U#4 Impeller nut guard installation

|

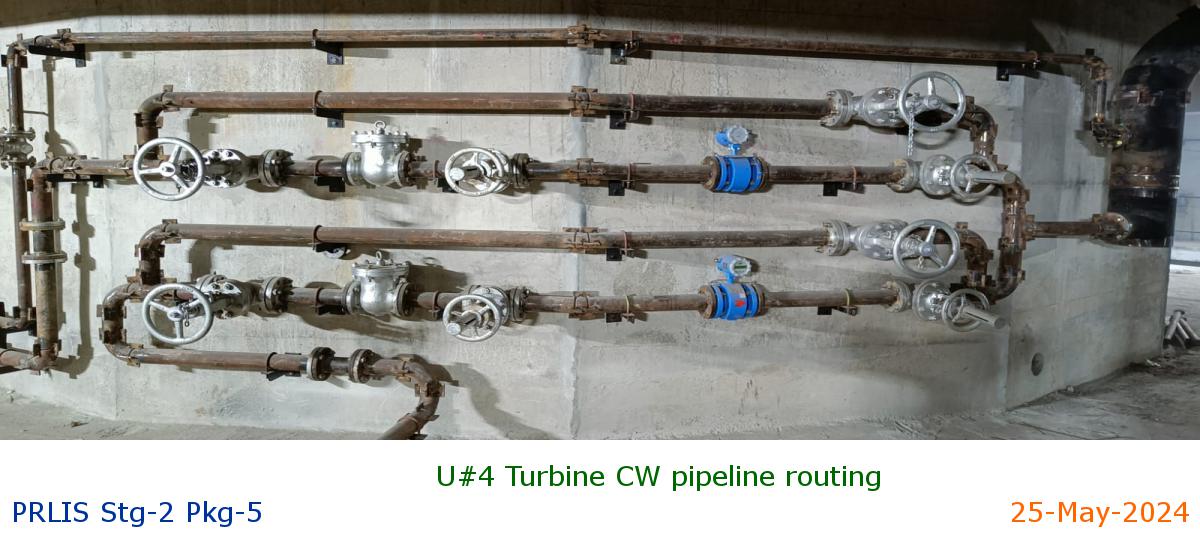

U#4 Turbine CW pipeline routing

|

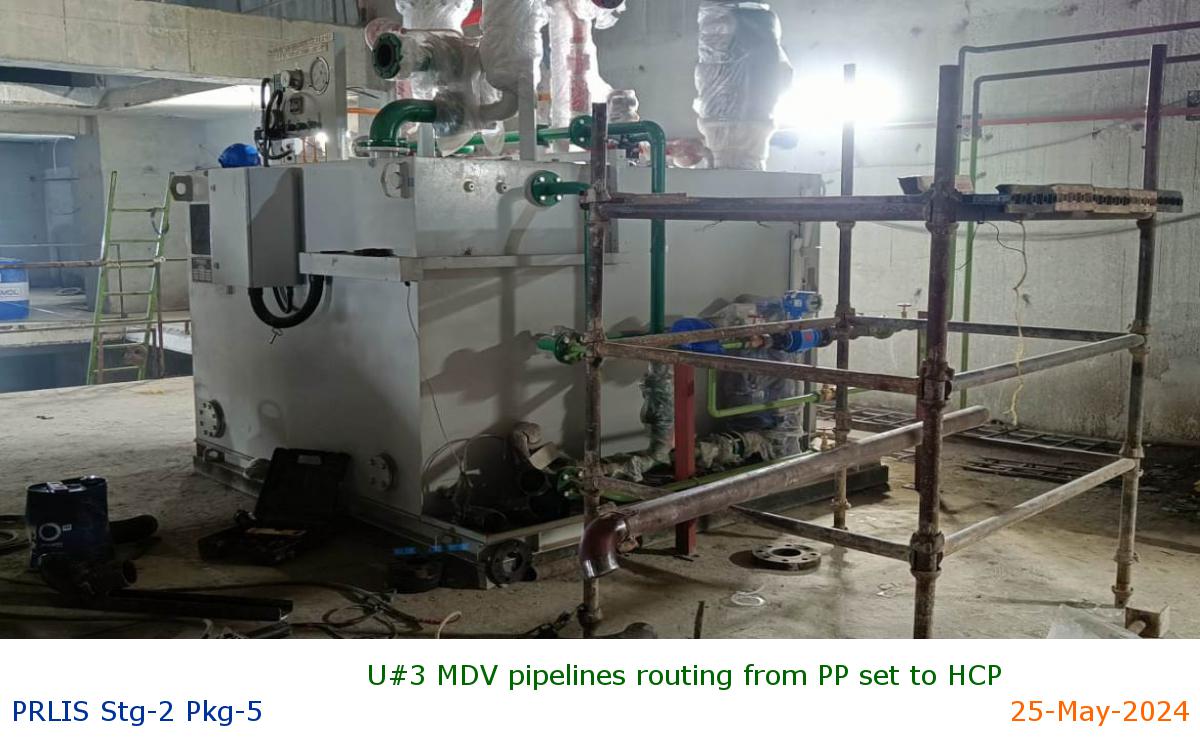

U#3 MDV pipelines routing from PP set to HCP

|

U#3 UGB oil filling completed

|

U#2 MDV Maintenance seal and body drain piping

|

Second set of compressor additional service bay

|

U#4 Pit air seal installation in progress

|

U#3 Top vapor seal installation

|

Compressors installation in additional servicebay

|

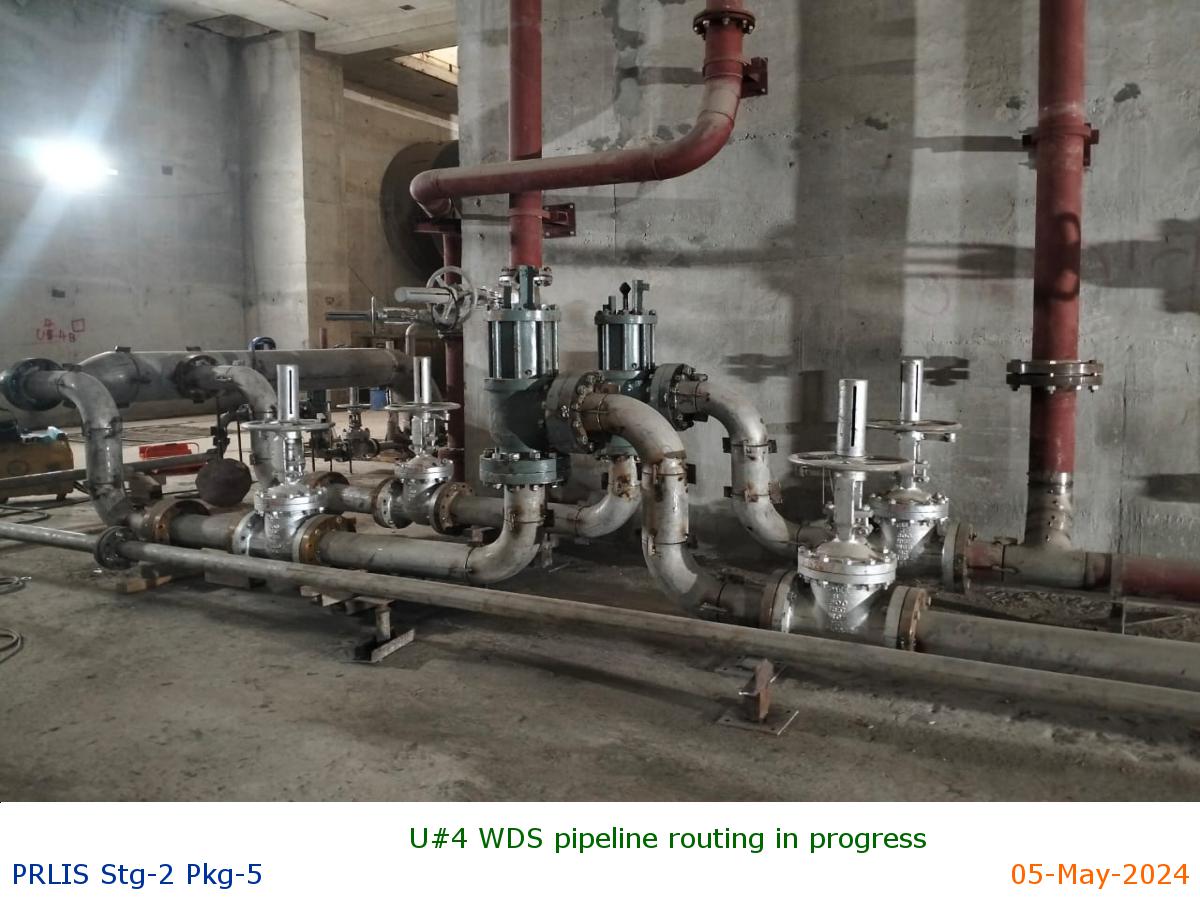

U#4 WDS pipeline routing in progress

|

U#3 Brake dust collector installation in progress

|

U#4 MDV cleaning in progres

|

U#4 Motor floor plates installation in progress

|

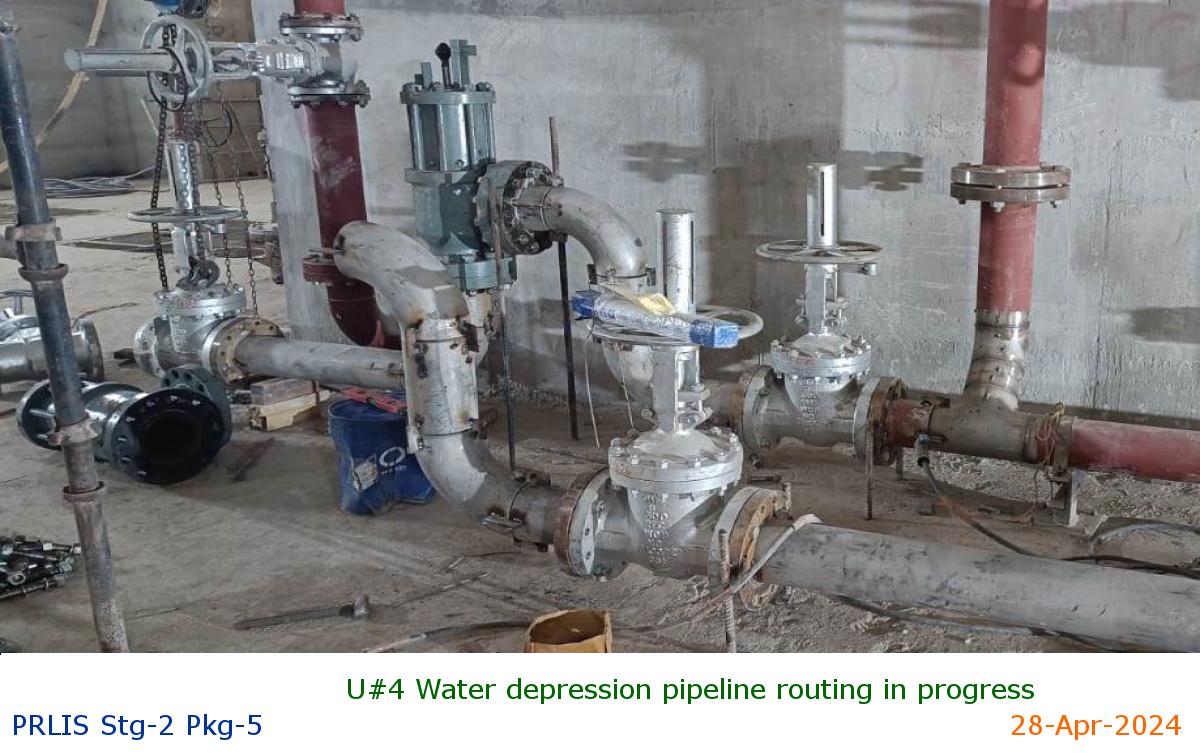

U#4 Water depression pipeline routing in progress

|

U#3 Water and air pipelines in pit welding in prog

|

U#3 oil manifold pipeline routing in progress

|

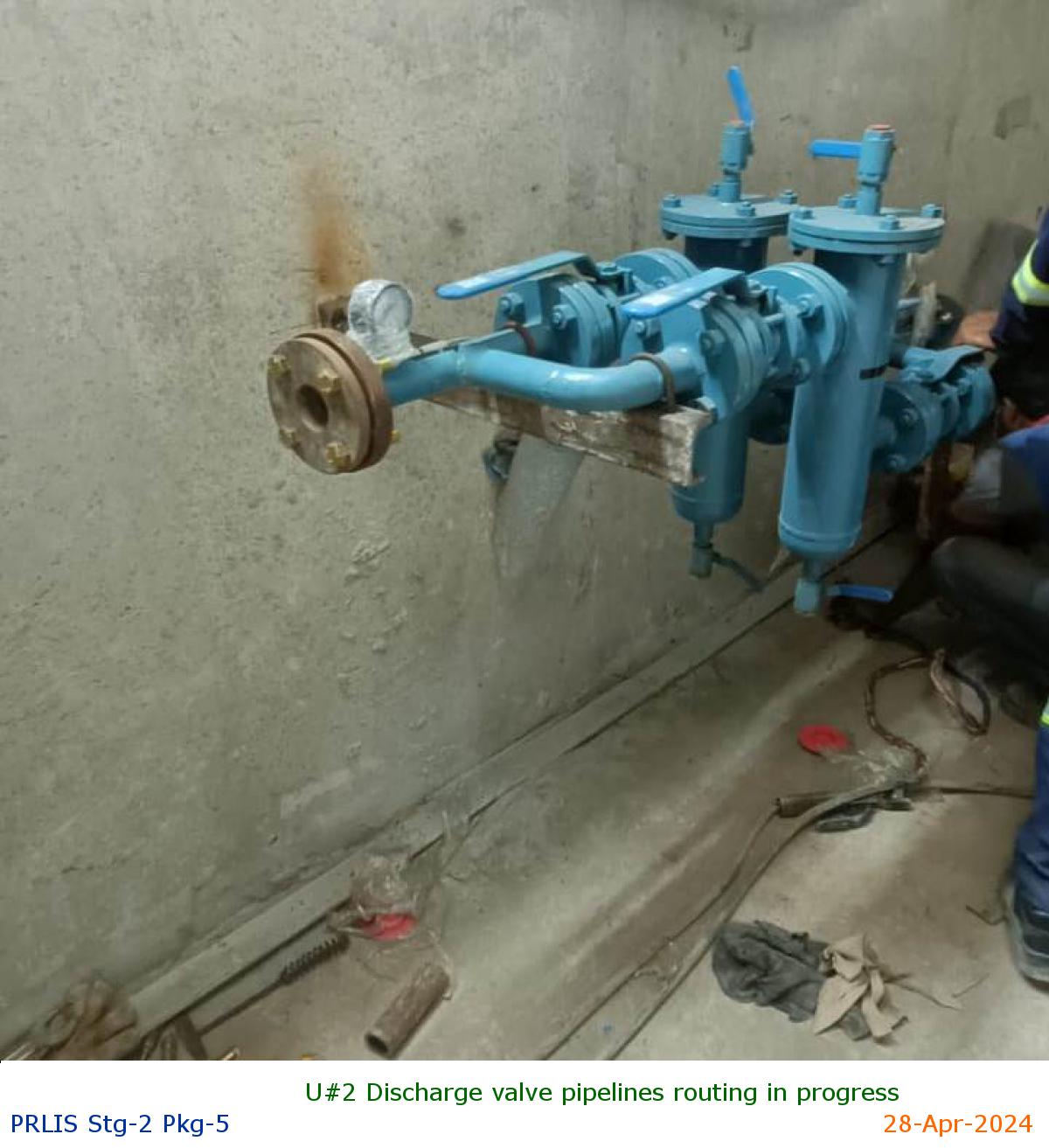

U#2 Discharge valve pipelines routing in progress

|

U#2 MDV Servomotor Secondary concreting completed

|

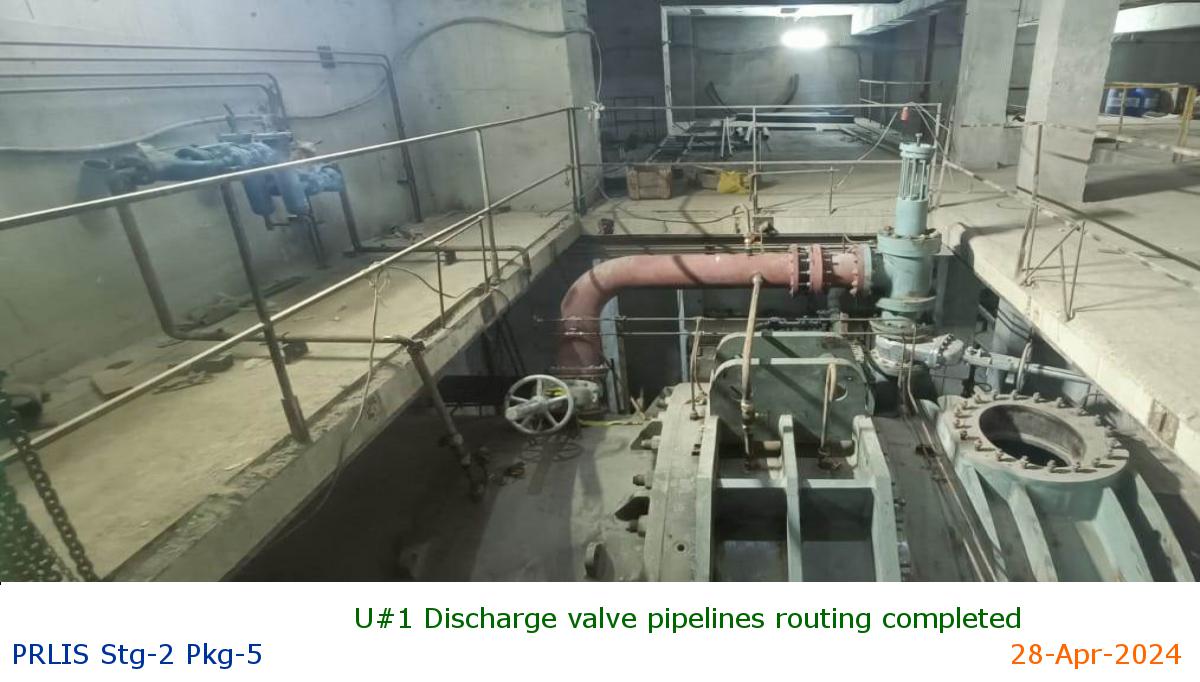

U#1 Discharge valve pipelines routing completed

|

U#4 CW pipeline routing in progress

|

U#3 Water and air pipelines inside turbine pit routing i/p

|

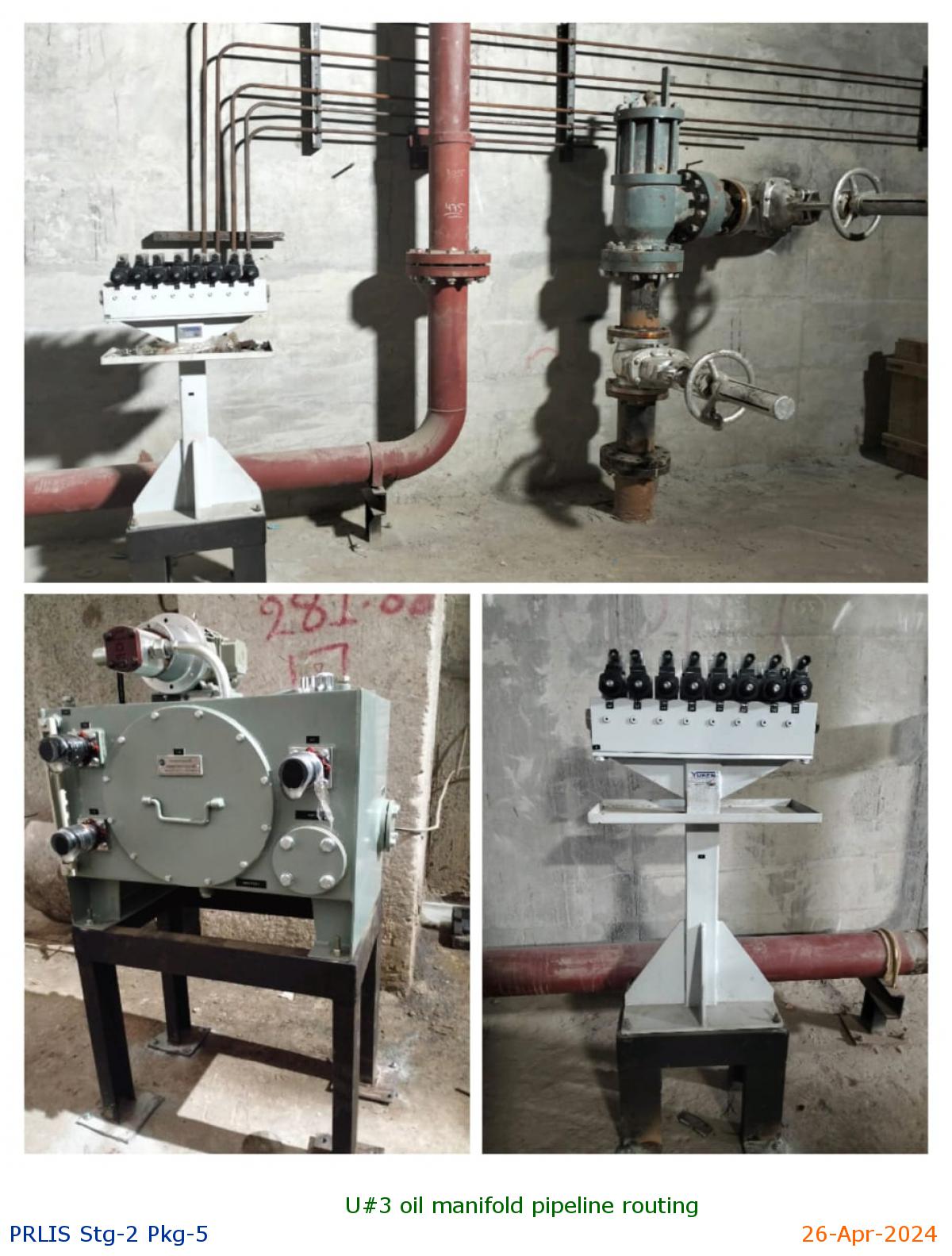

U#3 oil manifold pipeline routing

|

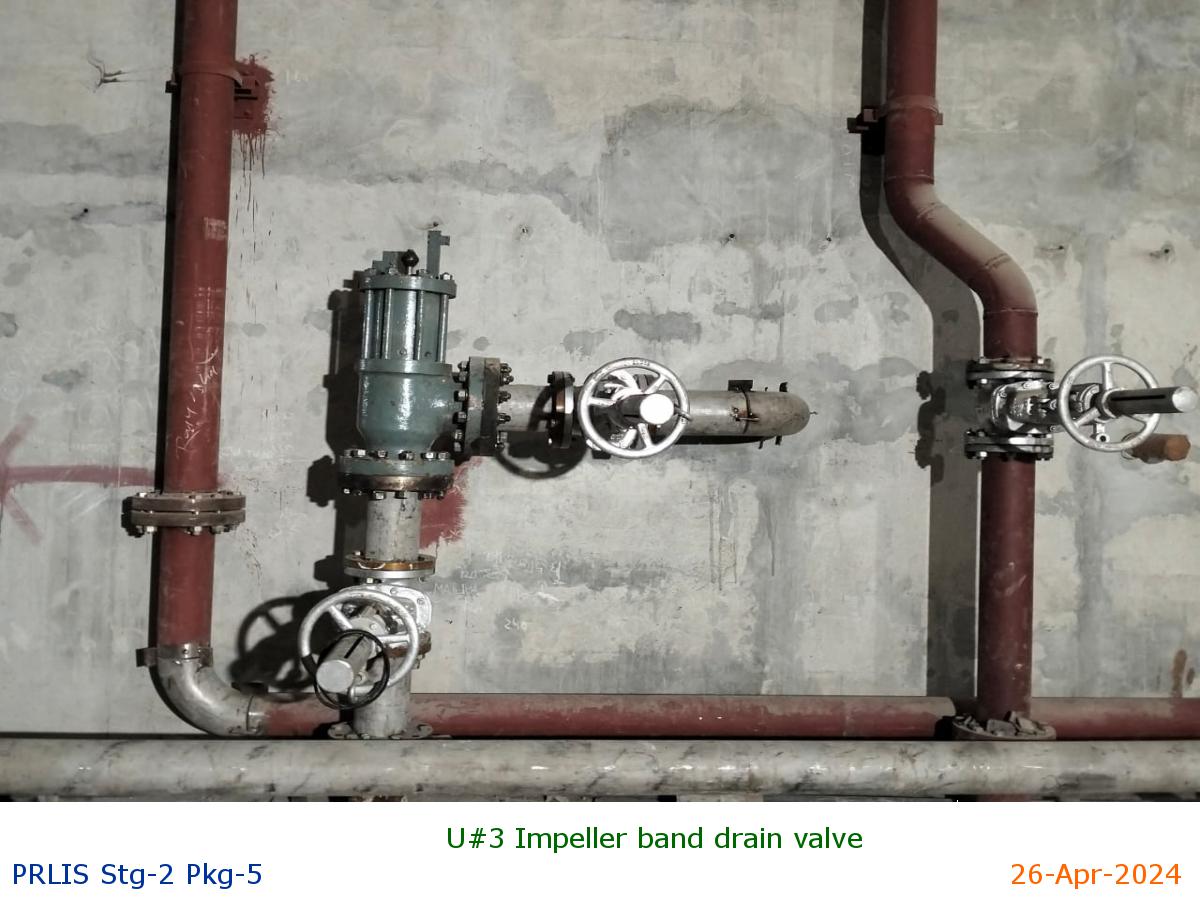

U#3 Impeller band drain valve

|

U#3 Top air baffle installation in progress

|

U#5 Rotor rim building in progress

|

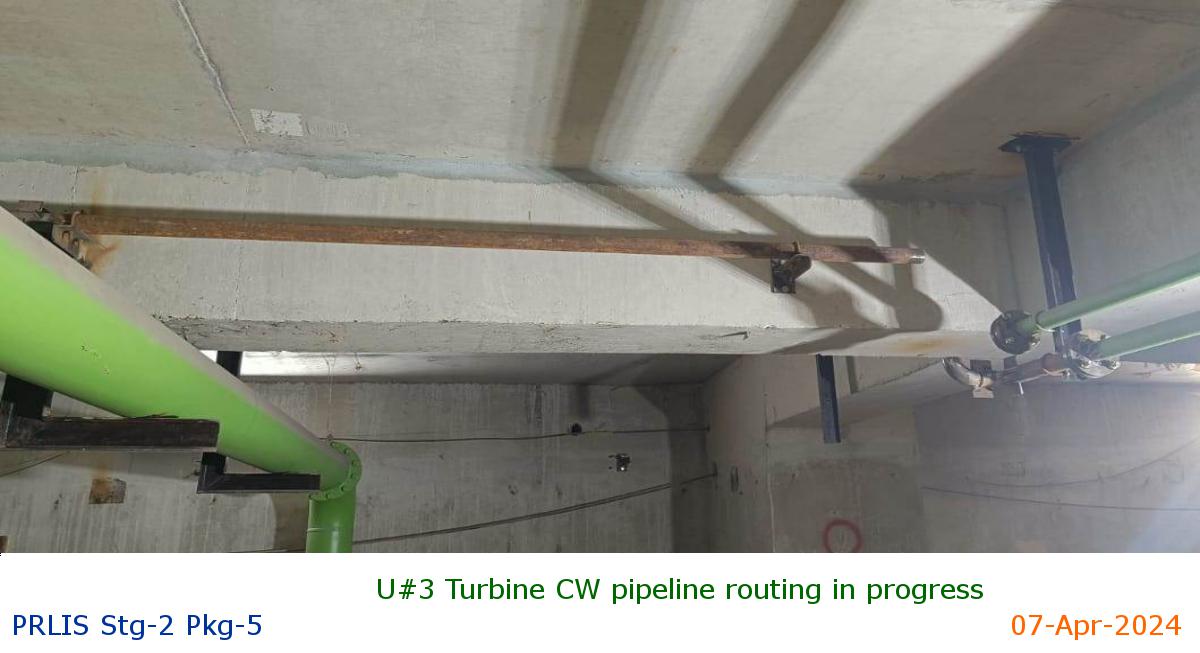

U#3 Turbine CW pipeline routing in progress

|

U#3 Water depression pipeline routing in progress

|

U#2 MDV Servomotor alignment completed

|

U#8 stayring joint welding is completed

|

U#7 stay ring joint welding in progress

|

U#5 Rotor rim building in progress

|

U#2 Bypass valve pipeline assy completed

|

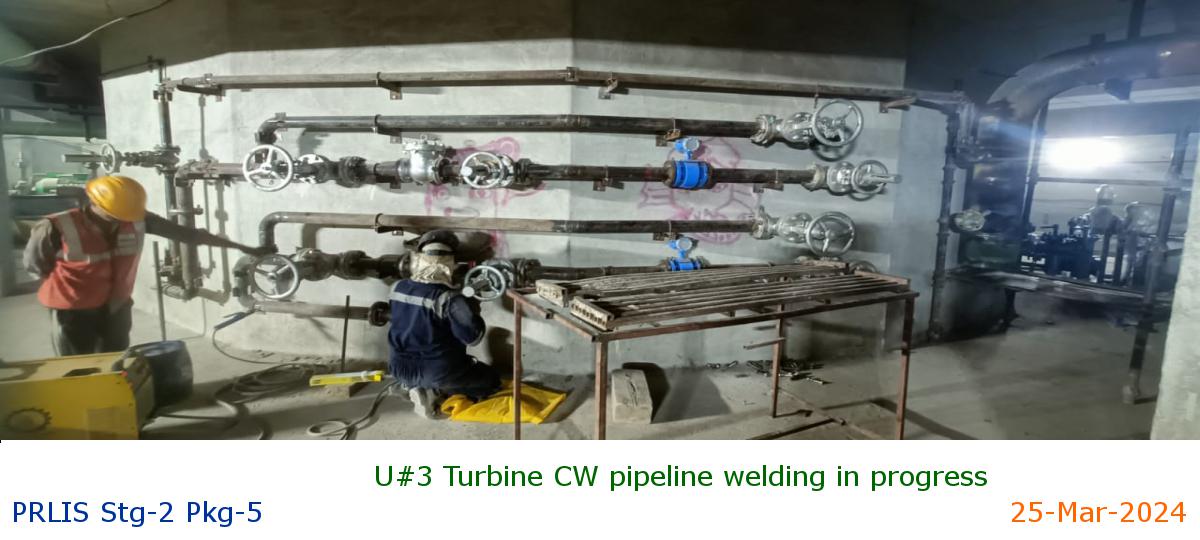

U#3 Turbine CW pipeline welding in progress

|

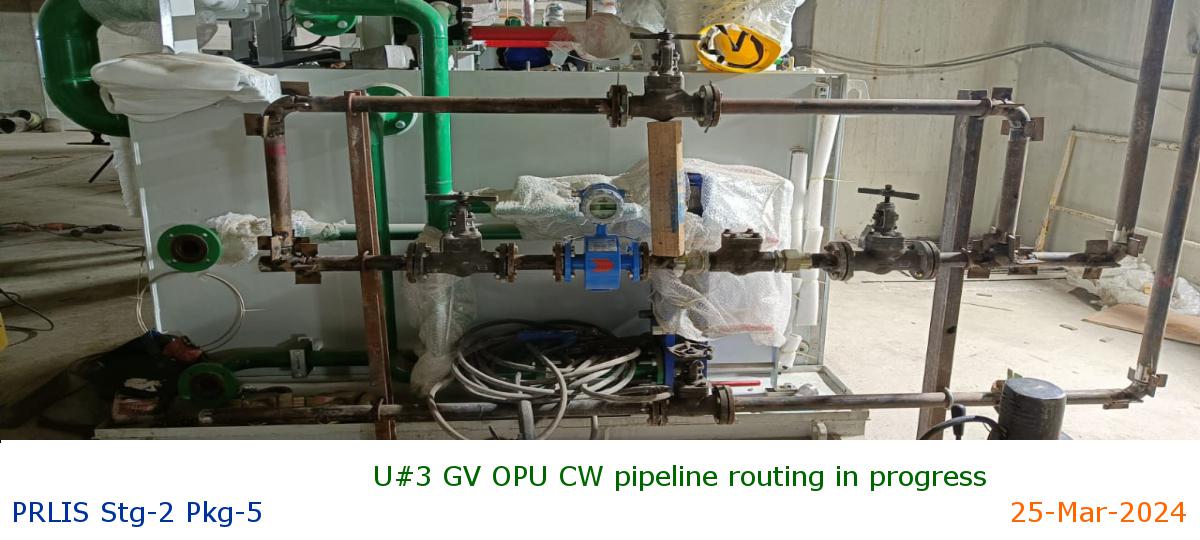

U#3 GV OPU CW pipeline routing in progress

|

U#1 MDV Servomotor alignment completed

|

U#8 stayring welding in progress

|

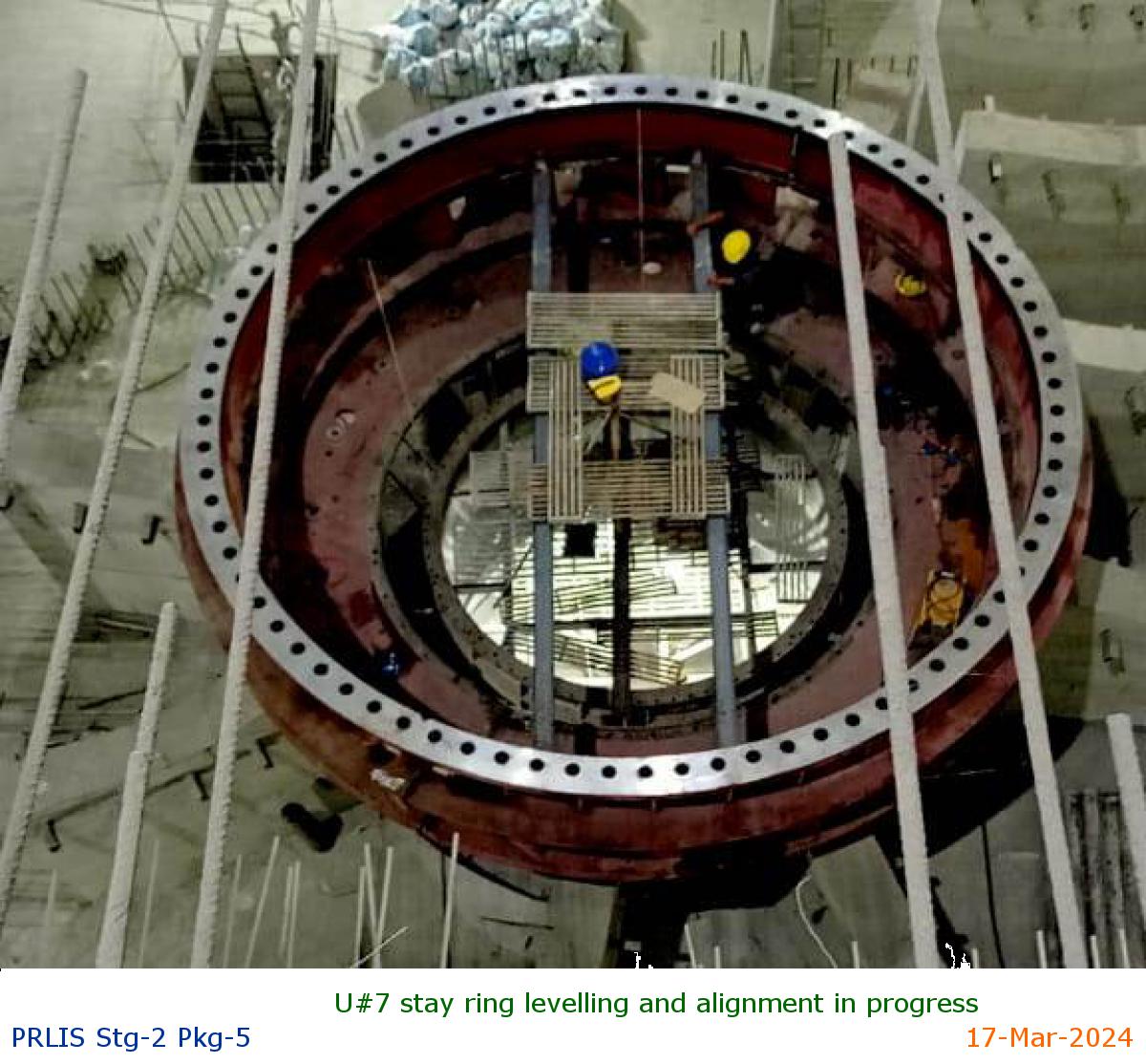

U#7 stay ring levelling and alignment in progress

|

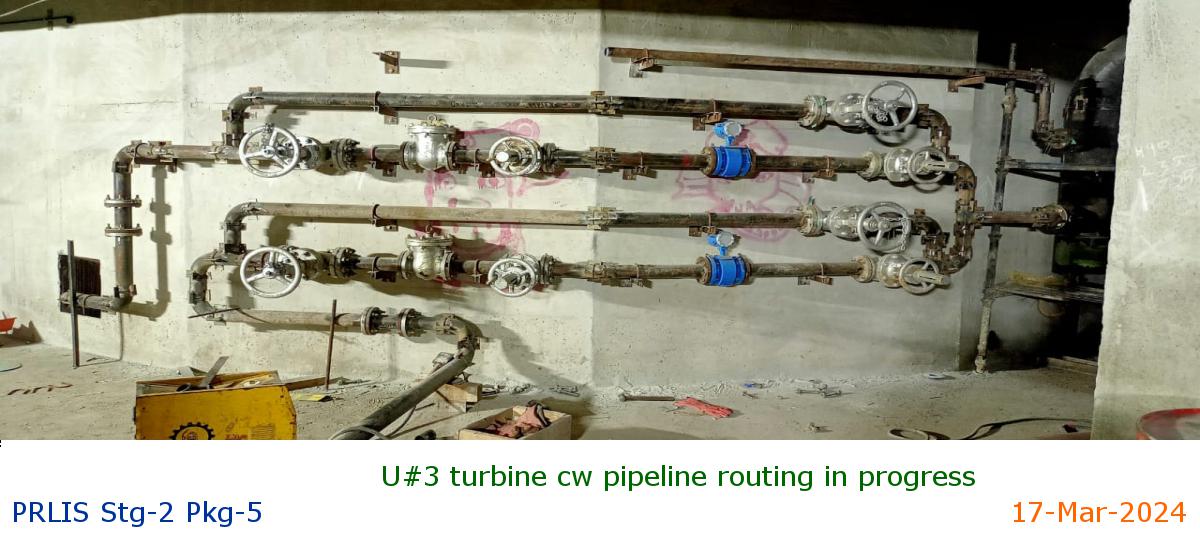

U#3 turbine cw pipeline routing in progress

|

U#1 MDV Servomotor alignment in progress

|

U#8 Stay ring halves joining completed

|

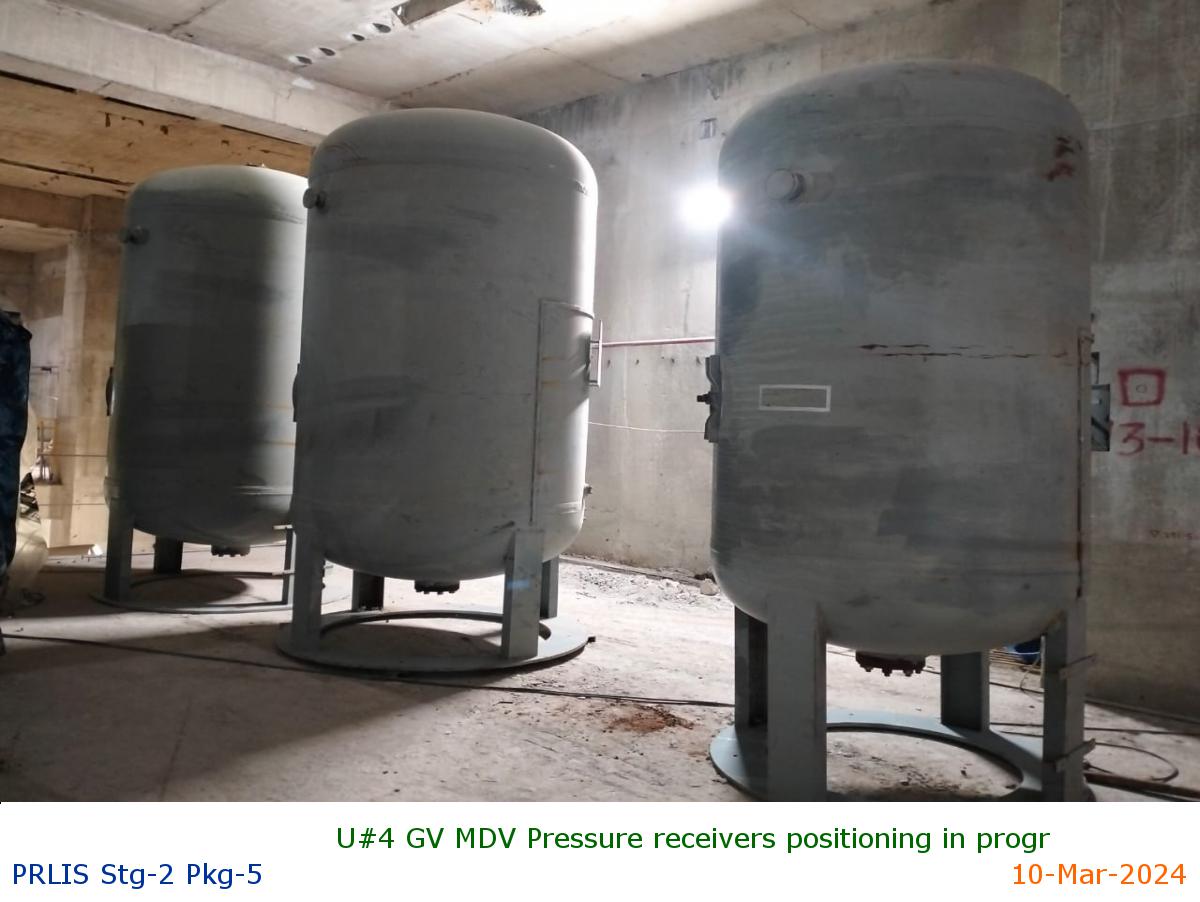

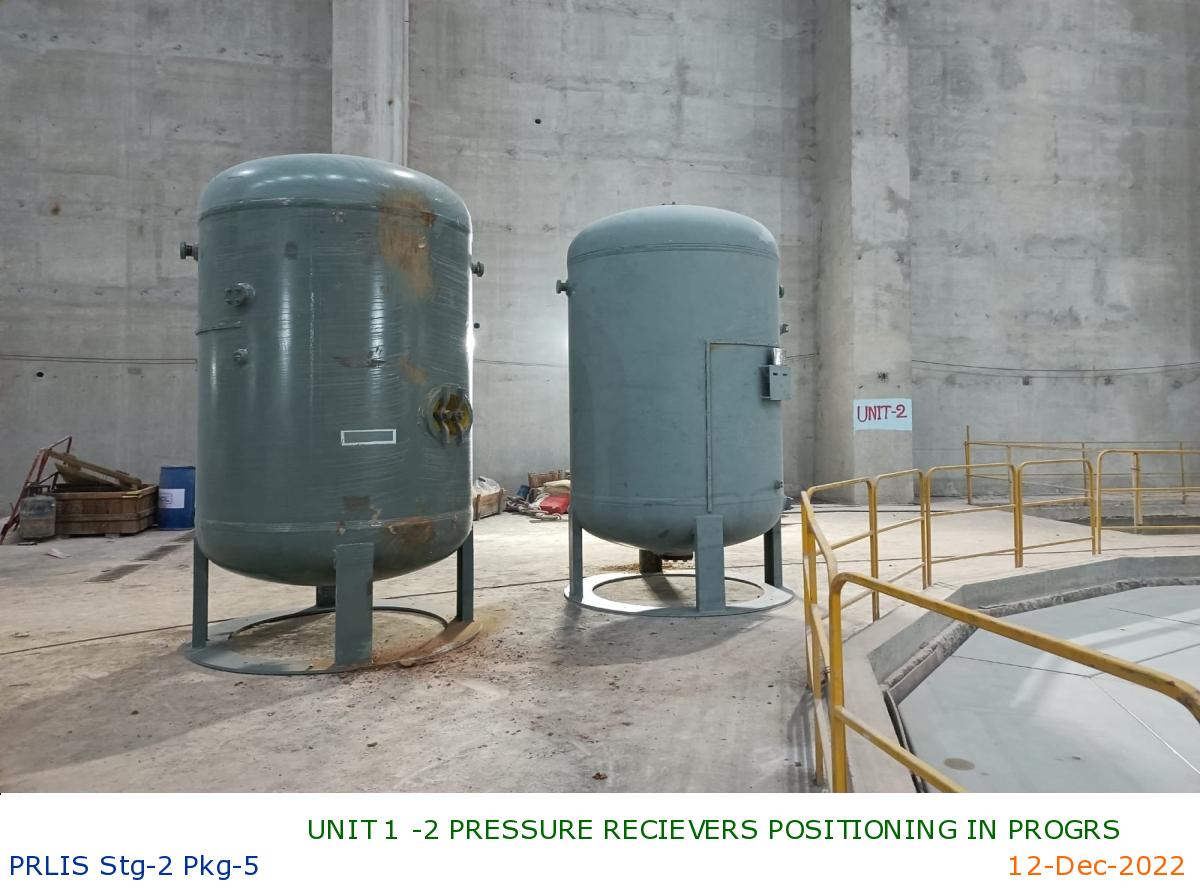

U#4 GV MDV Pressure receivers positioning in progr

|

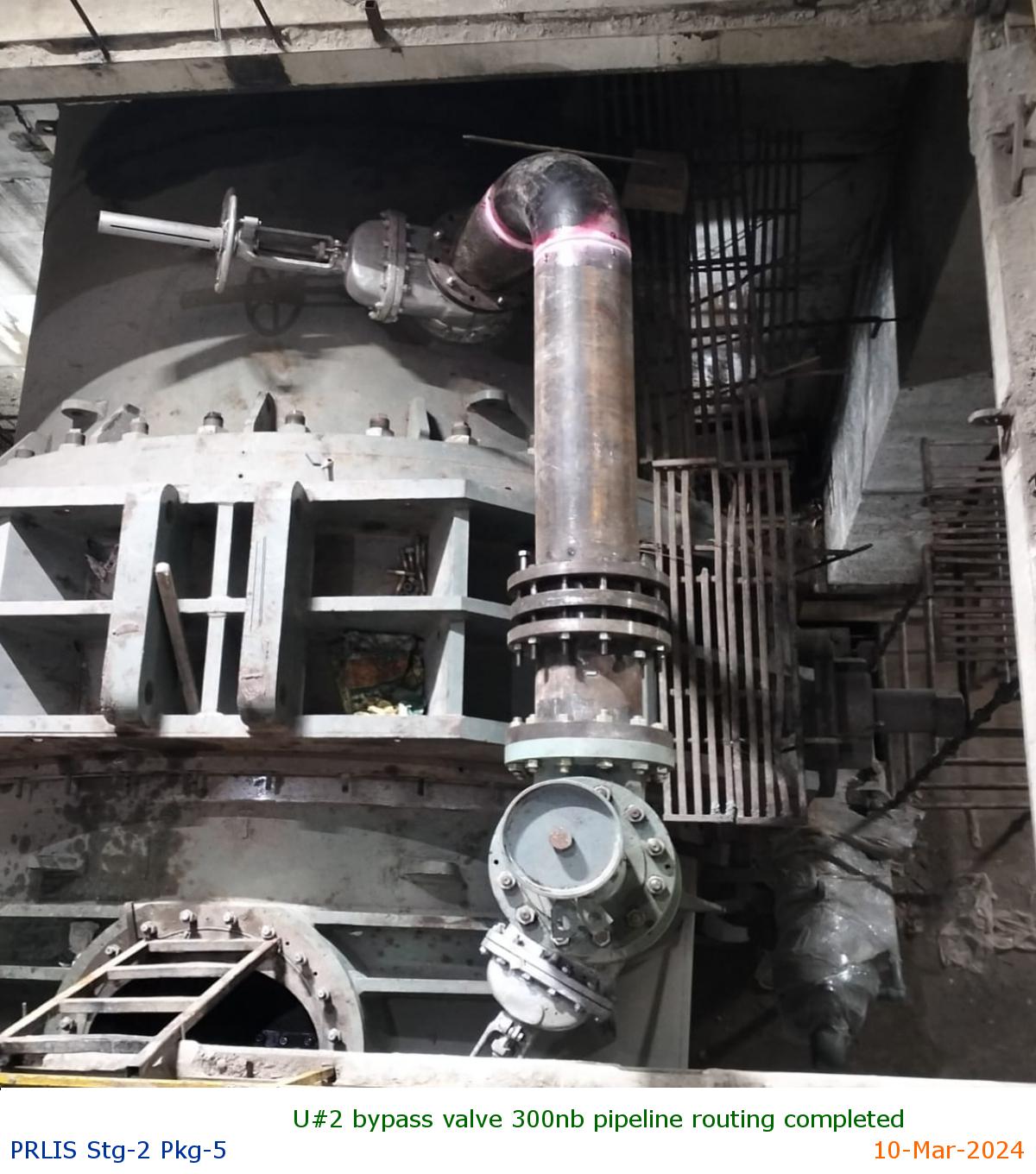

U#2 bypass valve 300nb pipeline routing completed

|

U-4 unit axis alignment in progress

|

U-6 spiral segments positioning in progress

|

U-3 pgb installation in progress

|

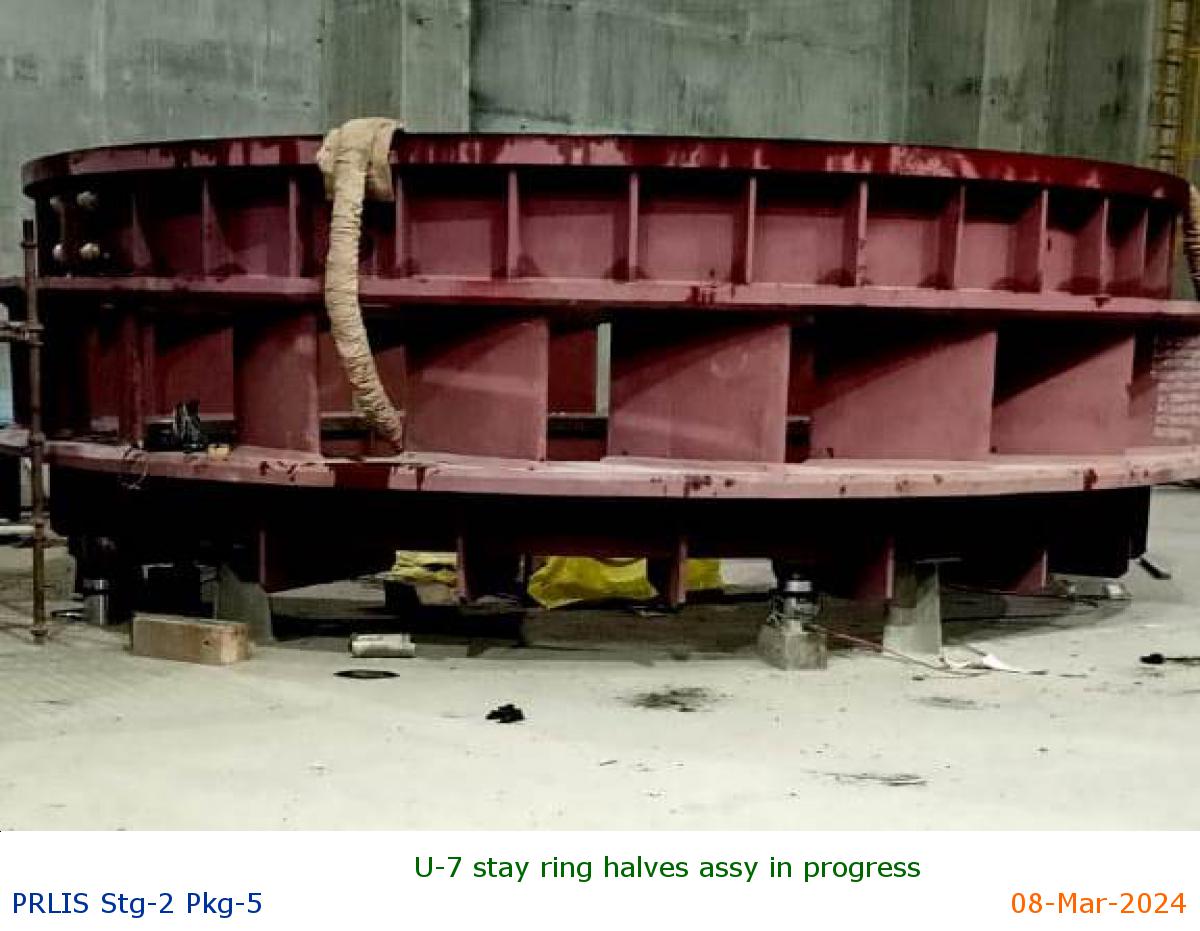

