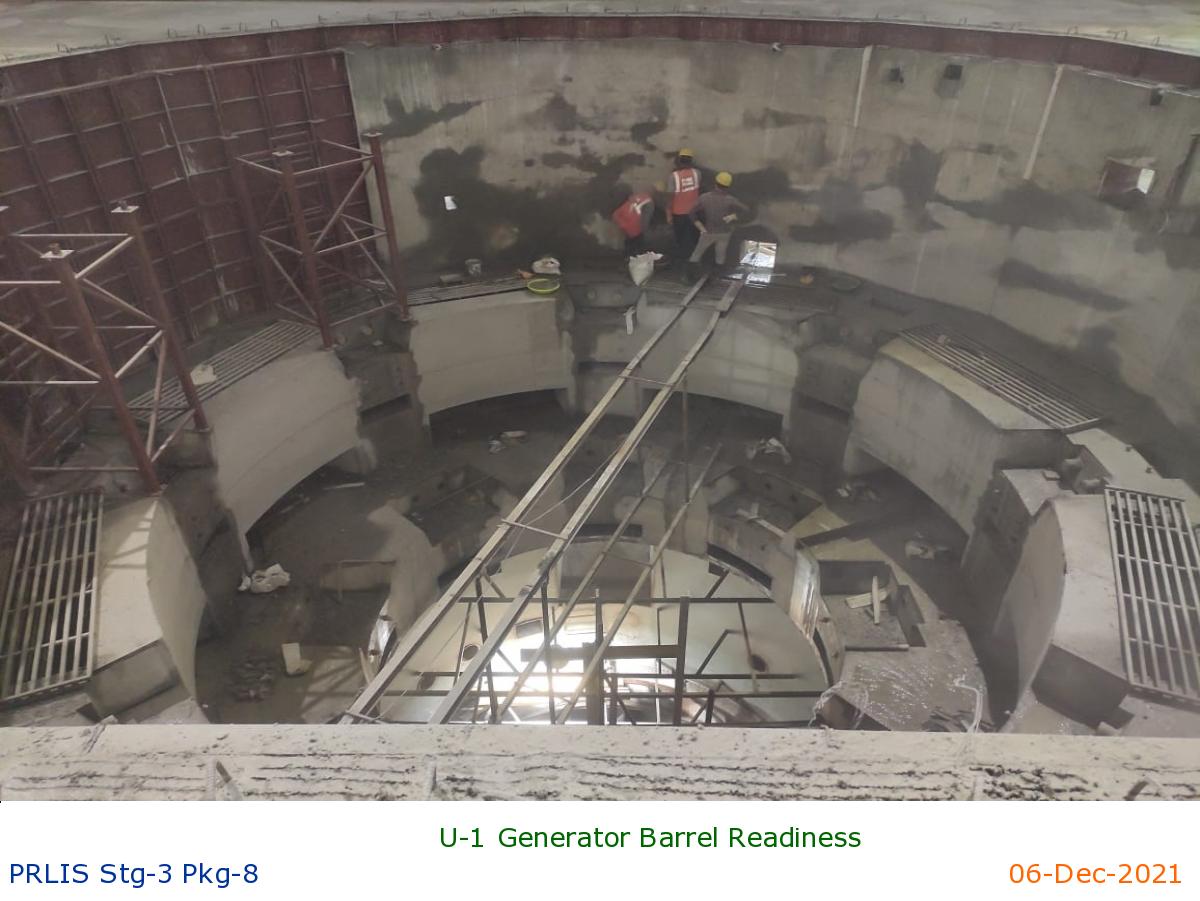

U-1 Generator Barrel Readiness

|

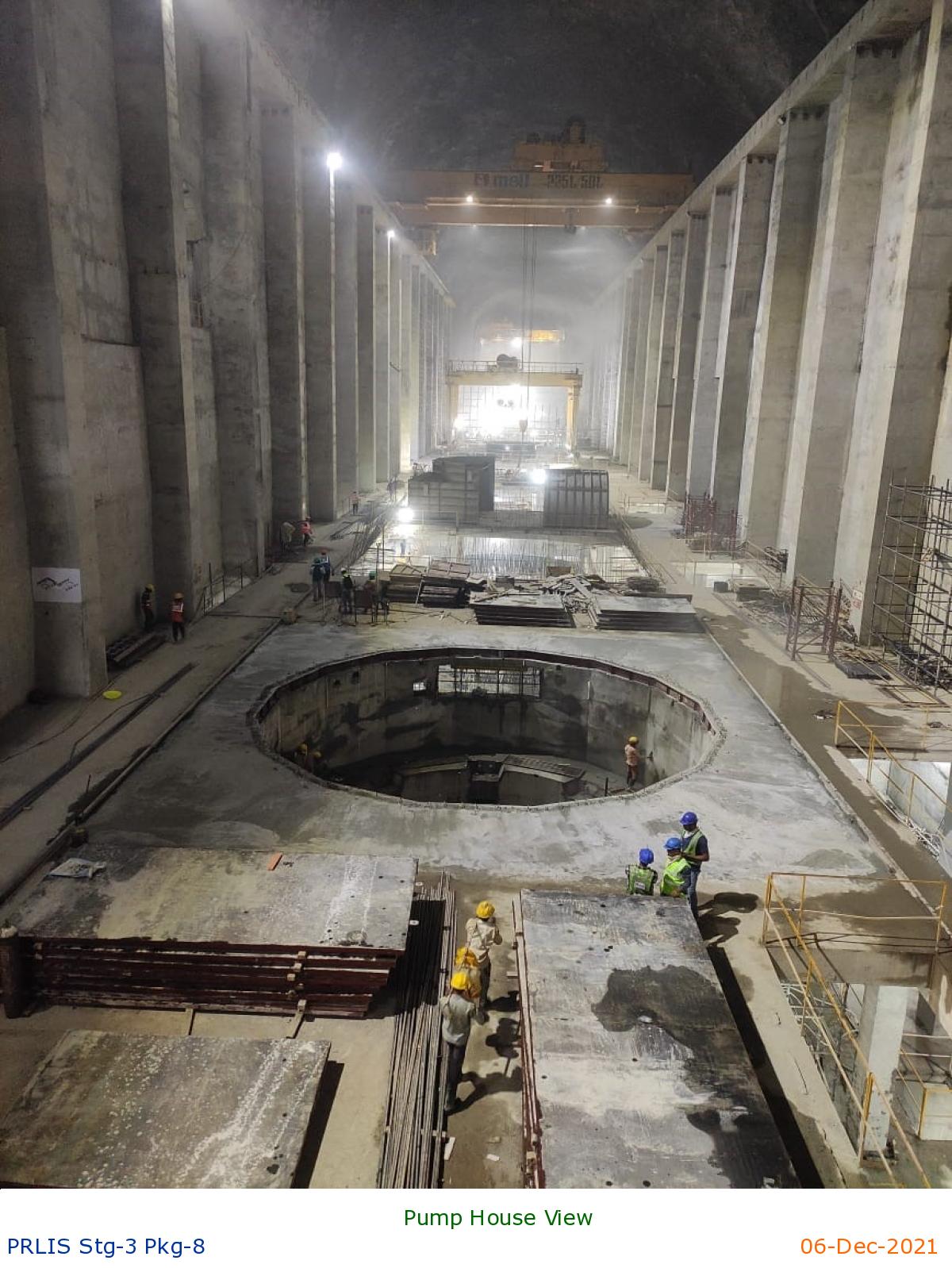

Pump House View

|