U-7 stay ring halves assy in progress

|

D&D sump-1 pump pedestals casting

|

U#6 stay ring welding

|

U#4 rotor poles installation

|

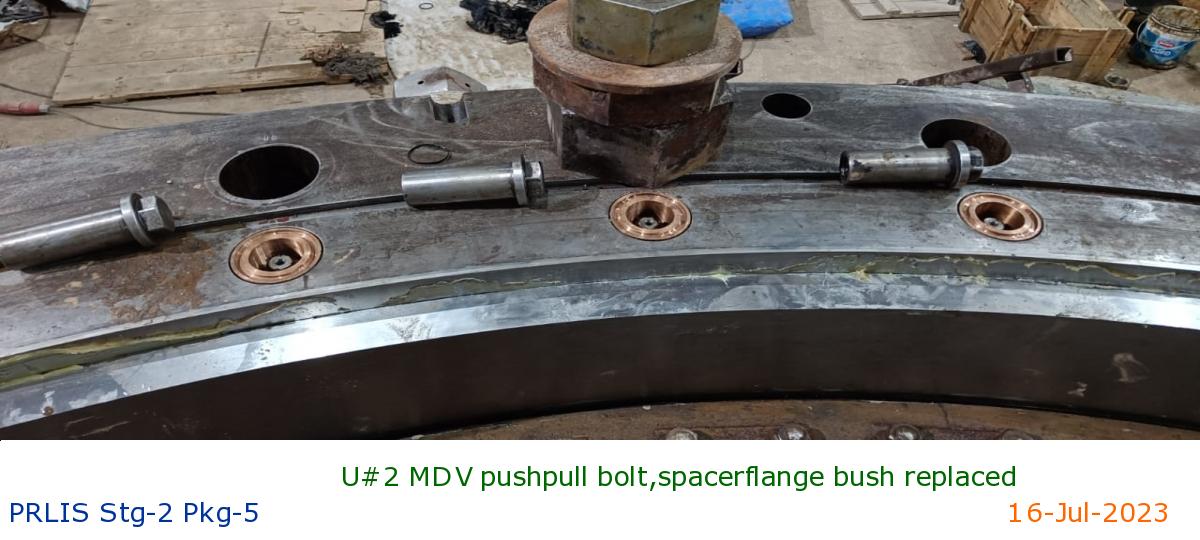

U#2 MDV Push pull bolt rework

|

U#5 Spring plate assy around bottom shaft

|

U#5 DT Elbow liner grouting

|

U#2 MDV outlet pipe and penstock welding in progre

|

U#1 OPU oil filling done for oil flushing

|

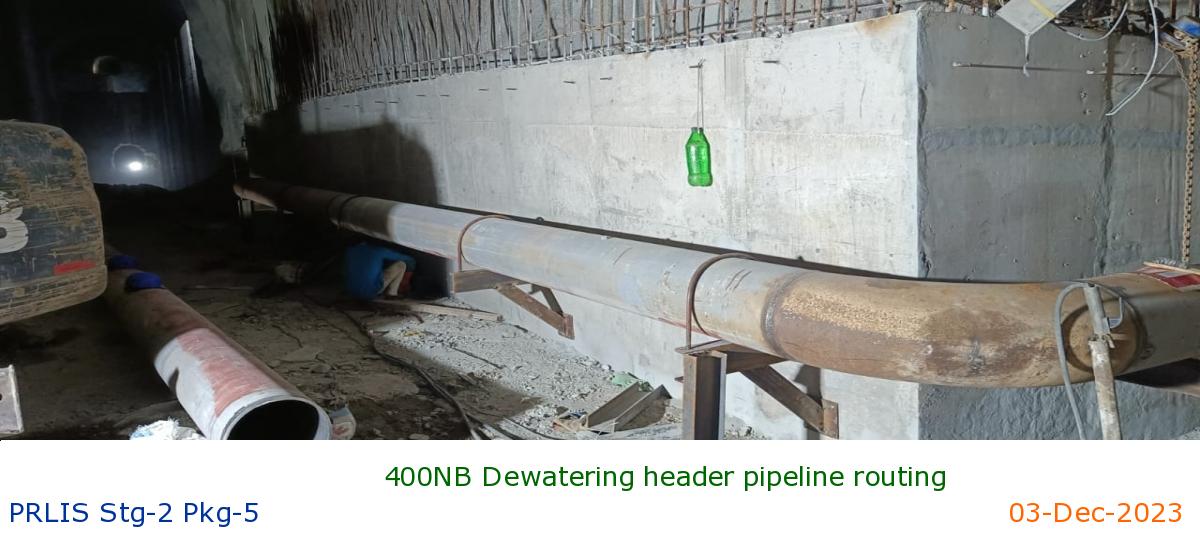

400NB Dewatering header pipeline routing

|

U#6 Stay ring halves levelling and joint tightenin

|

U#3 Top air guide trial assembly

|

U#2 Transformer oil leakage rectification works

|

U#2 MDV servomotor lowered to position

|

U#1 MDV rework in prorgess

|

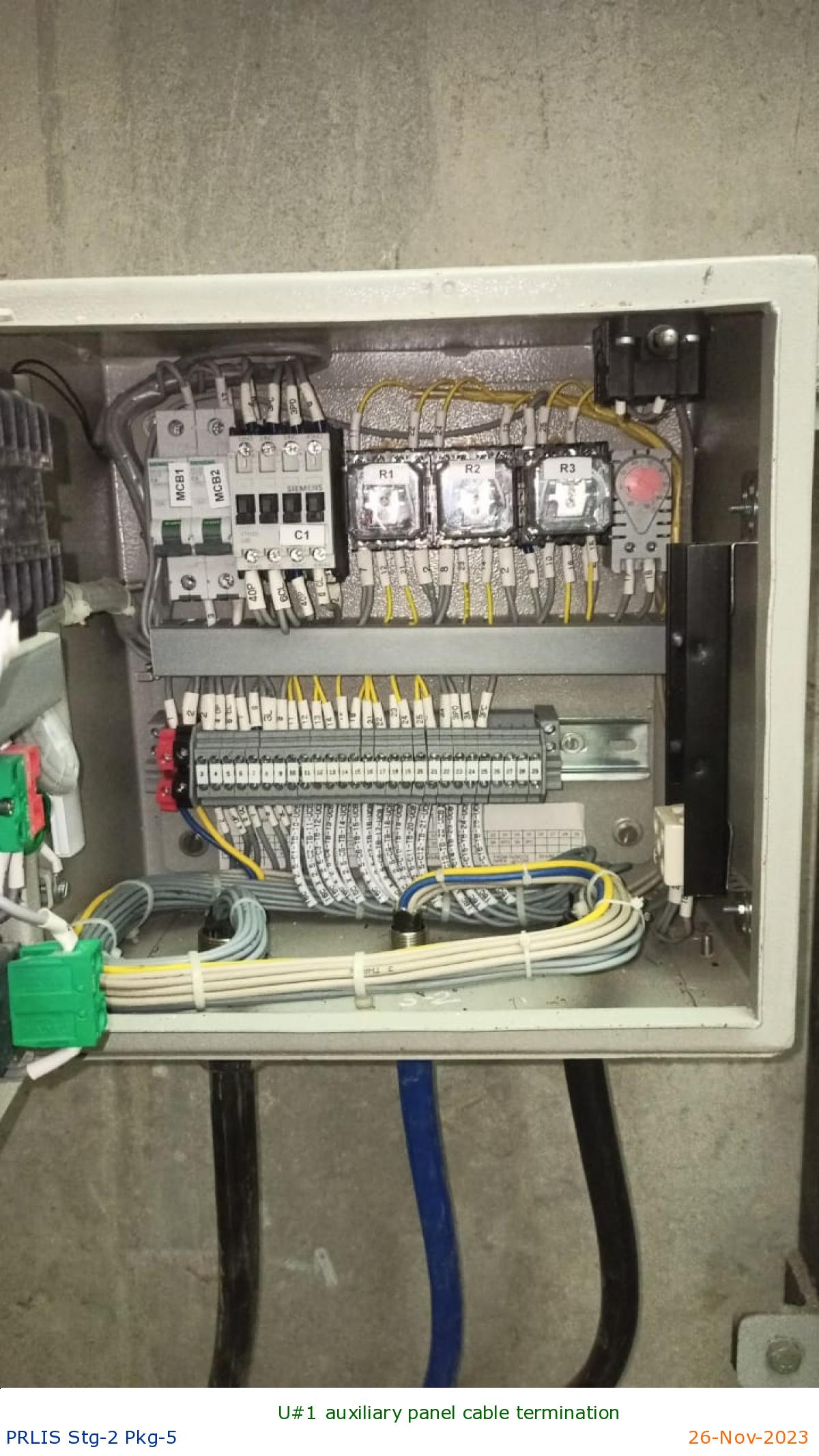

U#1 auxiliary panel cable termination

|

Station transformer ready for charging

|

Station air and WDS System in main service bay

|

U#6 Stay ring halves assembly in progress

|

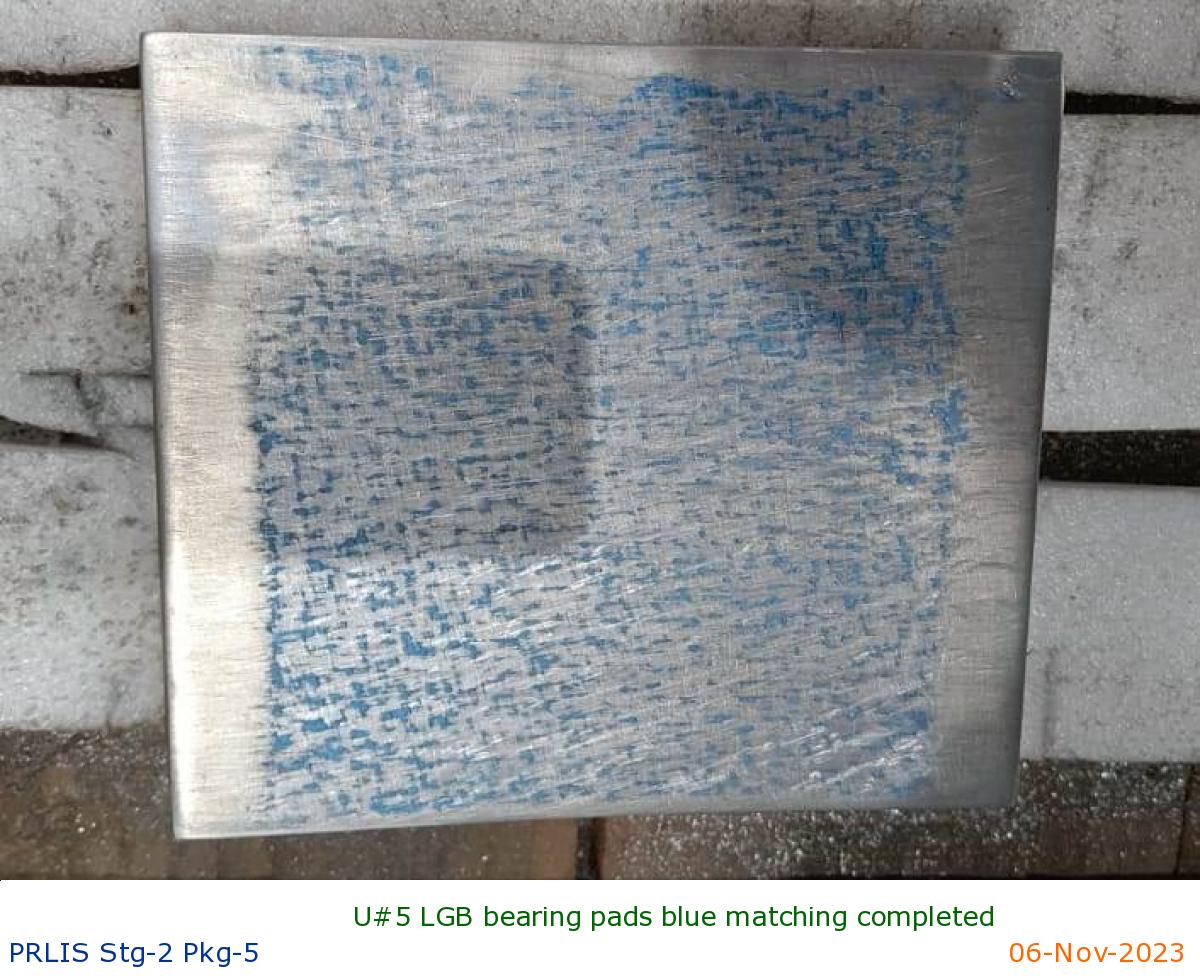

U#5 LGB bearing pads blue matching completed

|

U#2 MDV installation in prgoress

|

U#1 UAB and starter panels cabling

|

U#1 Auxiliaries cabling in progress

|

U#1 Auxiliaries cabling

|

U#1 Excitation Transformer

|

U#1 MDV Servomotor positioning

|

U#1 Bypass valve pipeline routing

|

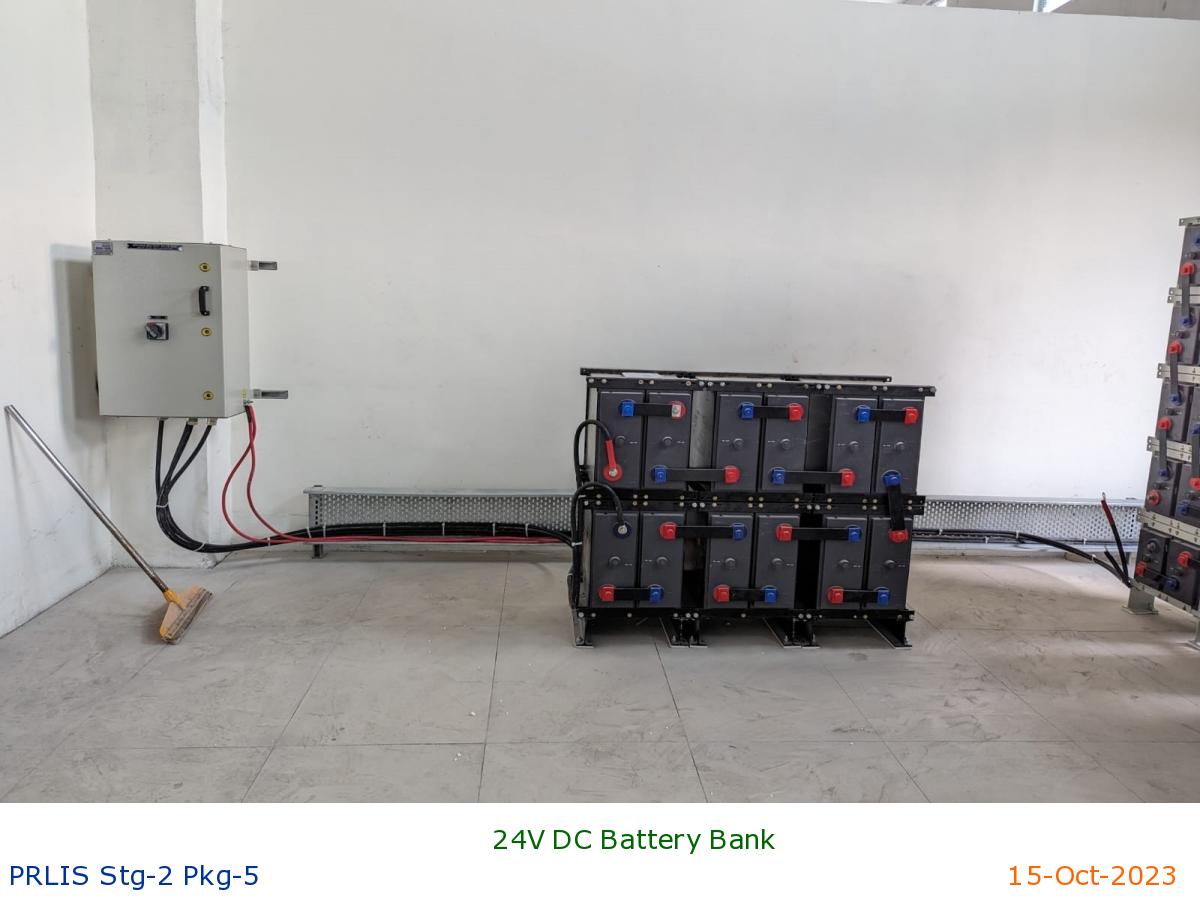

24V DC Battery Bank

|

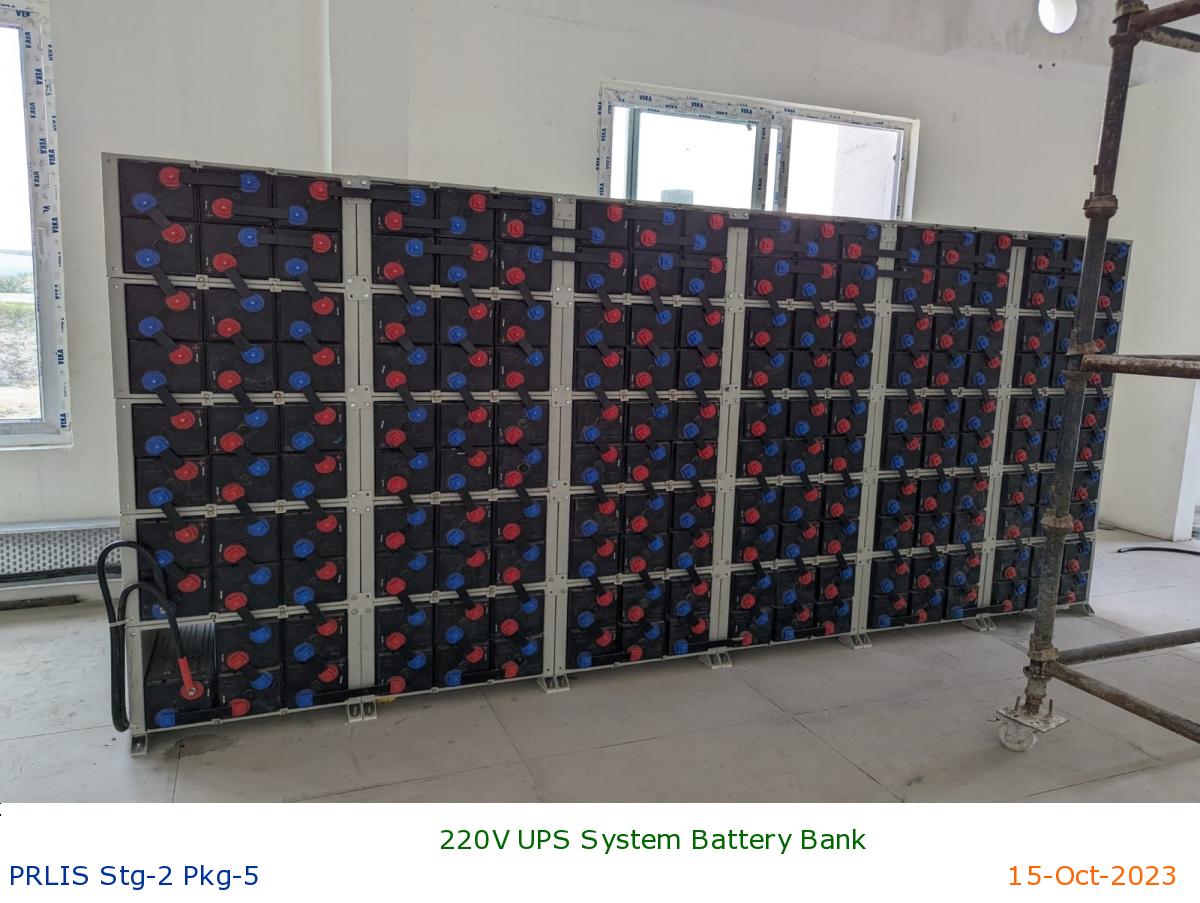

220V UPS System Battery Bank

|

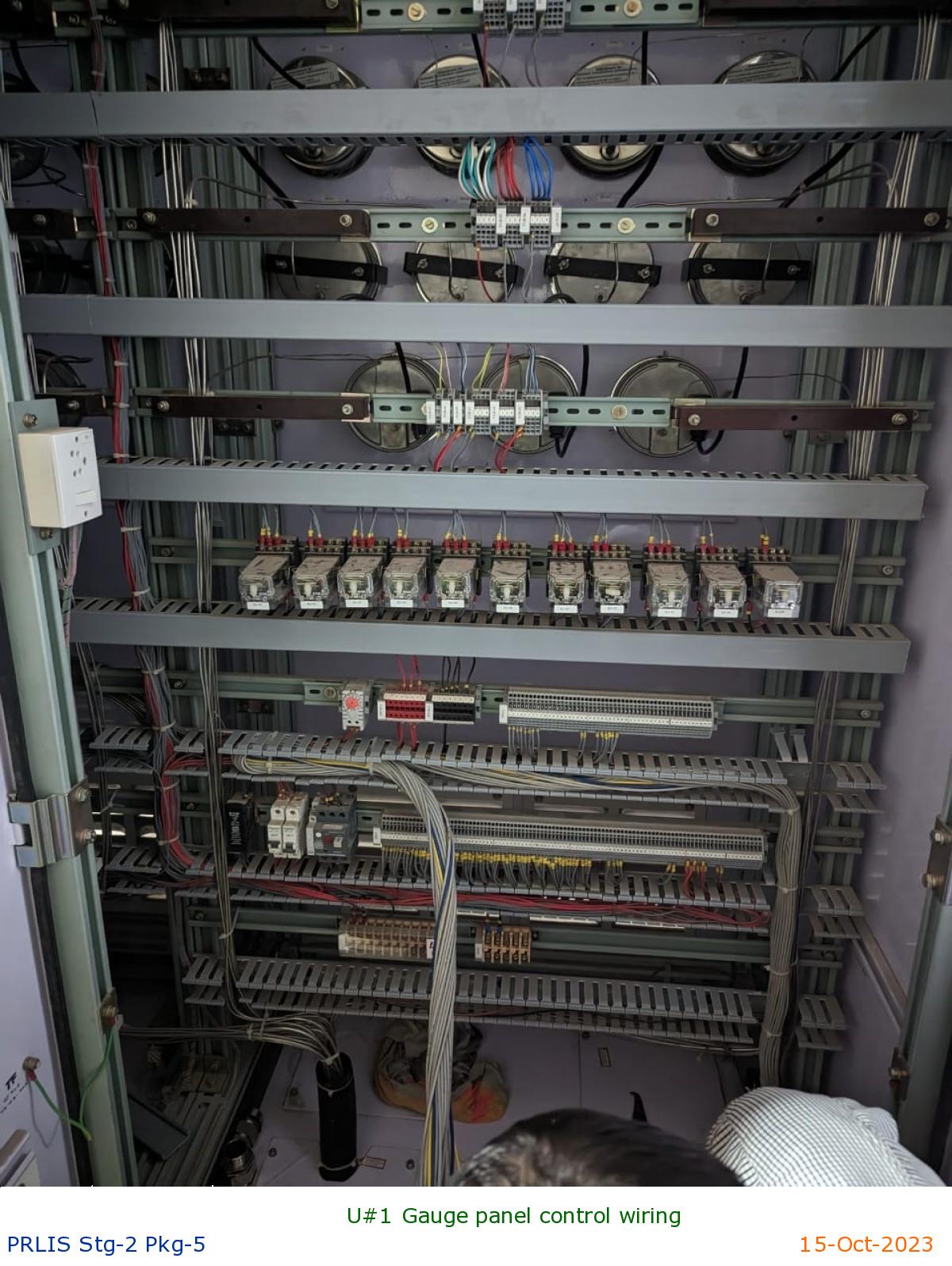

U#1 Gauge panel control wiring

|

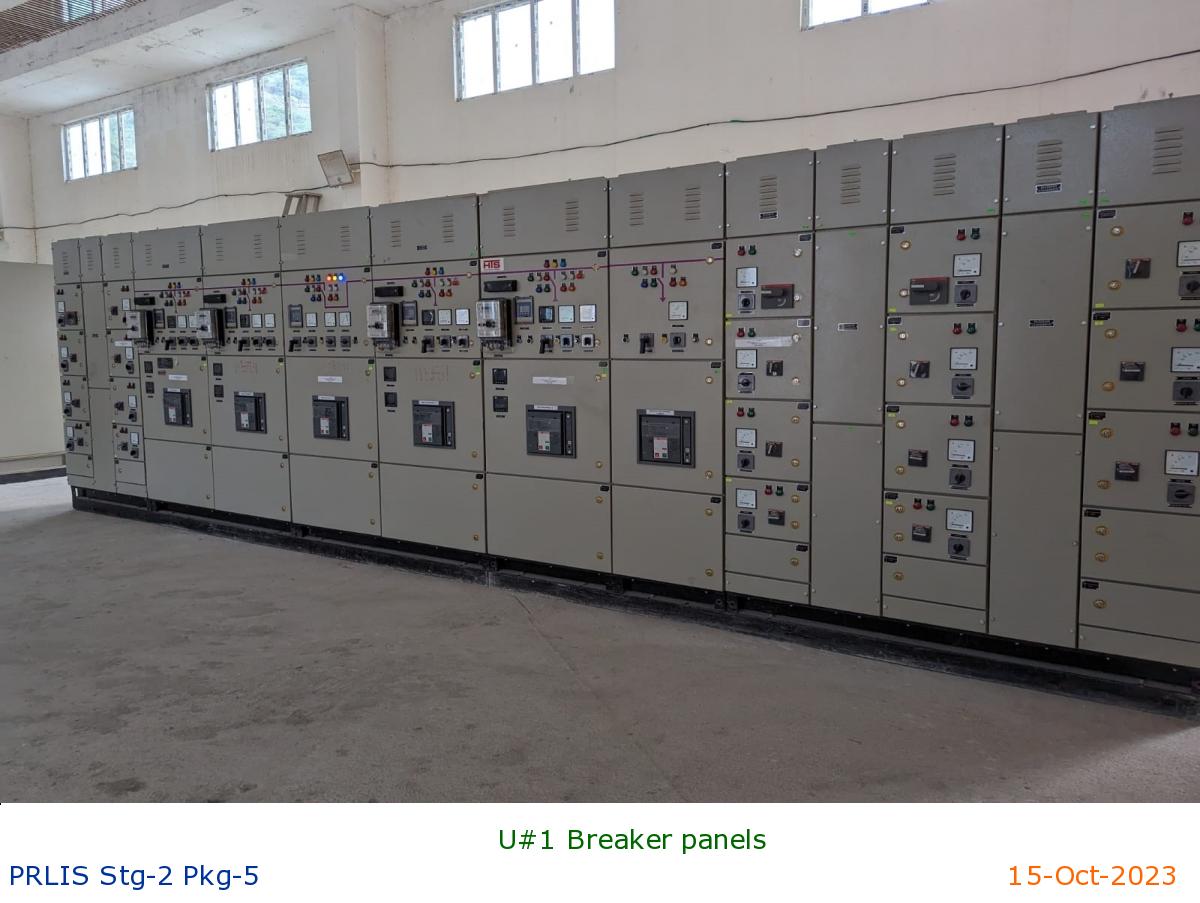

U#1 Breaker panels

|

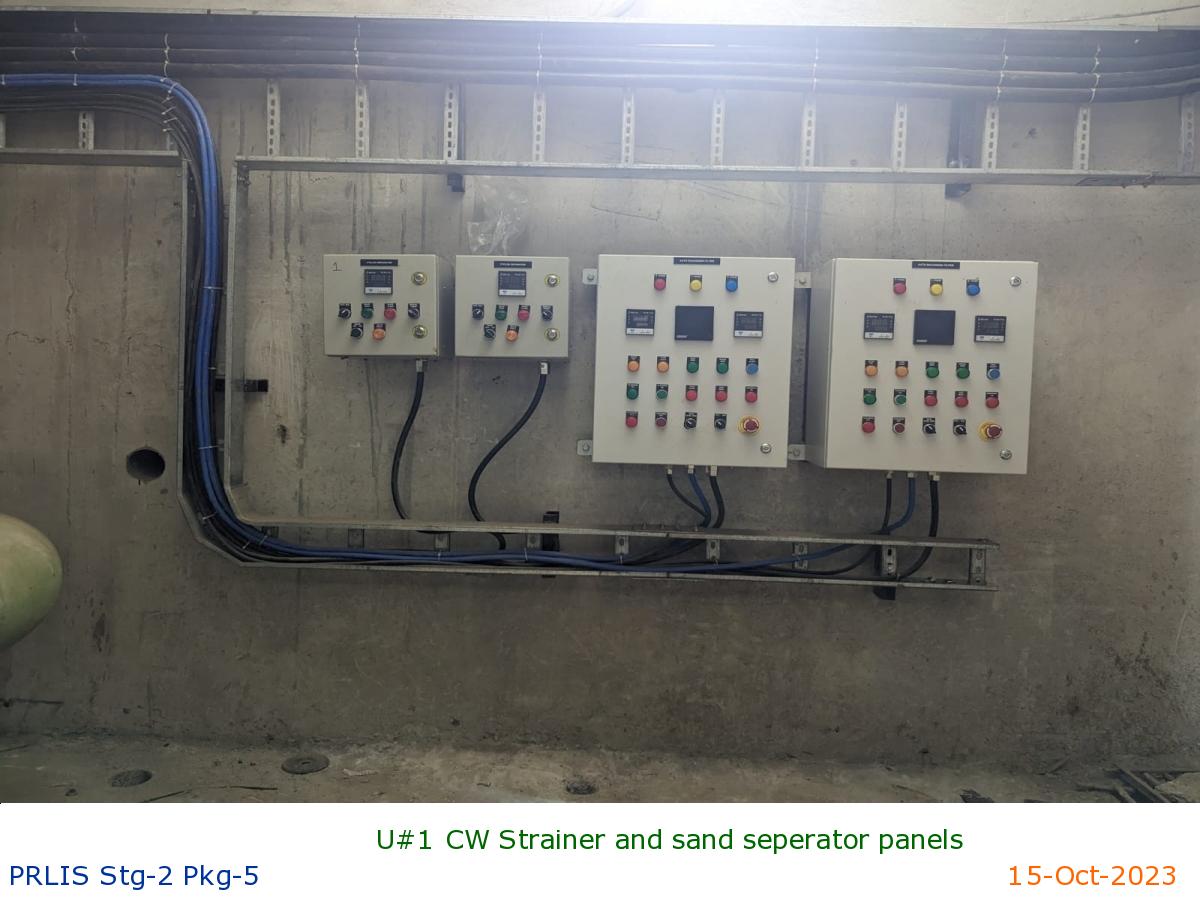

U#1 CW Strainer and sand seperator panels

|

U#1 Busduct CT Wiring

|

U#1 cable laying and termination

|

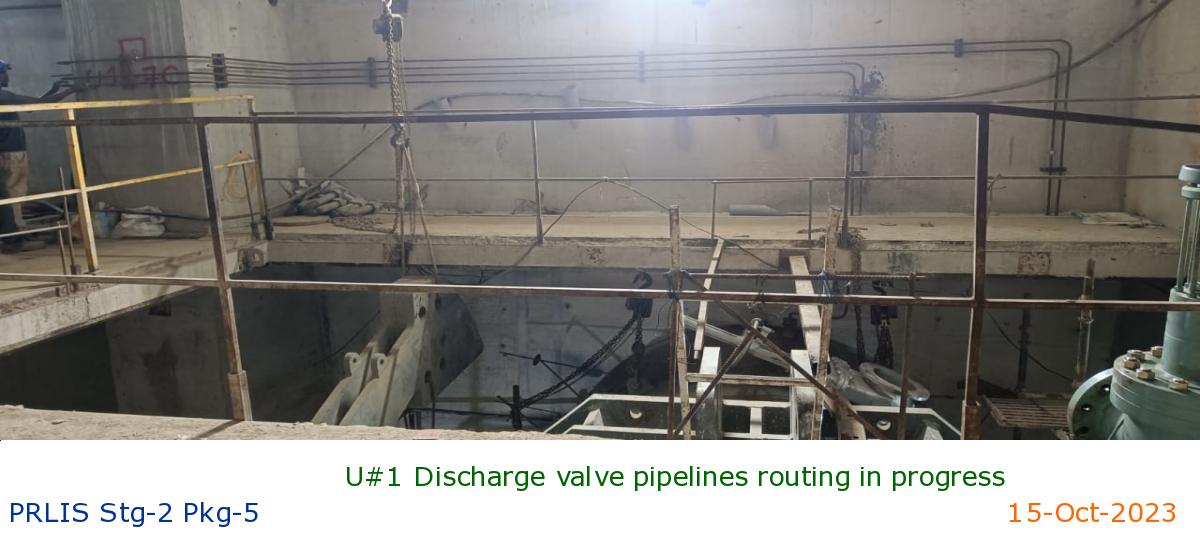

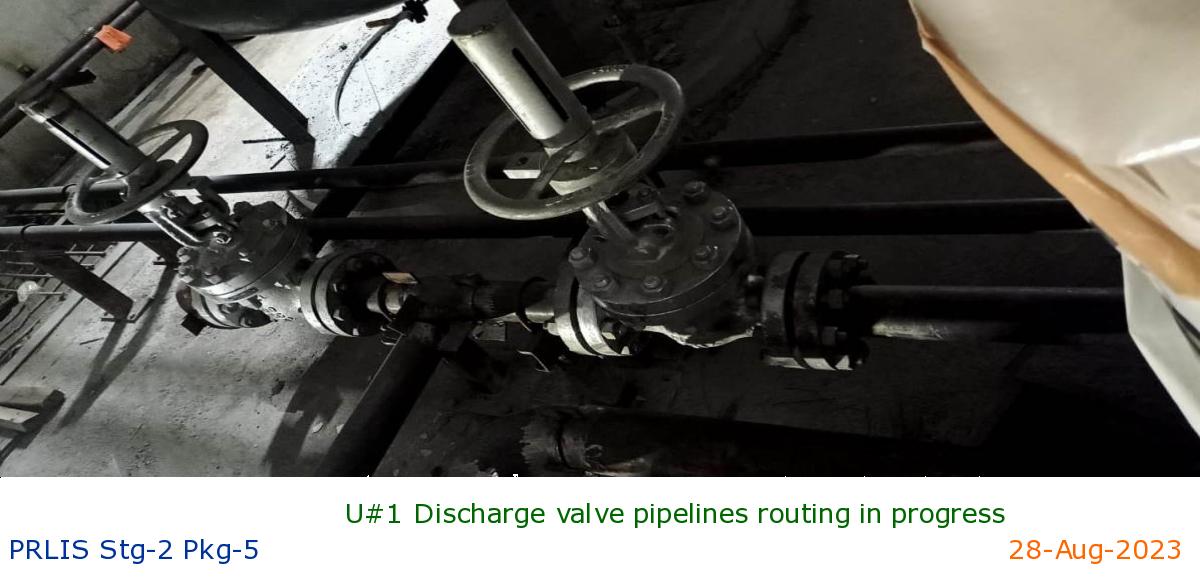

U#1 Discharge valve pipelines routing in progress

|

Station and WDS Compressors

|

U#1 Field efficiency pipeline routing

|

U#1 DT Water level indicator installed

|

U#1 GV Servo opening closing pipelines routing

|

U#1 CW Main outlet NRV installed

|

U#1 Bypass valve piping works i/p

|

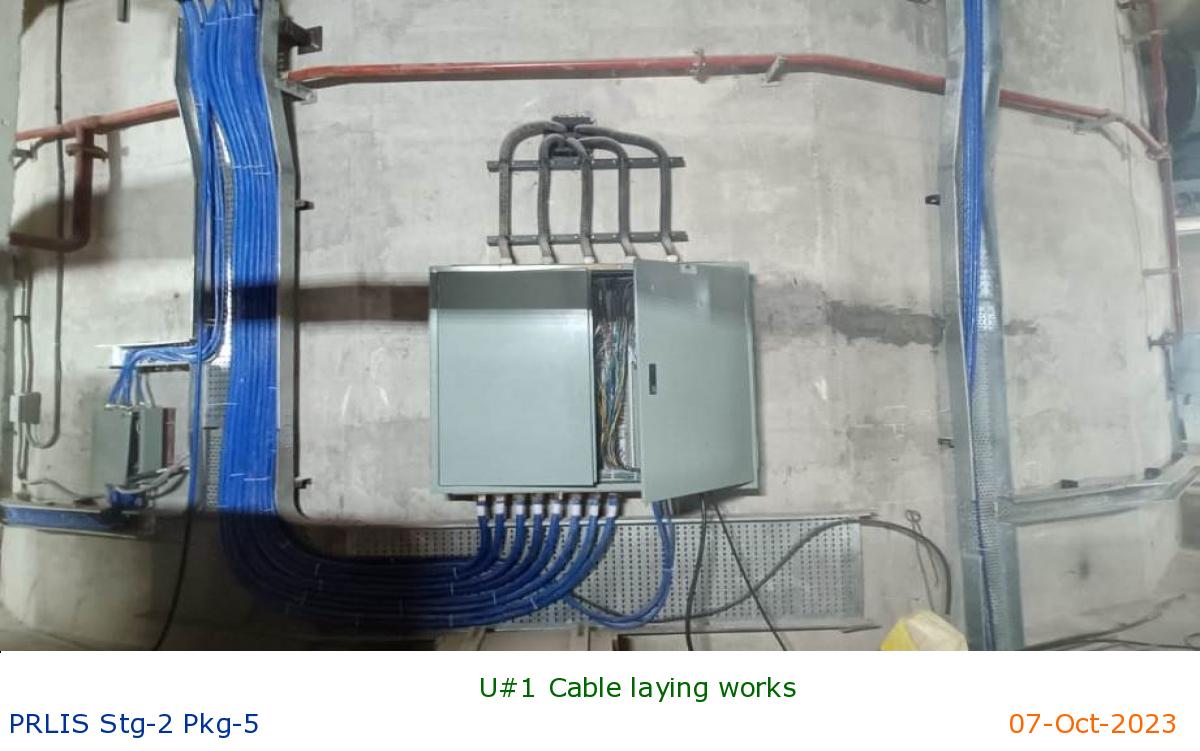

U#1 Cable laying works

|

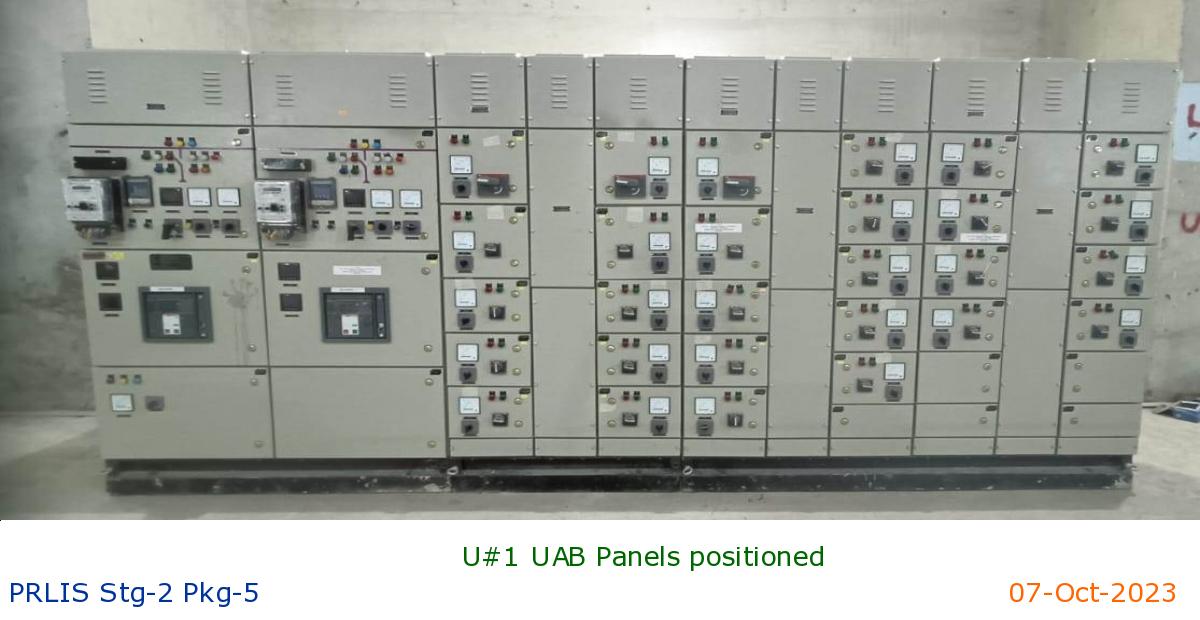

U#1 UAB Panels positioned

|

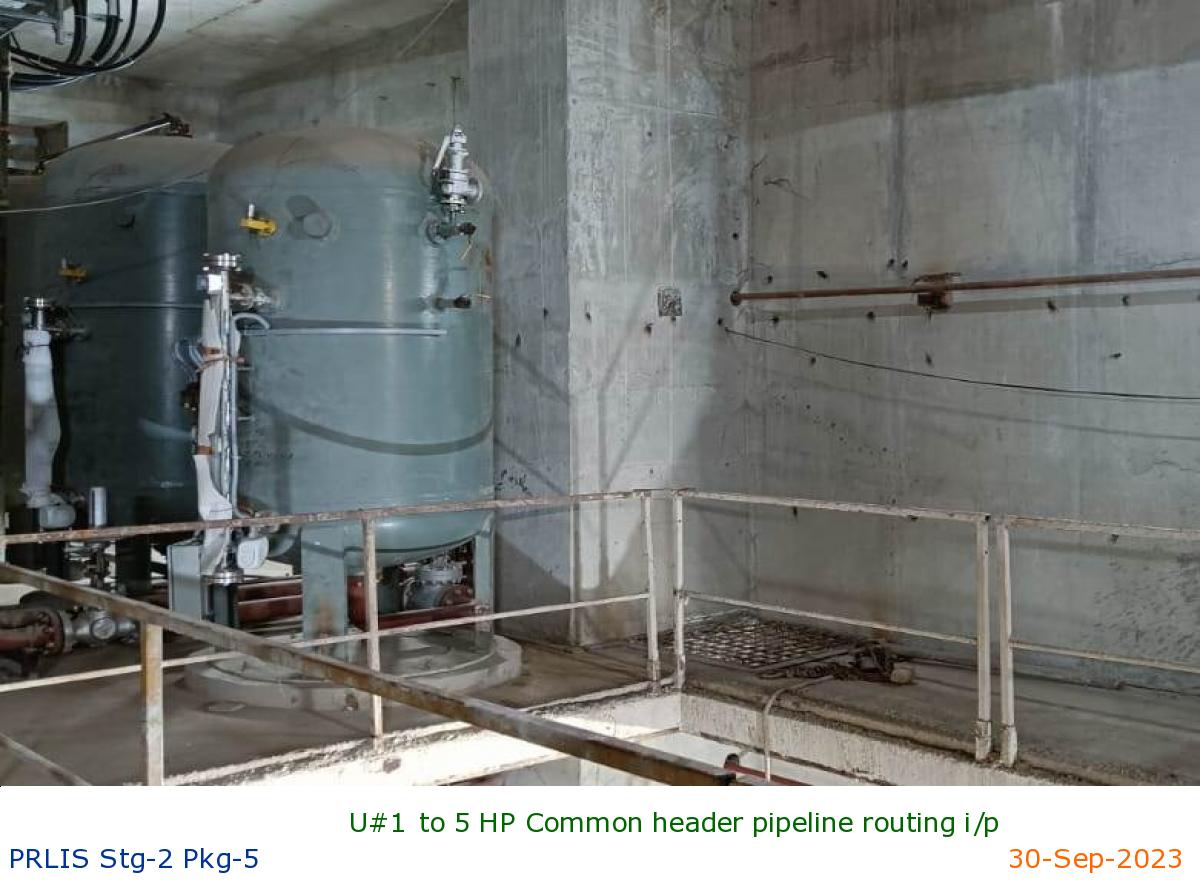

U#1 to 5 HP Common header pipeline routing i/p

|

Station air compressors and receivers erection

|

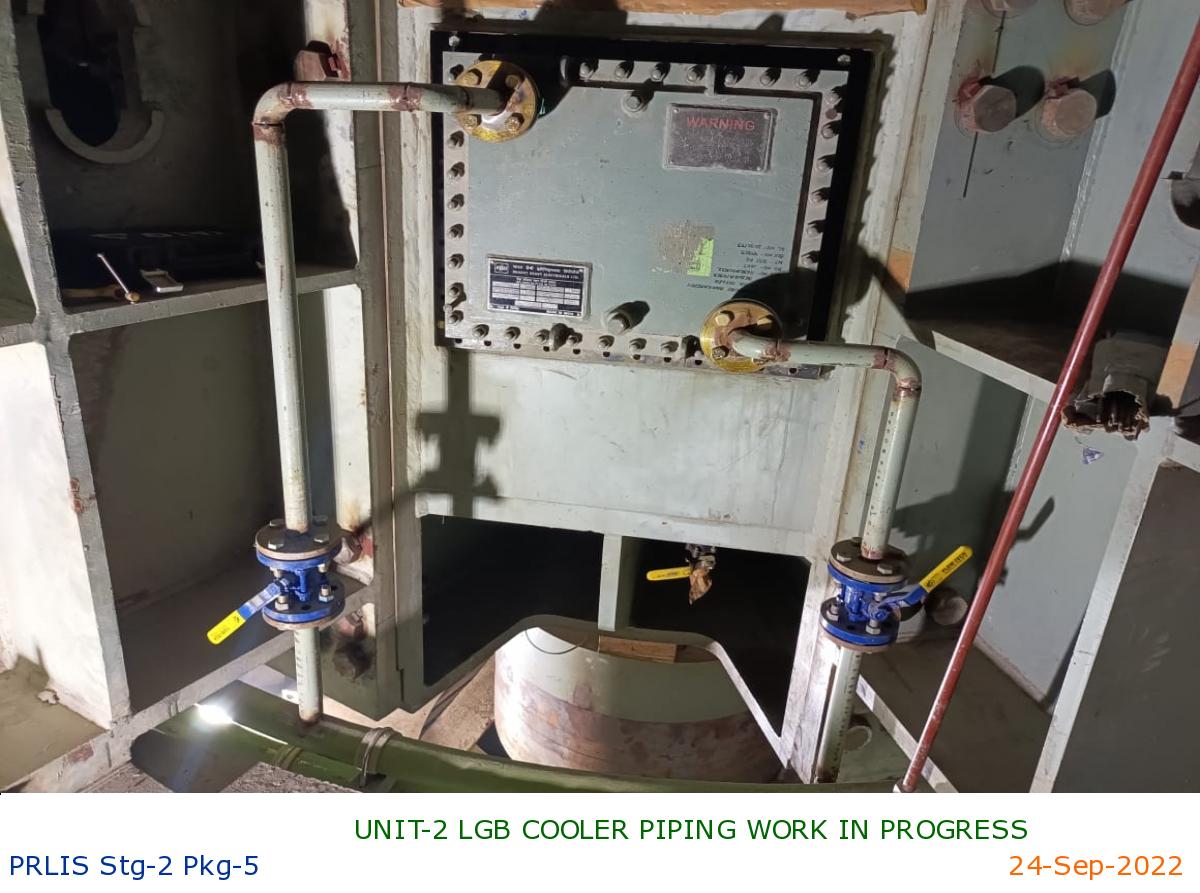

U#2 LGB CW pipeline final assembly

|

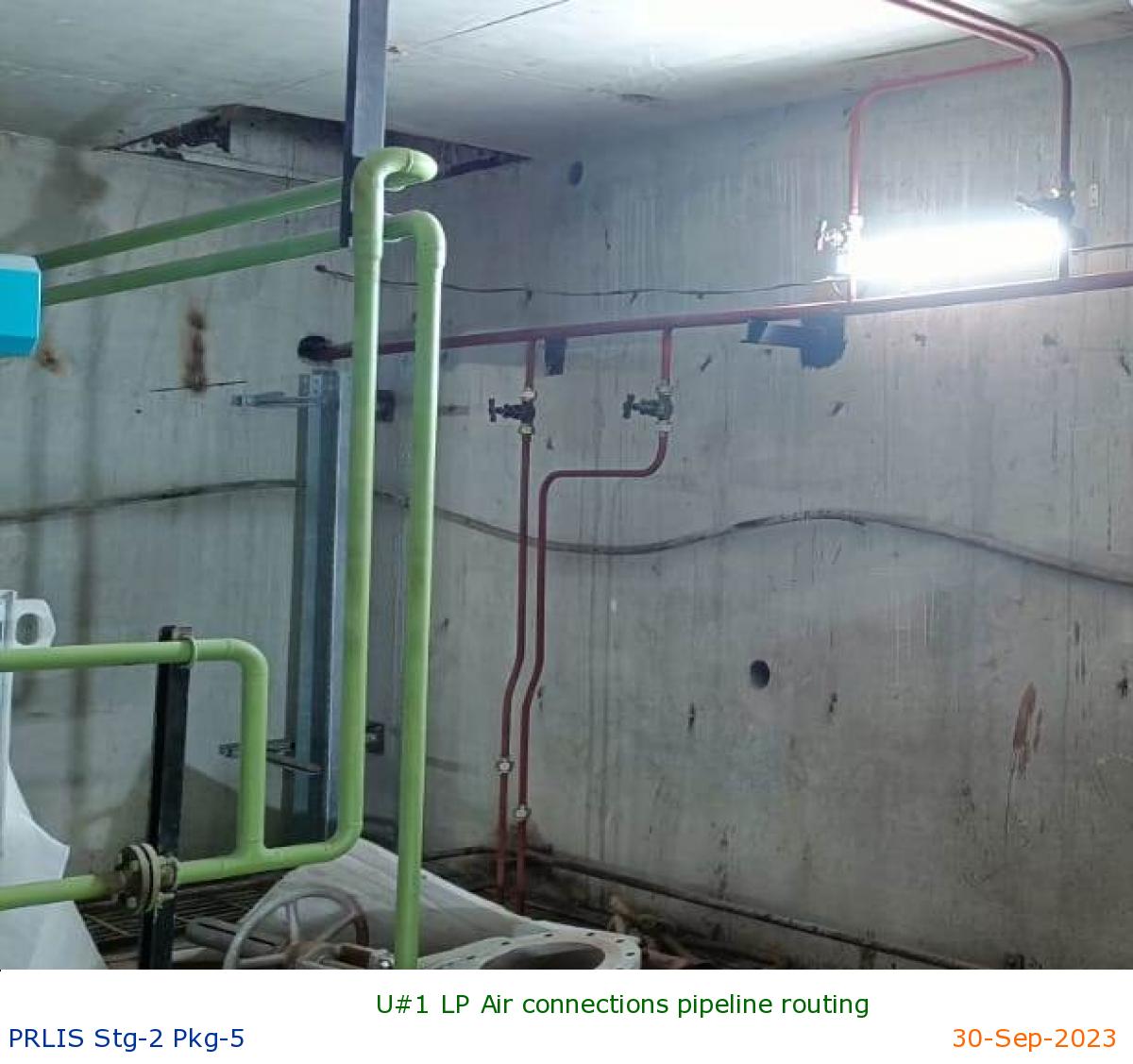

U#1 LP Air connections pipeline routing

|

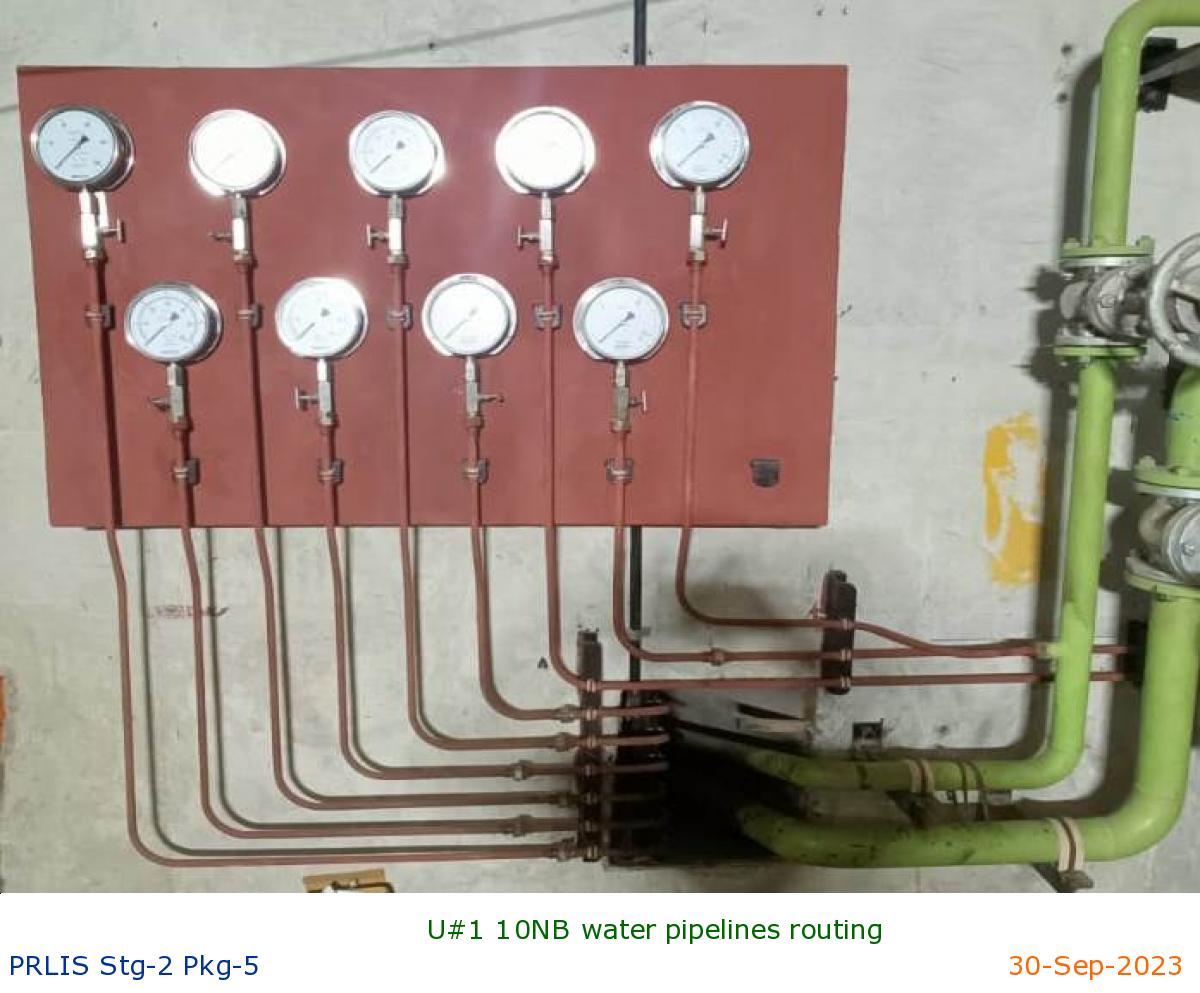

U#1 10NB water pipelines routing

|

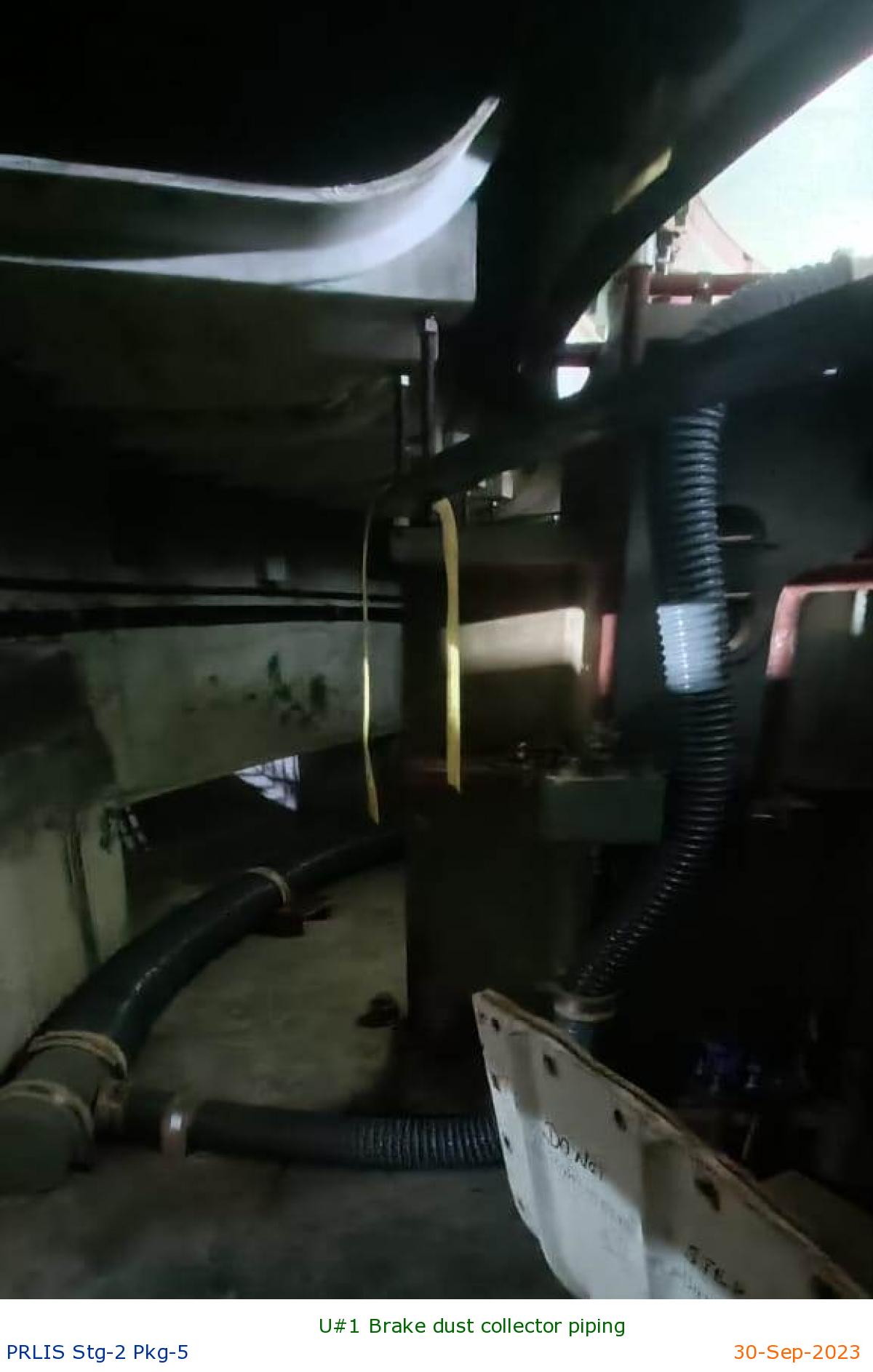

U#1 Brake dust collector piping

|

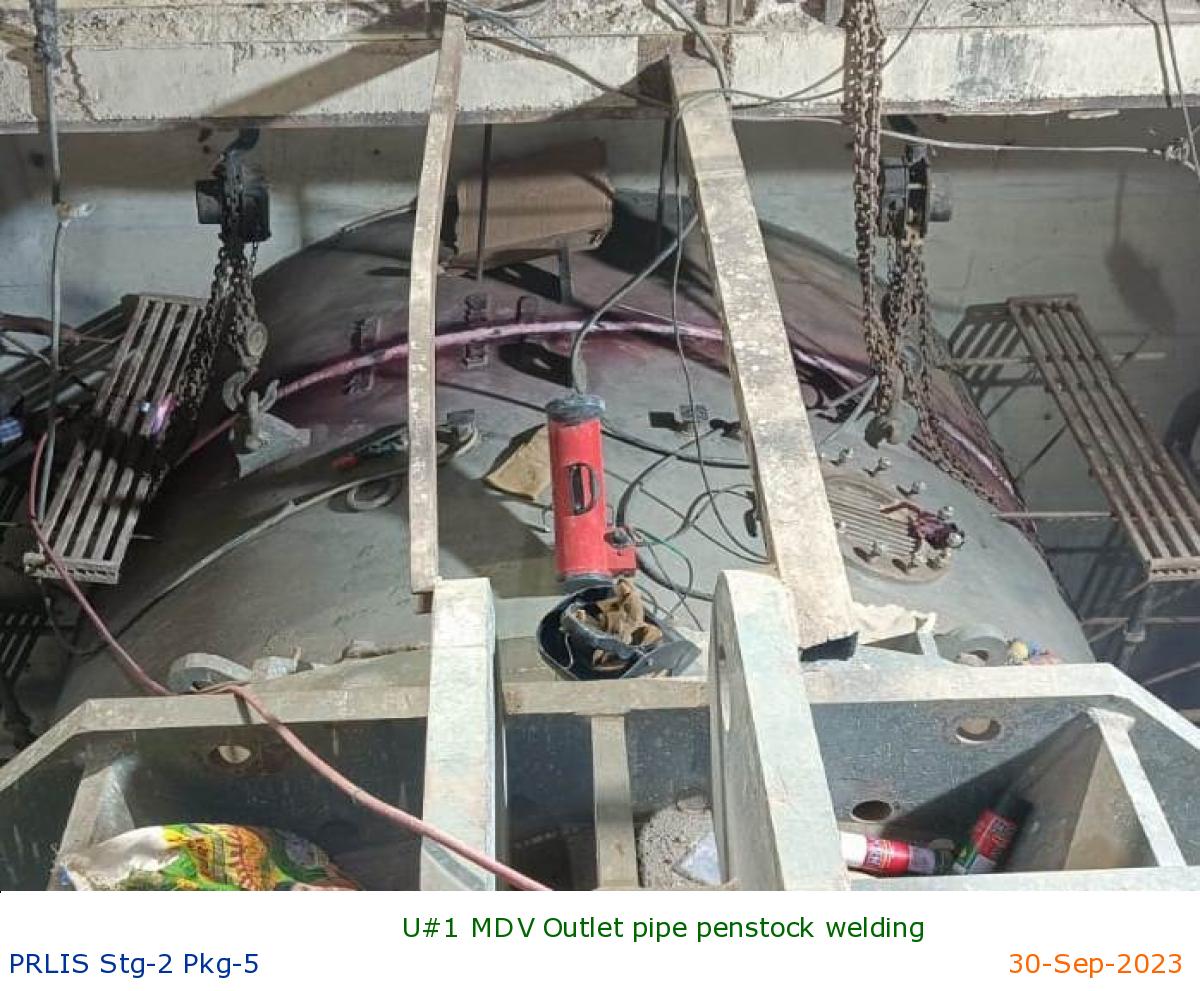

U#1 MDV Outlet pipe penstock welding

|

U#2 DT Drain valves installation in progress

|

U#1 Spiral drain valve installation completed

|

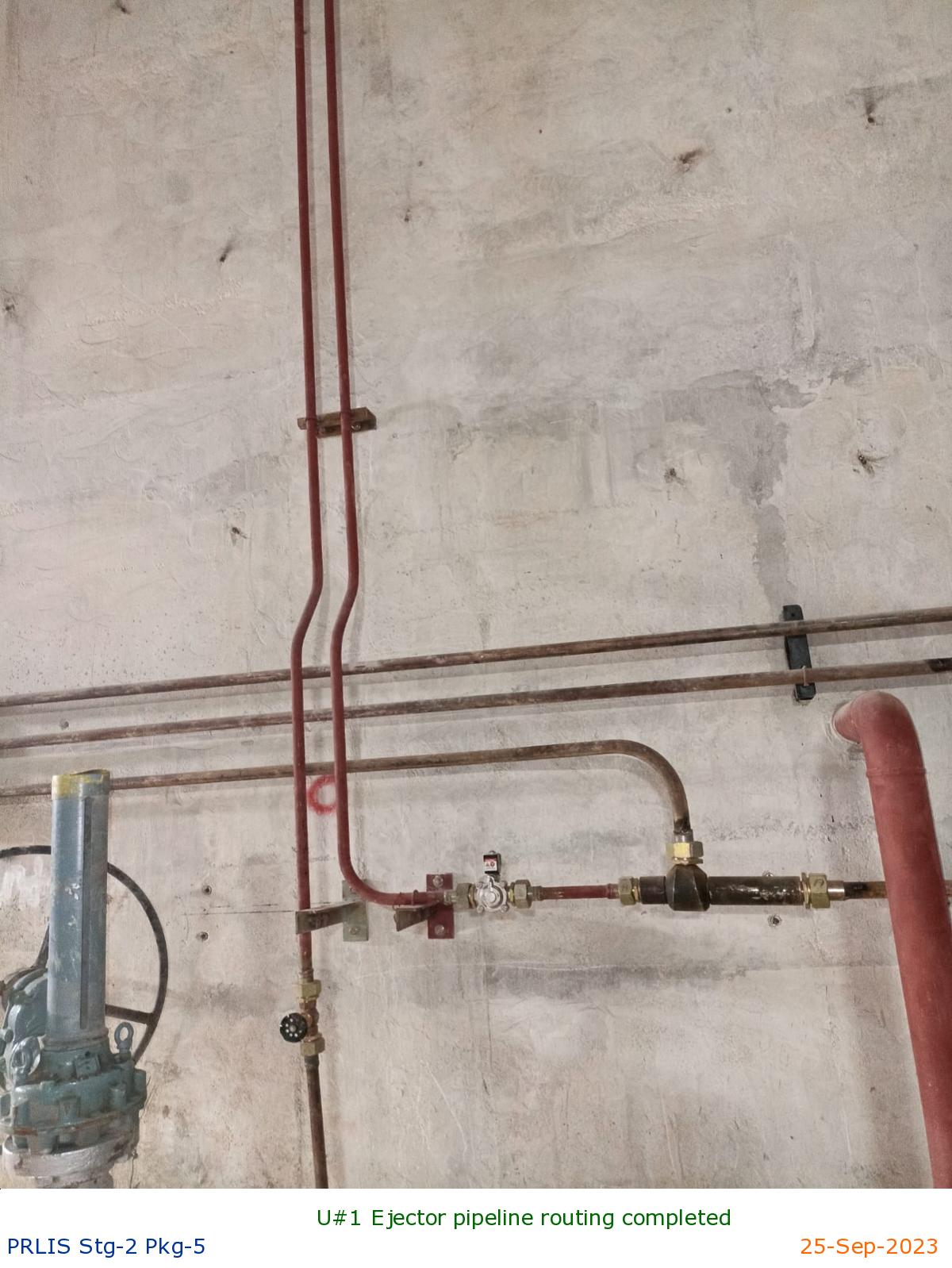

U#1 Ejector pipeline routing completed

|

U#1 DT Drain Valves installation completed

|

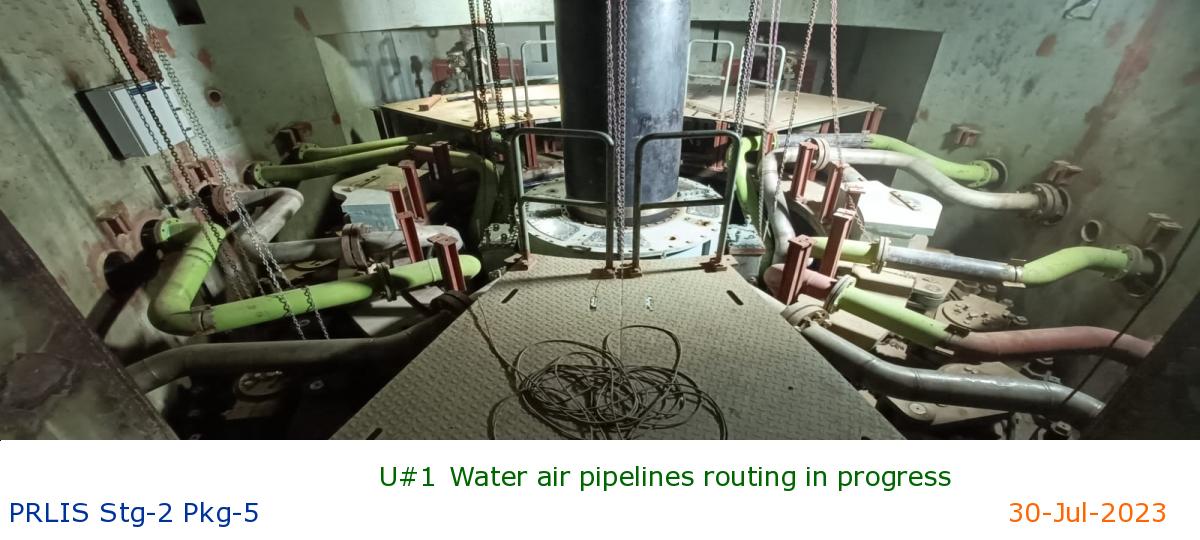

U#1 Water air pipelines inside turbine pit

|

U#6 Water Depression air receiver positioned

|

Compressed air pipeline routing in progress

|

HP & LP receivers positioning

|

U#1 Discharge valve pipelines routing in progress

|

U#1 Motor barell door installed

|

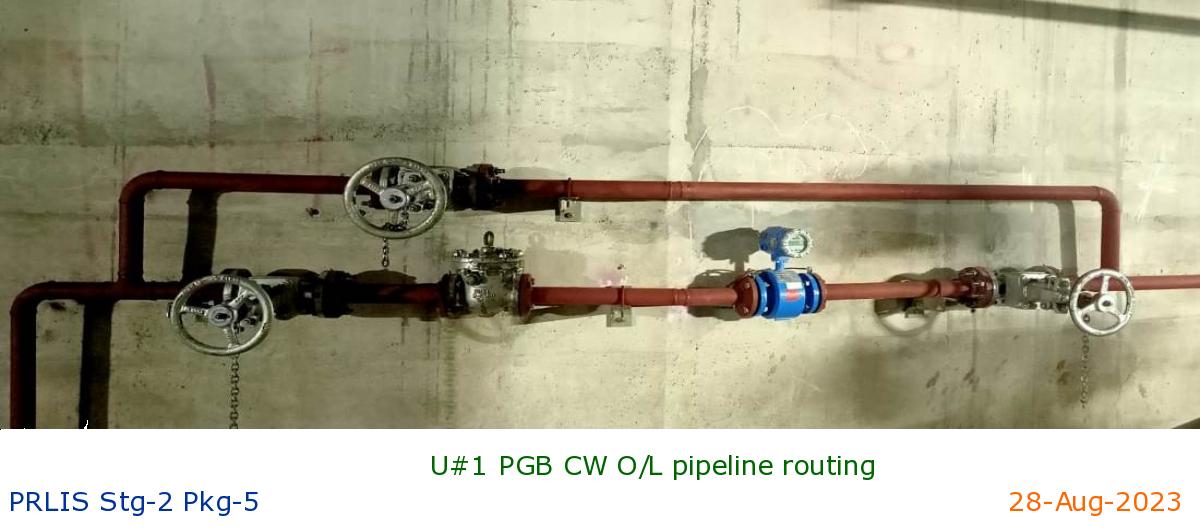

U#1 PGB CW O/L pipeline routing

|

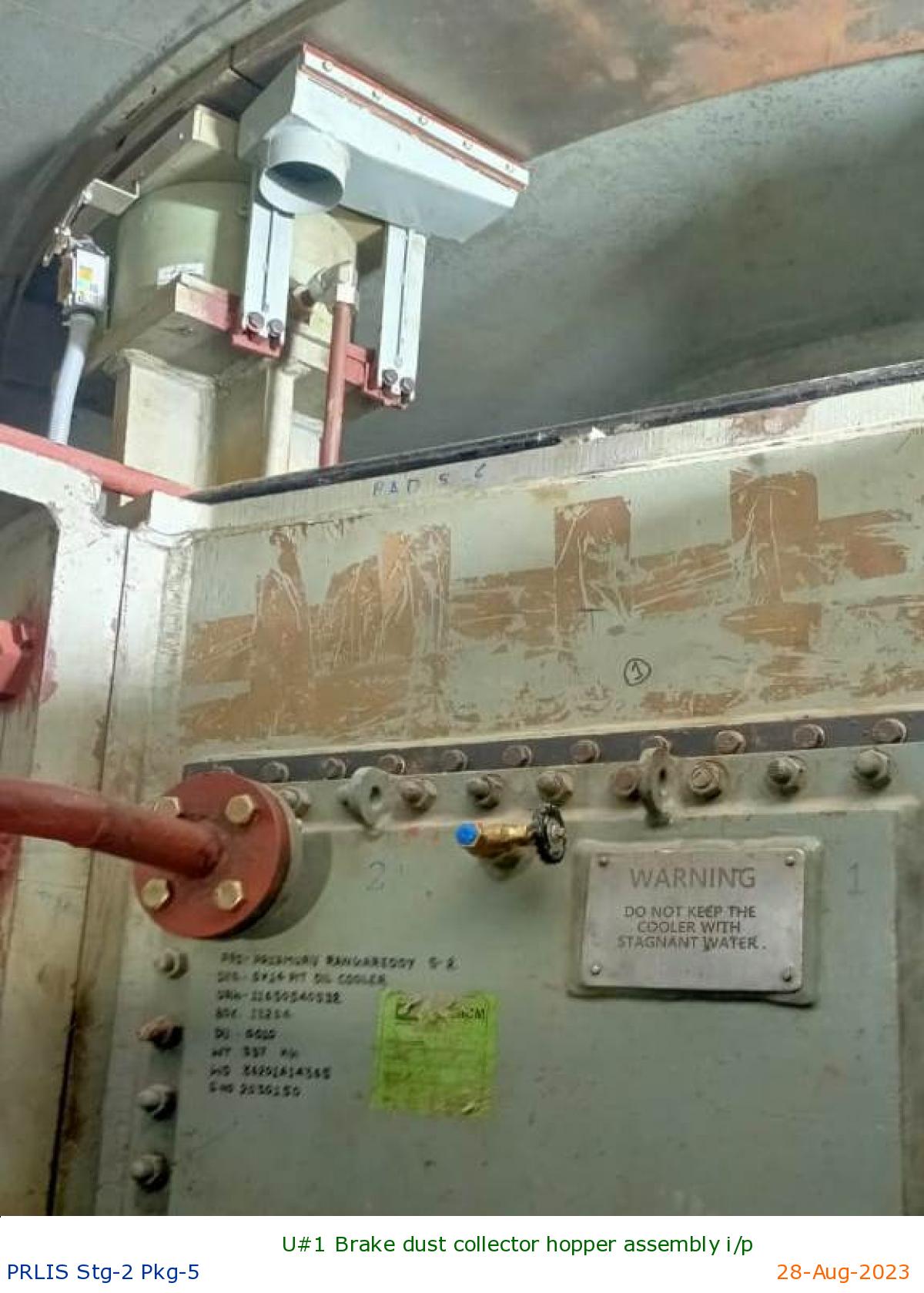

U#1 Brake dust collector hopper assembly i/p

|

Installation & algnment of ACEB panels completed

|

U#4,5 WDS air receivers positioning in progress

|

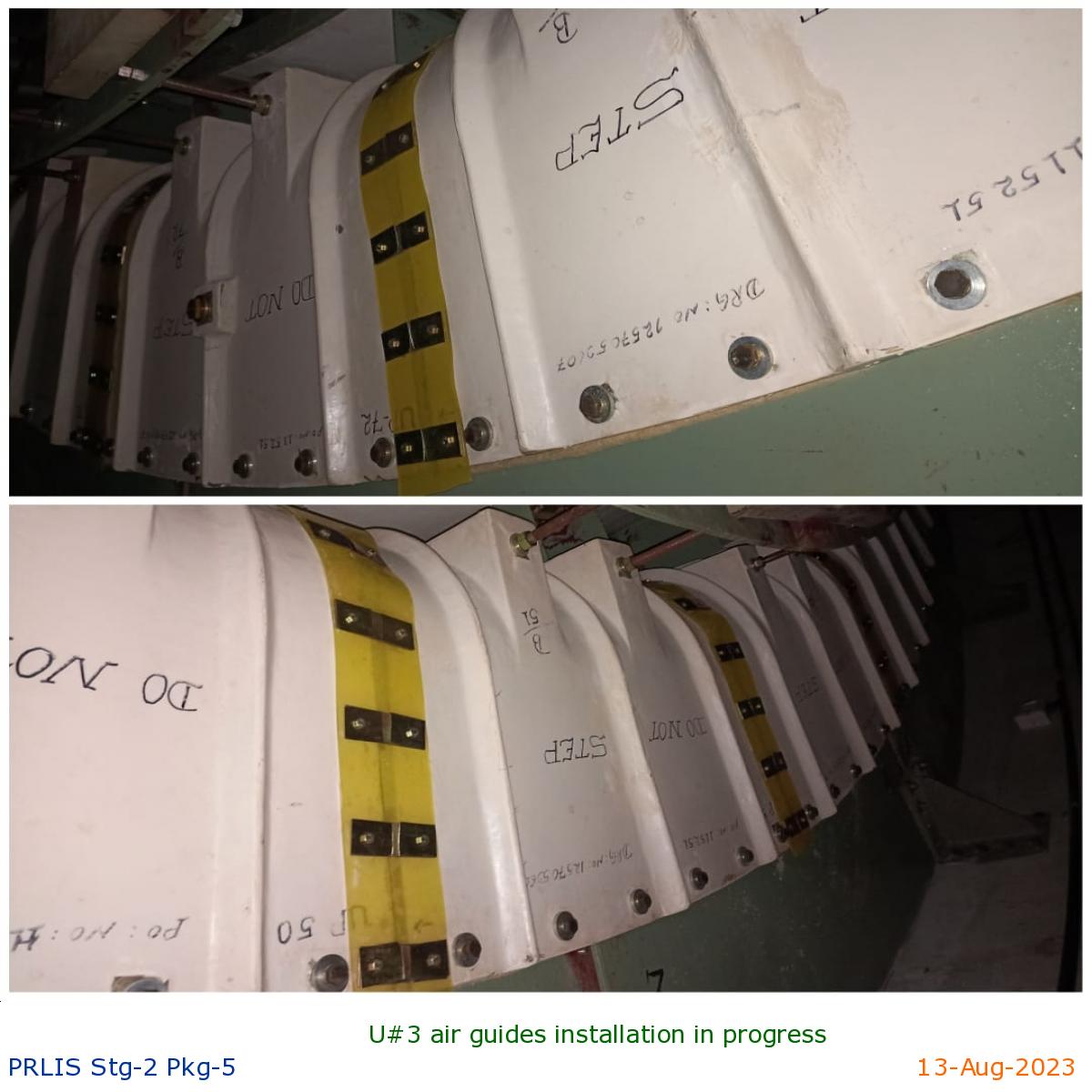

U#3 air guides installation in progress

|

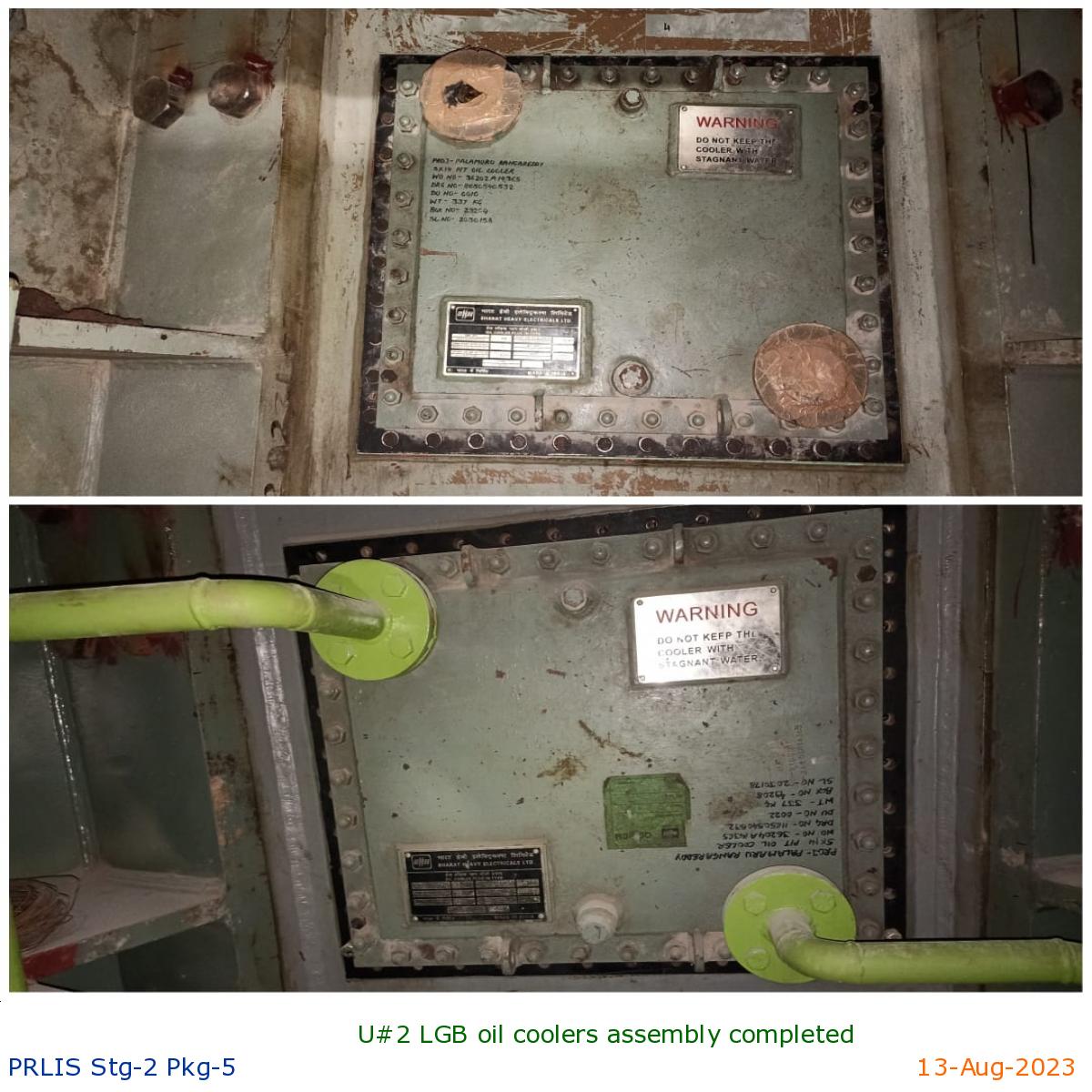

U#2 LGB oil coolers assembly completed

|

U#1 WDS pipeline routing completed

|

U#4 cyclone seperator erection is completed

|

U#3 CWS cyclone seperator and main header piping

|

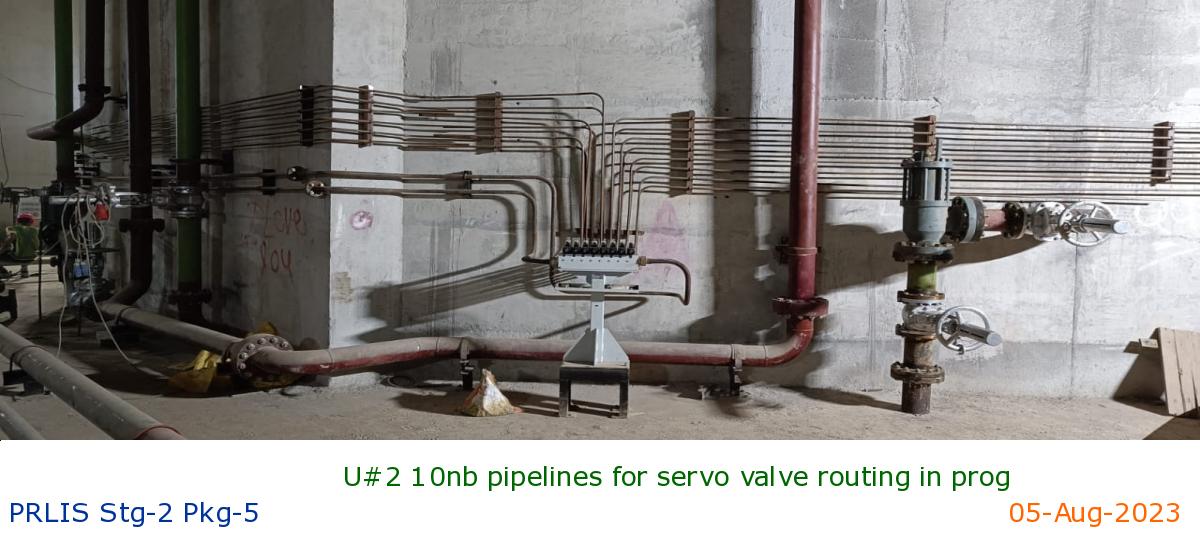

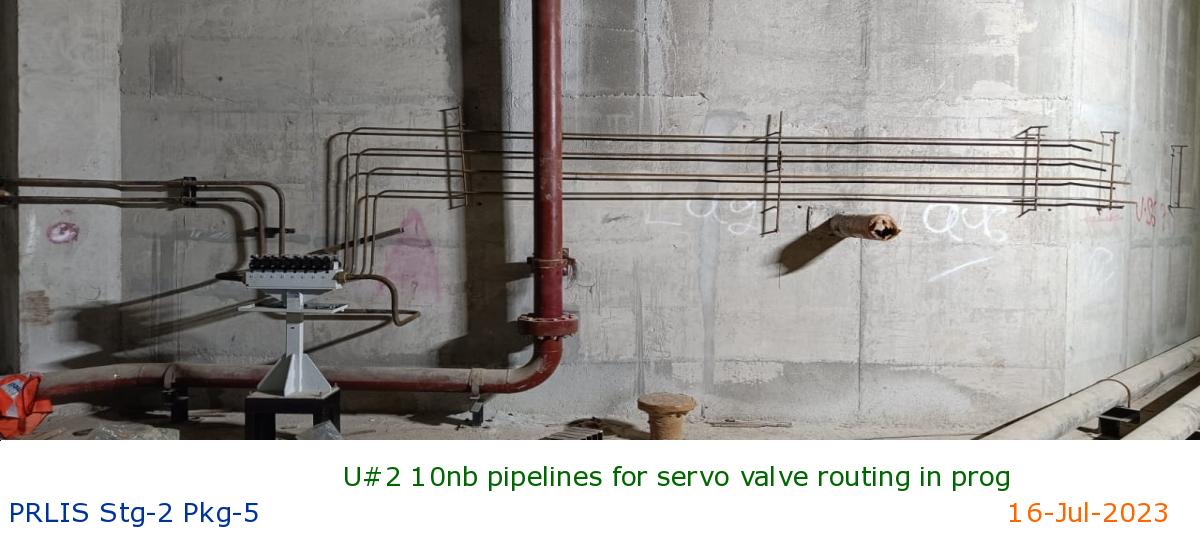

U#2 10nb pipelines for servo valve routing in prog

|

U#2 Band drain pipeline routing is completed

|

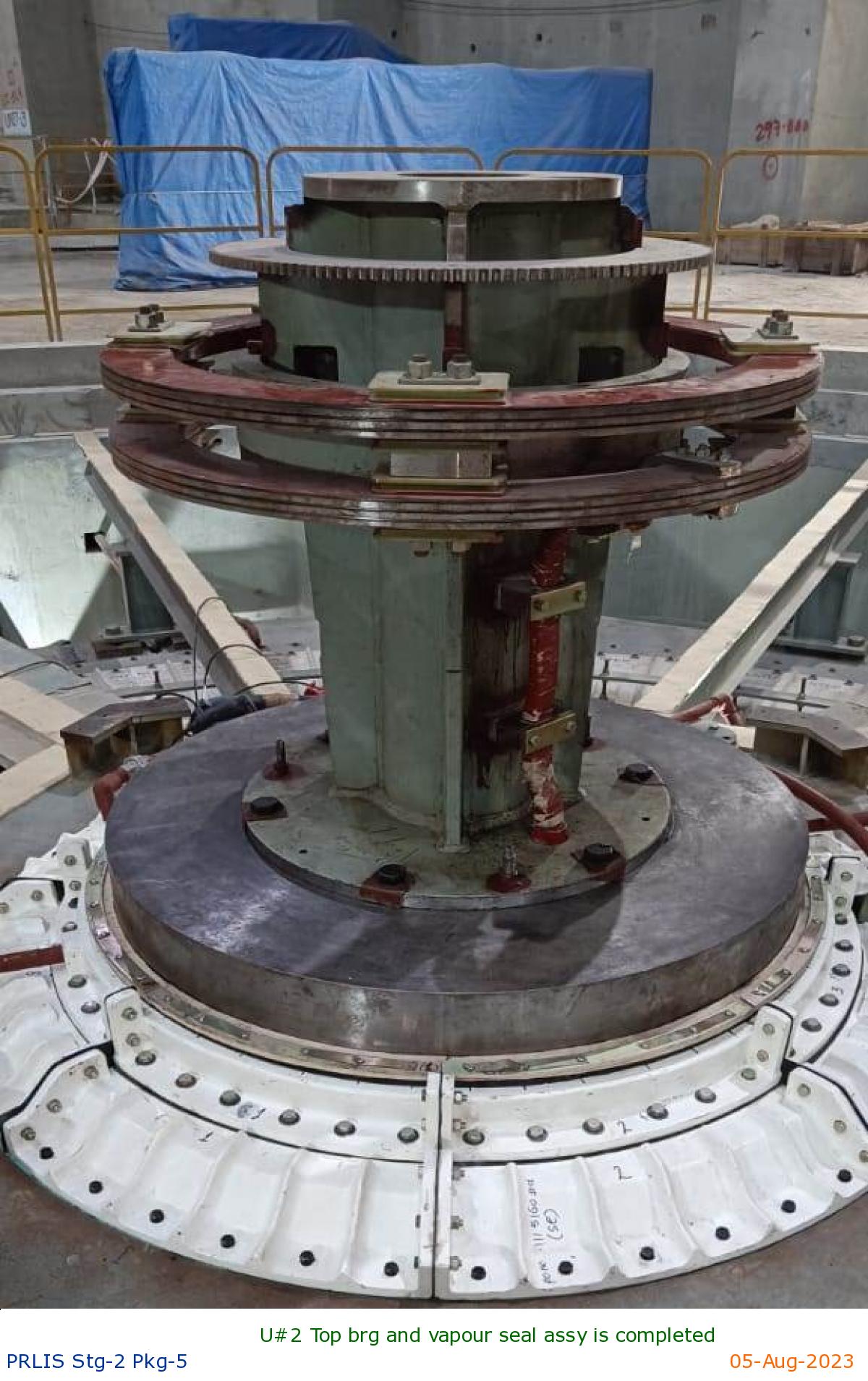

U#2 Top brg and vapour seal assy is completed

|

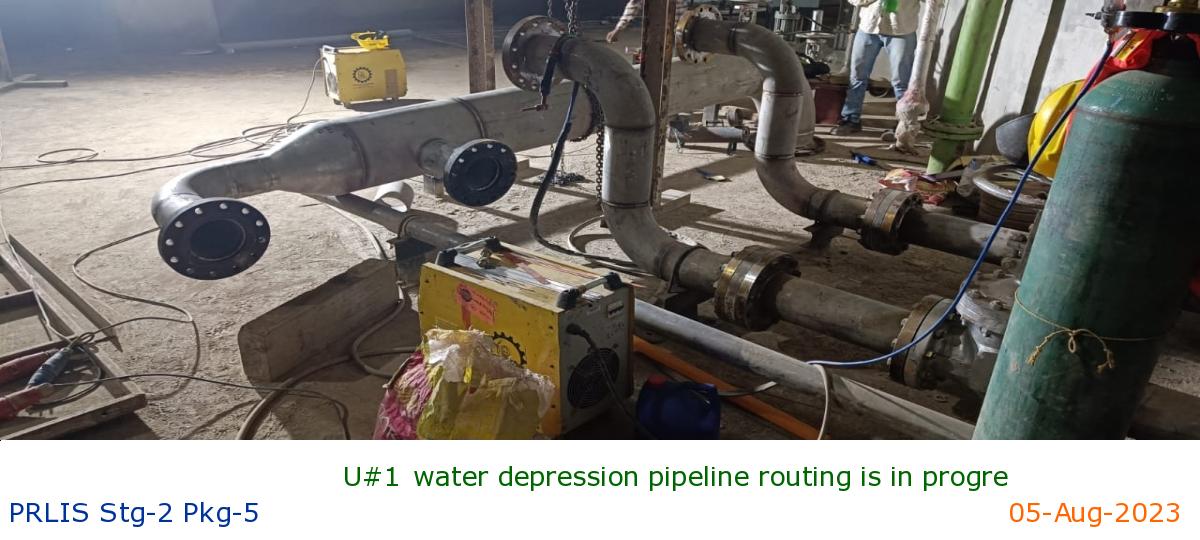

U#1 water depression pipeline routing is in progre

|

U#1 DTT routing from brg to panel is in progress

|

U#1 Brush gear casing installation is completed

|

U#1 LGB Cooler piping assy is completed

|

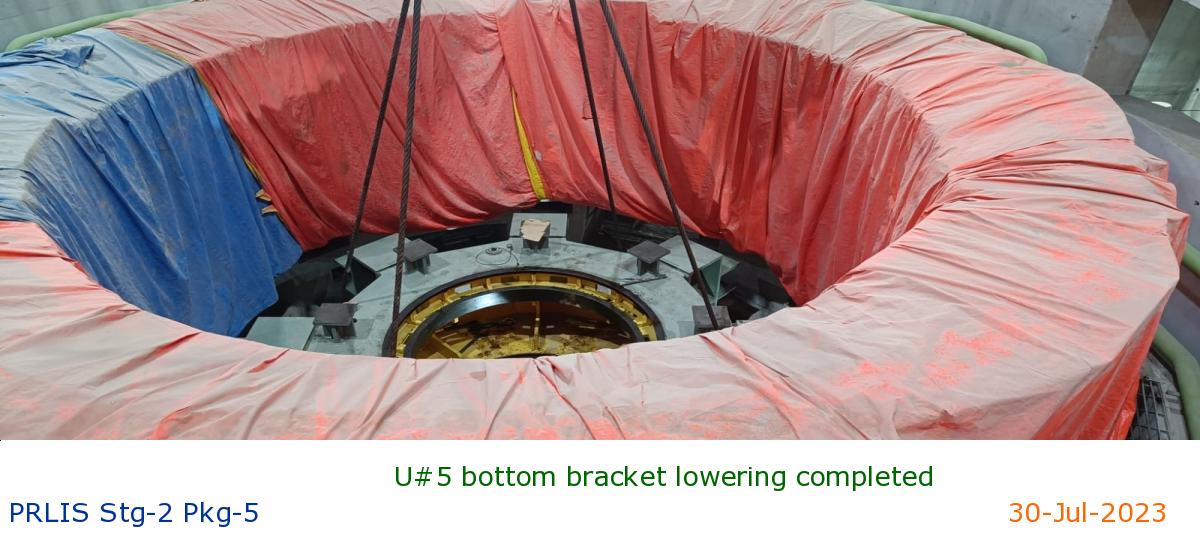

U#5 bottom bracket lowering completed

|

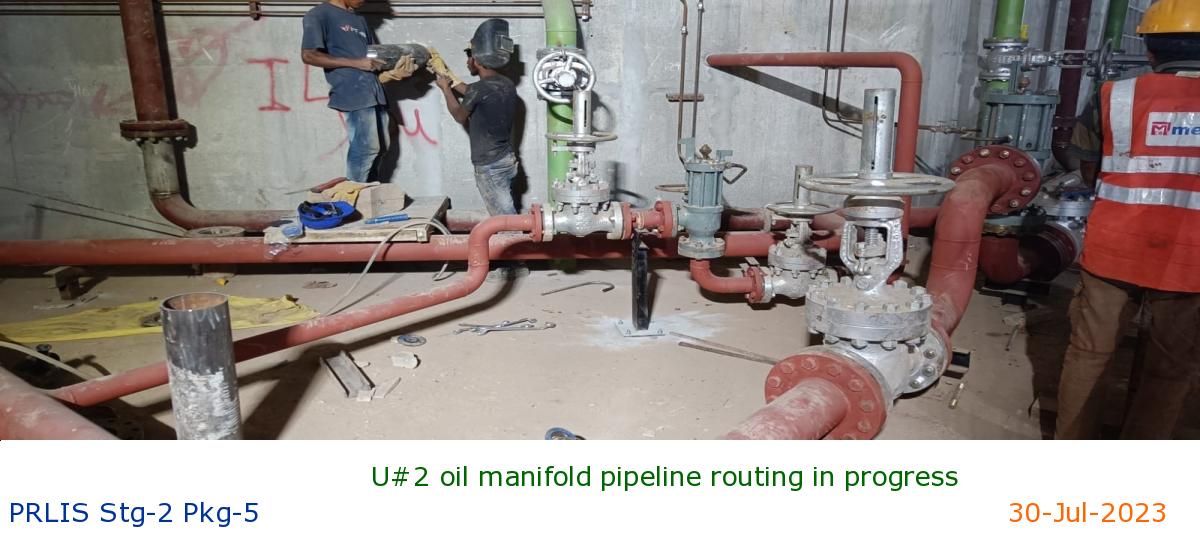

U#2 oil manifold pipeline routing in progress

|

U#2 motor transformer dry out completed

|

U#1 band drain pipeline routing is completed

|

U#1 oil manifold pipeline routing is completed

|

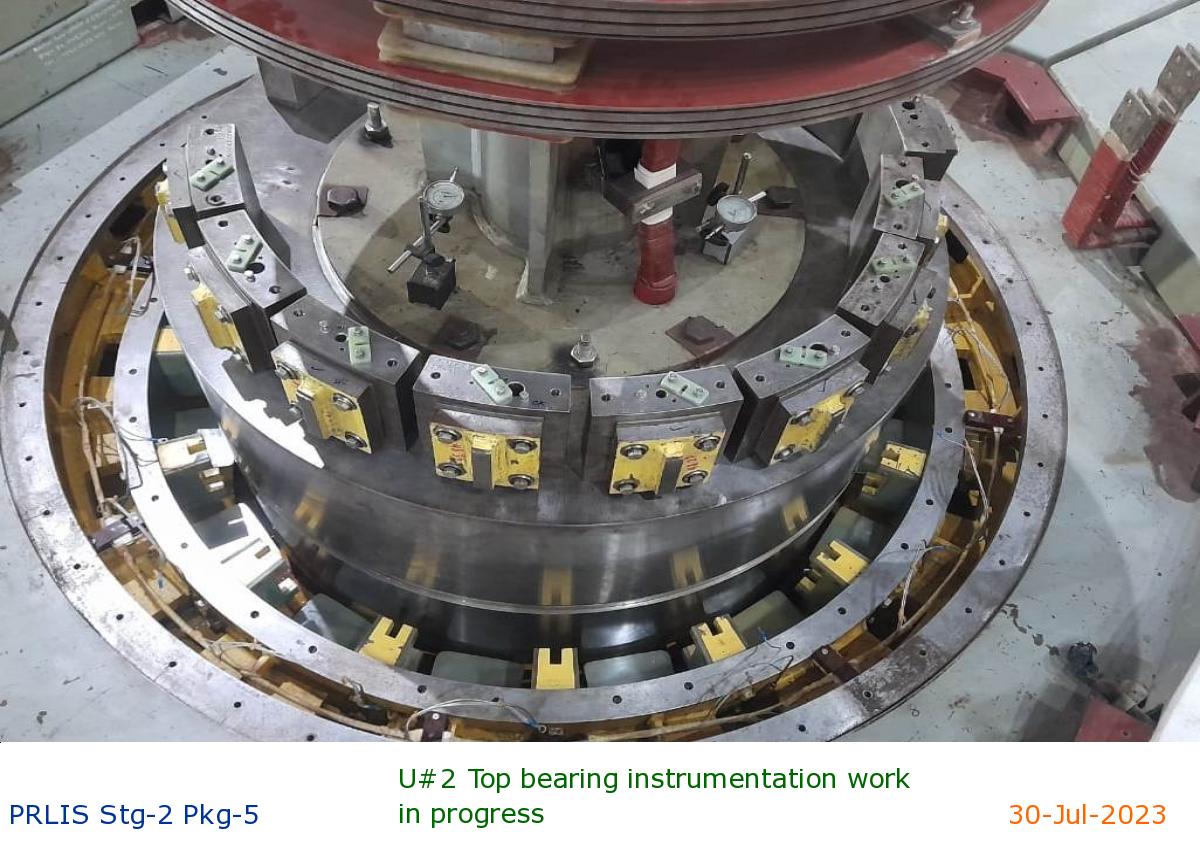

U#2 Top bearing instrumentation work

in progress

|

U#1 Water air pipelines routing in progress

|

U#1 Bottom vapour seal assy completed

|

U#1 Bottom oil coolers assy in progress

|

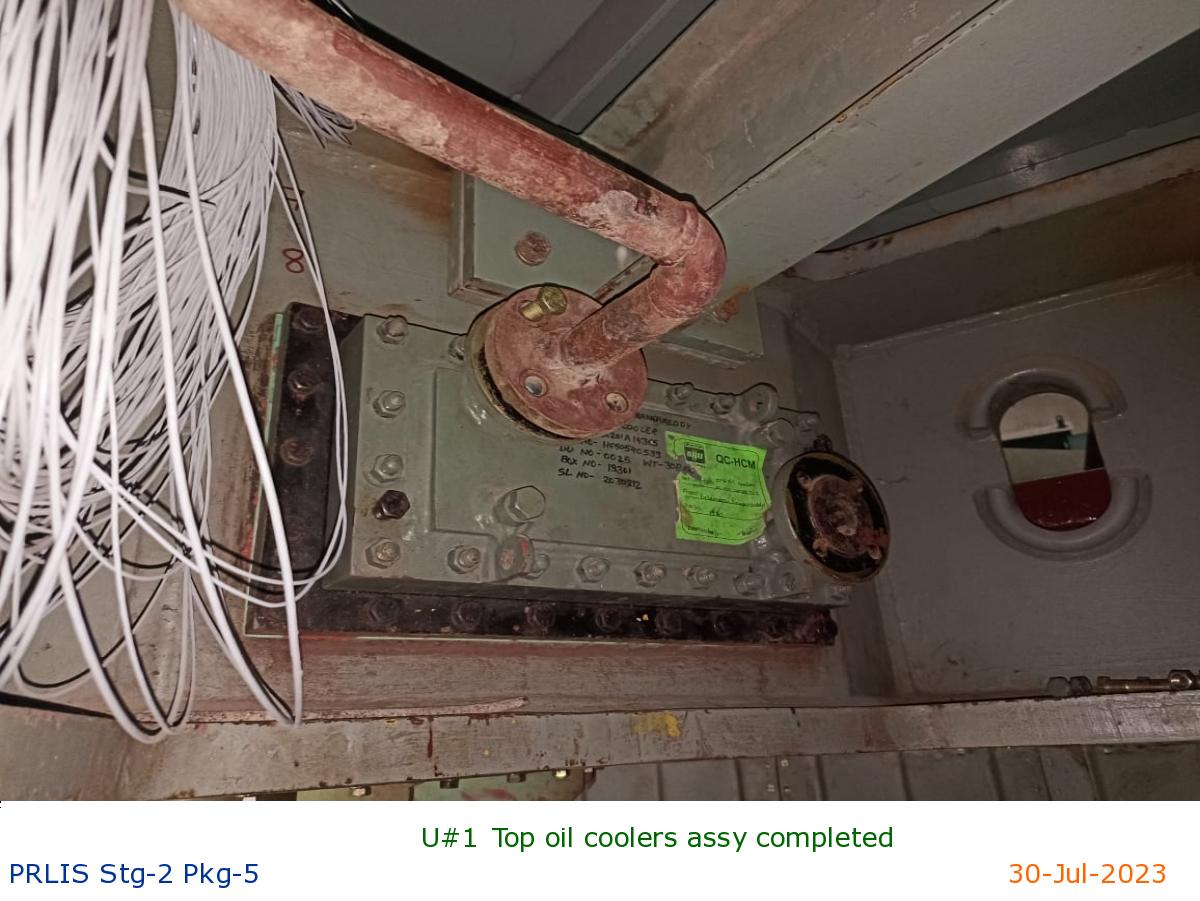

U#1 Top oil coolers assy completed

|

U#1 Top vapour seal assy completed

|

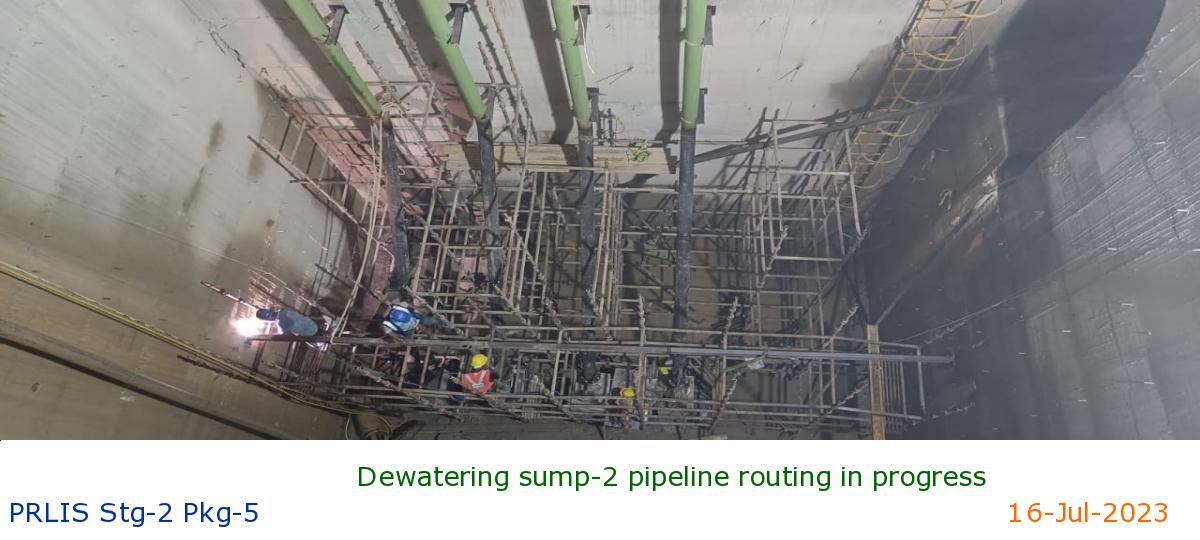

Dewatering sump-2 pipeline routing in progress

|

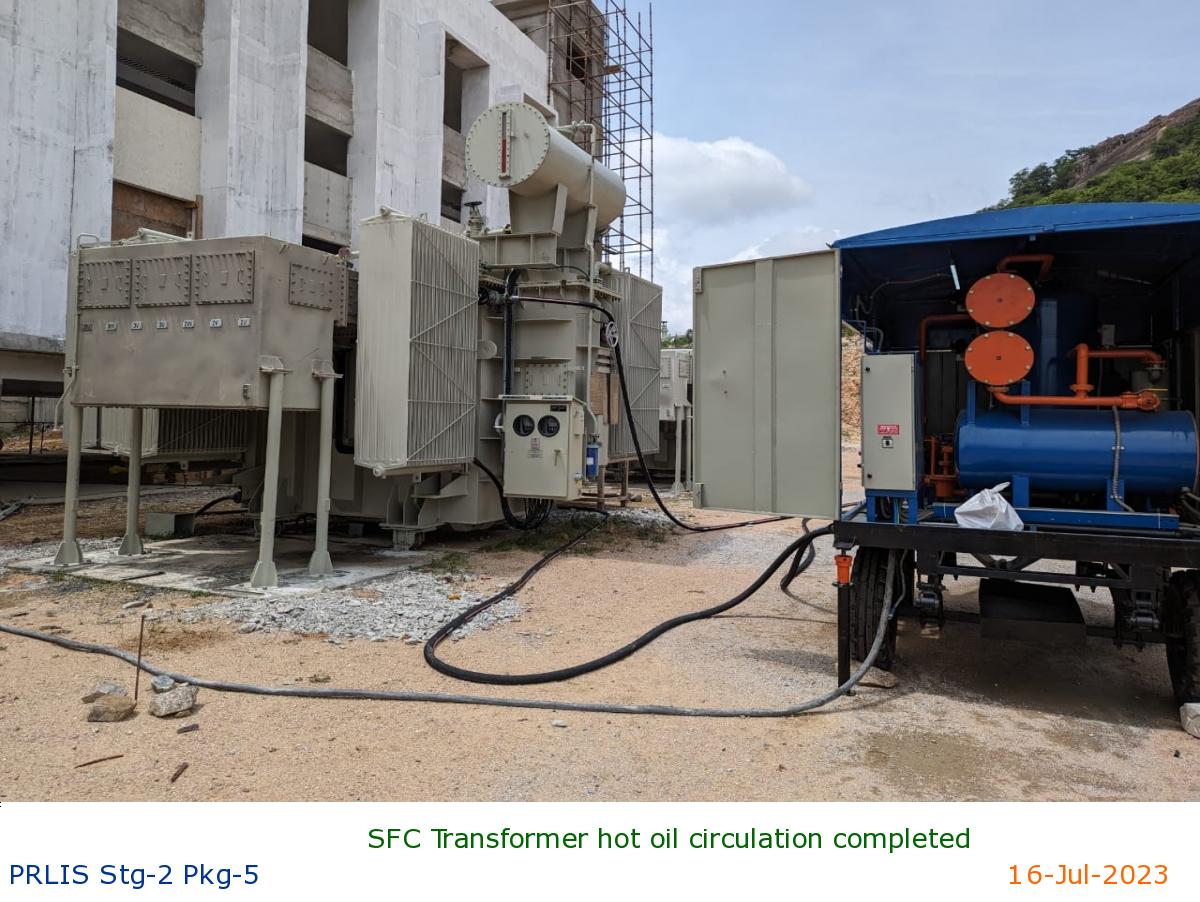

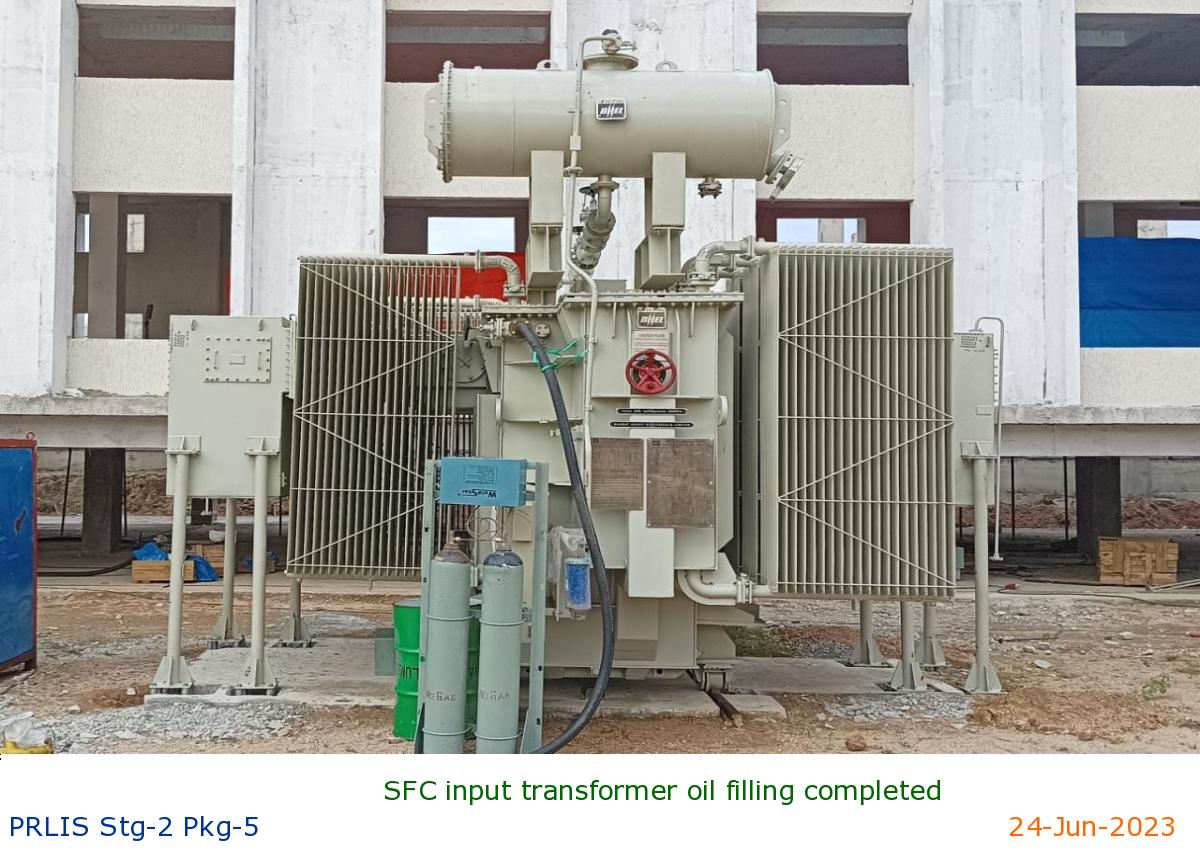

SFC Transformer hot oil circulation completed

|

U#2 10nb pipelines for servo valve routing in prog

|

U#2 MDV pushpull bolt,spacerflange bush replaced

|

U#2 Motor transformer

|

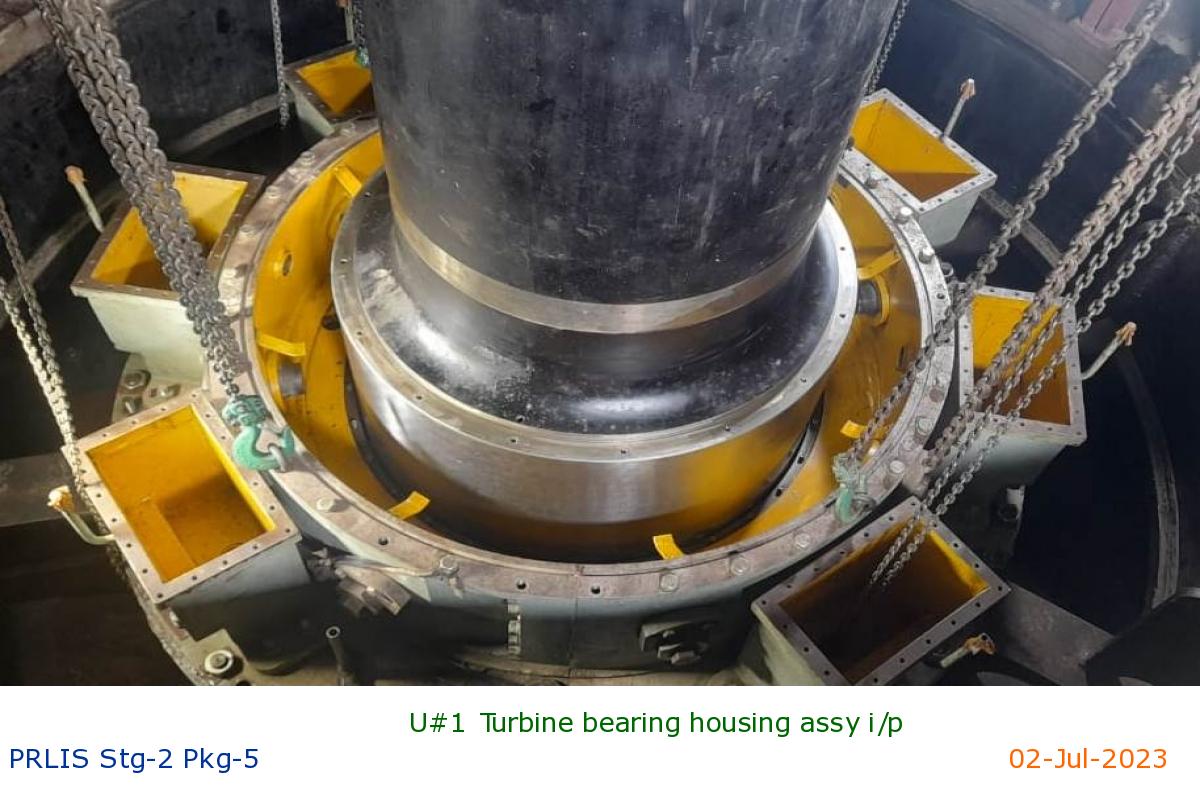

U#1 Turbine GB Housing assembly in progress

|

U#1 Motor transformer

|