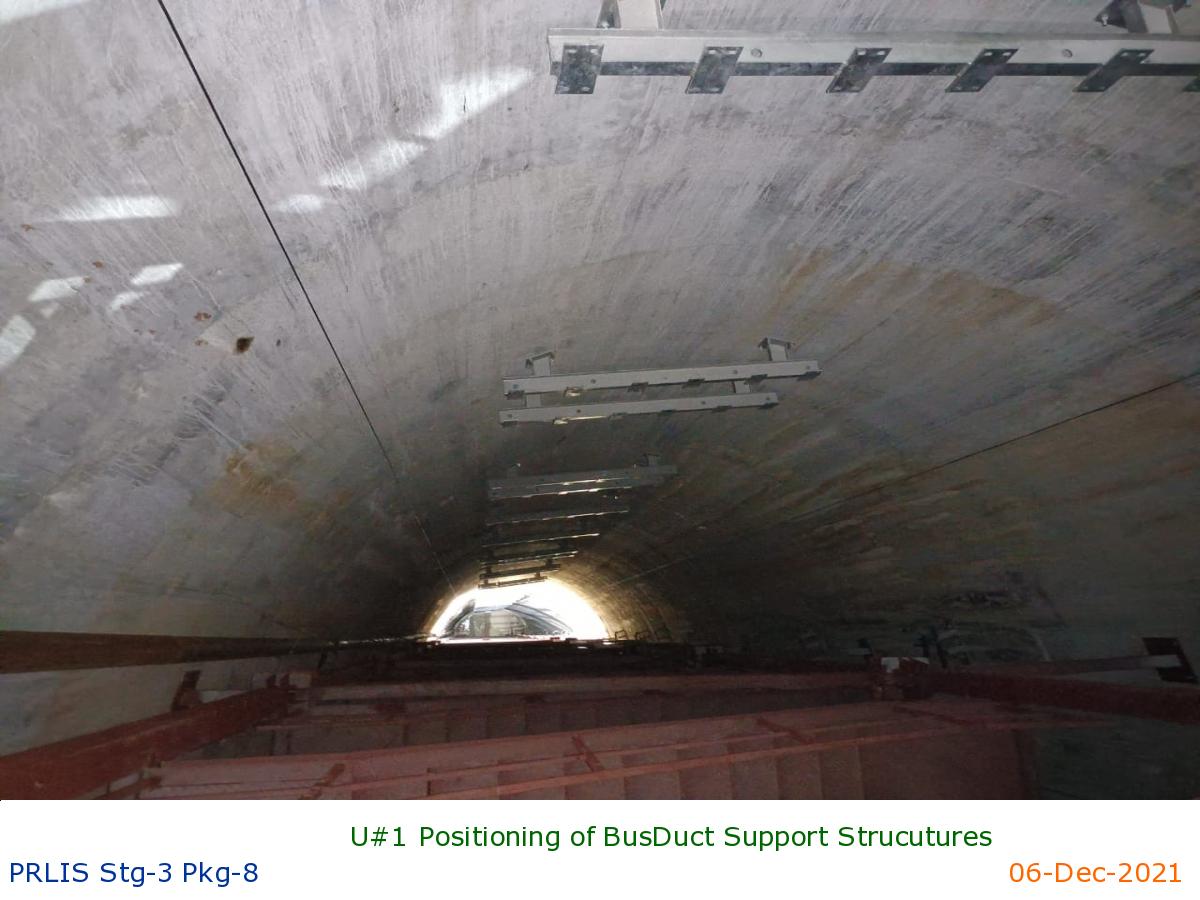

U#1 Positioning of BusDuct Support Strucutures

|

Assembly of Stator Lifting Frame is in progress

|

Unit 6-10 Civil Work under progress