U#4 Rotor rim building is in progress

|

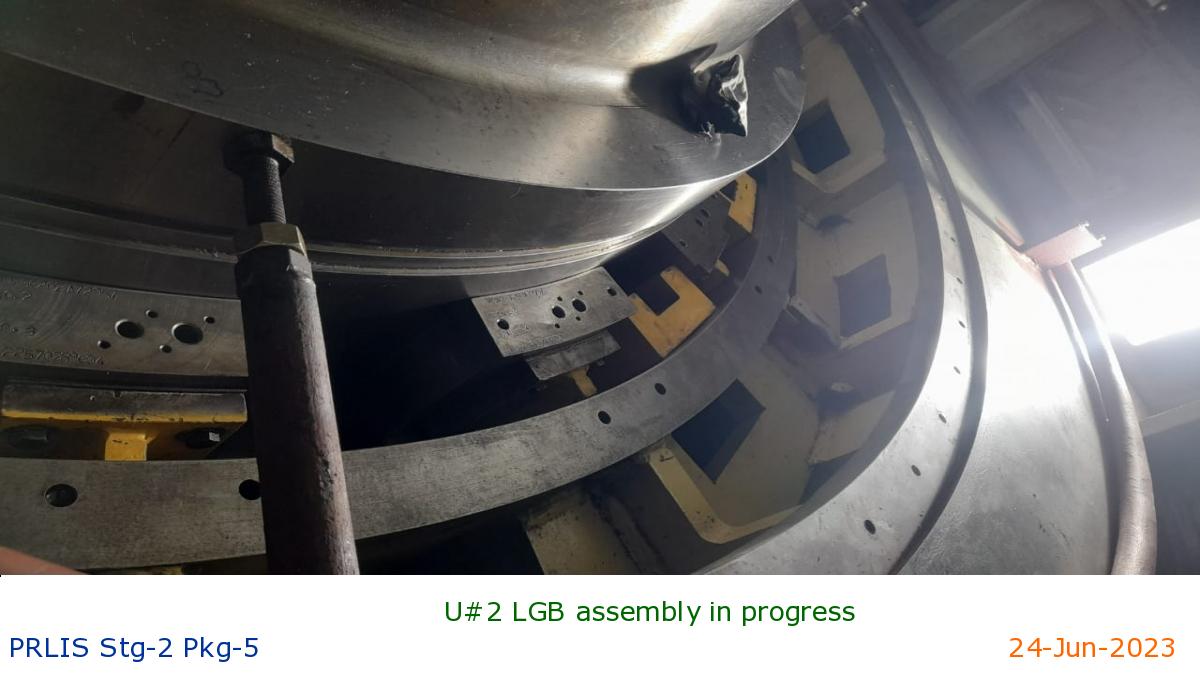

U#2 LGB Bearing final assy in progress

|

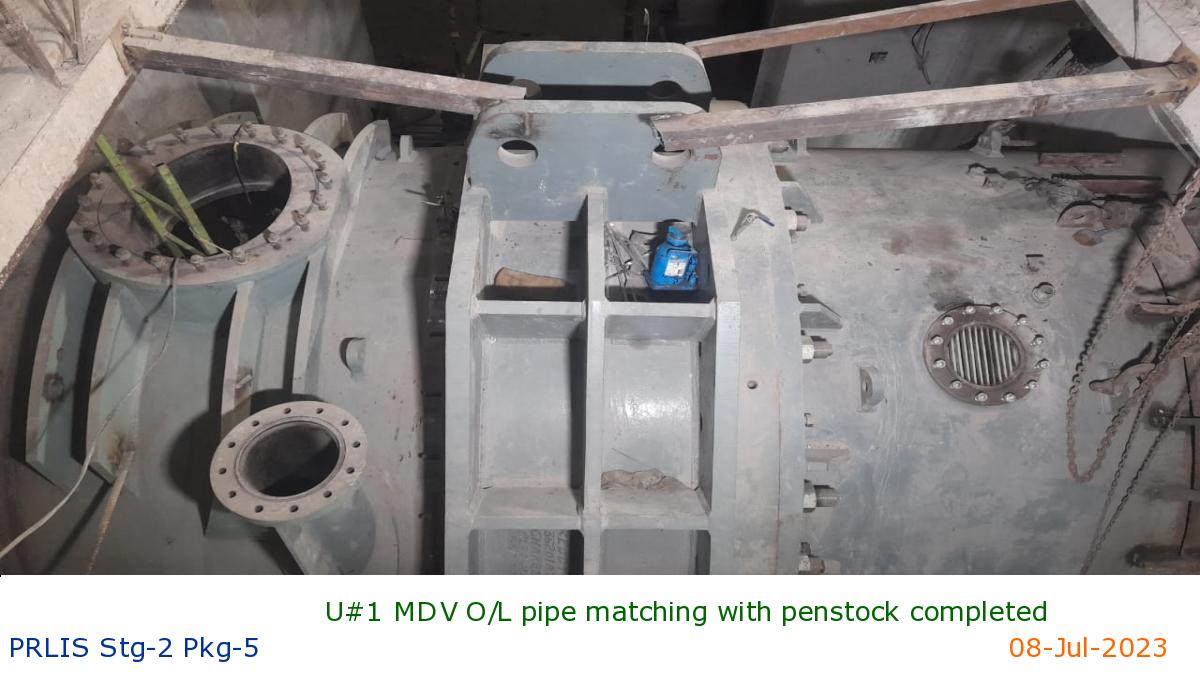

U#1 MDV O/L pipe matching with penstock completed

|

U#1 TGB Housing assy

|

U#4 Rotor rim building is in progress

|

U#4 brake jacks assy in progress

|

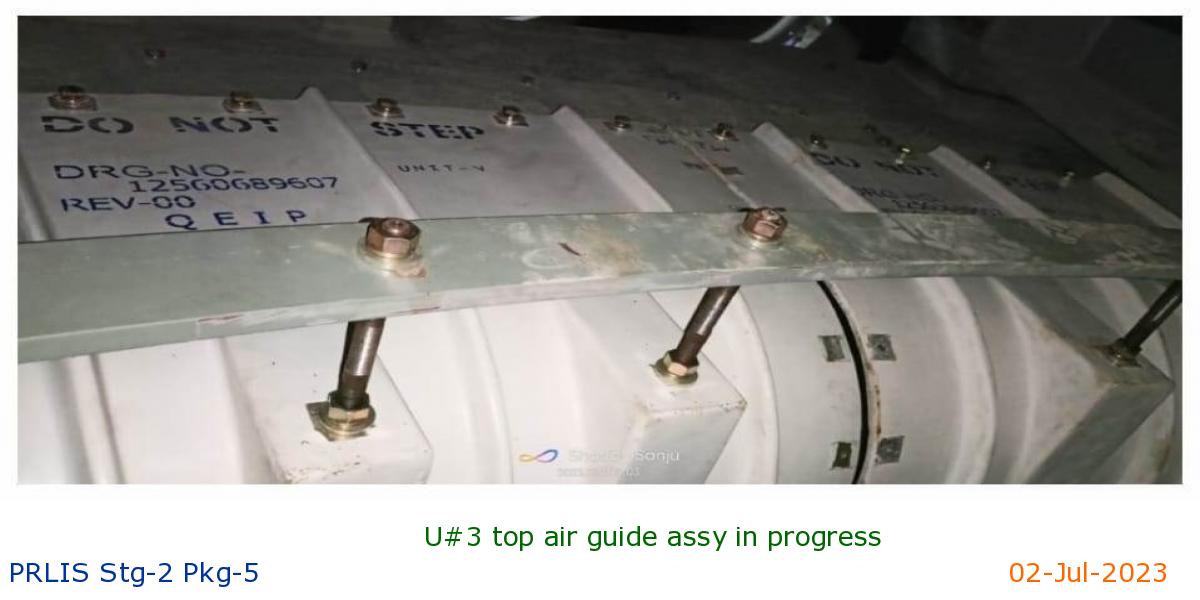

U#3 top air guide assy in progress

|

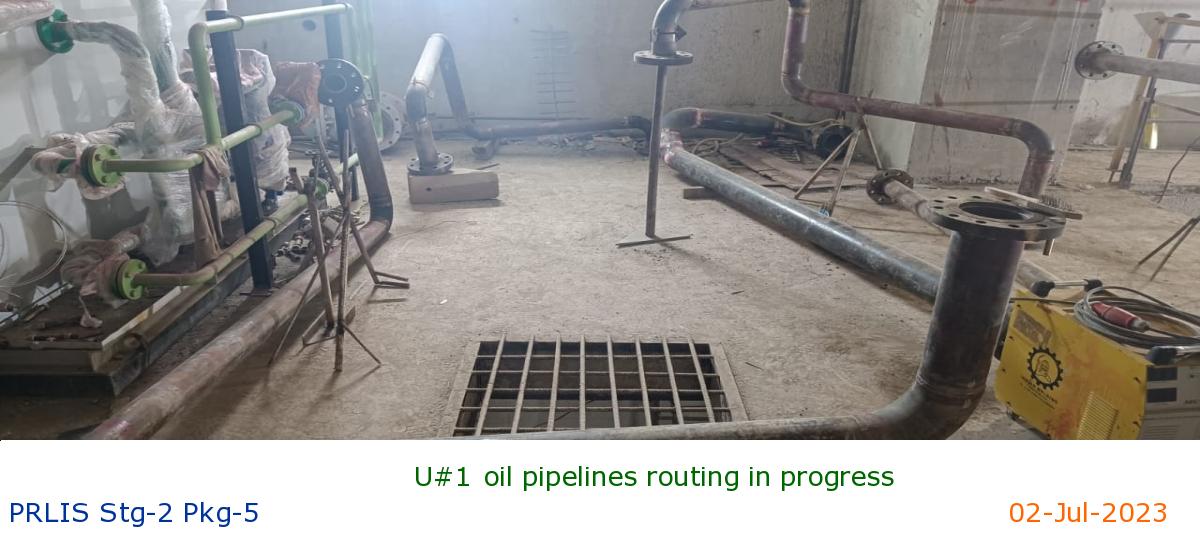

U#1 oil pipelines routing in progress

|

U#2 top bearing pads assy completed

|

U#1 Turbine bearing housing assy i/p

|

U#1 Servo operated valves pipeline routing i/p

|

SFC output transformer pressure test carried

|

SFC input transformer oil filling completed

|

U#5 Stator CW pipelines

|

U#4 Rotor rim building in progress

|

U#3 Top air guide installation in progress

|

U#2 LGB assembly in progress

|

U#1 LGB instrumentation in progress

|

U#2 Transformer ready for oil filling

|

U#1 Transformer ready for oil filling

|

D&D sump-2 autocoupling pedestals erection in prog

|

U#4 CWS pump to strainer piping in progress

|

U#3 Cws pipeline works in progress

|

U#2 turbine bearing sump assy in progress

|

SFC Transformer erection is in progress

|

U#4 CWS Strainer skid lowering to turbine floor

|

U#3 CWS cyclone seperator and main header piping

|

U#3 busduct installation at ground level

|

U#1 Busduct installation at ground level

|

U#1 Transformer erection is completed

|

U#1 shaft seal testing is completed

|

U#2 shaft seal testing is completed

|

Panels installation is in progress

|

Panels installation is in progress

|

Panels installation is in progress

|

U#4 CW Strainer skid works are in progress

|

U#4 CW pump motor skid works are in progress

|

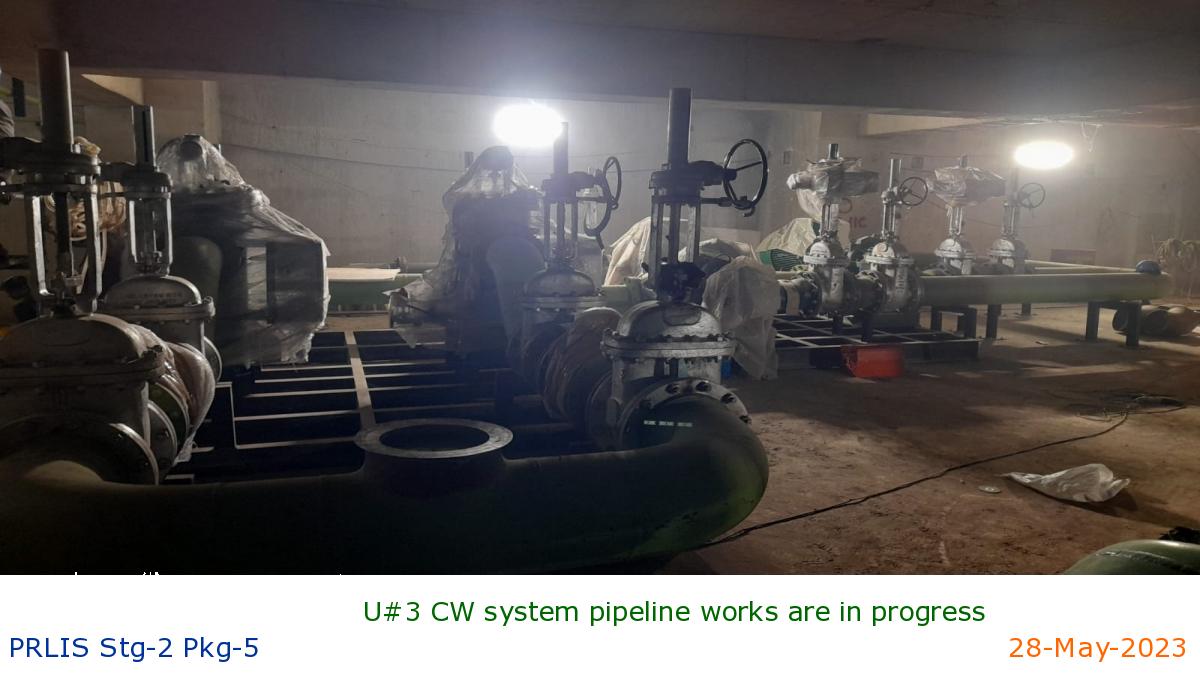

U#3 CW system pipeline works are in progress

|

U#3 cyclone seperators installation in progress

|

U#2 shaft seal installation is completed

|

U#2 transformer bushings installation is complete

|

U#1 transformers bushing installation completed

|

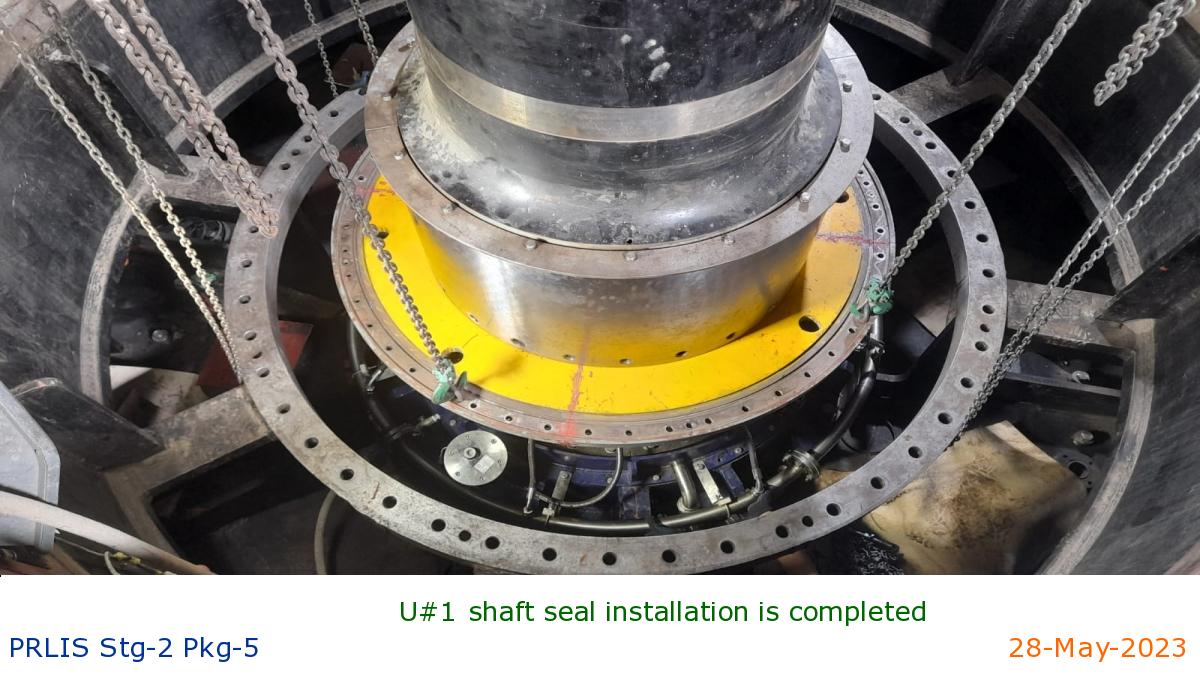

U#1 shaft seal installation is completed

|

U#5 View inside turbine pit

|

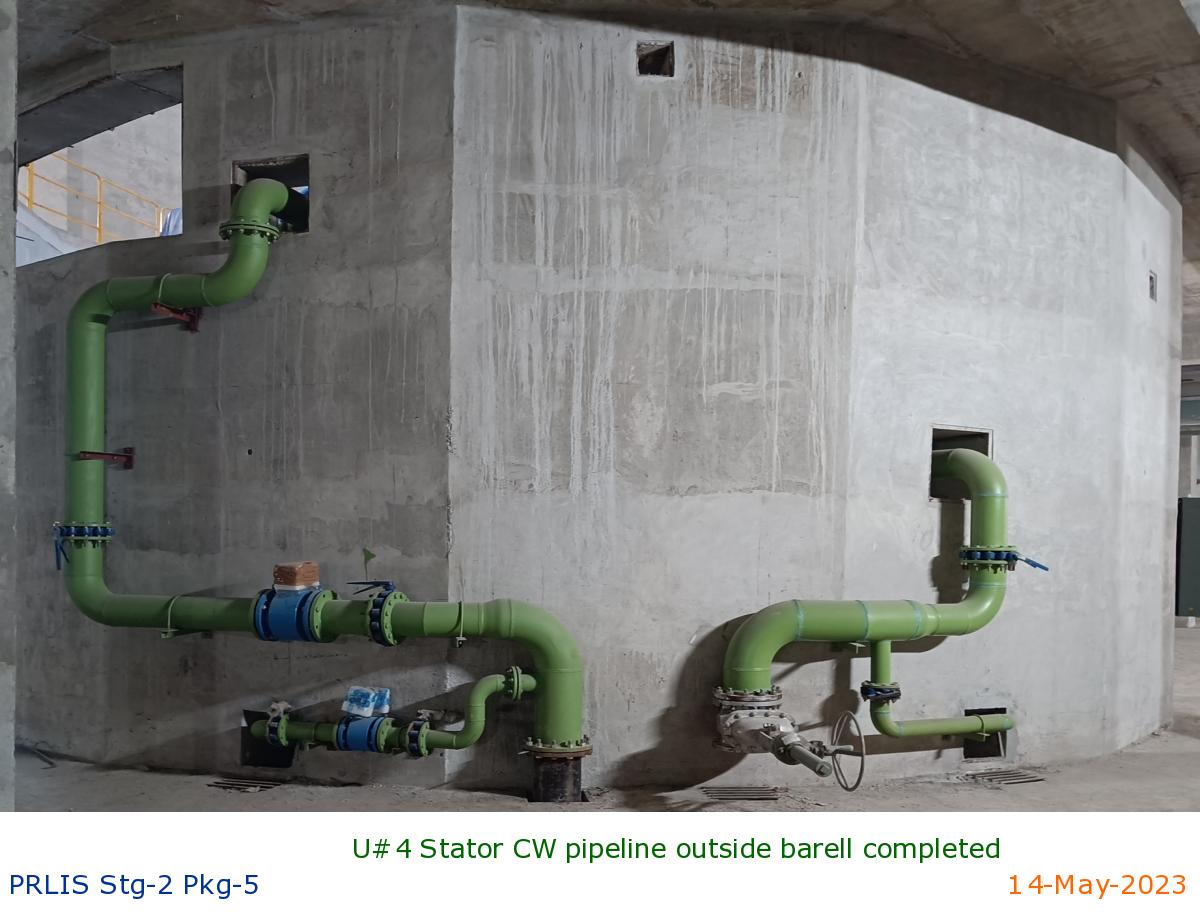

U#4 Stator CW pipeline outside barell completed

|

U#4 Stator CW pipeline inside barell routing i/p

|

U#4 CW system works in progress

|

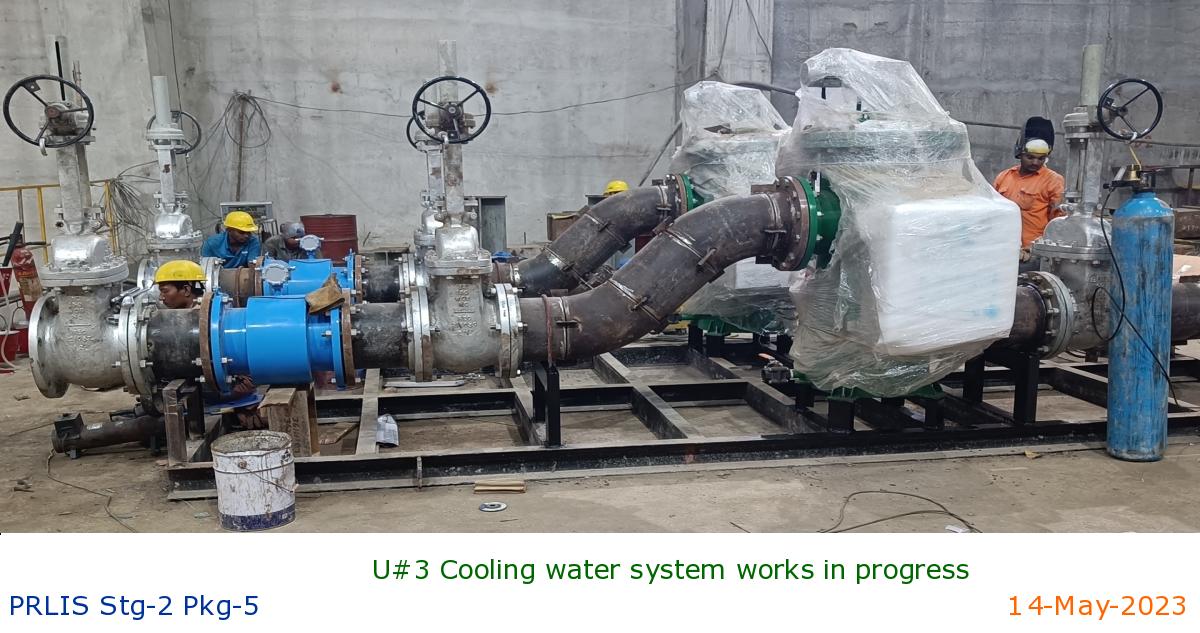

U#3 Cooling water system works in progress

|

U#1 water depression pipeline routing is in progre

|

U#1 shaft seal installation in progress

|

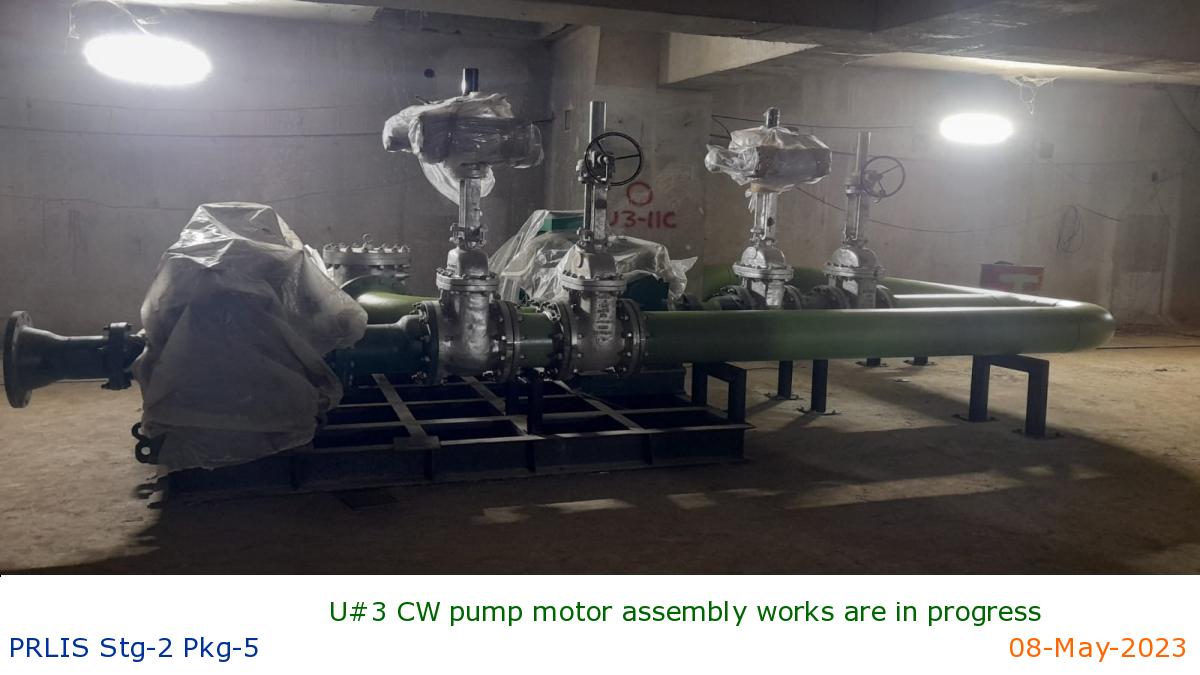

U#3 CW pump motor assembly works are in progress

|

U#2 nutguard assembly and welding completed

|

U#1 water depression pipeline routing is in progre

|

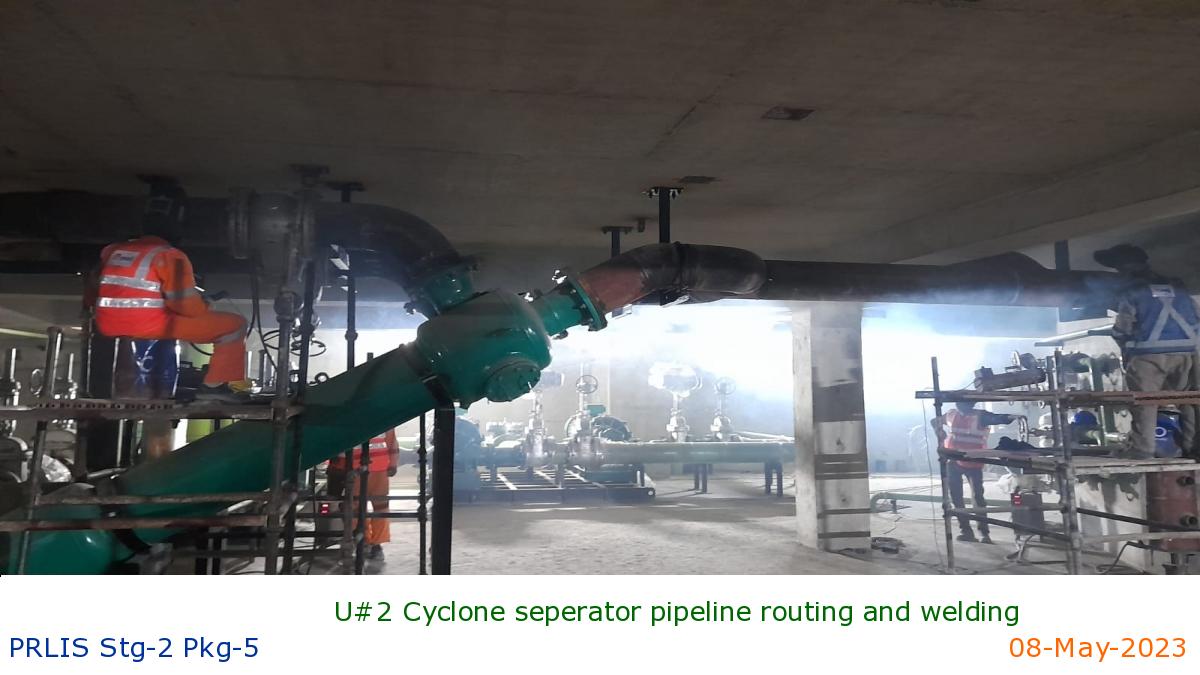