|

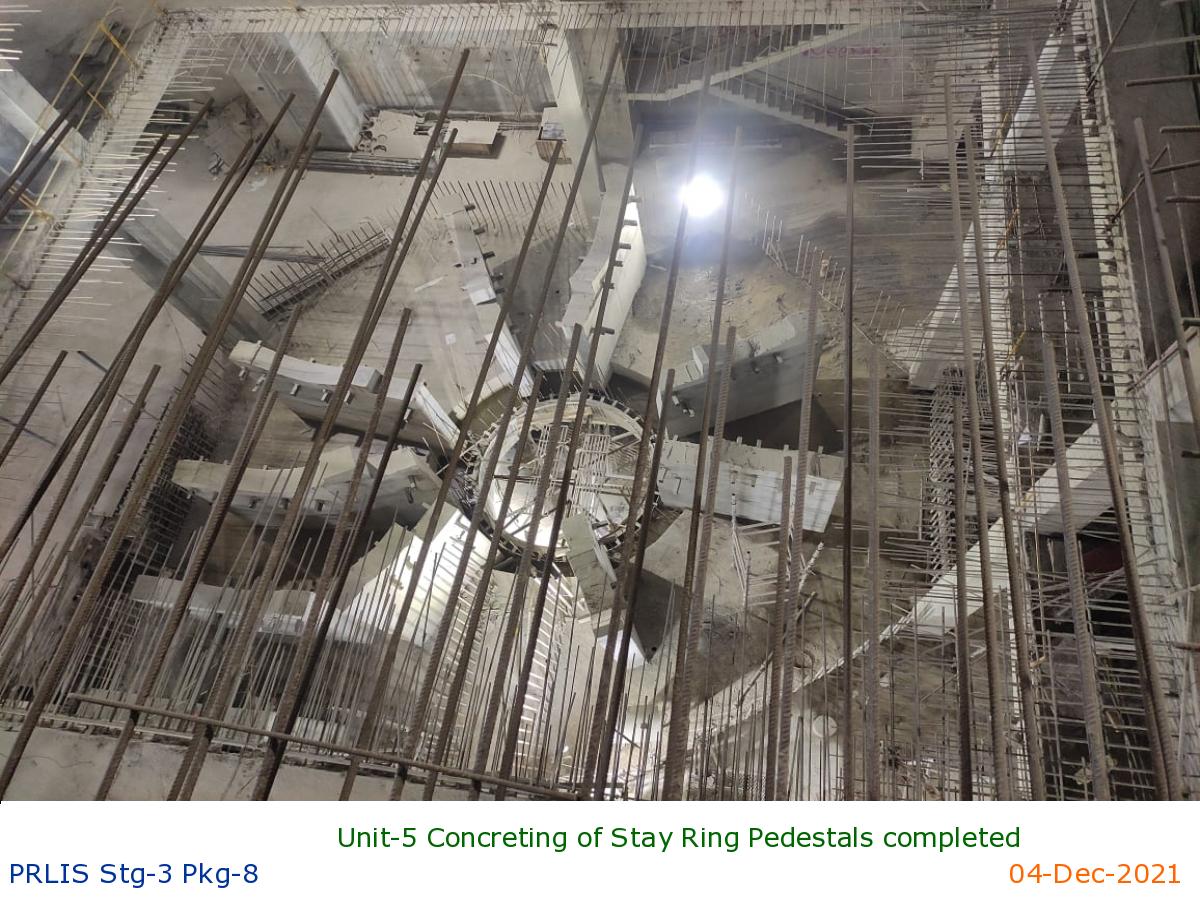

Unit-5 Concreting of Stay Ring Pedestals completed

|

Unit-4 Erection of Foundation Ring completed.

|

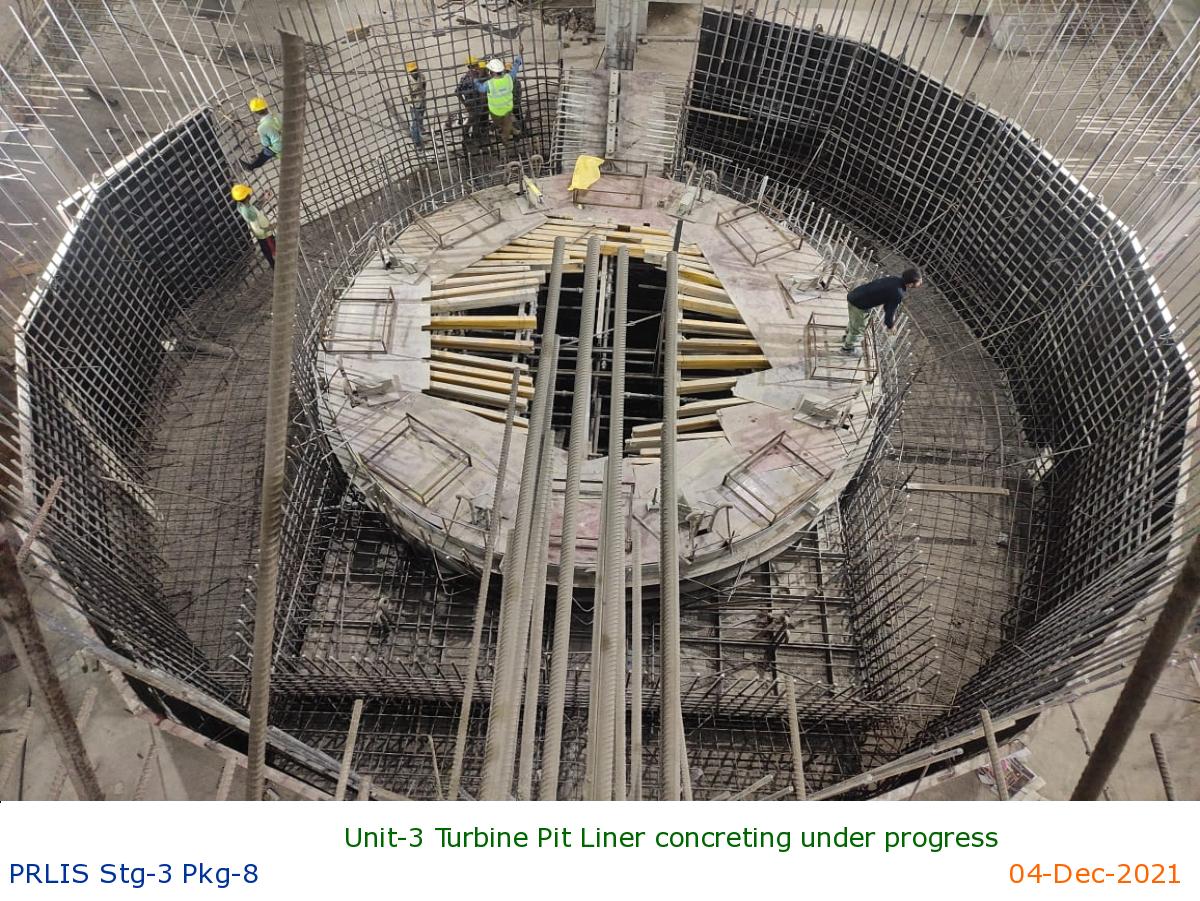

Unit-3 Turbine Pit Liner concreting under progress

|