U#2 Cyclone seperator pipeline routing and welding

|

U#1 nutguard assembly and welding completed

|

U#5 Installation of Pump platform is completed

|

U#2 Water depression pipeline routing in progress

|

U#5 GV servomotor alignment completed

|

U#2 CW main header near DT routing completed

|

U#1 CW main headers near dt routing completed

|

Water depression receivers positioning in progress

|

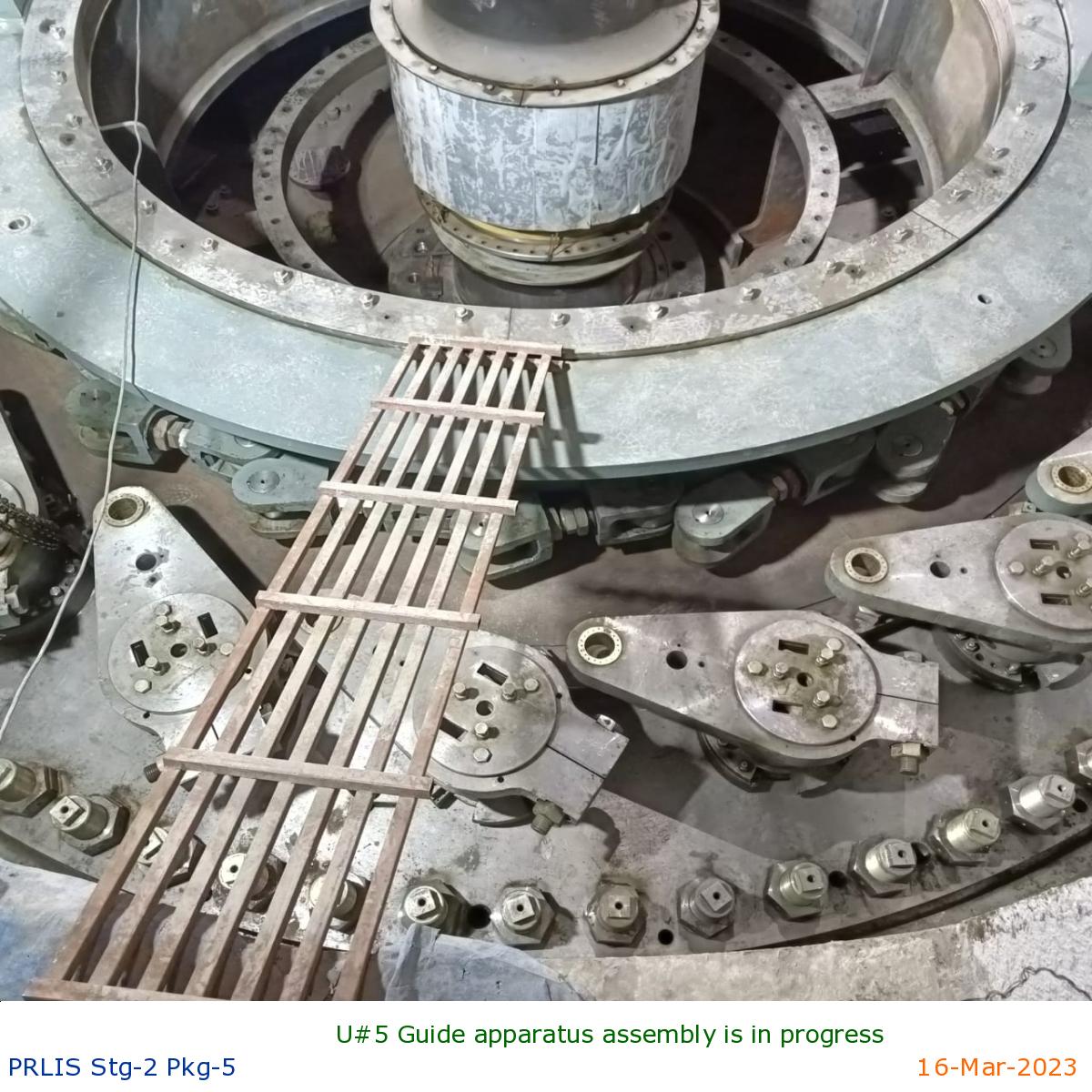

U#5 Guide apparatus assembly is in progress

|

U#1 mdv inlet and outlet pipe fitup in progress

|

U#4 Motor CW pipeline outside barell routing i/p

|

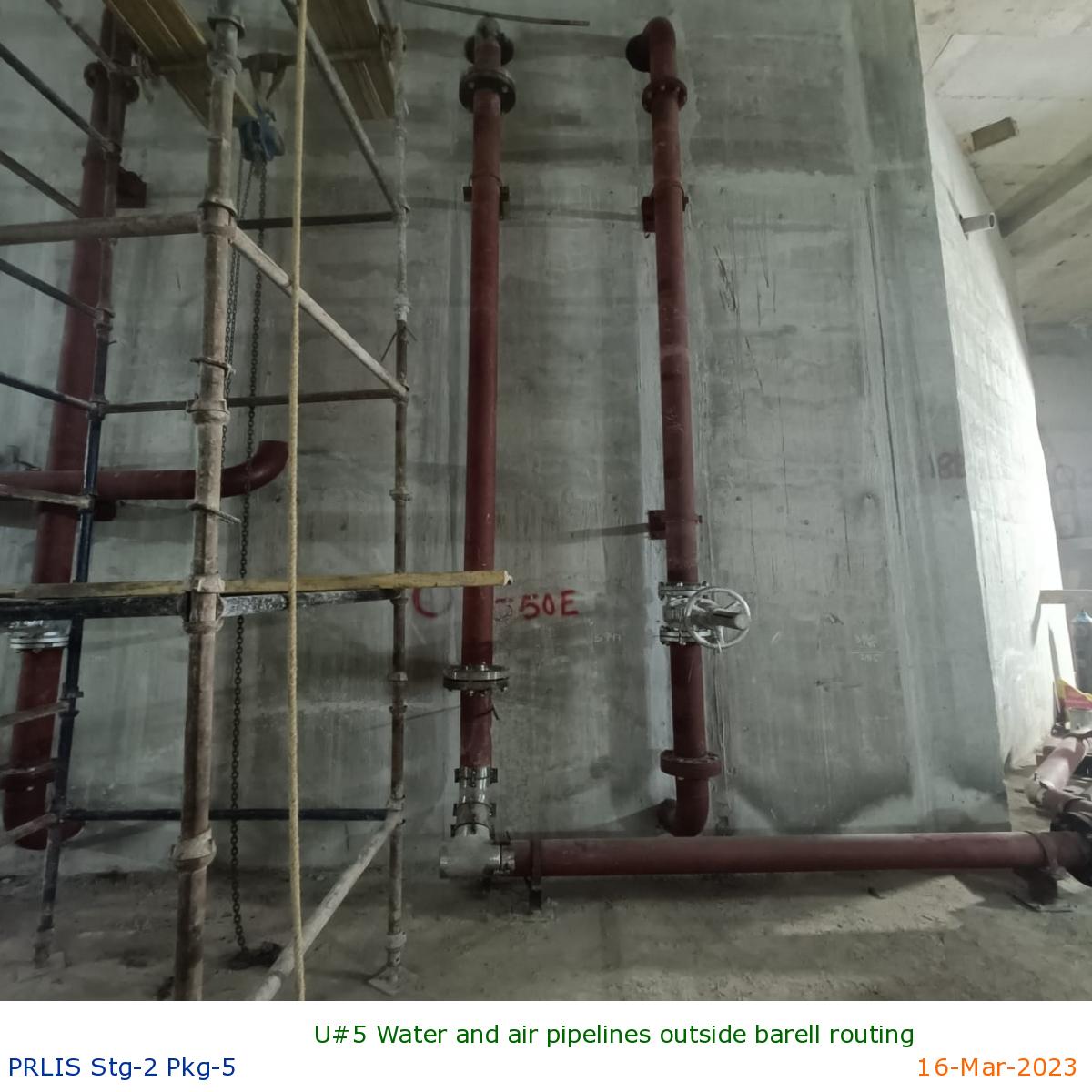

U#5 Water and air pipelines outside barell routing

|

U#5 Guide apparatus assembly is in progress

|

U#2 MDV inlet pipe welding is completed

|

U#2 Top oil vapour pipeline routing is completed

|

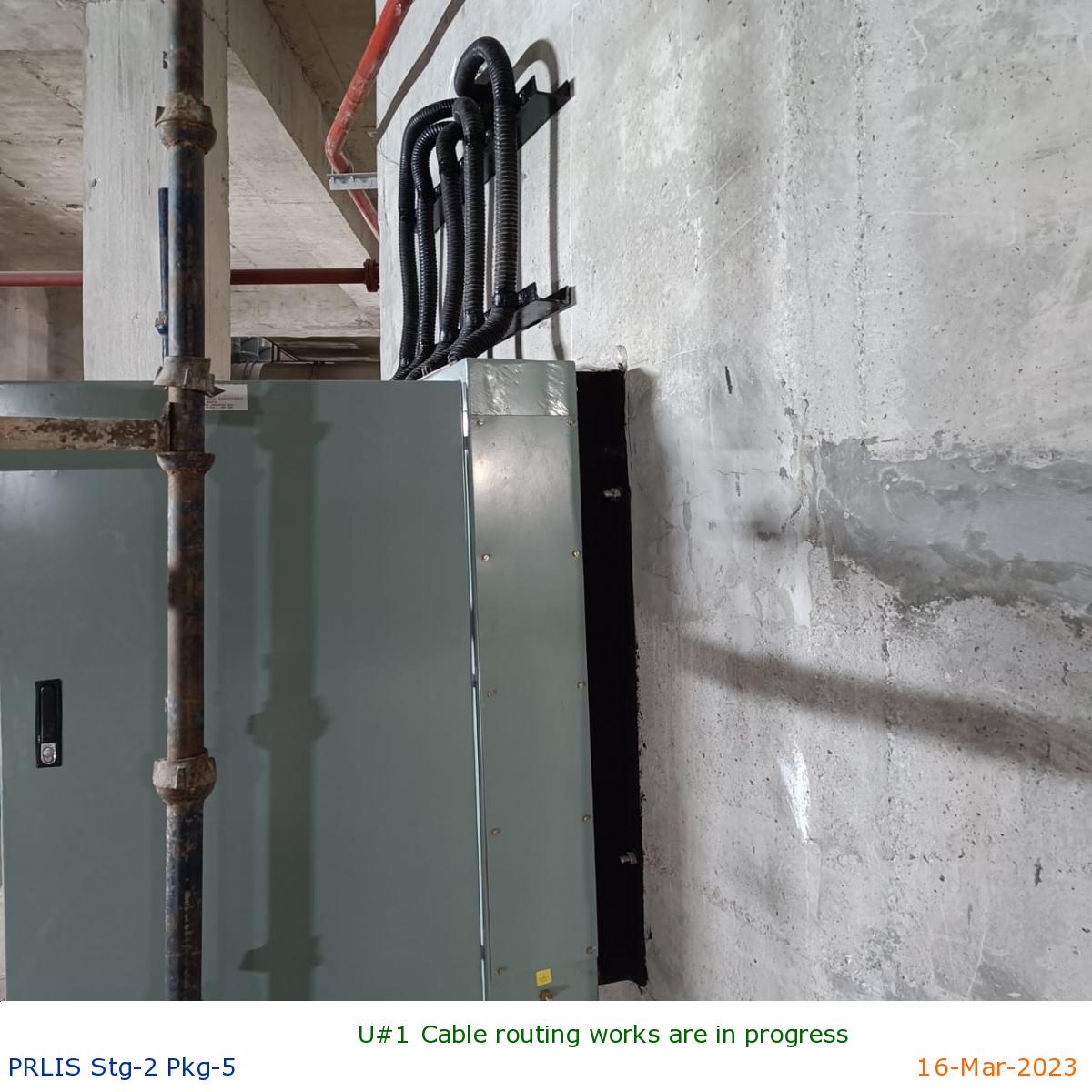

U#1 Cable routing works are in progress

|

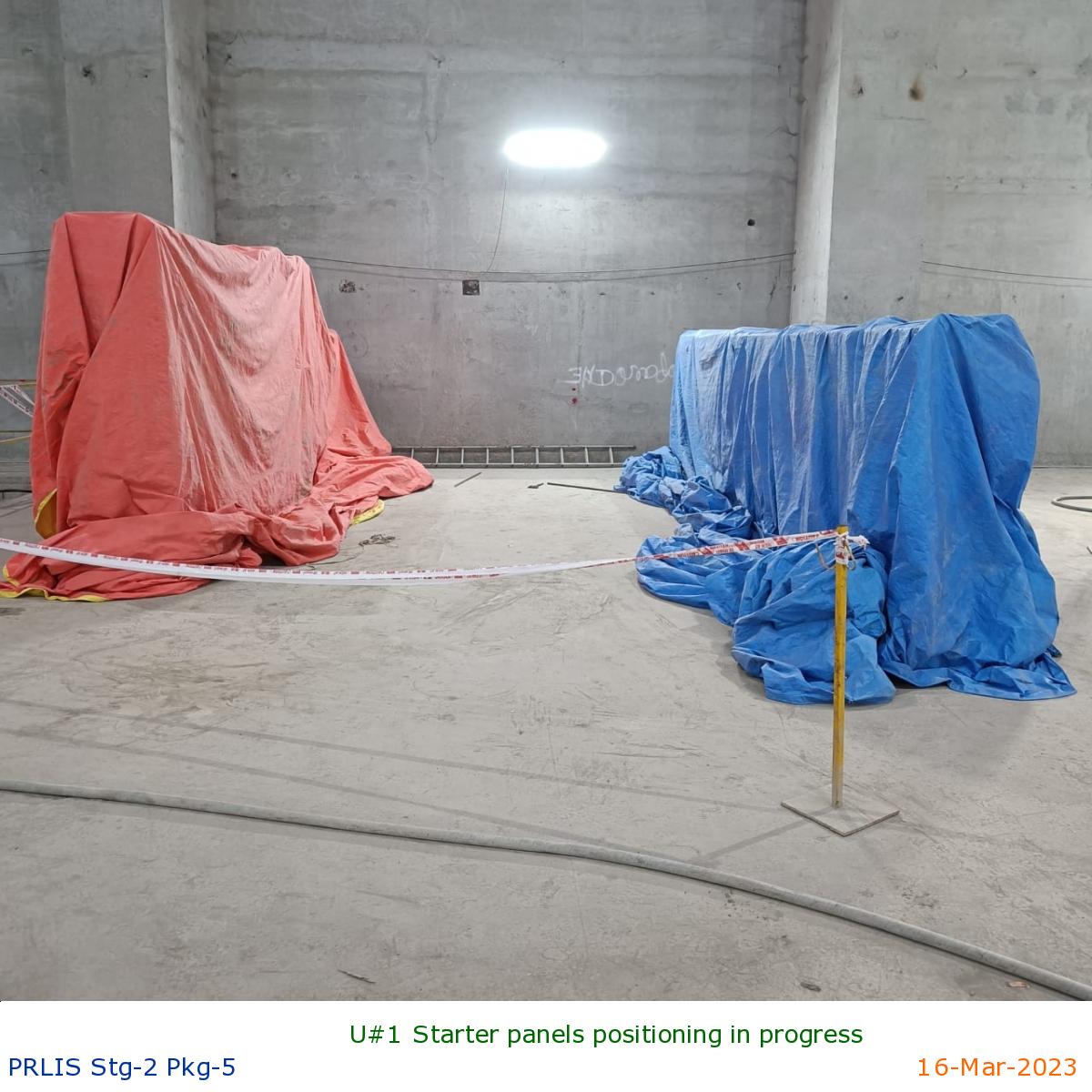

U#1 Starter panels positioning in progress

|

UNIT 1-2 POSITIONING OF PRESSURE RECEIVERS IN PROG

|

UNIT1-2 POSITIONING OF FIRE FIGHTING PANEL COMPD

|

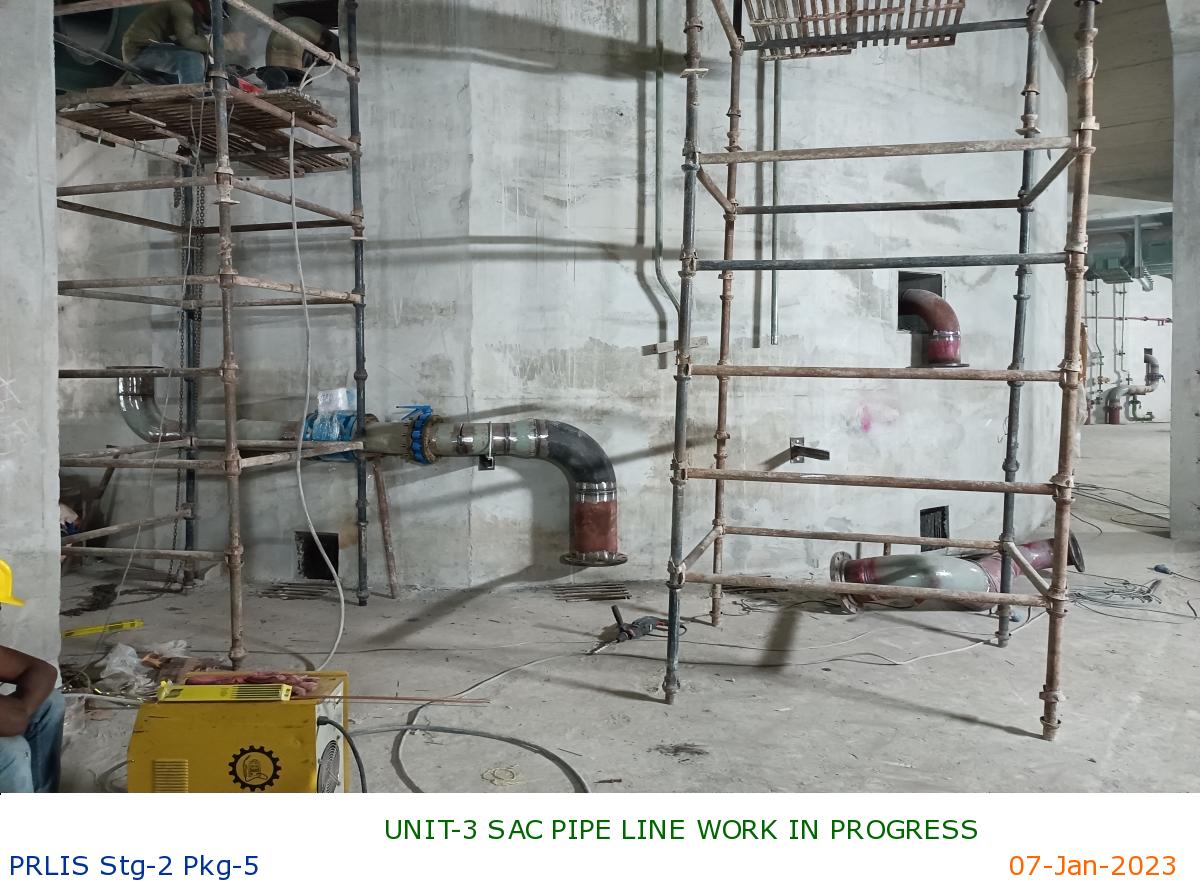

UNIT-3 SAC PIPE LINE WORK IN PROGRESS

|

UNIT-5 FLOOR PLATE SUPPORT FIXING IN PROGRESS.

|

UNIT-2 DC LEAD WOK IN PROGRESS

|

UNIT-3 ALIGHNMENT OF TUBULAR SHAFT AND SLIP RINGS COMPD

|

UNIT-1 TOP BOTTOM VAPOUR PIPING COMPLETED

|

WATAER DEPRESSION PIPE LINE HAEDER AT DV FLOOR

|

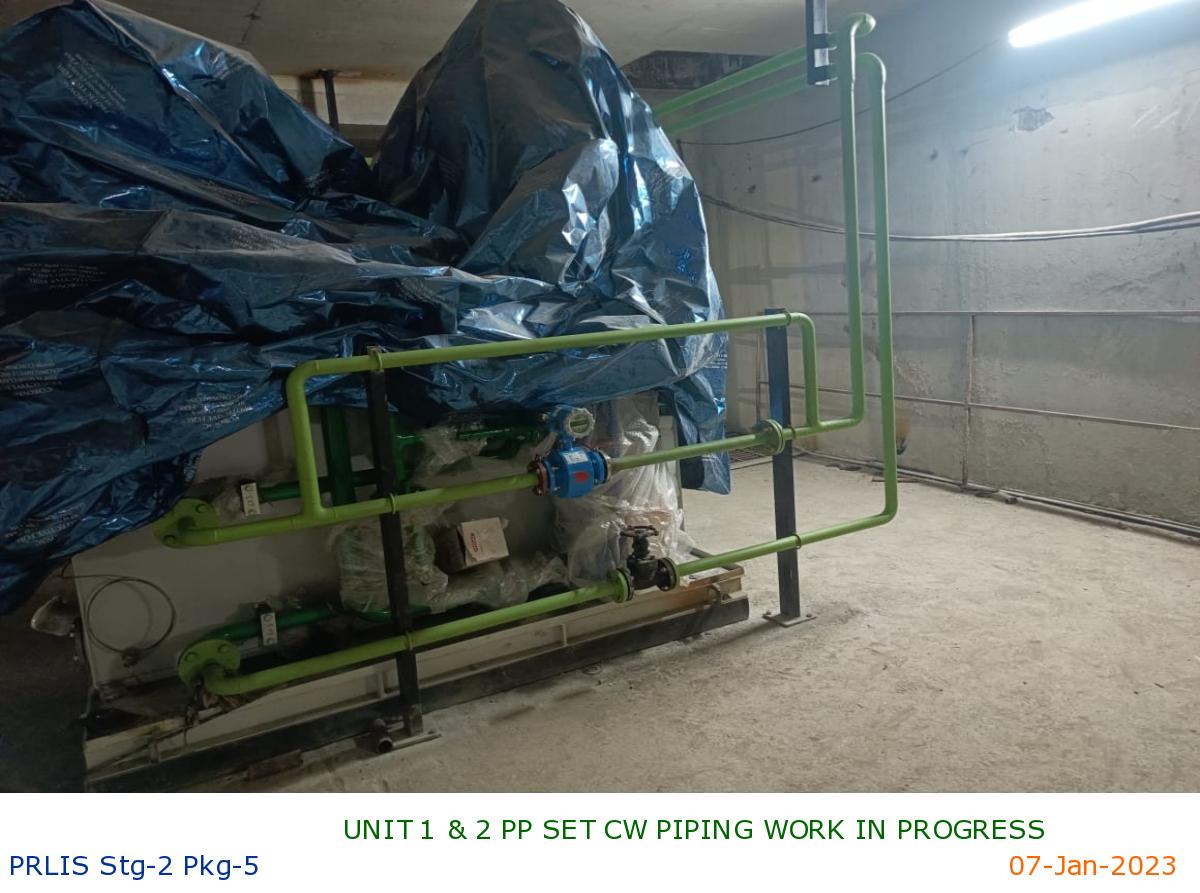

UNIT 1 & 2 PP SET CW PIPING WORK IN PROGRESS

|

UNIT-3 POSITIONING OF pp SETS COMPLETED

|

UNIT-5 INSPECTION AND CLEANING OF GUIDE VANES

|

UNIT-4 STATOR AND LOWER BRACKET

|

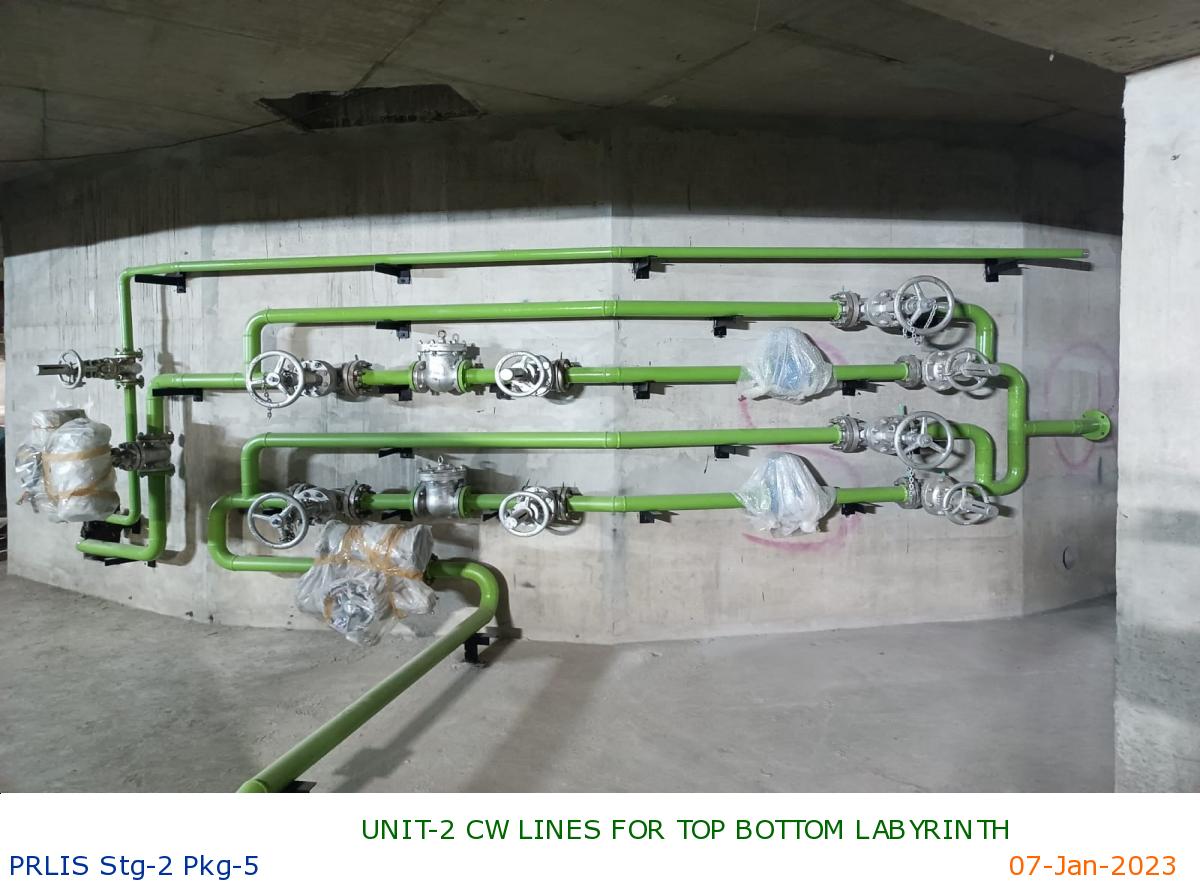

UNIT-2 CW LINES FOR TOP BOTTOM LABYRINTH

|

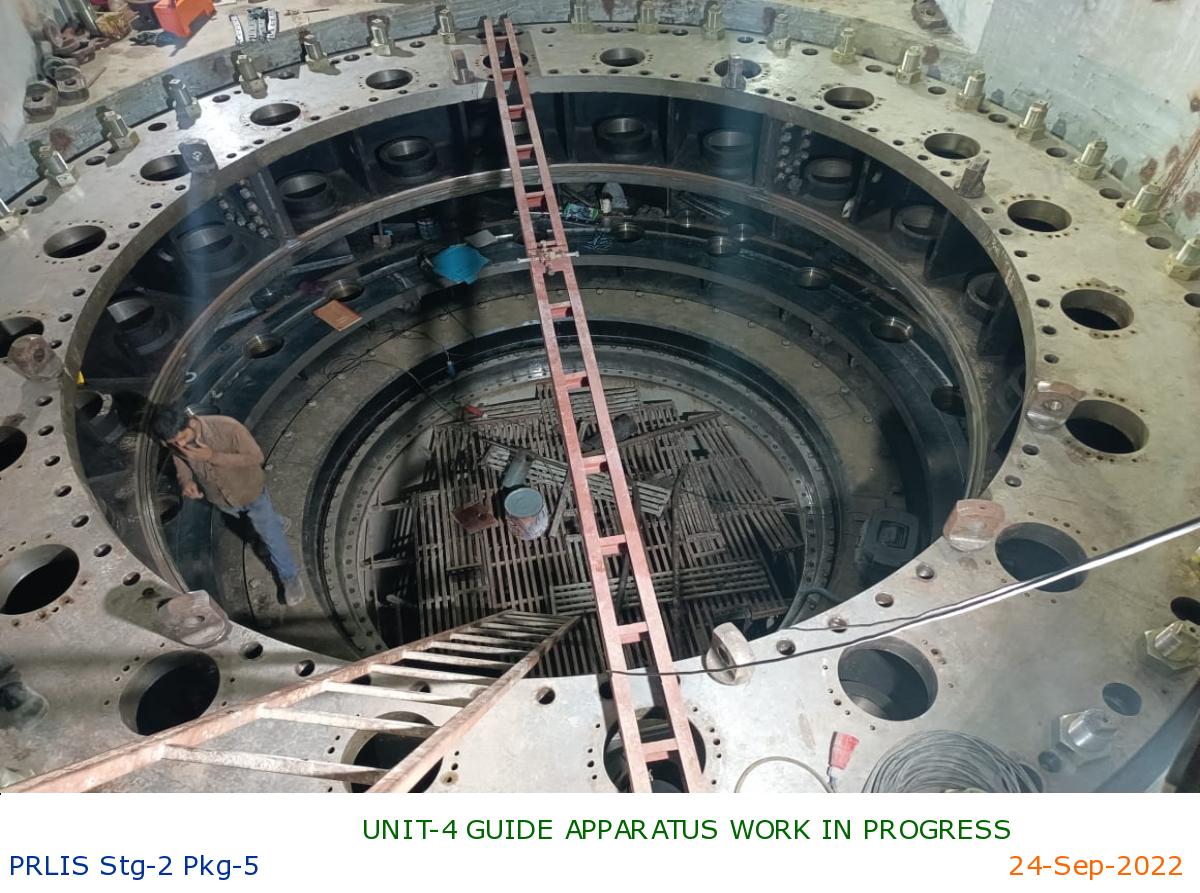

UNIT-4 INSTALLATION OF GUIDE APPARATUS COMPLETED

|

UNIT-3 COMBINED ALIGNMENT OF UNIT COMPLETED

|

UNIT-5 WELDING OF OTC IN PROGRESS

|

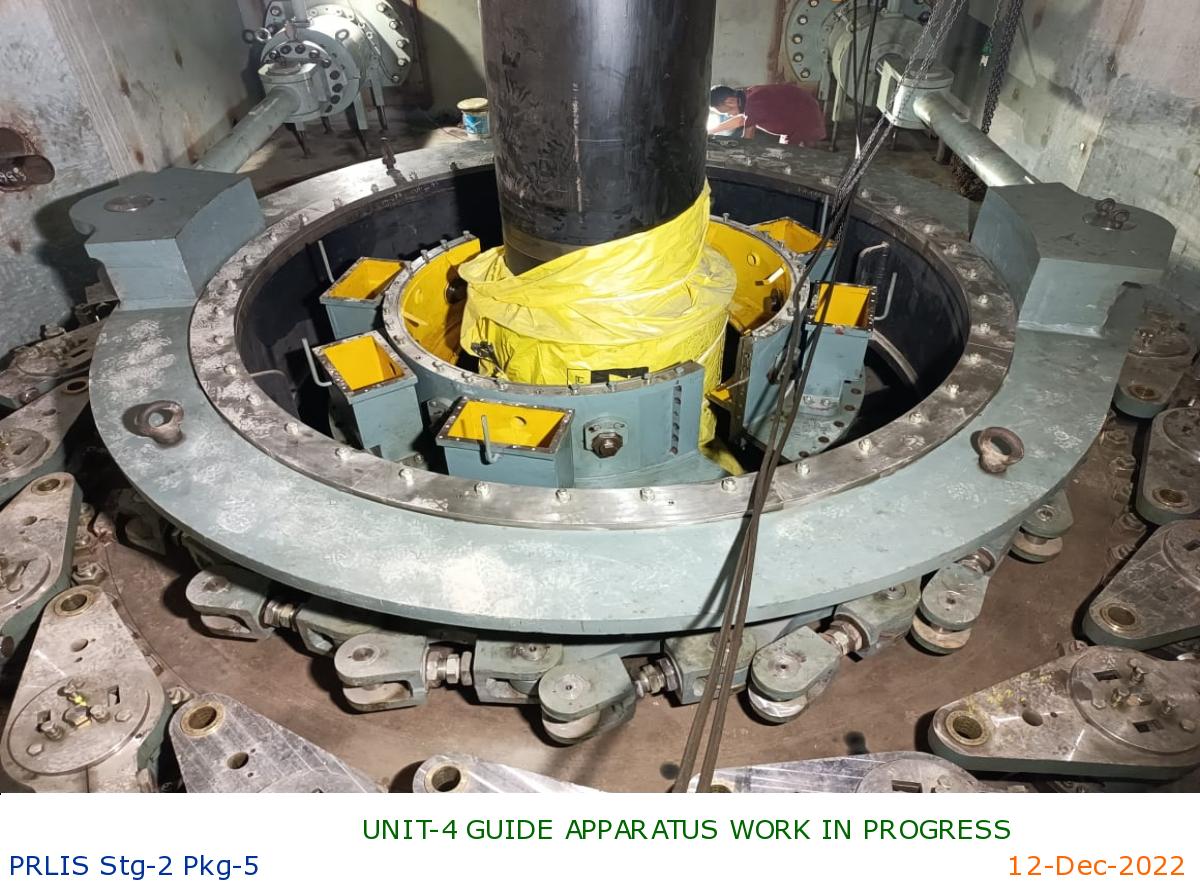

UNIT-4 GUIDE APPARATUS WORK IN PROGRESS

|

UNIT 1 -2 PRESSURE RECIEVERS POSITIONING IN PROGRS

|

UNIT1-10 WATER SYSTEM HEADER WORK IN PROGRESS

|

UNIT-2 STATOR AND ROTOR

|

UNIT-1 POSITIONING OF PP SETS COMPLETED

|

UNIT-2 LABYRINTH COOLING WATER PIPE LINES

|

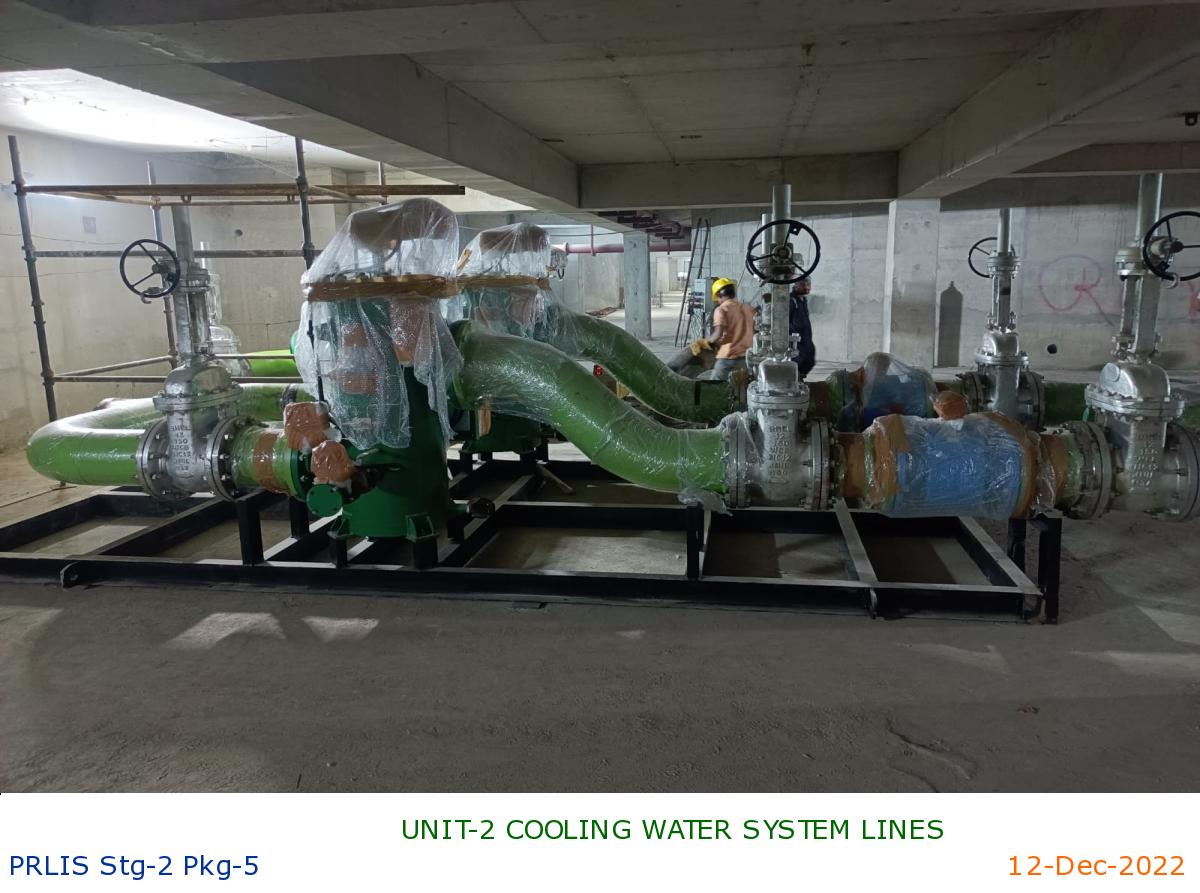

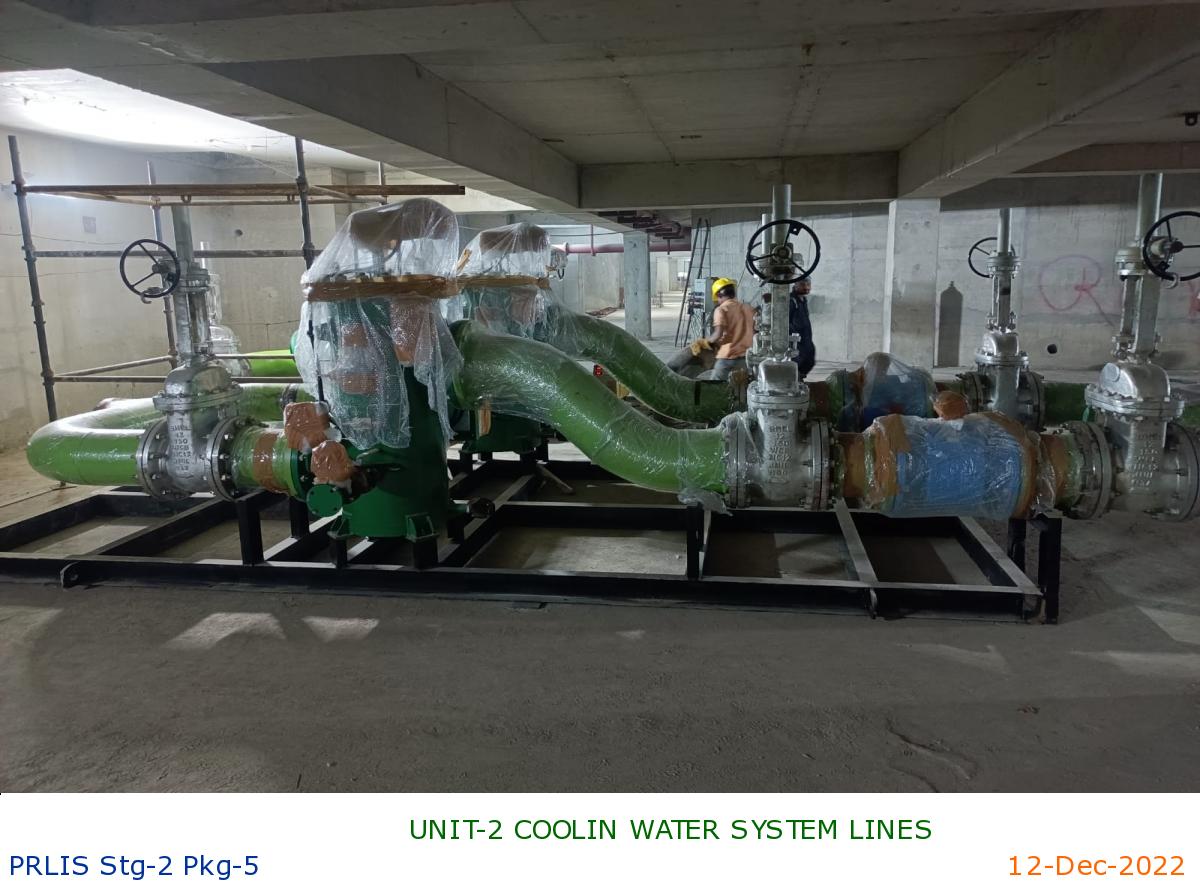

UNIT-2 COOLING WATER SYSTEM LINES

|

UNIT-2 COOLIN WATER SYSTEM LINES

|

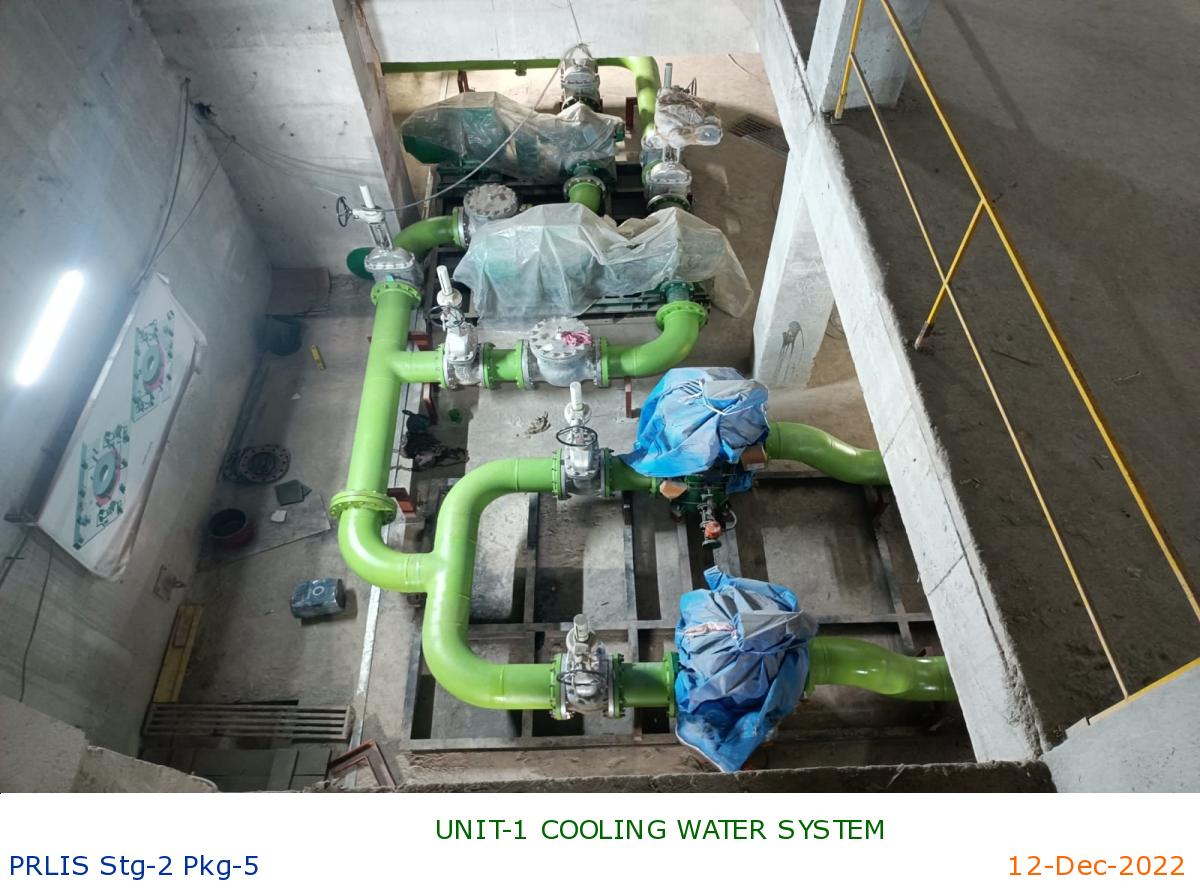

UNIT-1 COOLING WATER SYSTEM

|

SURGE POOL VIEW FROM TOP

|

UNIT-3 THRUST BEARING ASSEMBLY

|

UNIT-1 TOP,BOTTOM LABYRINTH COOLING WATER LINES

|

UNIT-5 PIVOT RING SEGMENTS

|

UNIT-1 TOP VAPOUR SEAL ASSEMBLY

|

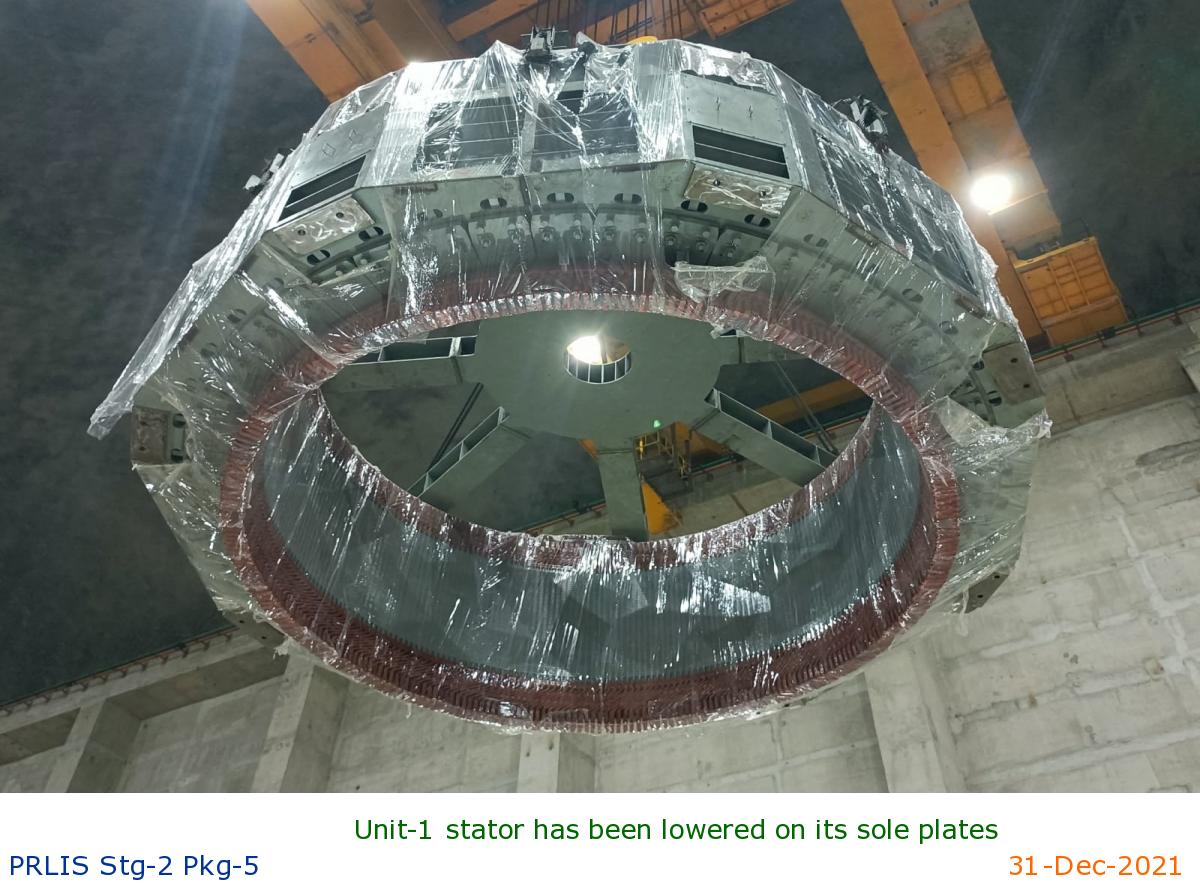

UNIT-5 STATOR HAS BEEN LOWERED ON ITS SOLE PLATES

|

UNIT-3 ROTOR HAS BEEN LOWERED.