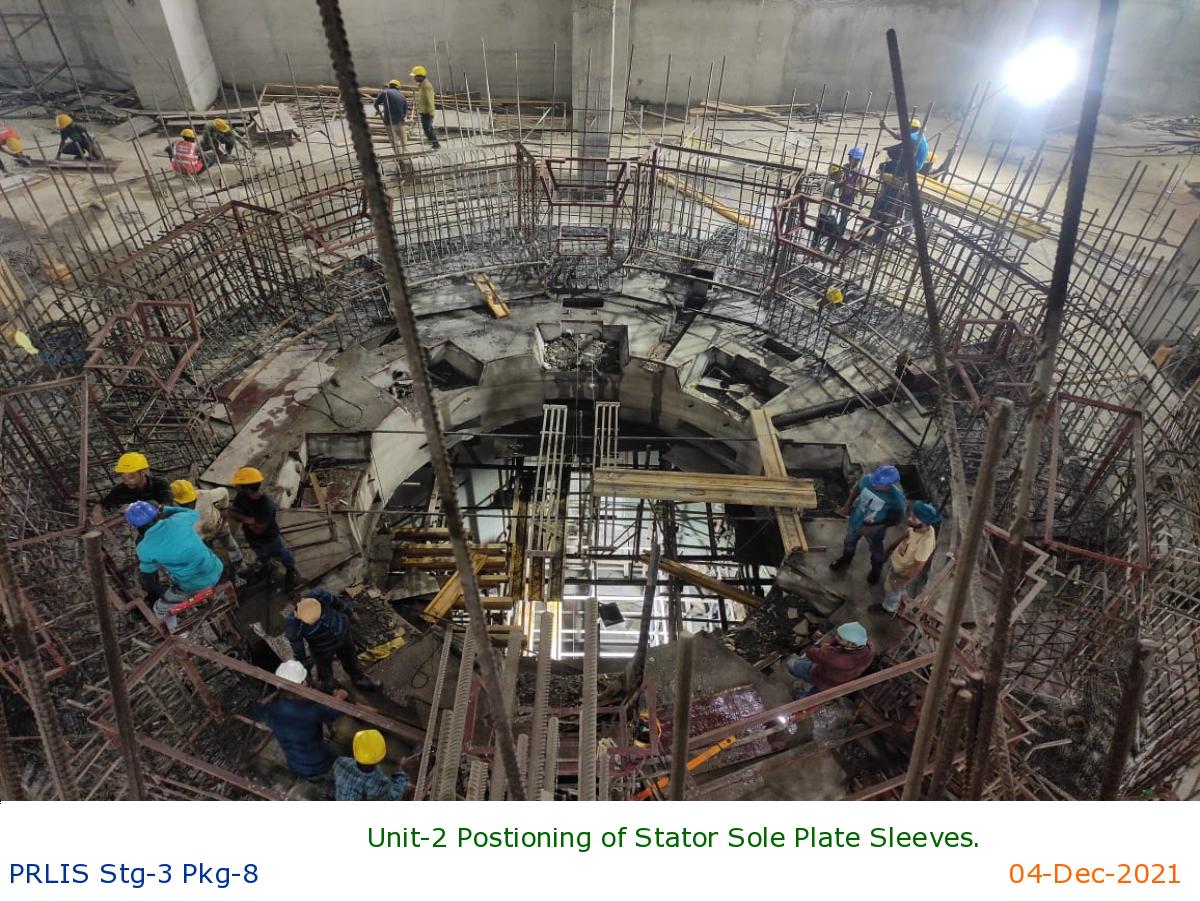

Unit-2 Postioning of Stator Sole Plate Sleeves.

|

Unit-1 Motor Barrell concreting completed.