|

UNIT-3 LOWERING OF BOTTOM SHAFT

|

UNIT-6 DT CONE LOWERED

|

UNIT-4 IMPELLER/SHAFT LOWERING I

|

BUS DUCT WORK UNIT 3 TO 5 IN PROGRESS

|

CONTROL ROOM BUILDING

|

CONTROL ROOM -LAYING OF CABLE TRAYS IN PROGRESS

|

UNIT-5 GOUTING OF SPIRAL CASING COMPLETED

|

UNIT-7 CONCRETING OF DT LINER COMPLETED.

|

UNI-5 STAOR IS READY FOR LOWERING.

|

UNIT-4 REGULATING RING

|

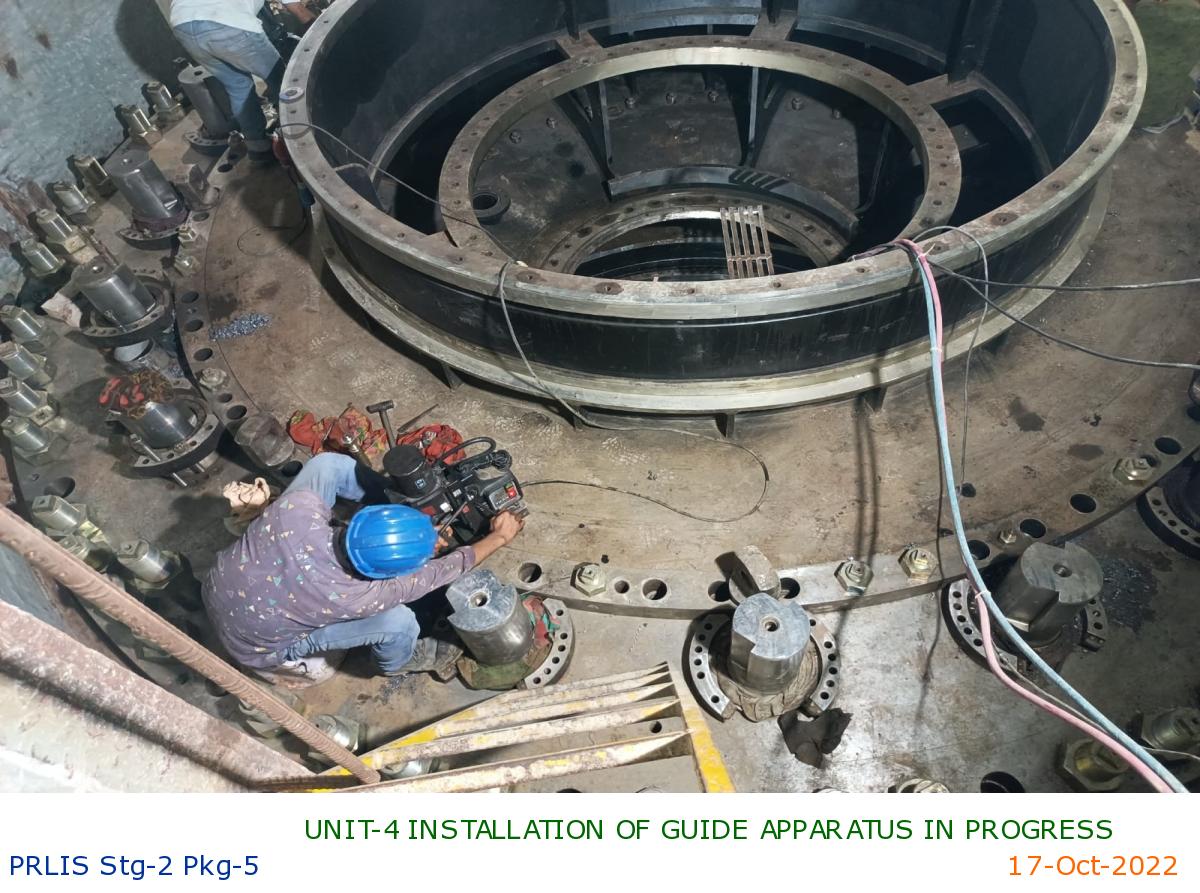

UNIT-4 INSTALLATION OF GUIDE APPARATUS IN PROGRESS

|

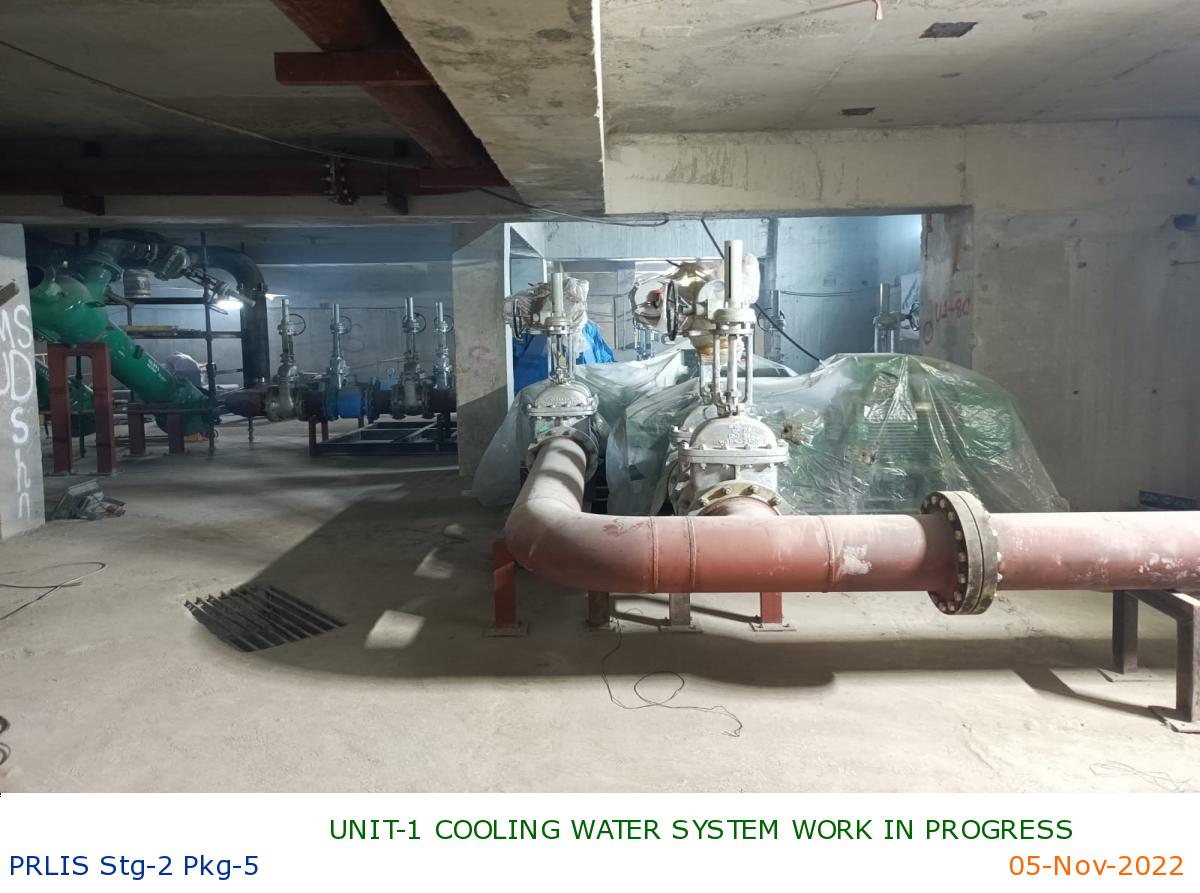

UNIT-2 COOLING WATER PIPE LINE WORK IN PROGRESS

|

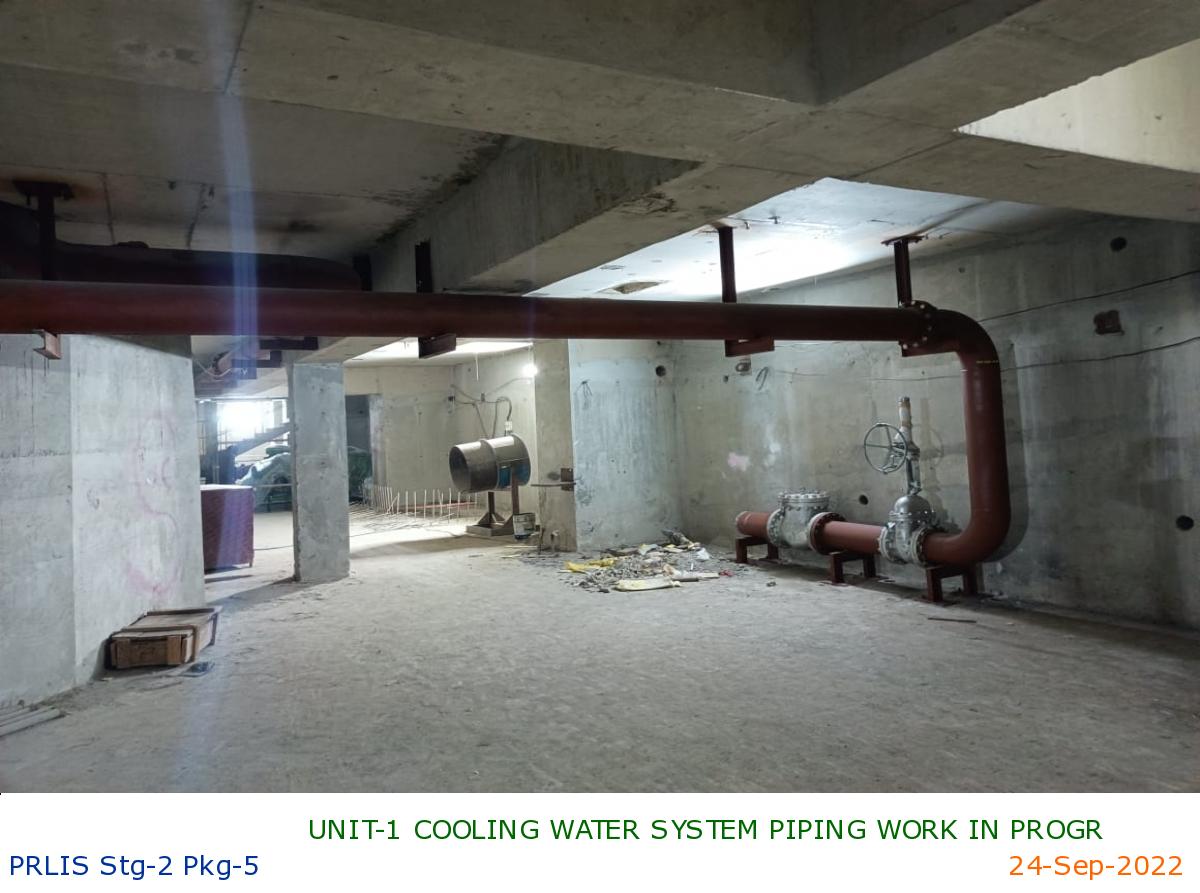

UNIT-1 COOLING WATER SYSTEM WORK IN PROGRESS

|

UNIT-1 AND 2 CARBON DUST COLLECTOR

|

UNIT-3 INSTALLATION OF PUMP PIT PLATFORM COMPTD

|

UNIT-2 BOTTOM AIR GUIDE ASSLY COMPLETED.

|

MOTOR FLOOR VIEW

|

UNIT-2 SHAFT CURRENT MONITORING CT

|

UNIT-1 WATER DEPRESSION SYSTEM WORK IN PROGRESS.

|

UNIT-1 WATER AND AIR PIPING WORK IN PROGRESS.

|

UNIT-4 INSTALLATION OF GUIDE APPARATUS IN PROGRESS

|

UNIT-5 BAZING OF STATOR BAR JOINTS COMPD

|

UNIT-5 BARREL CONCRETING IN PROGRESS

|

UNIT-1 ERECTION OF CW SYSTEM IN PROGRESS

|

UNIT-1 ERECTION OF COOLING WATER SYSTEM

|

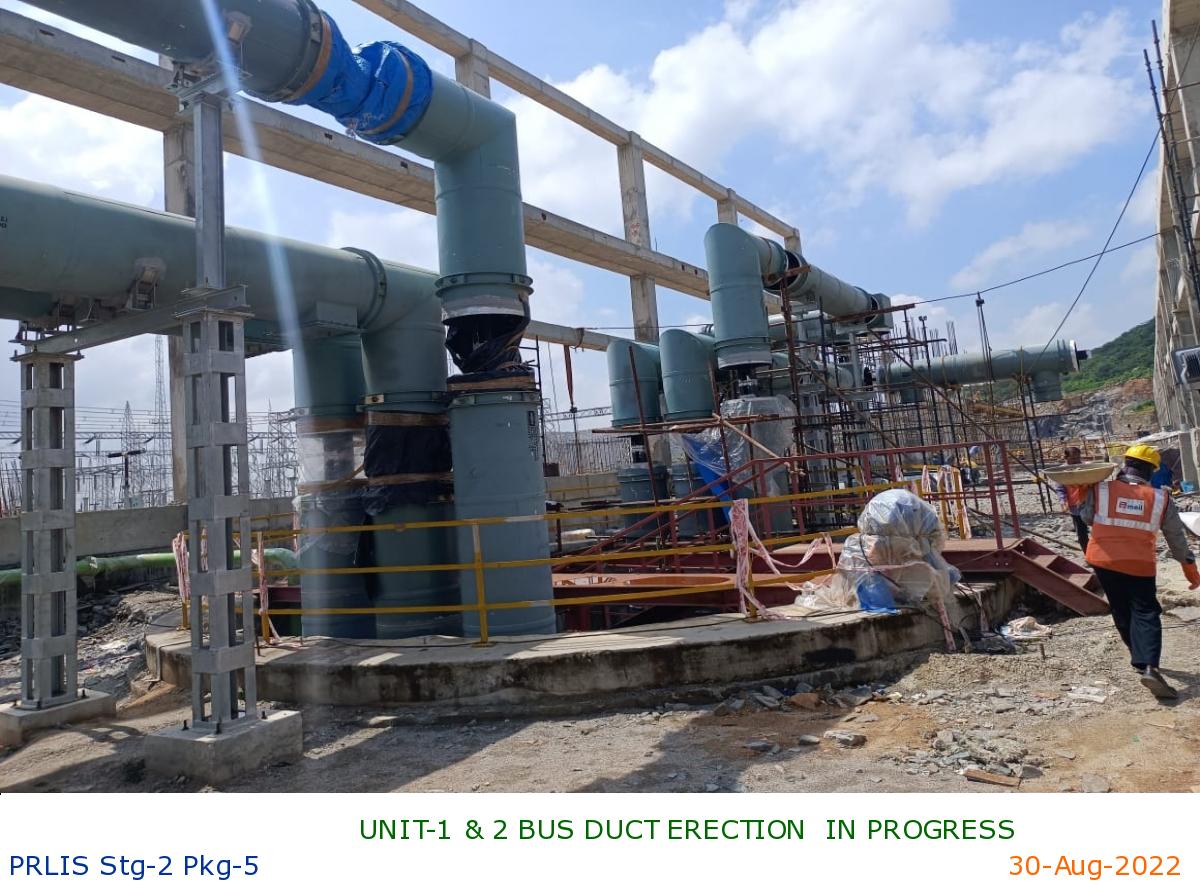

UNIT1,2,3- BUS DUCT ERECTION IN PROGRESS

|

PANELS ERECTION IN PROGRESS IN CONTROL ROOM

|

UNIT-2 LGB COOLER PIPING WORK IN PROGRESS

|

UNIT-3 INSTALLATION OF PUMP PIT PLATFORM COMP

|

MOTOR FLOOR VIEW

|

UNIT-5 LAYING OF STATOR TOP AND BOTTOM BARS COMPTD

|

UNIT-4 GUIDE APPARATUS WORK IN PROGRESS

|

UNIT-2 BOTTOM AIR GUIDE ASSLY COMPLETED.

|

UNIT-2 INSTALLATION OF PIT AIR SEAL COMPTD

|

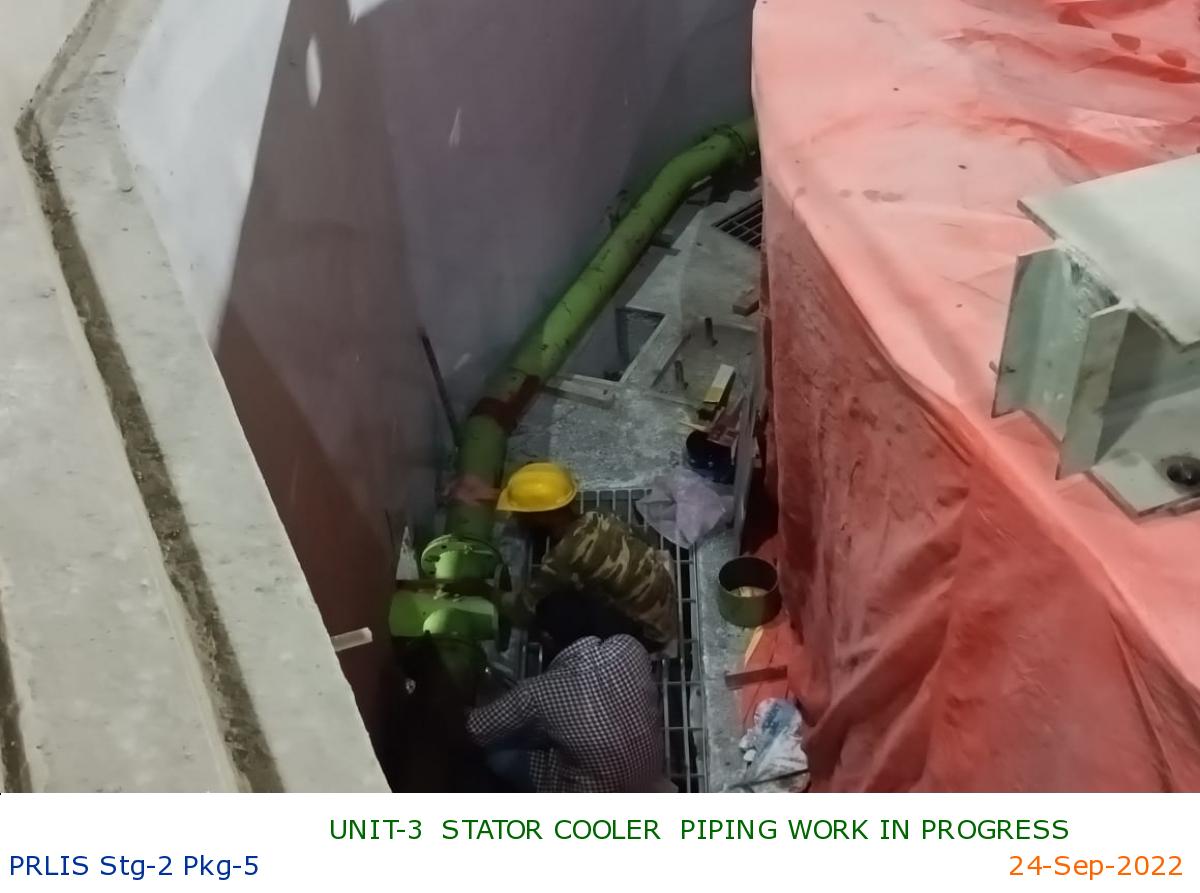

UNIT-3 STATOR COOLER PIPING WORK IN PROGRESS

|

UNIT-1 COOLING WATER SYSTEM PIPING WORK IN PROGR

|

UNIT-5 BARREL CONCRETING IN PROGRESS

|

UNIT-1 BUS DUCT( MOTOR FLOOR TO VERTICAL SHAFT)

|

UNIT-10 INSTALLATION OF DRAFT TUBE LINER COMPLETED

|

UNIT-6 STAY RING AND SPIRAL PEDESTALS

|

UNIT-4 STATOR LOWERING

|

UNIT-3 STATOR ON ITS SOLE PLATES

|

UNIT-1 BUS DUCT

|

UNIT-3 ROTOR IS READY FOR LOWERING

|

UNIT-2 LGB COOLER SUPPORT FIXING IN PROGRESS

|

UNIT-5 BUS DUCT

|

UNI-5 BARREL CONCRETING IN PROGRESS

|

UNIT-4 CENTERING OF STATOR COMPLETED

|

UNIT-4 ASSEMBLY OF PIVOT RING SEGMENTS IN PROGRESS

|

UNIT-3 ASSEMBLY OF GUIDE APPARATUS

|

UNIT-1 & 2 BUS DUCT ERECTION IN PROGRESS

|

MOTOR FLOOR VIEW

|

UNIT-3 ROTOR IS READY FOR LOWERING

|

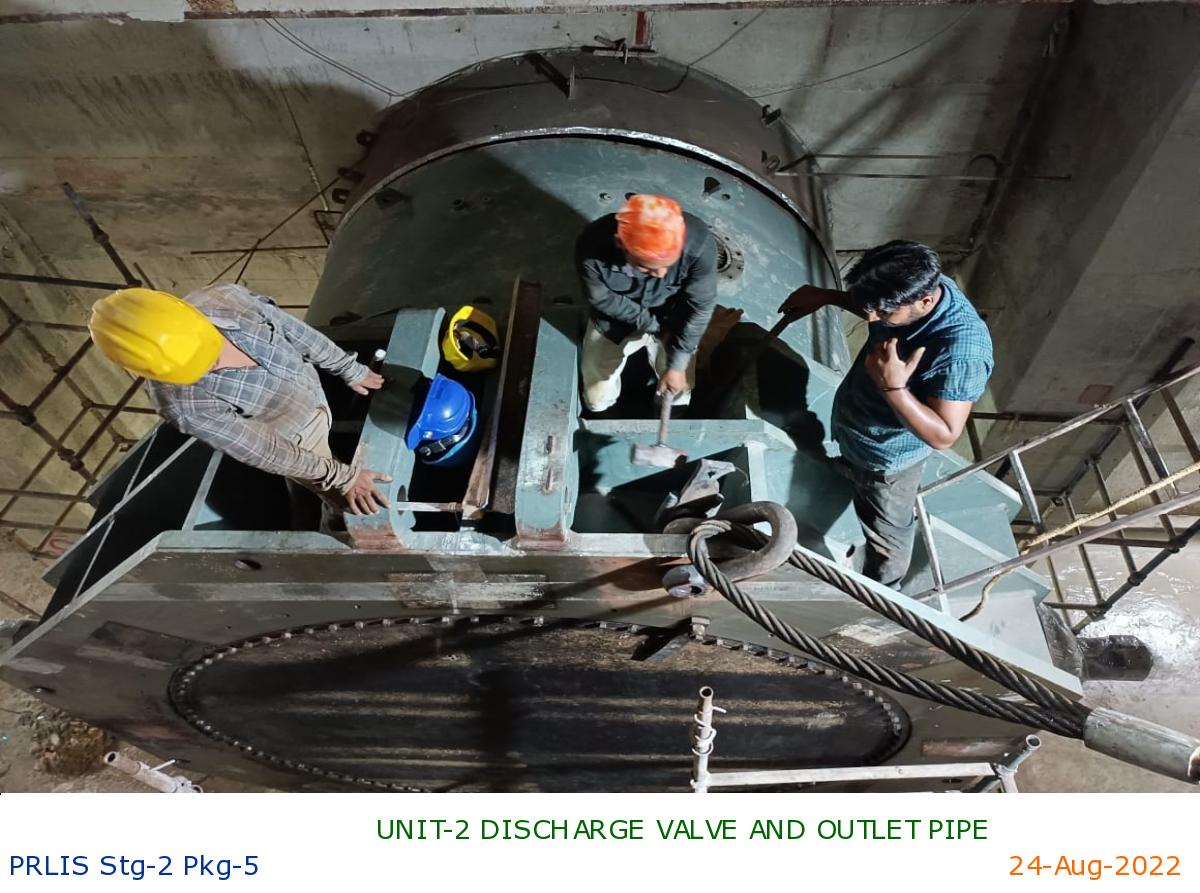

UNIT-2 DISCHARGE VALVE AND OUTLET PIPE

|

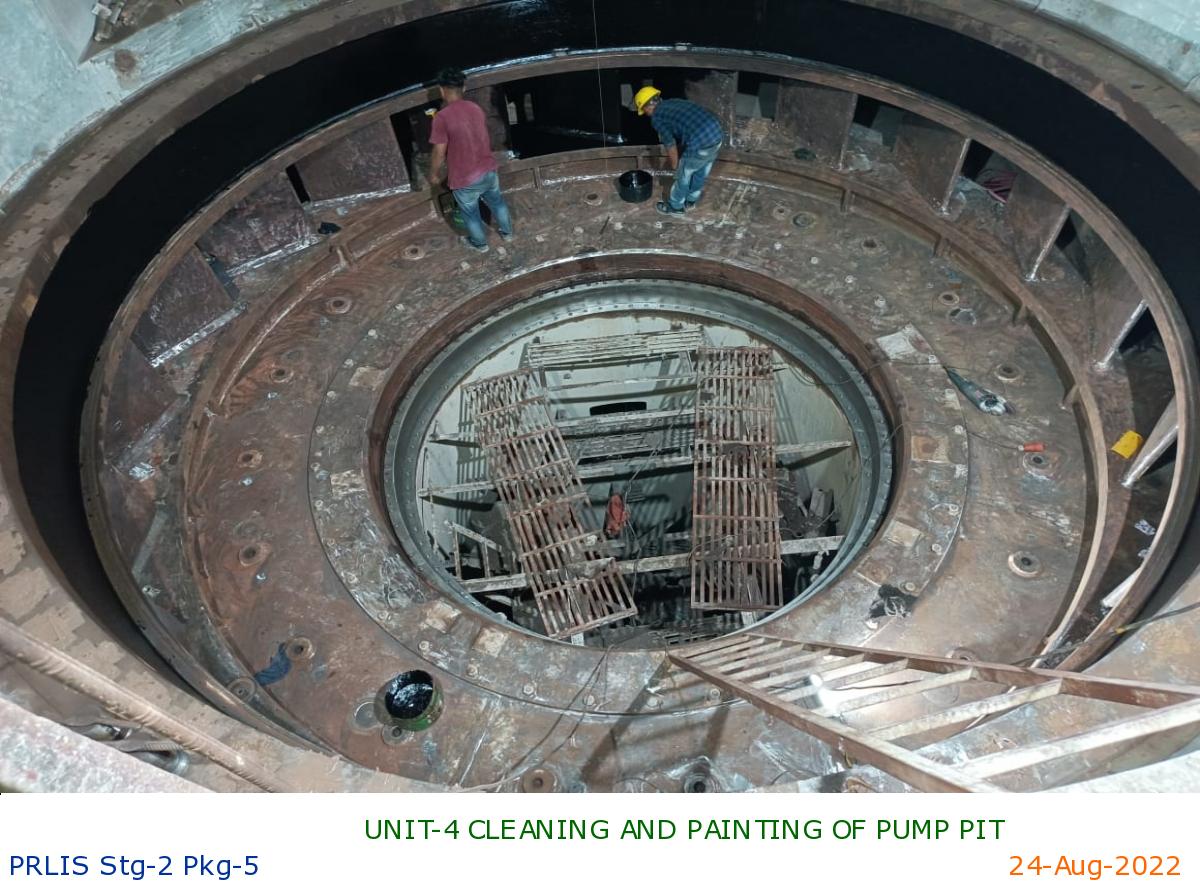

UNIT-4 CLEANING AND PAINTING OF PUMP PIT

|

UNIT-4 LOWERING OF STATOR

|

MOTOR FLOOR VIEW

|

UNIT-5 BARREL CONCRETING IN PROGRESS

|

UNIT-2 TOP AIR GUIDE AND BAFFLES ASSEMBLY COMD

|

UNIT-2 PUMP PIT PLATFORM COMPLETED

|

UNIT-4 STATOR LOWERING

|

UNIT-5 INSTALLATION OF BUS DUCT IN PROGRESS

|

UNIT-10 INSTALLATION OF DRAFT TUBELINER COMPLETED

|

UNIT-7 INSTALLATION OF DRAFT TUBE LINER COMPLETED

|

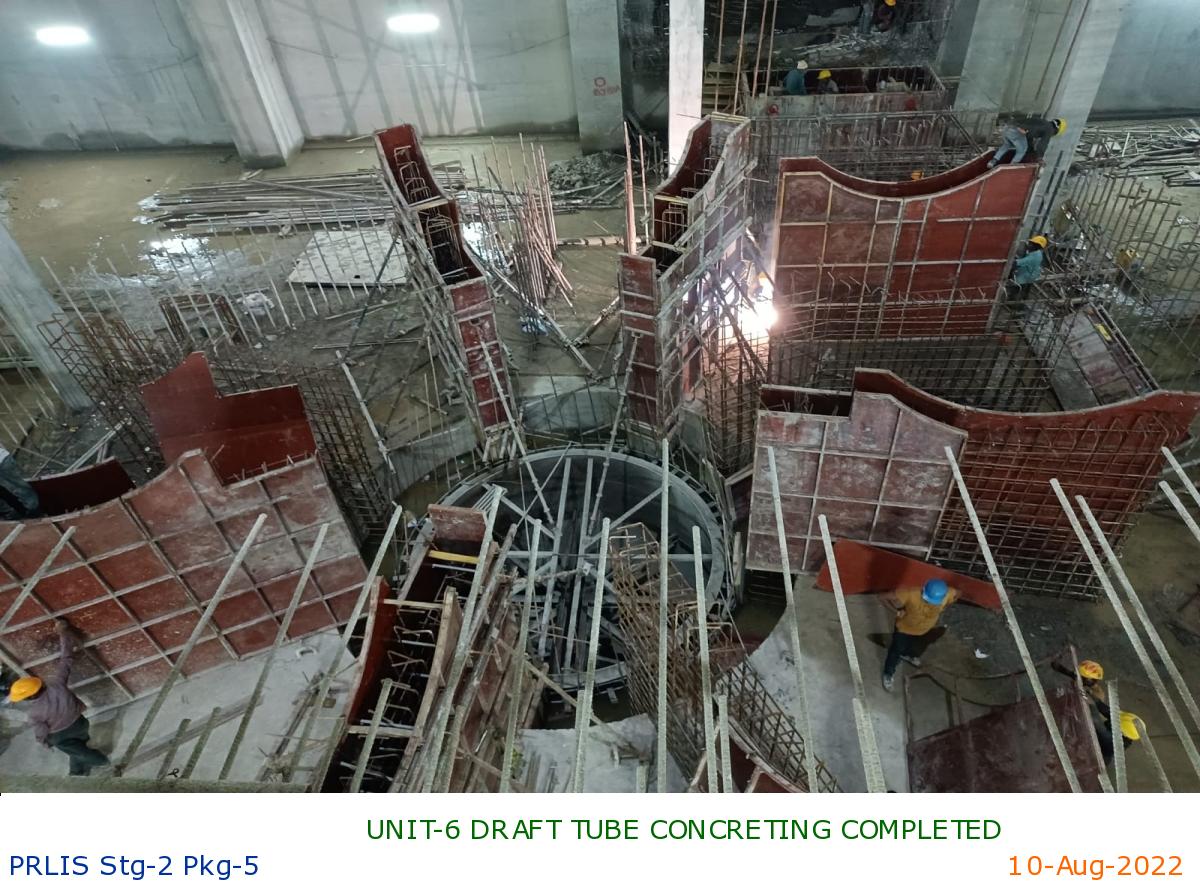

UNIT-6 DRAFT TUBE CONCRETING COMPLETED

|

CONTROL ROOM BUILDING

|

MOTOR FLOOR VIEW

|

UNIT-2 HYDRAULIC TESTING OF DISCHARGE VALVE COMPD

|

UNIT-3 ROTOR FAN MOUNTING IN PROGRESS

|

UNIT-5 BARREL CONCRETING IN PROGRESS

|

UNIT-4 BARREL CONCRETING COMPLETED

|

UNIT-3 GUIDE APPARATUS

|

UNIT-2 FLOOR PLATES SUPPORTS

|

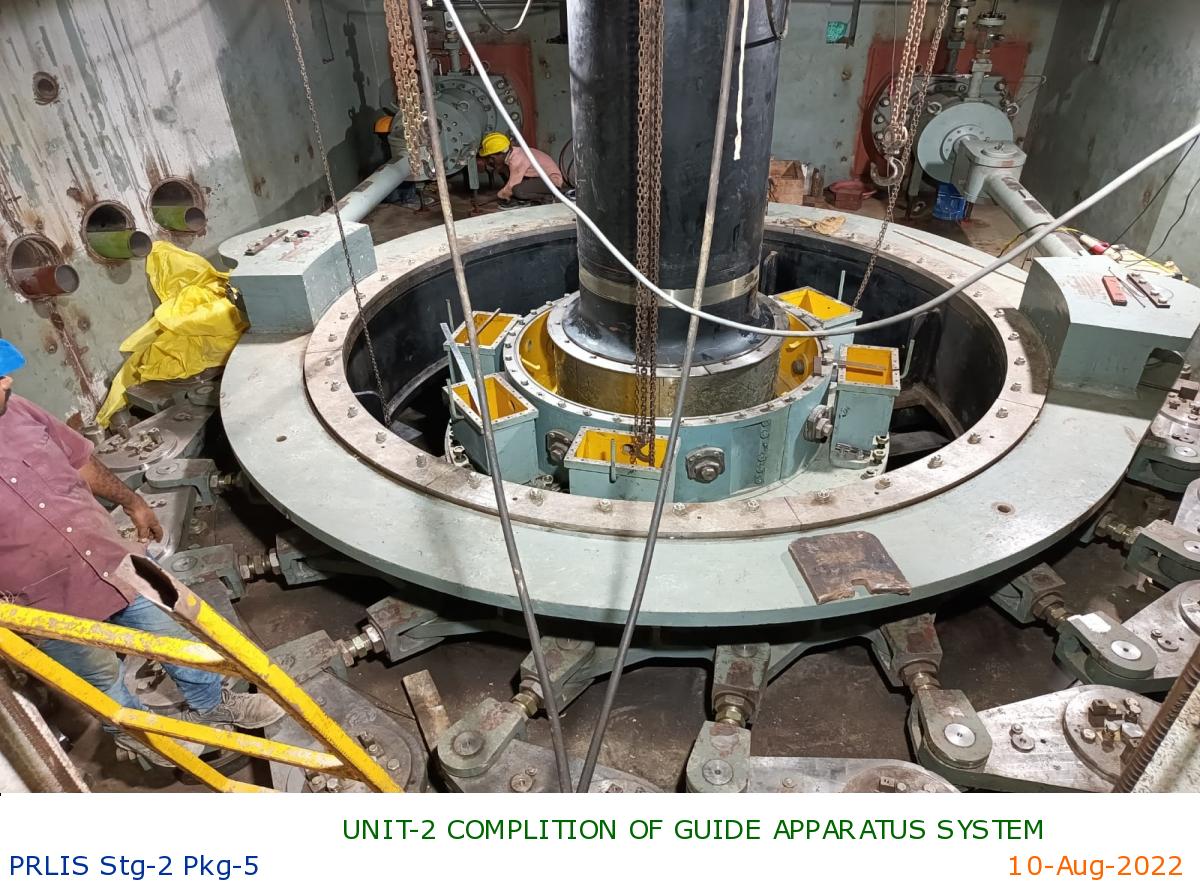

UNIT-2 COMPLITION OF GUIDE APPARATUS SYSTEM

|

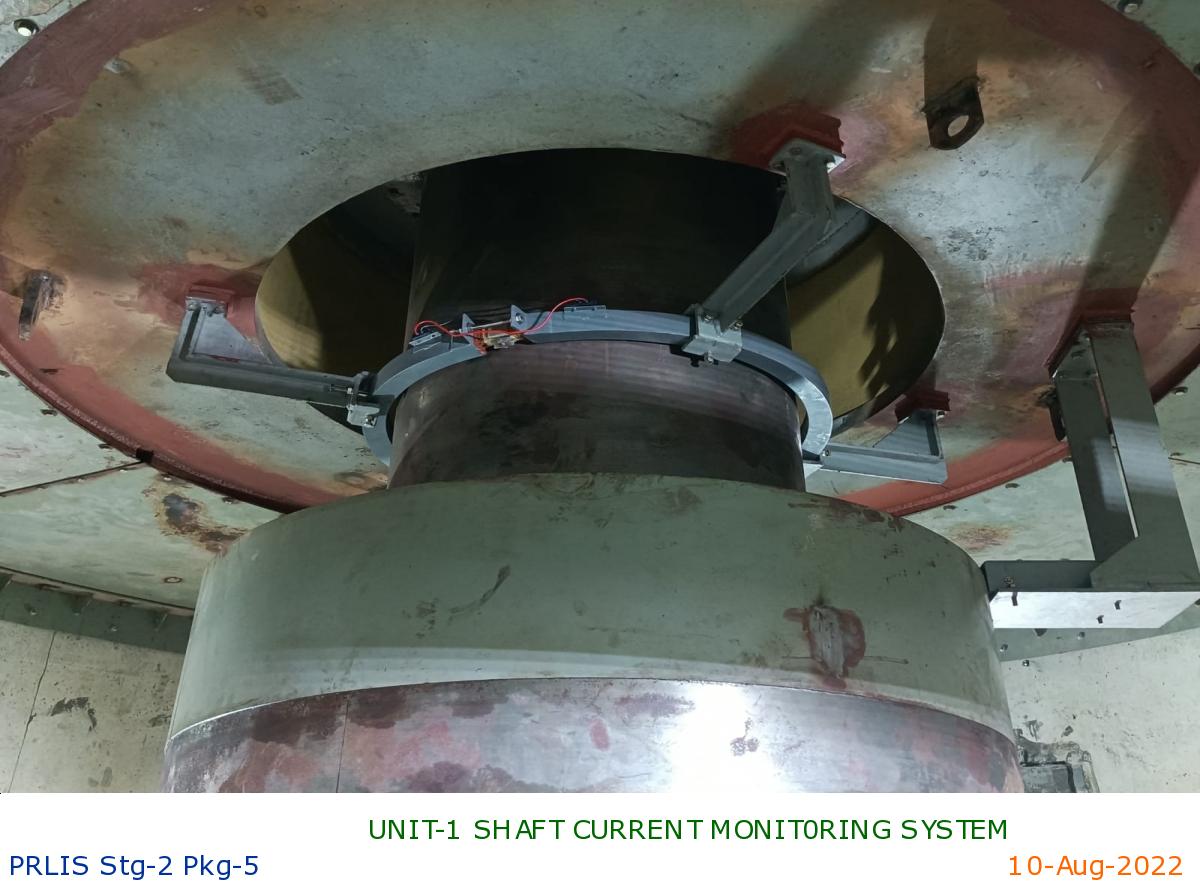

UNIT-1 SHAFT CURRENT MONIT0RING SYSTEM

|

UNIT-1 PUMP PIT PLATFORM

|

U-3 STATOR

|

U-2 NUT GUARD ASSEMBLY IN PROGRESS

|

U-3 ROTOR RIM RADIUS CORRECTION IN PROGRESS

|

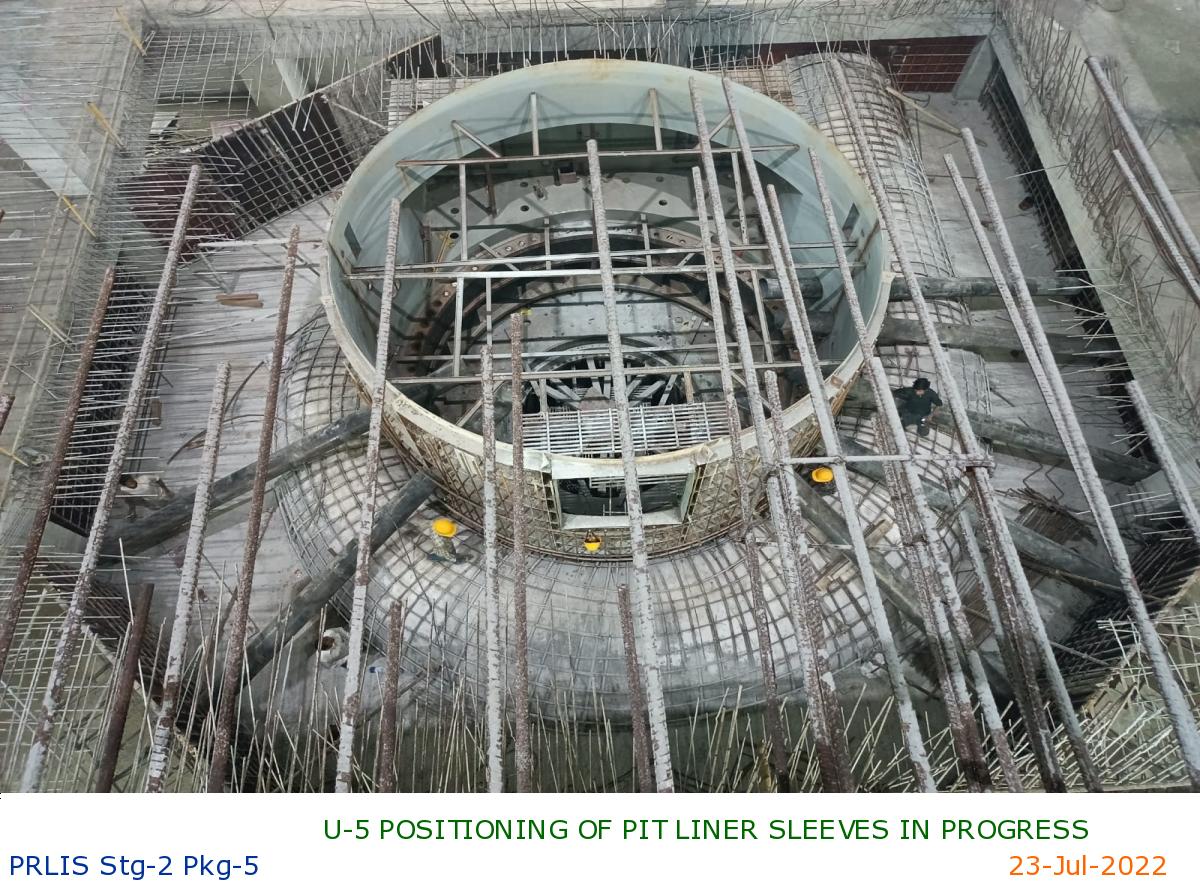

U-5 POSITIONING OF PIT LINER SLEEVES IN PROGRESS

|

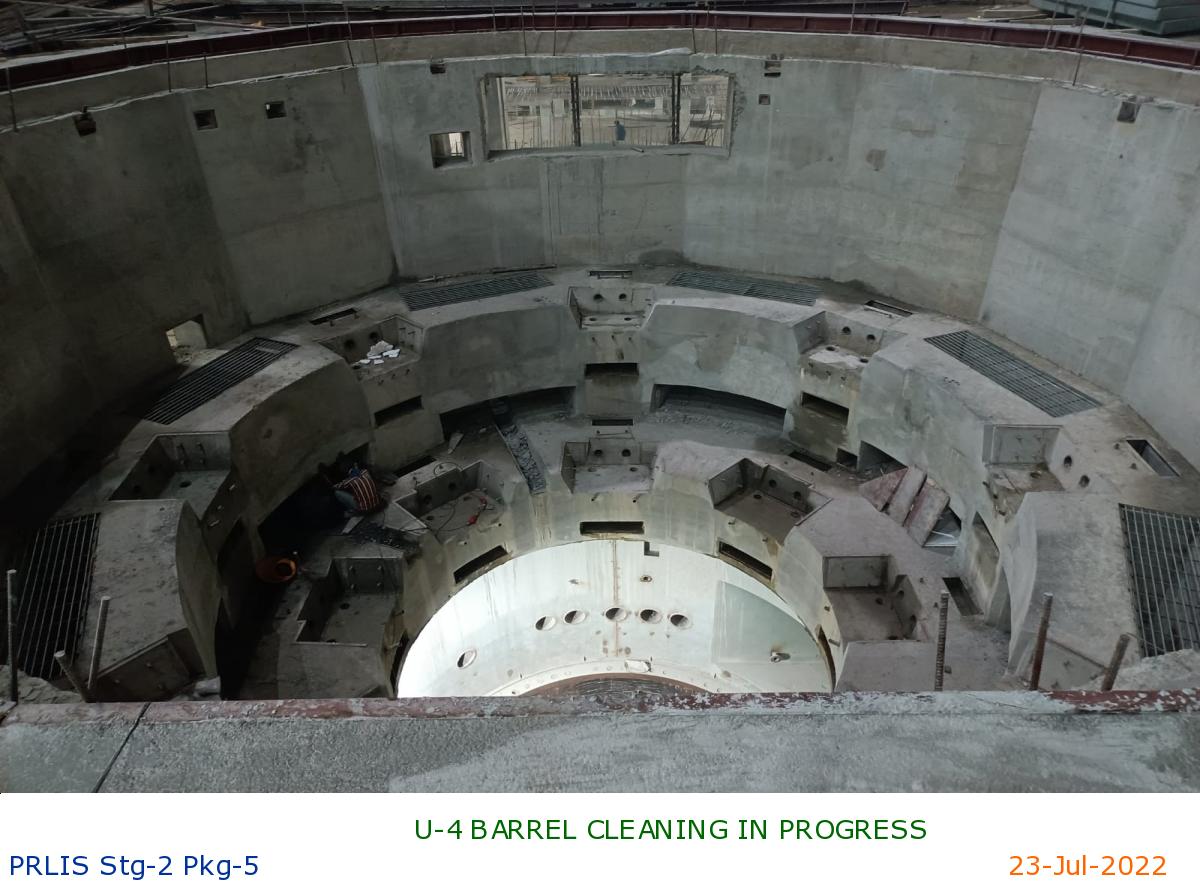

U-4 BARREL CLEANING IN PROGRESS

|

U-3 gV LINK LEVELLING IN PROGRESS

|

U-2 FLOOR PLATES SUPPORT FIXING IN PROGRESS

|

U-1 TOP AIRGUIDE AND BAFFLES

|

motor floor view

|

MOTOR FLOOR VIEW

|

UNIT-1 HYDRAULIC TESTING OF DISCHARGE VALVE

|

UNIT-1 PUMP PIT PLATFORM

|

UNIT-5 CONCRETING OF SPIRAL IN PROGRESS

|

UNIT-4 BARRELL CONCRETING COMPLETED

|

UNIT-3 ALIGNMENT OF SERVO MOTORS COMPLETED

|

UNIT-2 UNIT ALIGNMENT COMPLETED

|

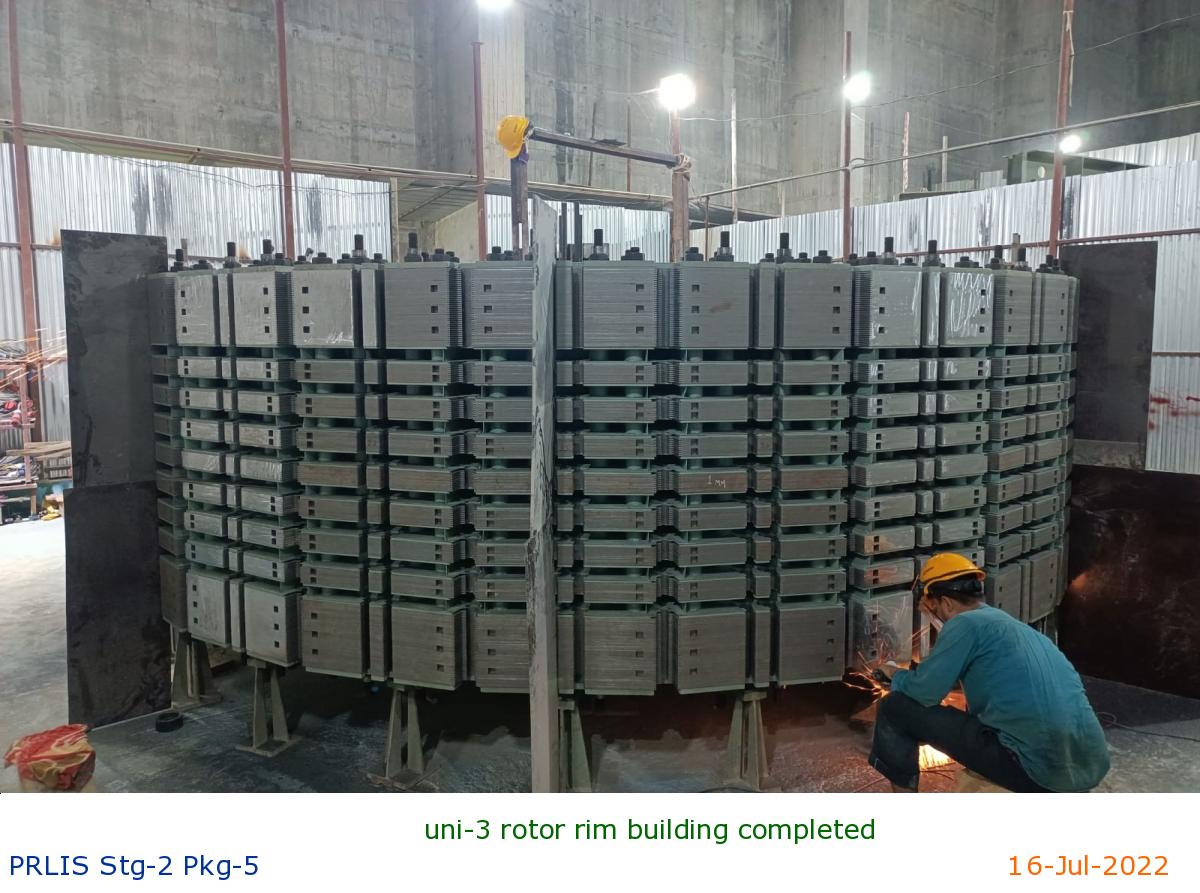

uni-3 rotor rim building completed

|

unit-4 bus duct

|

unit-1 trial assbly of pump pit platform comltd

|

unit-6 concreting of draft tube completed by cstmr

|

unit-3 alignment of GV servomotors in progress

|

motor floor view

|

unit-5 GV mounting plate positioning in progress

|

unit-3 centering and levelling of stator completed

|

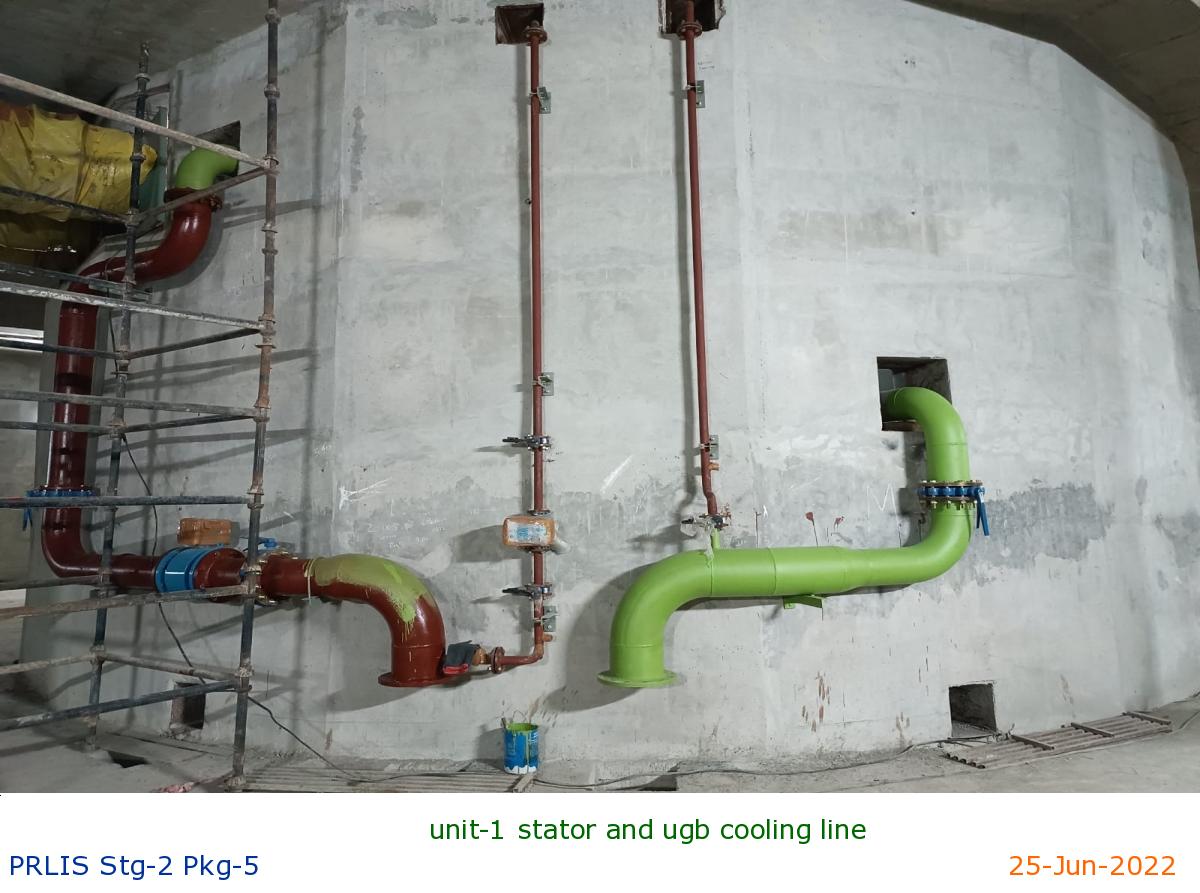

unit-1 stator and ugb cooling line

|

unit-4 barrel concreting in final stage

|

unit-2 alignment of gv servo motors completed

|

unit-4 brazing of stator bar joints in progress

|

unit-2 alignment of unit is under progress

|

unit-3 rotor rim building in progress

|

unit-2 rotor has been lowered

|

UNIT-2 HV TEST ON ROTORS POLES COMPLETED

|

UNIT1-3 WATER AND AIR PIPE LINES WORKS IN PROGRESS

|

UNIT-4 STATOR TOP BARS LAYING IN PROGRESS

|

UNIT-4 BARREL CONCRETING IN PROGRESS

|

UNIT-2 THRUST BEARING ASSLY

|

UNIT-3 STATOR AND LGB BRACKET

|

UNIT-5 LOWERING OF BOTTOM SHAFT /THRUST BEARING

|

UNIT-3 ASSEMBLY OF GUIDE APPARATUS IN PROGRESS

|

UNIT-2 ALINGMENT OF gv SERVO MOTORS IN PROGRESS

|

UNIT-1 ALIGNMENT OF SERVO MOTORS COMPLETED

|

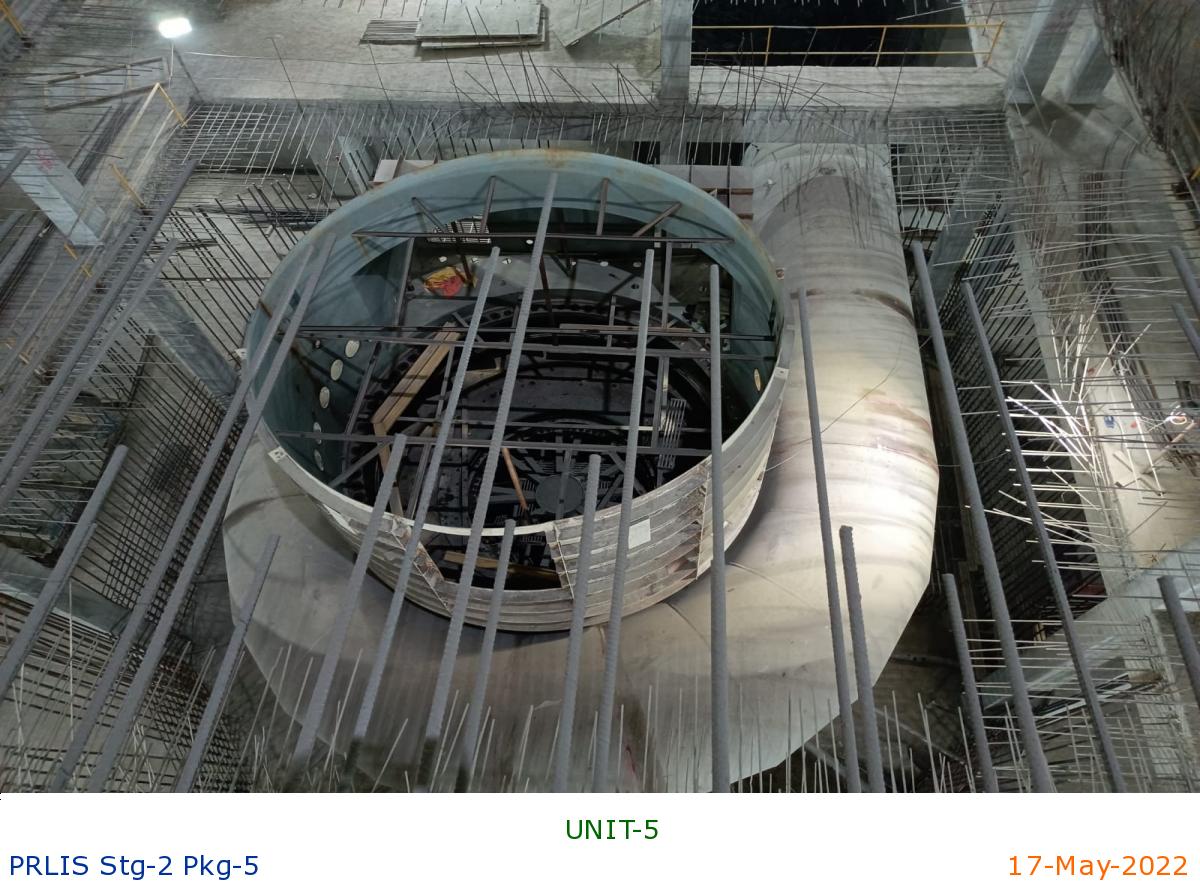

UNIT-5

|

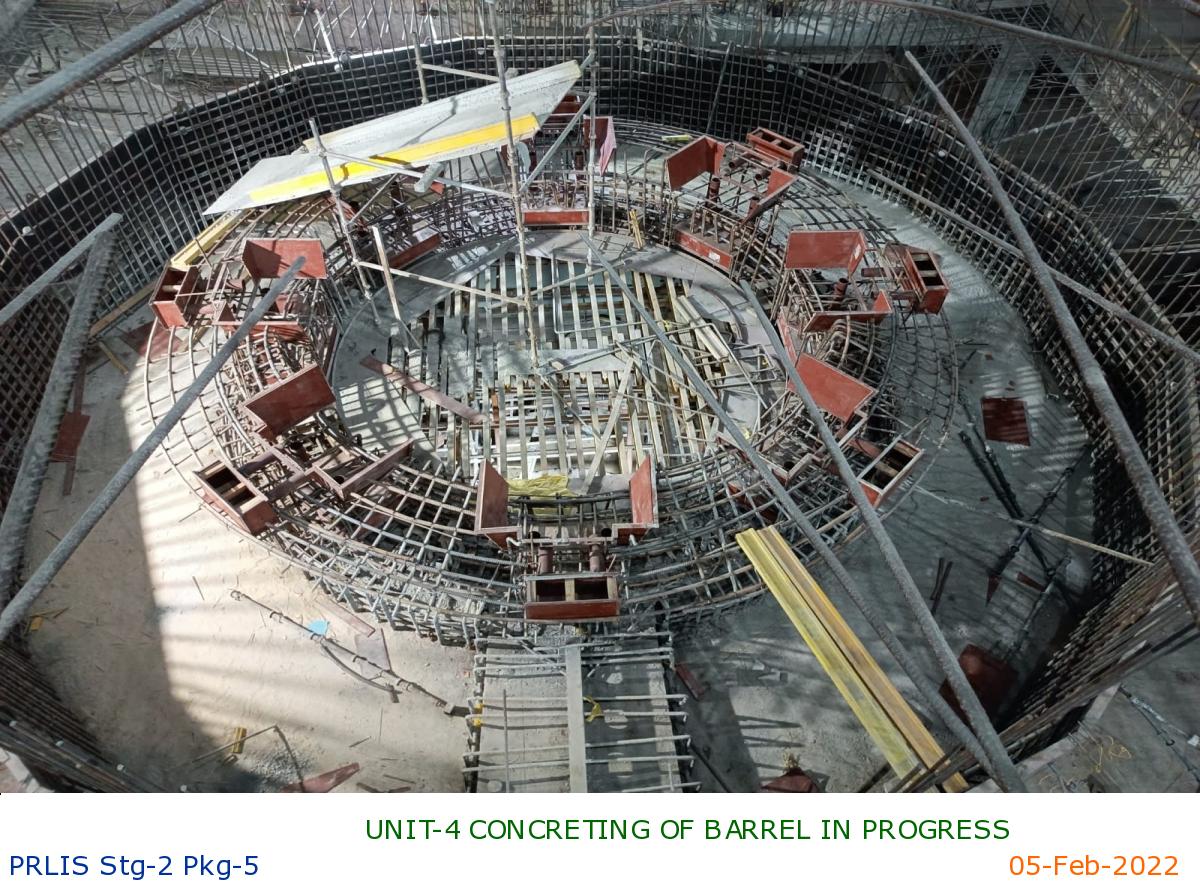

UNIT-4 CONCRETING OF BARREL IN PROGRESS

|

UNIT-1 TRIAL ASSEMBLY OF STATOR COOLERS

|

UNIT-3 IMPELLER

|

UNIT-2 POLES MOUNTING COMPLETED

|

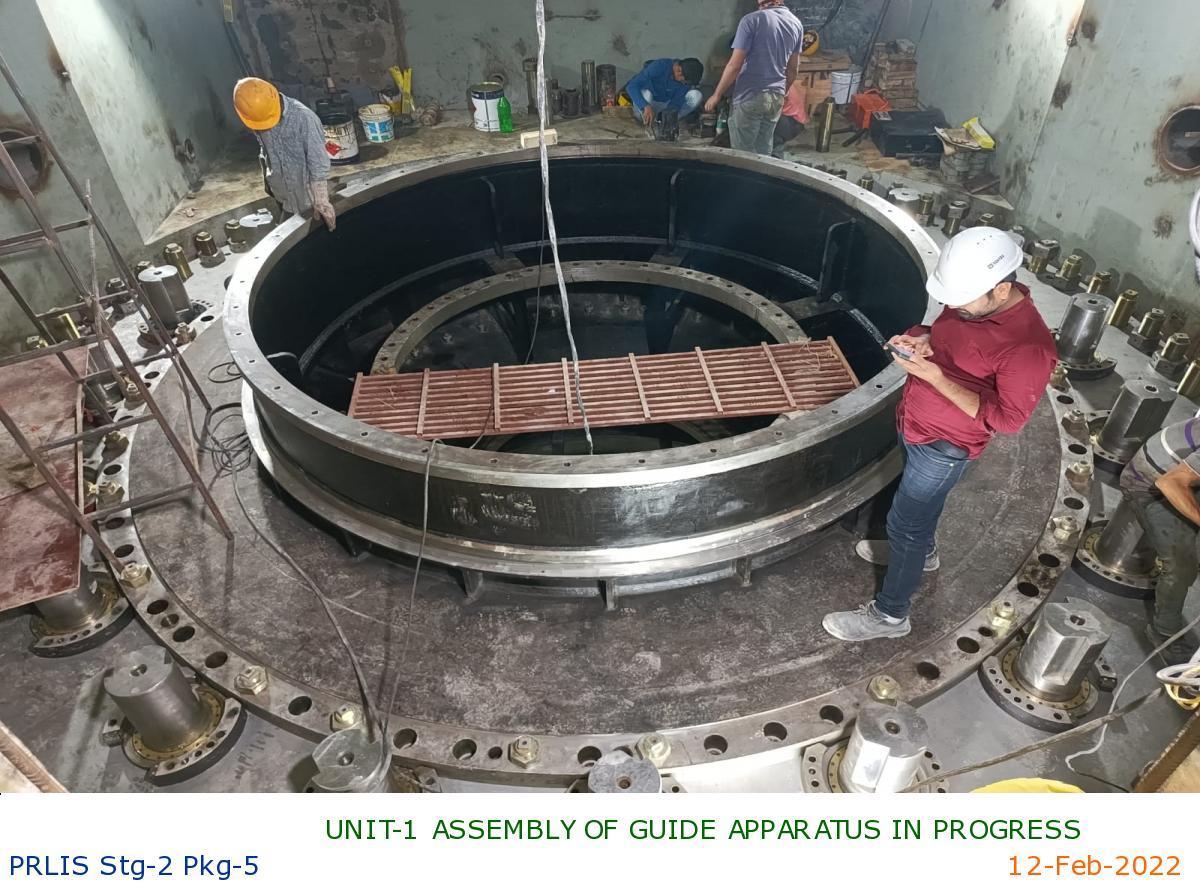

UNIT1 ASSEMBLY OF GUIDE APPARATUS IN PROGRESS

|

UNIT-1 BOXUP OF UNIT IS UNDER PROGRESS

|

UNIT-4 BUS DUCT ERECTION IN PROGRESS

|

UNIT-1 ROTOR RIM BUILDING IN PROGRESS

|

MOTOR FLOOR VIEW

|

UNIT -2 BOTTOM BRACKET

|

SPIRAL AND PIT LINER

|

UNIT-4 CONCRETING OF BARREL IN PROGRESS

|

UNIT-3 DOWELLING OF ITC AND OTC

|

UNIT--2 NO WORK DUE TO MATERIAL NOT RECIEVED

|

UNIT-1 ALIGNMENT OF UNIT IN PROGRESS

|

UNISTATOR BAR TO BAR JOINT BRAZING COMPLETEDT-3

|

UNIT-2

|

UNIT-3 ASSEMBLY OF SEAL RETAINERS AND FACE SEALS

|

UNIT-4 BARRELL CONCRETING IS UNDER PROGRESS

|

UNIT-5 UNIT RELEASED FOR CONCRETING

|

UNIT -1 ROTOR LOWERING

|

UNIT-2 STATOR HAS BEEN LOWERED ON SOLE PLATES.