|

PRLIS Stage-3: View of from Main Service Bay

|

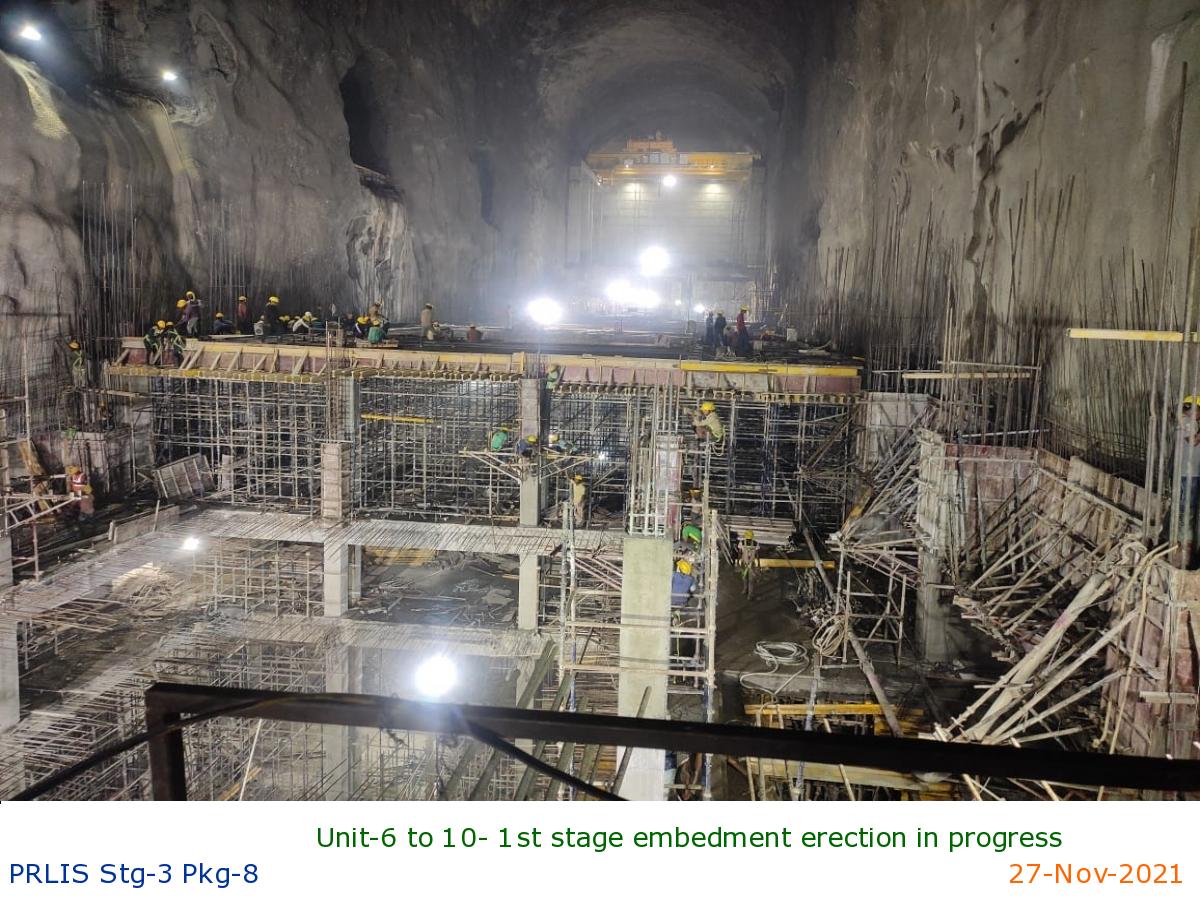

Unit-6 to 10- 1st stage embedment erection in progress

|

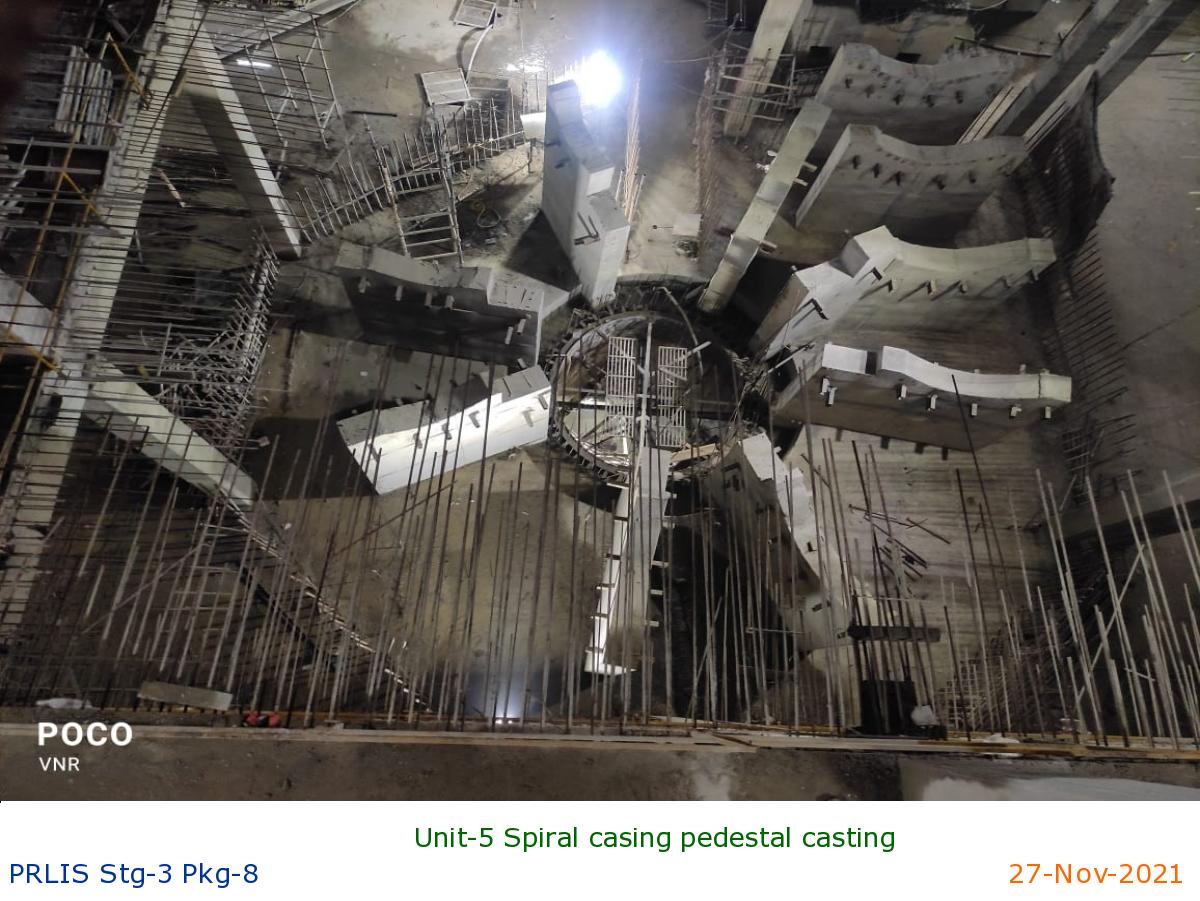

Unit-5 Spiral casing pedestal casting

|

Unit-4 Foundation ring assy in progress

|

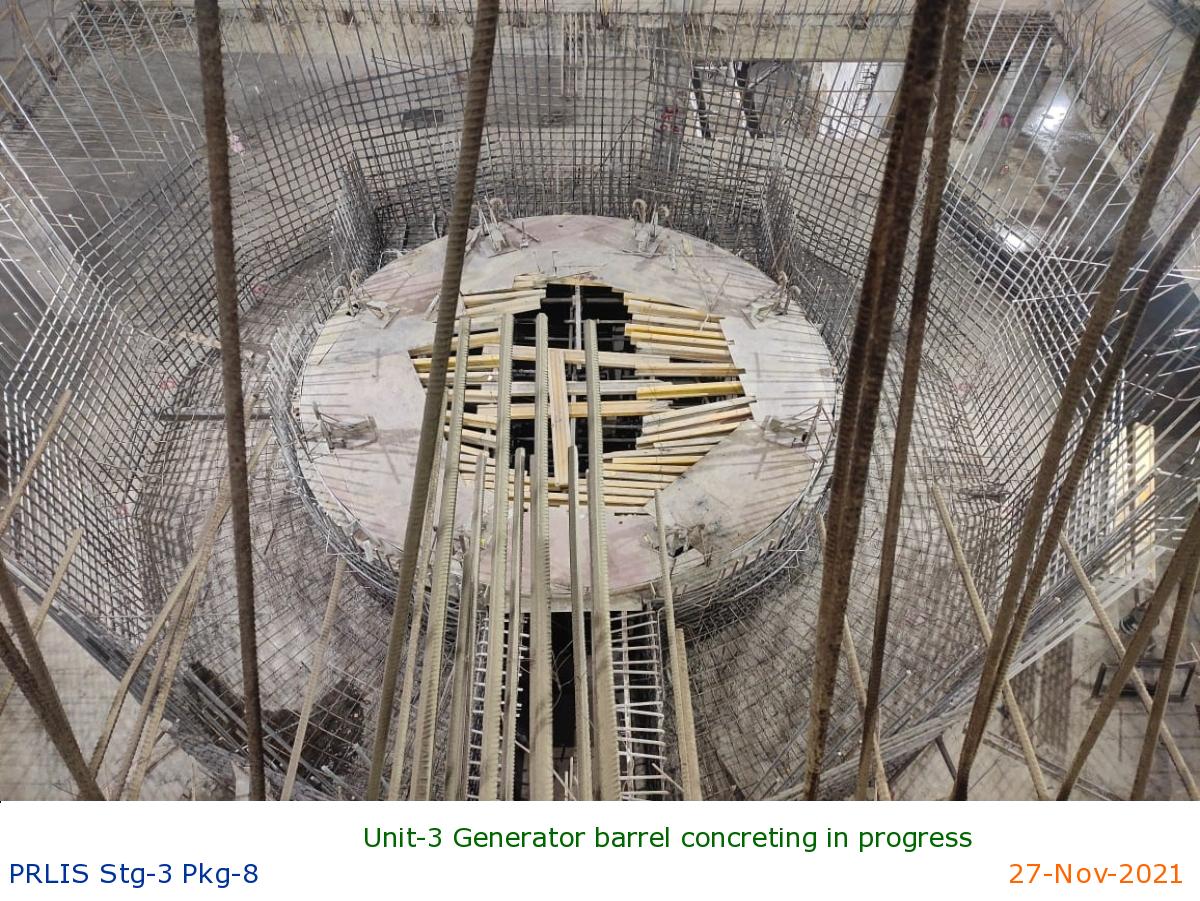

Unit-3 Generator barrel concreting in progress

|

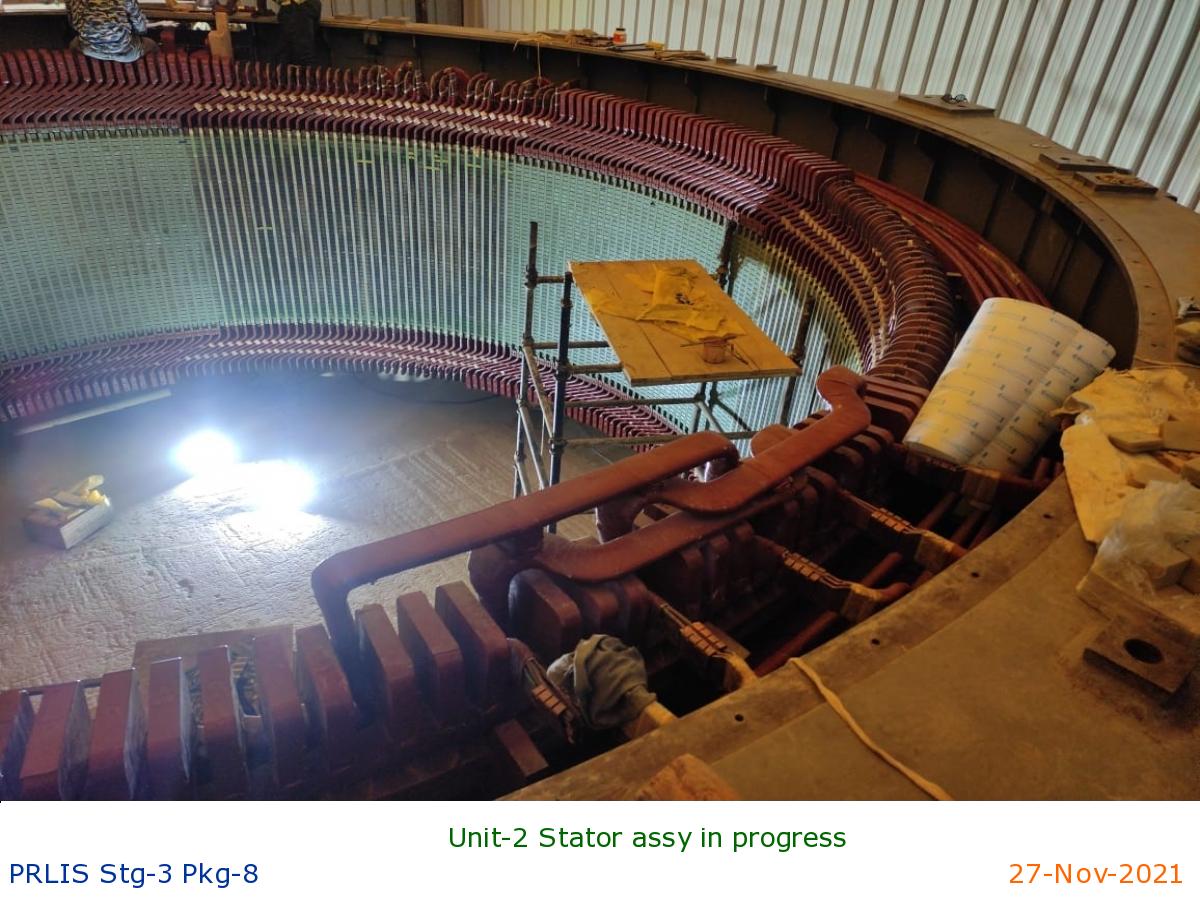

Unit-2 Stator assy in progress

|

Unit-2 Generator barrel concreting in progress

|

Unit-1 Generator barrel concreting in progress

|