|

UNIT-1 GUIDE APPARATUS WORK IS IN PROGRESS

|

UNIT-5 INSTALLATION OF PIT LINER COMPLETED

|

UNIT-4 BARRELL CONCRETING IN PROGRESS

|

UNIT-3 CENTERING AND LEVELLING OF PIVOT RING/OTC

|

UNIT-1 LOWERING OF BOTTOM SHAFT/ THRUST BEARING

|

UNIT-2 LOWERING OF TOP ITC COMPLETED

|

UNIT-1 LOWERING OF STATOR COMPLETED

|

UNIT-3 JOINING OF STATOR SEGMENTS

|

BUS DUCT UNIT 1,2 AND 3

|

MOTOR FLOOR VIEW

|

UNIT-1 ROTOR

|

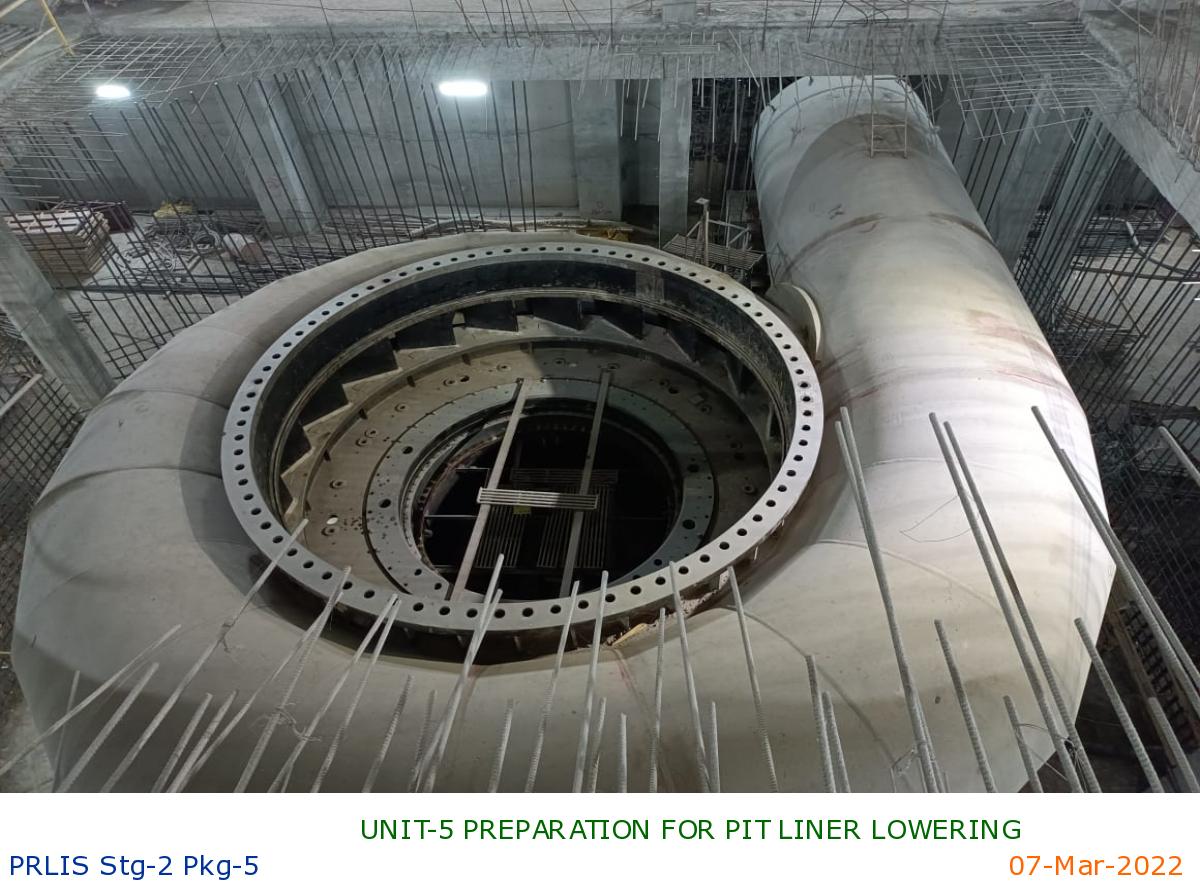

UNIT-5 PREPARATION FOR PIT LINER LOWERING

|

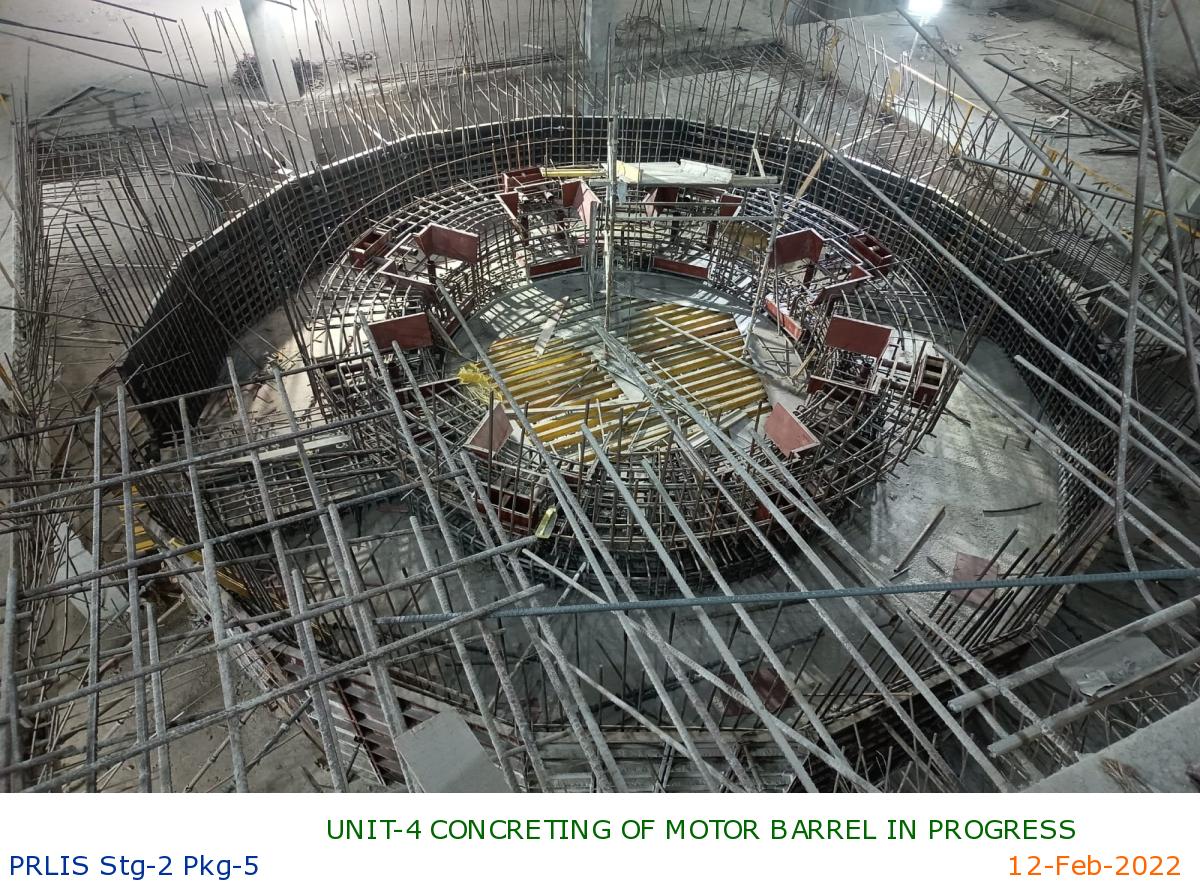

UNIT-4 CONCRETING OF MOTOR BARREL IN PROGRESS

|

UNIT-3 PREPARATION FOR PIVOT RING LOWERING

|

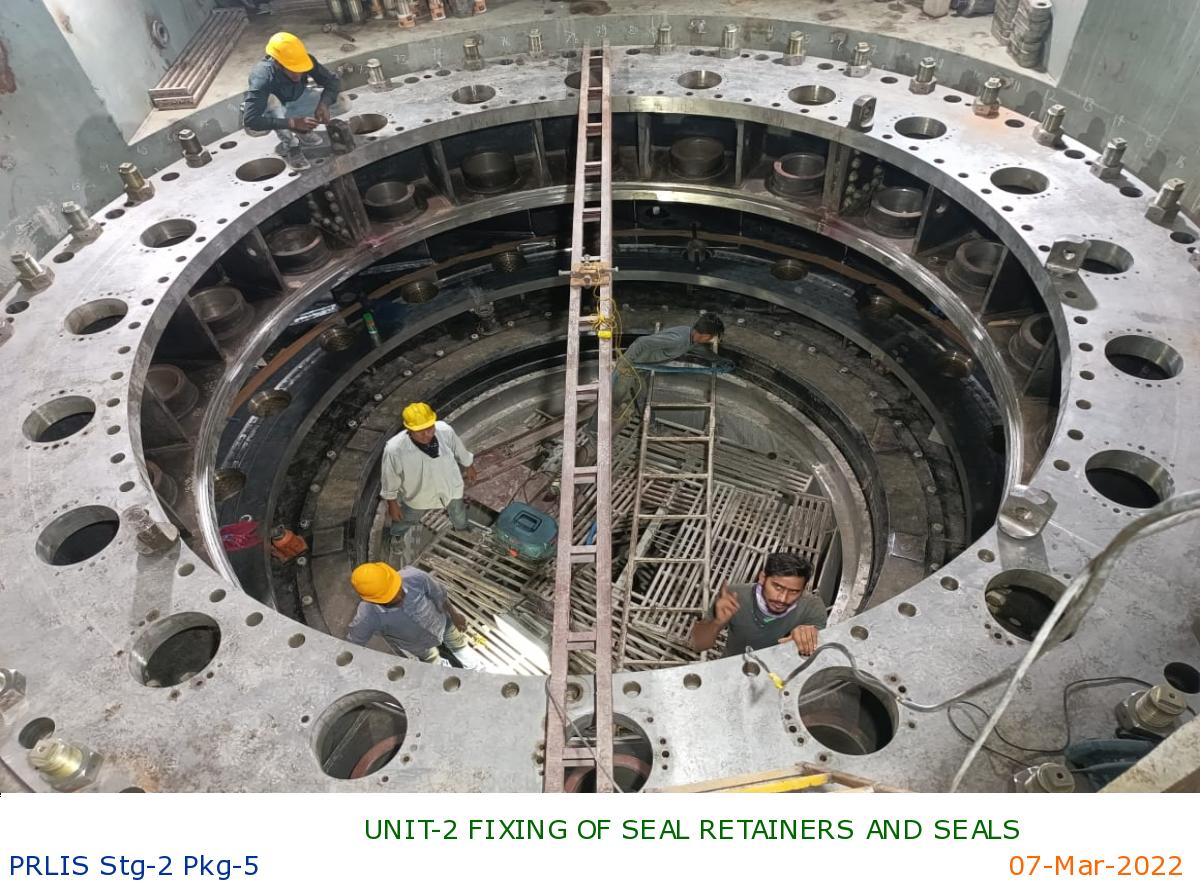

UNIT-2 FIXING OF SEAL RETAINERS AND SEALS

|

UNIT-1 impeller with shaft lowered in pit

|

CONTROL ROOM BUILDING

|

SWITCHYARD AREA

|

DELIVERY LINES( PENSTOCK) UNIT 1 TO 5

|

UNIT-3 BUS DUCT ERECTION IN PROGRESS

|

UNIT-5 WELDING OF DT CONE AND FOUNDATION RING I

|

UNIT-4 CONCRETING OF MOTOR BARREL IN PROGRESS

|

UNIT-3 CONCRETING OF BARREL COMPLETED

|

UNIT-1 FINAL VH OF ROTOR POLES COMPLETED

|

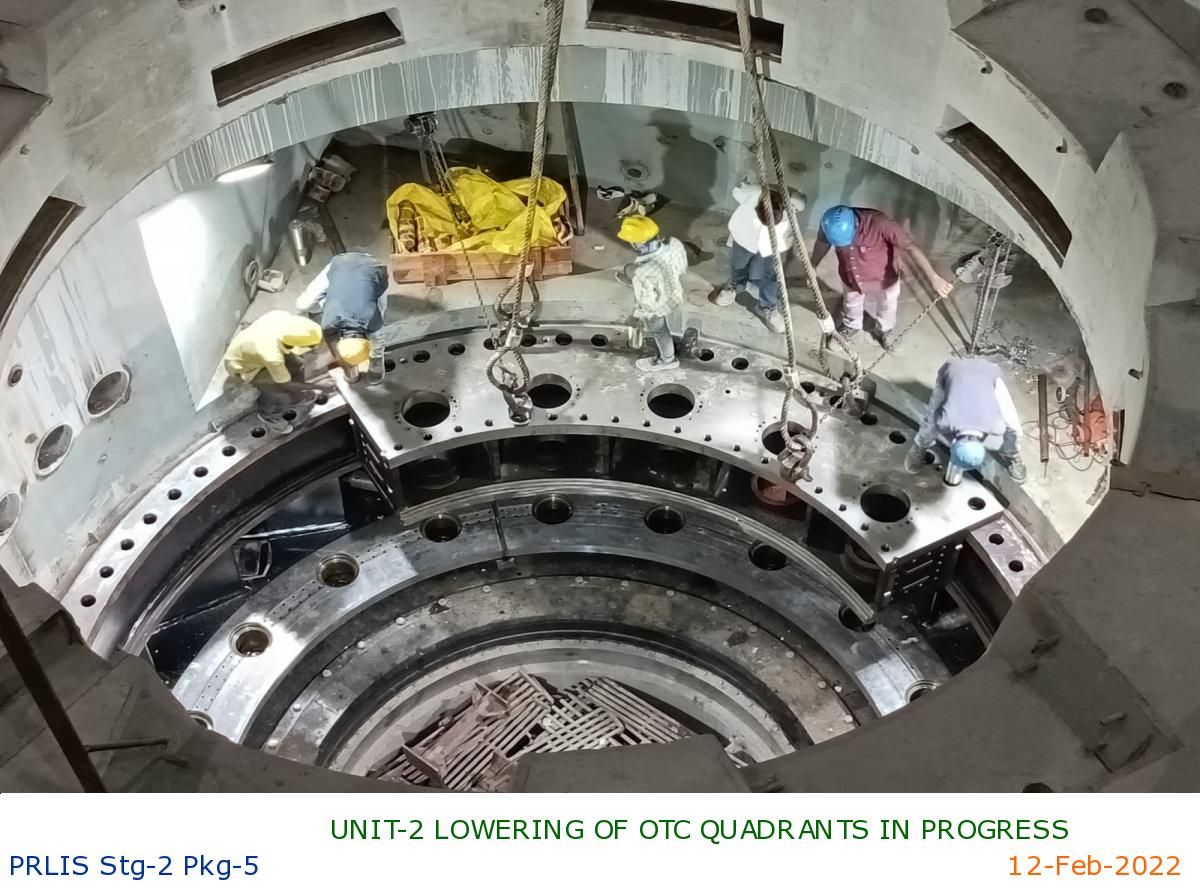

UNIT-2 LOWERING OF OTC QUADRANTS IN PROGRESS

|

UNIT-1 ASSEMBLY OF GUIDE APPARATUS IN PROGRESS

|

UNIT-1 ERECTION BUS DUCT IN PROGRESS

|

UNIT-5 ERECTION OF FOUNDATION RING IN PROGRESS

|

UNIT-4 CONCRETING OF BARREL IN PROGRESS

|

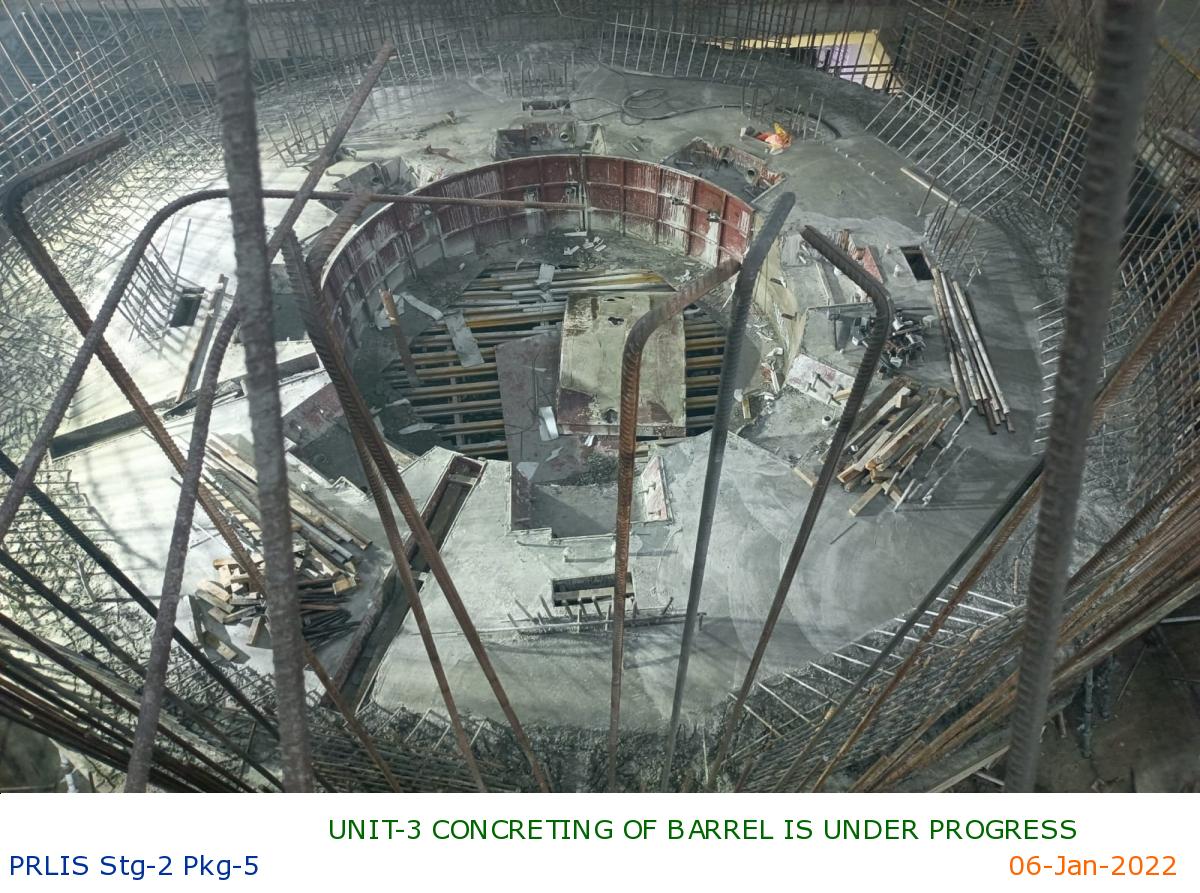

UNIT-3 CONCRETING OF BARREL IS UNDER PROGRESS

|

UNIT-2 LOWERING OF PIVOT RING QUADRANTS

|

UNIT-1SOLDERING OF ROTOR POLE CONNECTION

|

UNIT-1 POSITIONING OF GUIDE VANES

|

CONTROL ROOM

|

UNIT1 AND 2 ERECTION OF BUS DUCT IN PROGRESS

|

VIEW OF MOTOR FLOOR UNIT- 1 TO10

|

VIEW OF UNIT 6-10

|

UNIT-6 ERECTION OF DRAFT TUBE IN PROGRESS

|

UNIT-5 POSITIONING OF FOUNDATION RING

|

UNIT-4 CONCRETING OF BARREL IN PROGRESS

|

UNIT-3 POSITIONING OF STATOR SLE PLATE SLEEVES COMPLETED

|

UNIT-2 GROUTING OF STAY RING AREA COMPLETED

|

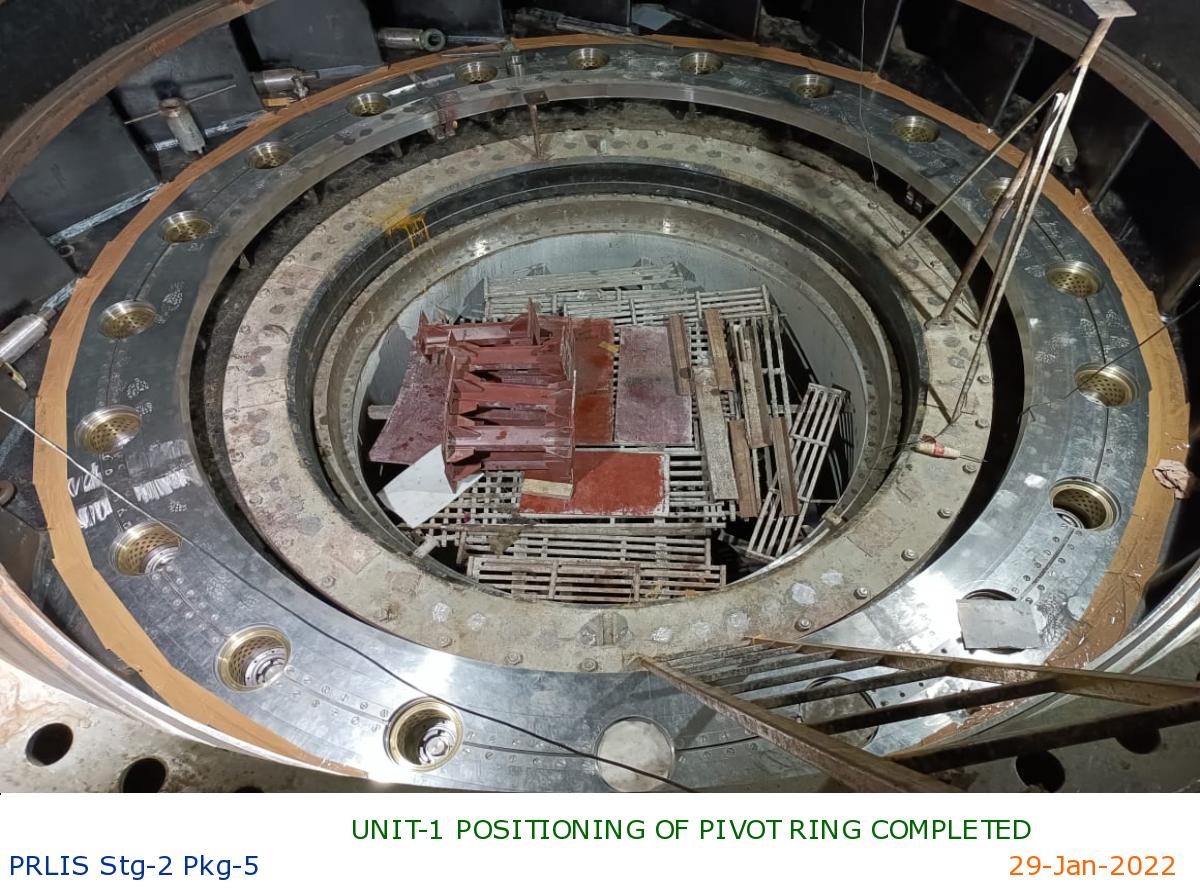

UNIT-1 POSITIONING OF PIVOT RING COMPLETED

|

UNIT-1 TIGHTEING OF POLE KEYS IN PROGRESS

|

UNIT-5 LEVEL CHECK OF STAY RING AFTER HYDRO TEST

|

MOTOR FLOOR

|

UNIT-5 HYDRAULIC TESTING OF SPIRAL CASING

|

UNIT-4 CONCRETING OF BARREL IS UNDER PROGRESS

|

UNIT-3 CONCRETING OF BARREL IS UNDER PROGRESS

|

UNIT-2 BARREL CASTING COMPLETED

|

UNIT-1 MOUNTIN OF POLE

|

UNIT-1 WELDING OF OTC SEGMENTS IN PROGRESS

|

UNIT-1 MOUNTING OF ROTOR POLES IN PROGRESS

|

UNIT-5 WELDING OF SPIRAL SEG AND MAKE-UP PIECES

|

UNIT-4 CONCRETING OF PIT LINER IN PROGRESS

|

UNIT-3 CONCRETING OF BARREL IS UNDER PROGRESS

|

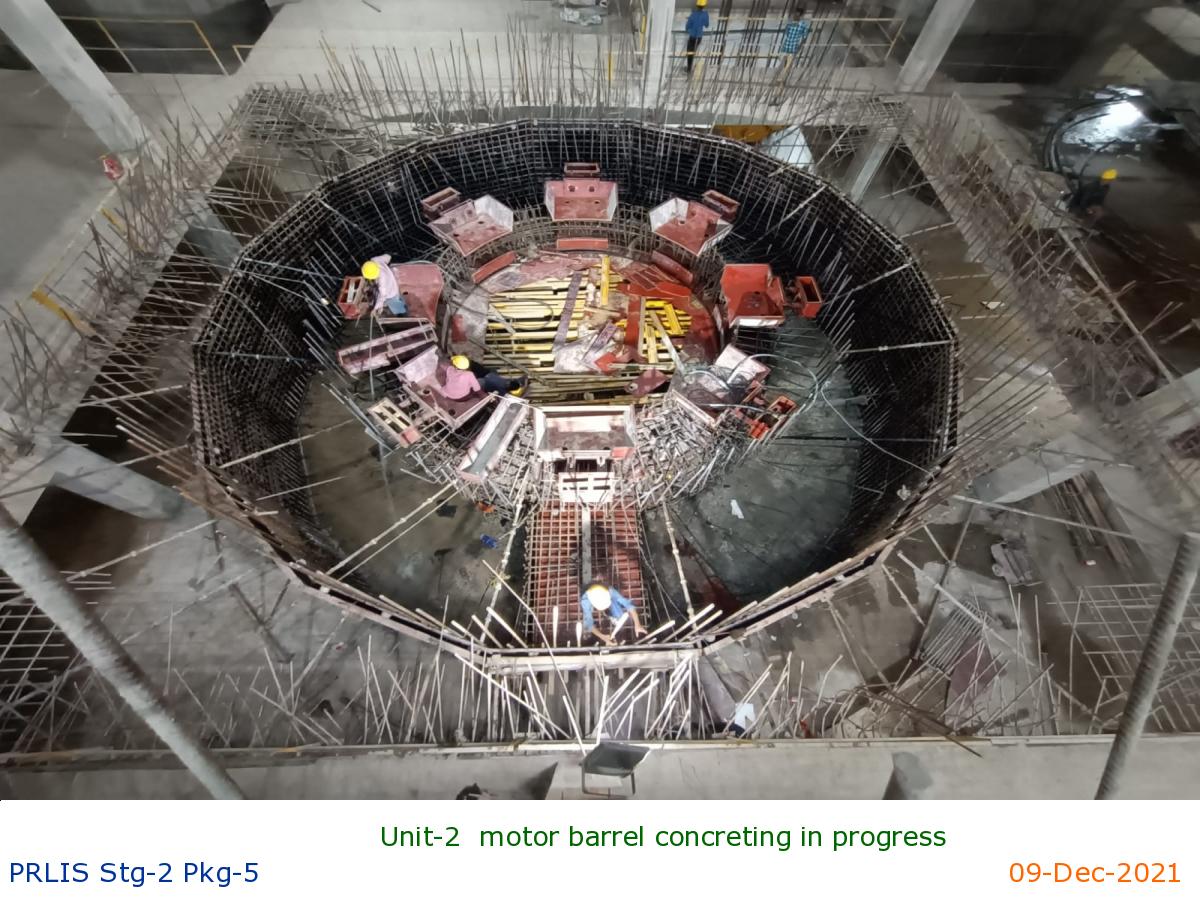

UNIT-2 MOTOR BARREL CONCRETING IN PROGRESS

|

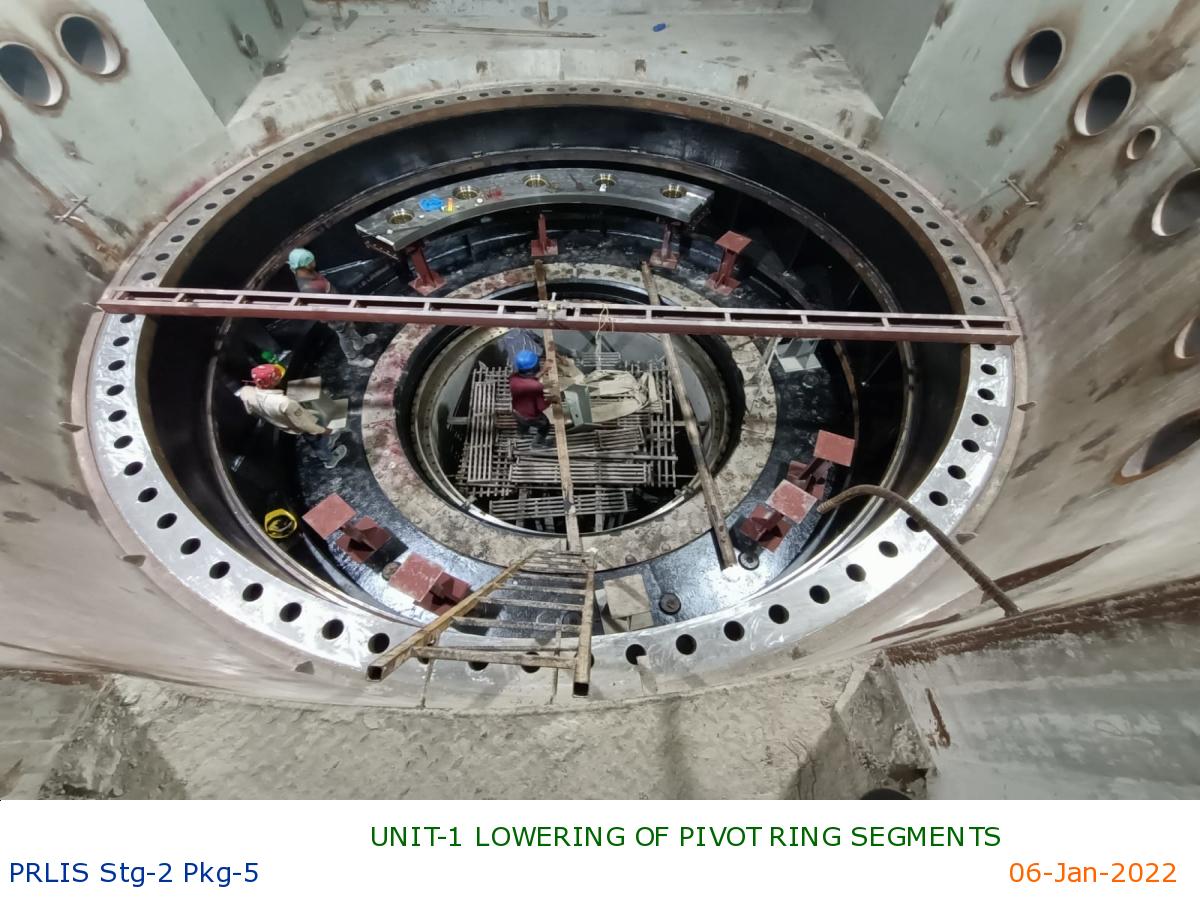

UNIT-1 LOWERING OF PIVOT RING SEGMENTS

|

Unit- cleaning of pump pit in progress

|

Unit-1 measurement of rotor rim dia in progress

|

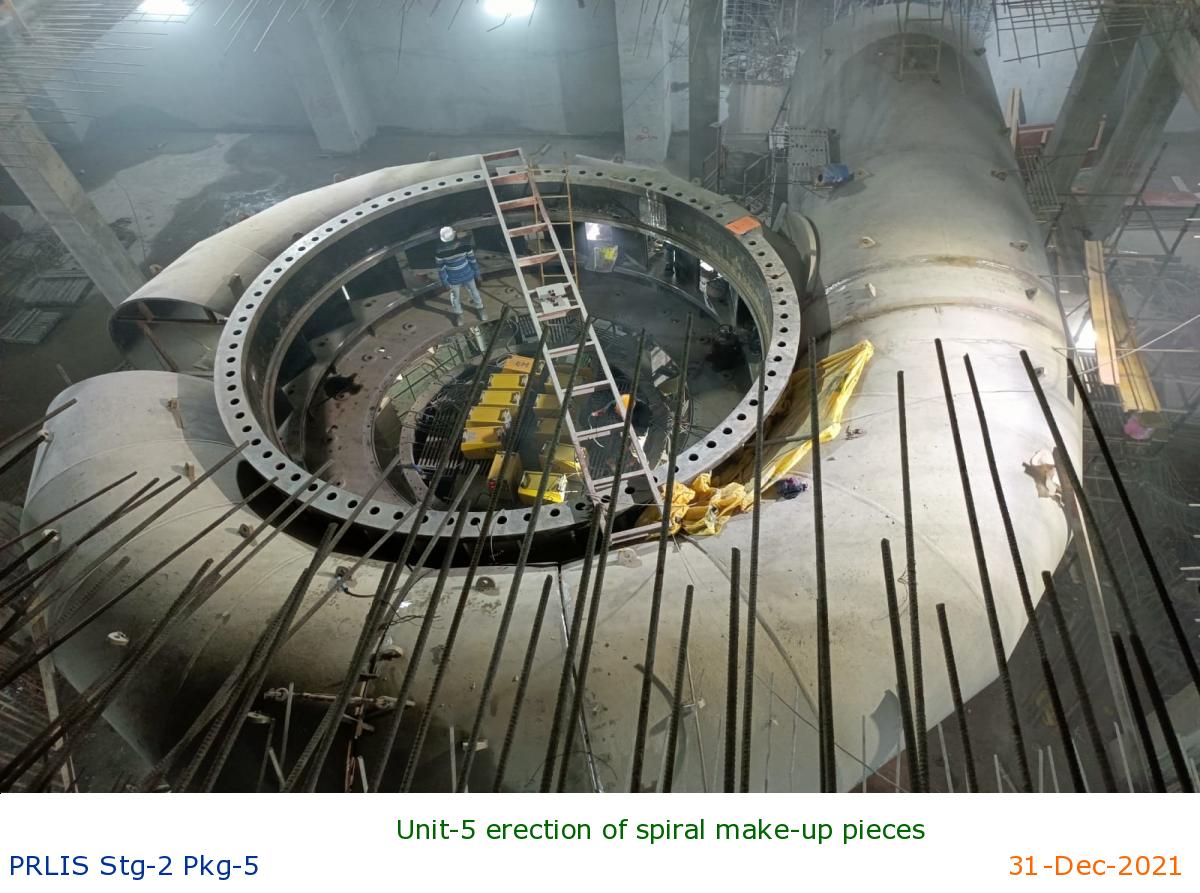

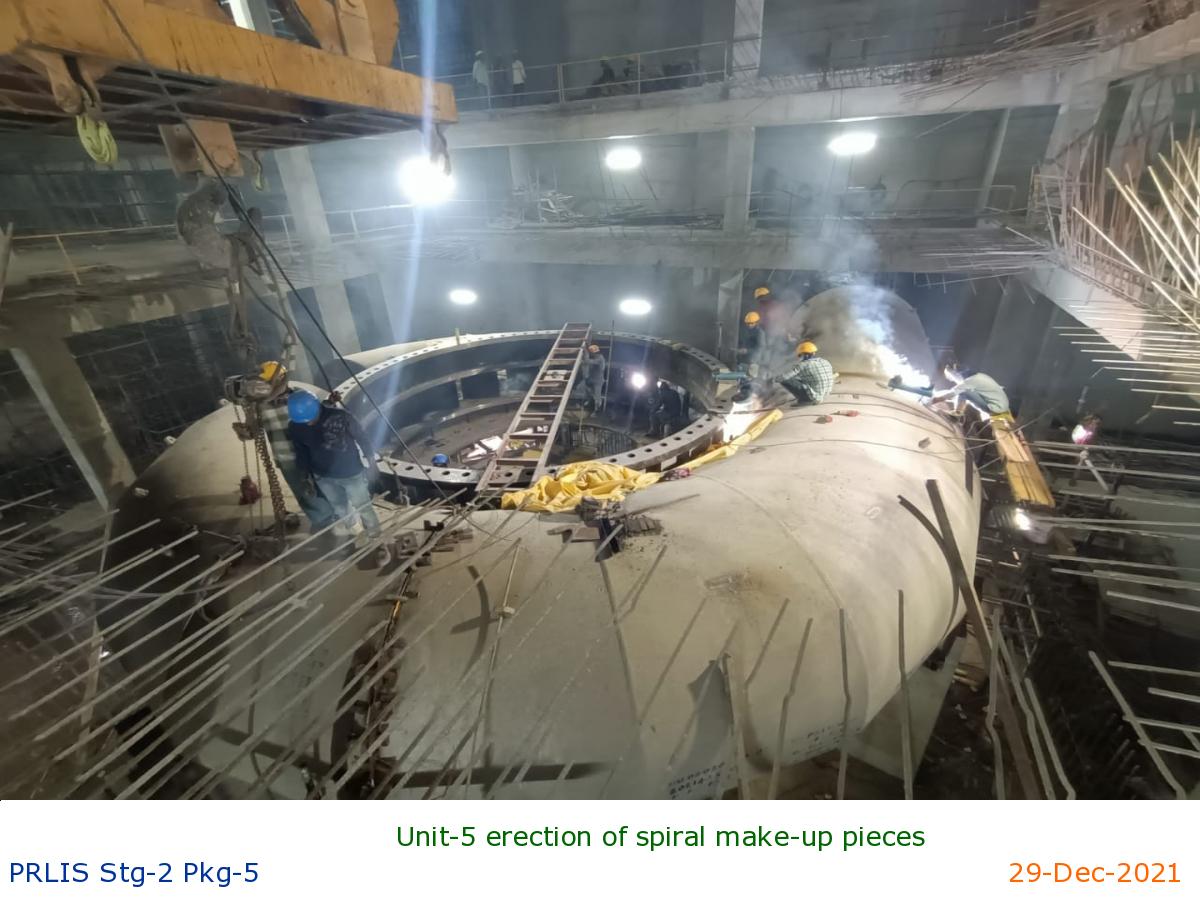

Unit-5 erection of spiral make-up pieces

|

Unit-4 concreting of pit liner in progress

|

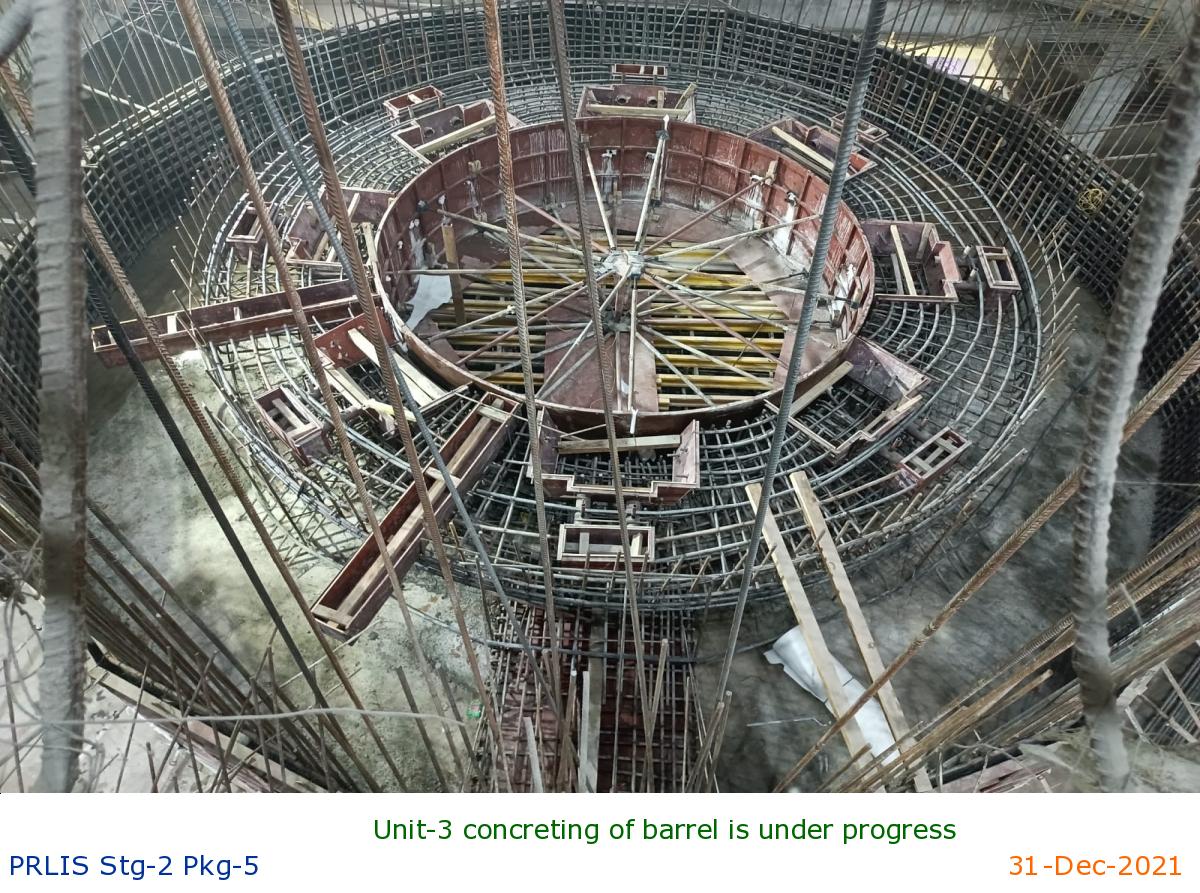

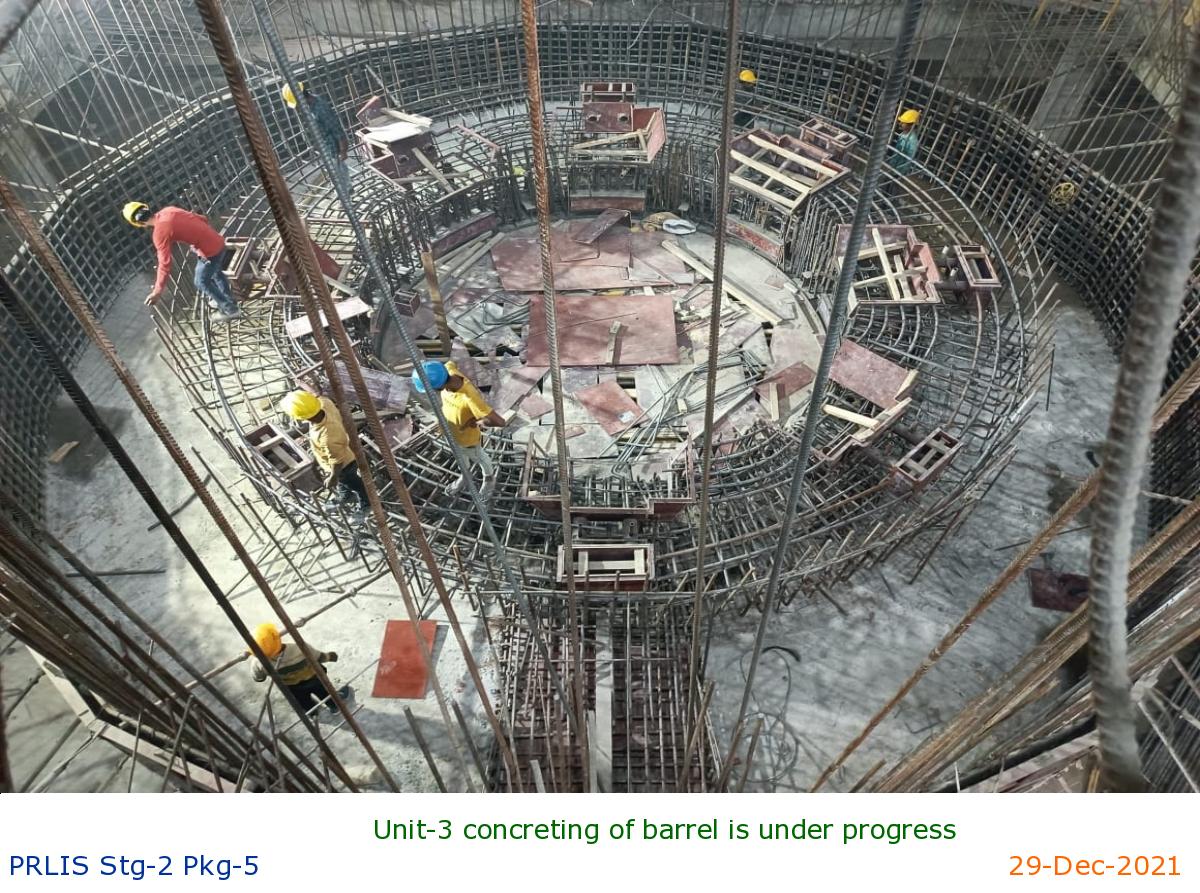

Unit-3 concreting of barrel is under progress

|

Unit-2 positioning of stator sole plate sleeves

|

Unit-1 top view

|

Unit-1 stator has been lowered on its sole plates

|

Unit-2 bus duct erection in progress

|

Unit-1 torque tightening of rotor rims completed

|

Unit-5 erection of spiral make-up pieces

|

Unit-4 concreting of pit liner in progress

|

Unit-3 concreting of barrel is under progress

|

Unit-2 bus duct erection in progress

|

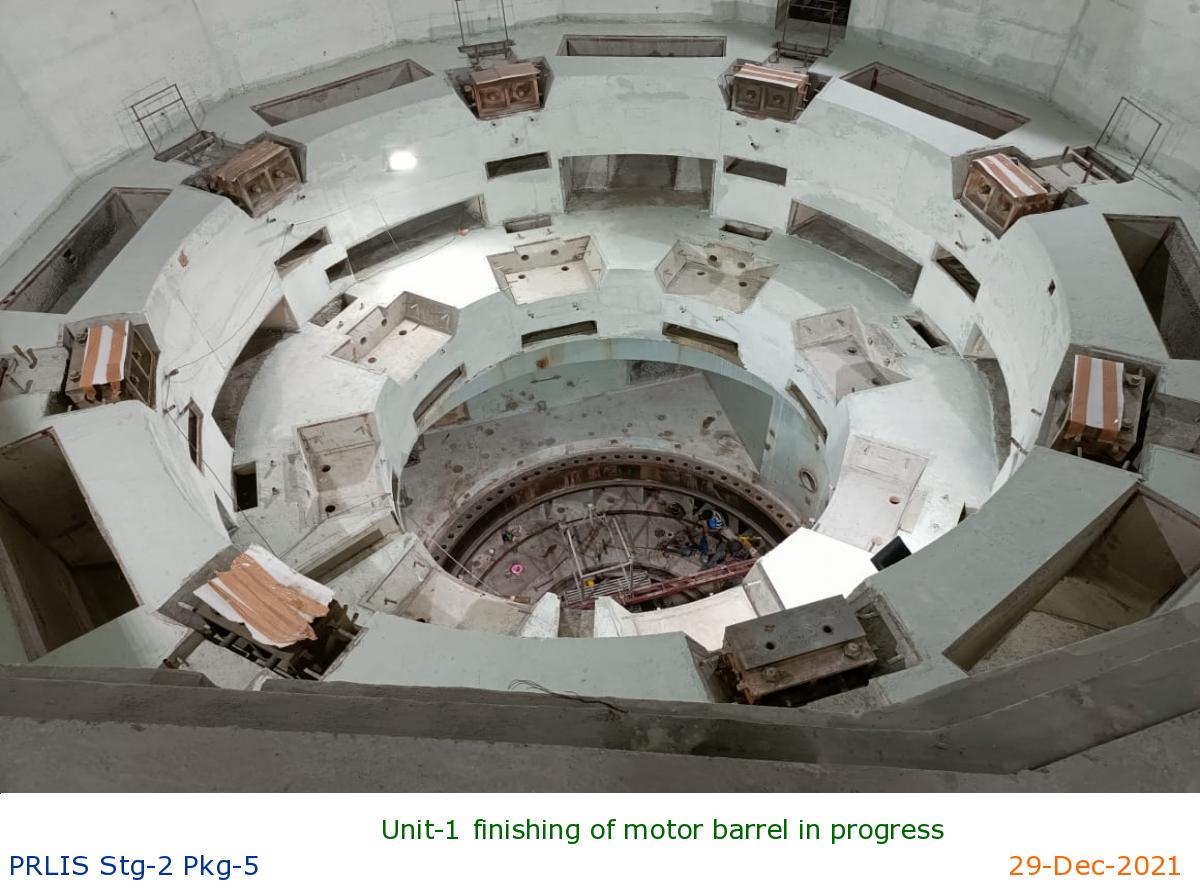

Unit-1 finishing of motor barrel in progress

|

Unit-1 tightening of rotor rims in progress

|

Unit-5 welding of spiral segments in progress

|

Unit-4 concreting of pit liner in progress

|

Unit-3 positioning of LGB sloe plate sleeves

|

Unit-2 motor barrel concreting in progress

|

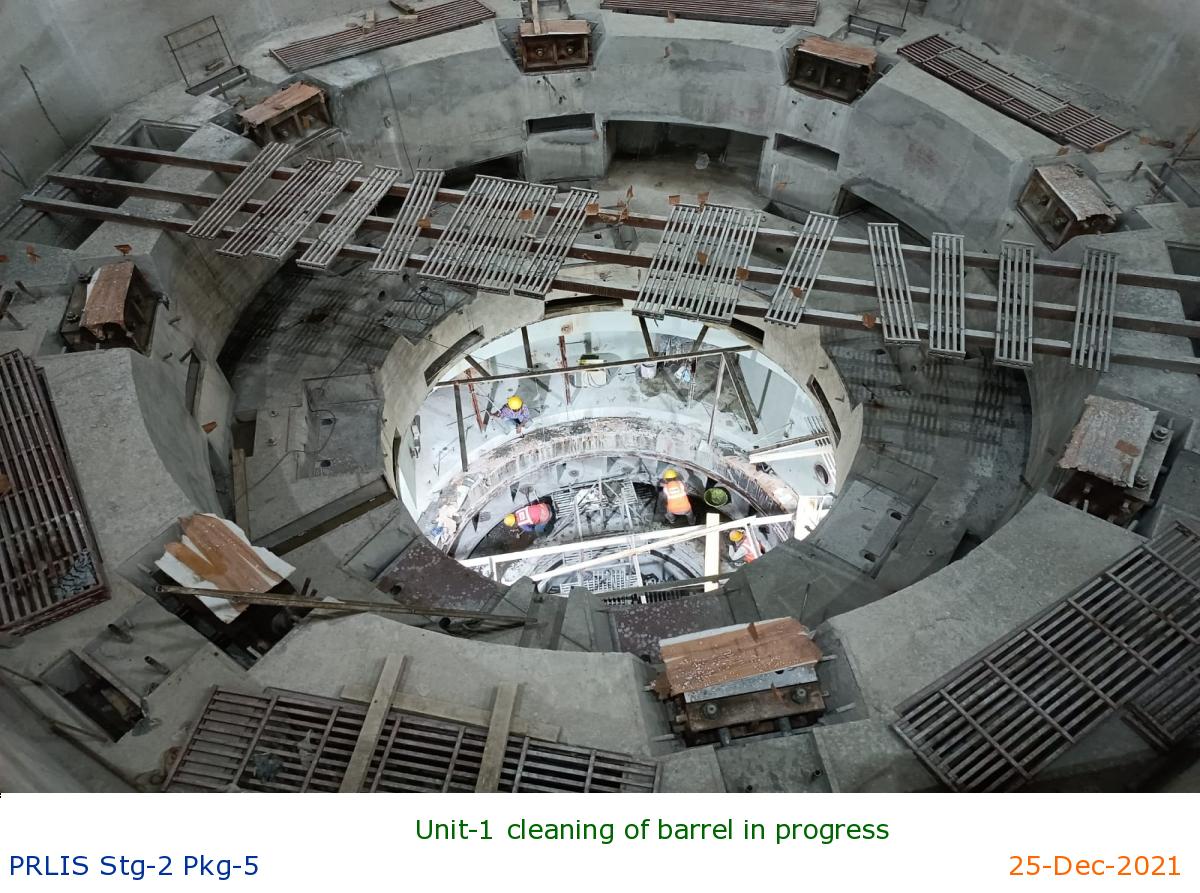

Unit-1 cleaning of barrel in progress

|

Unit-5 Welding of spiral segments in progress

|

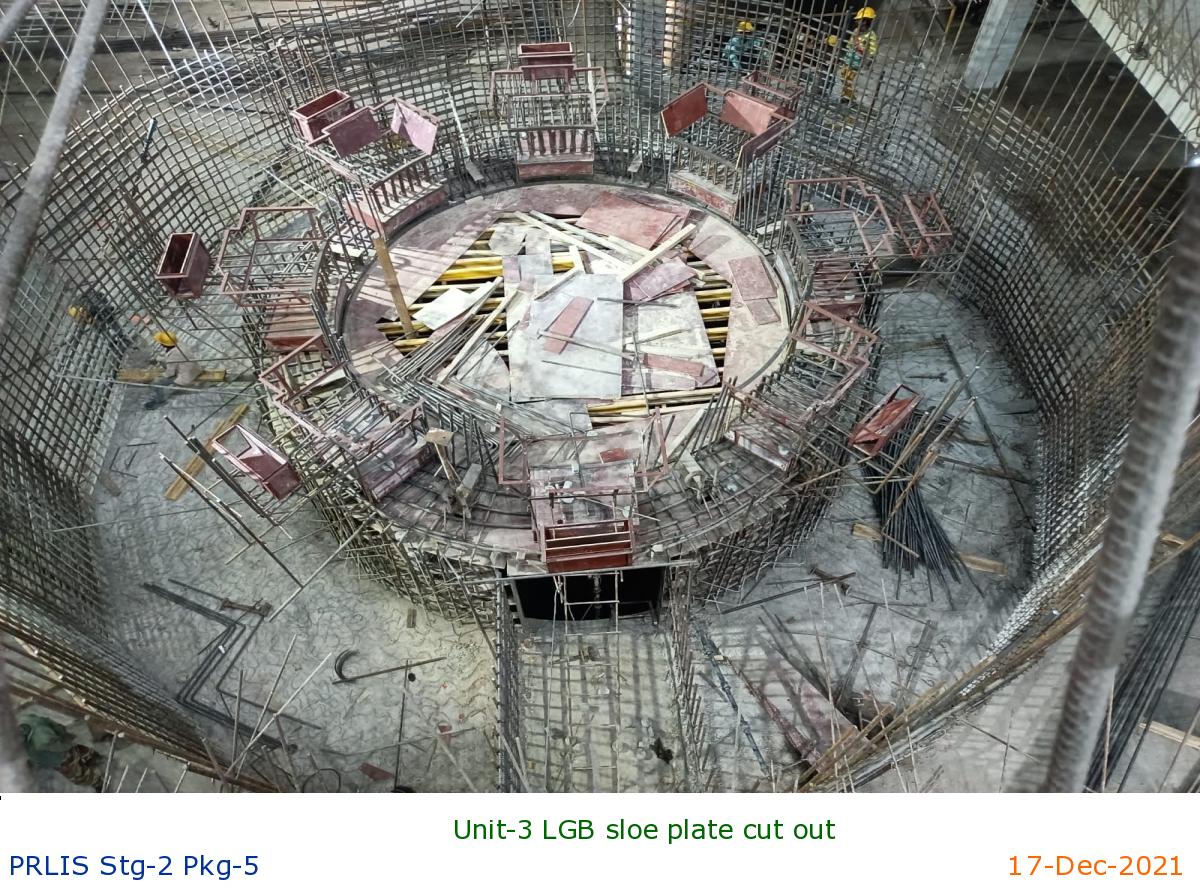

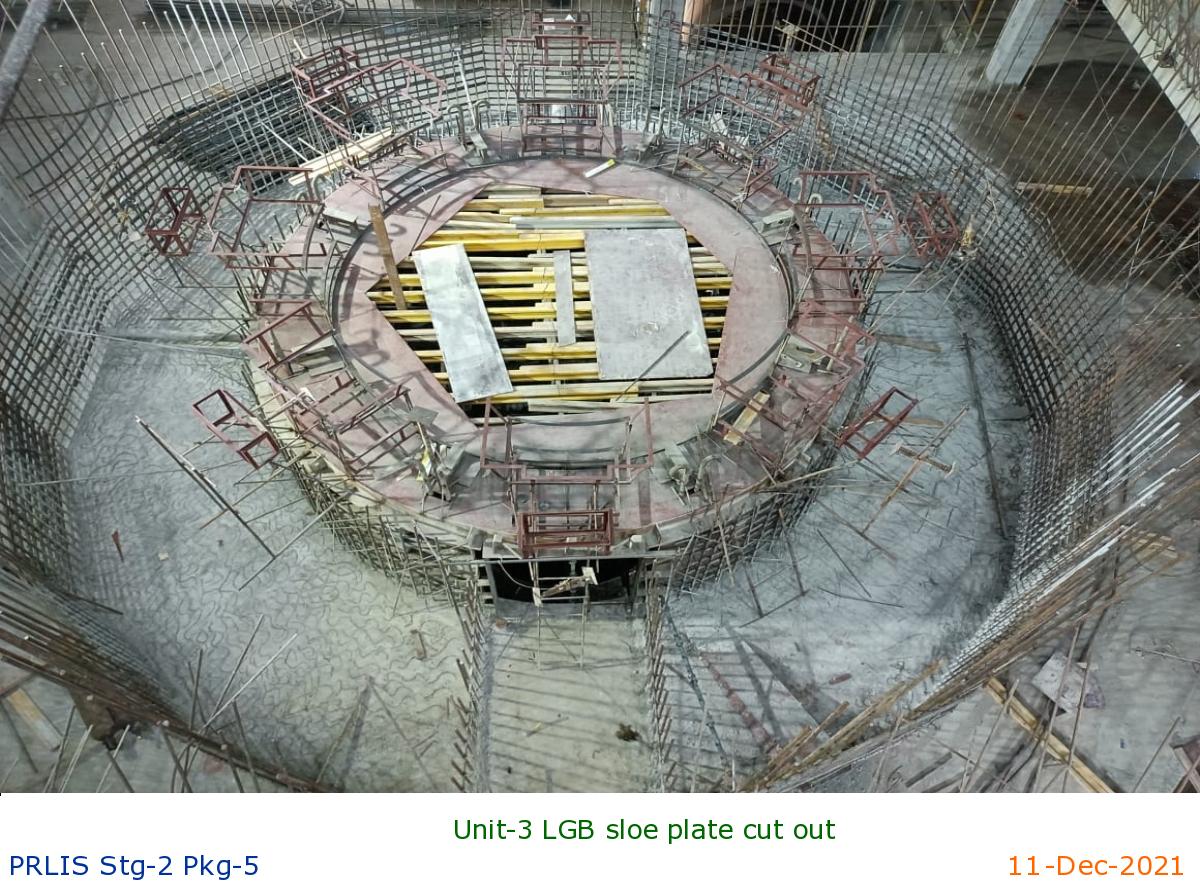

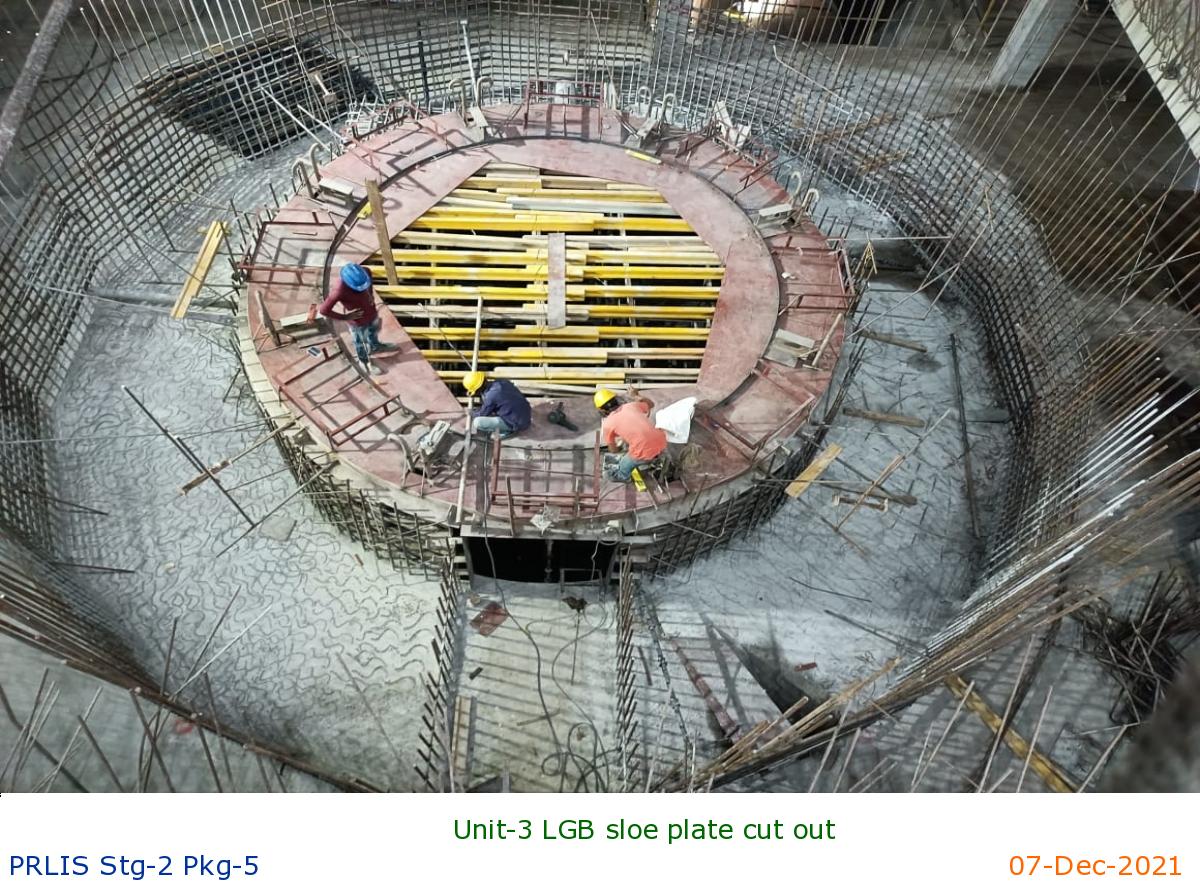

Unit-3 LGB Sloe plate cut out

|

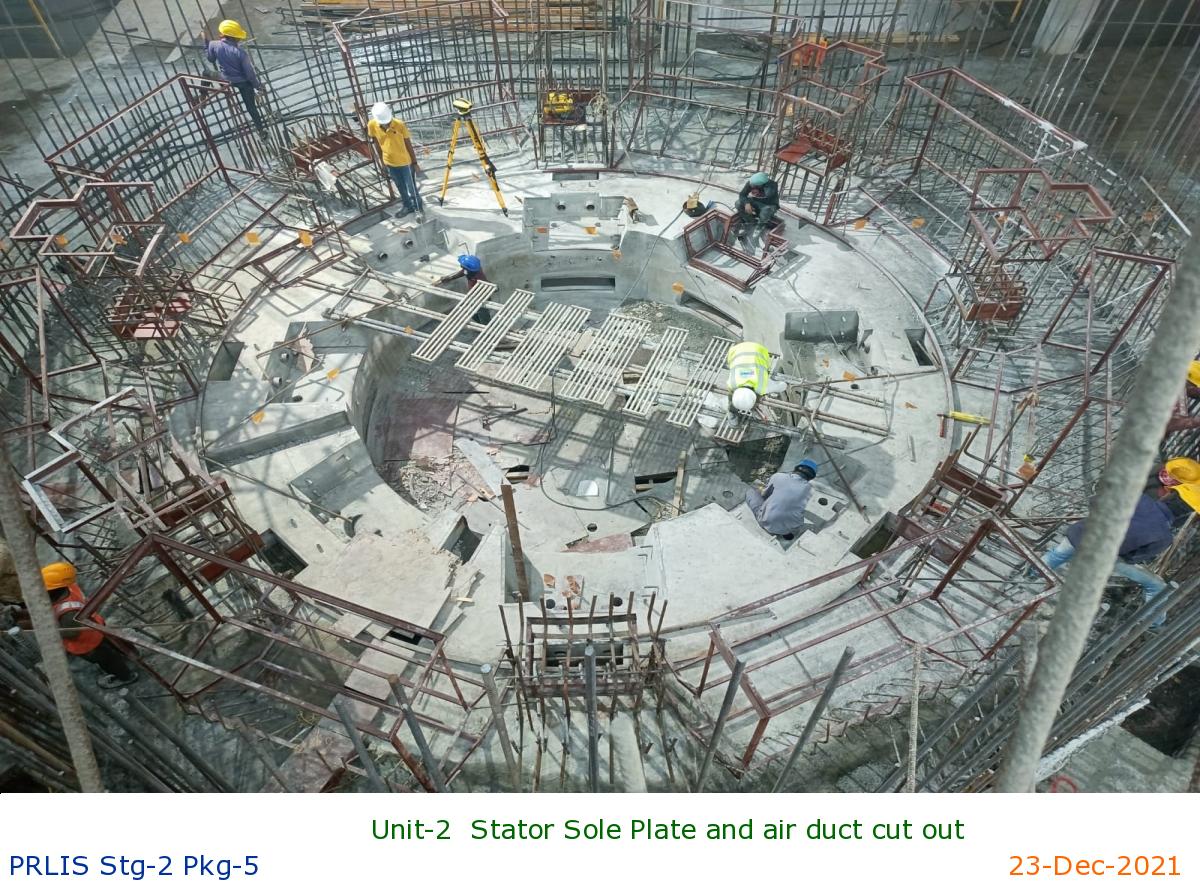

Unit-2 Stator Sole Plate and air duct cut out

|

Unit-1 Grouting of spiral and foundation ring

|

Unit-1 Rotor rim building completed

|

Unit-5 erection of spiral segments in progress

|

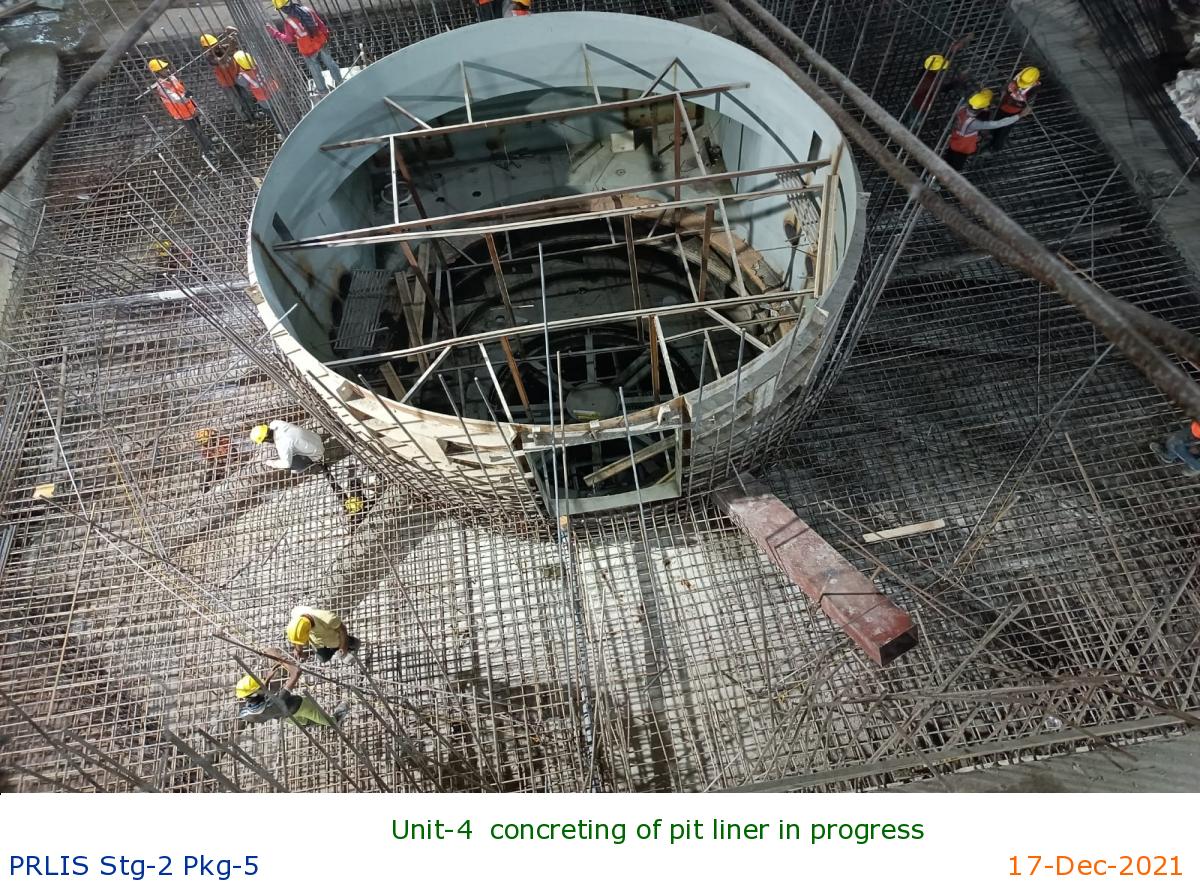

Unit-4 concreting of pit liner in progress

|

Unit-3 motor barrel concreting in progress

|

Unit-2 motor barrel concreting in progress

|

Unit-1 cleaning of motor barrel in progress

|

Unit-1 erection bus duct in progress

|

Unit-1 rotor rim building completed

|

Unit-1 rotor rim building in progress.

|

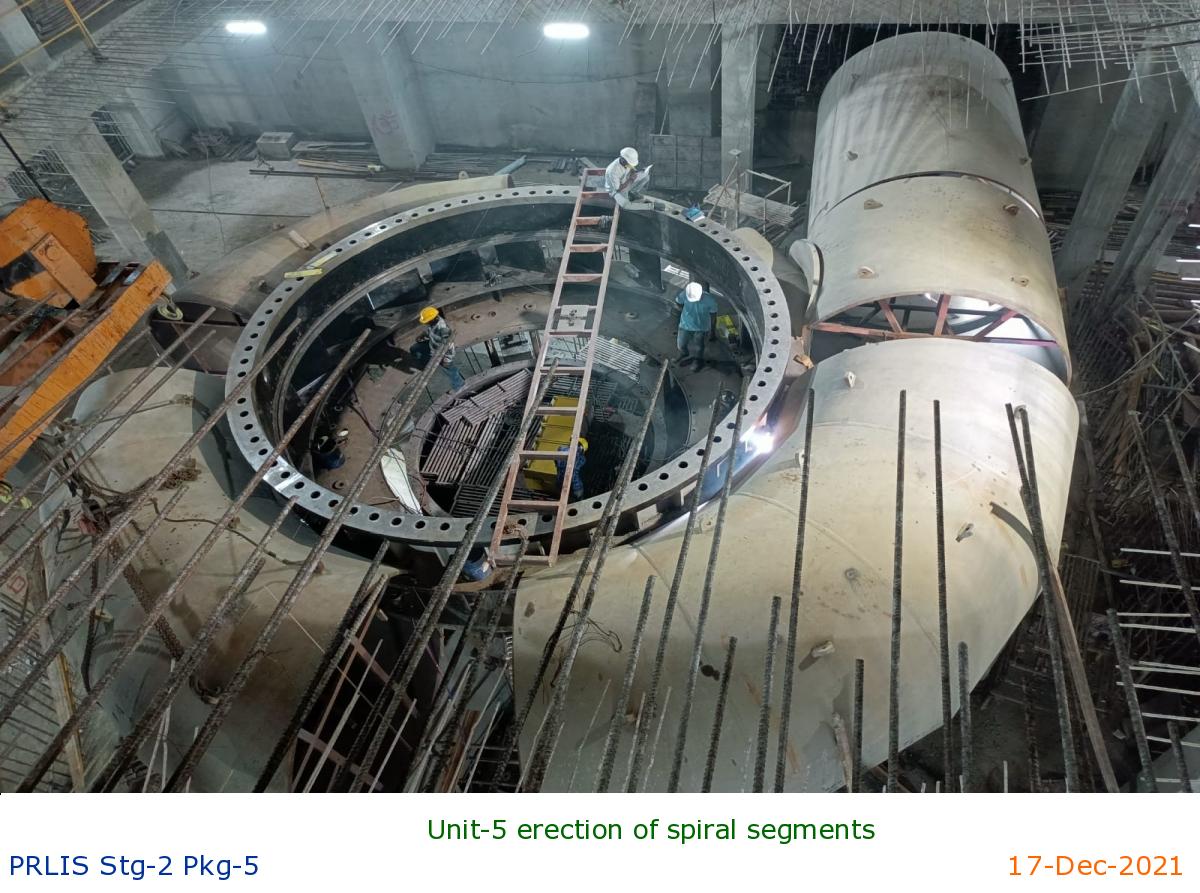

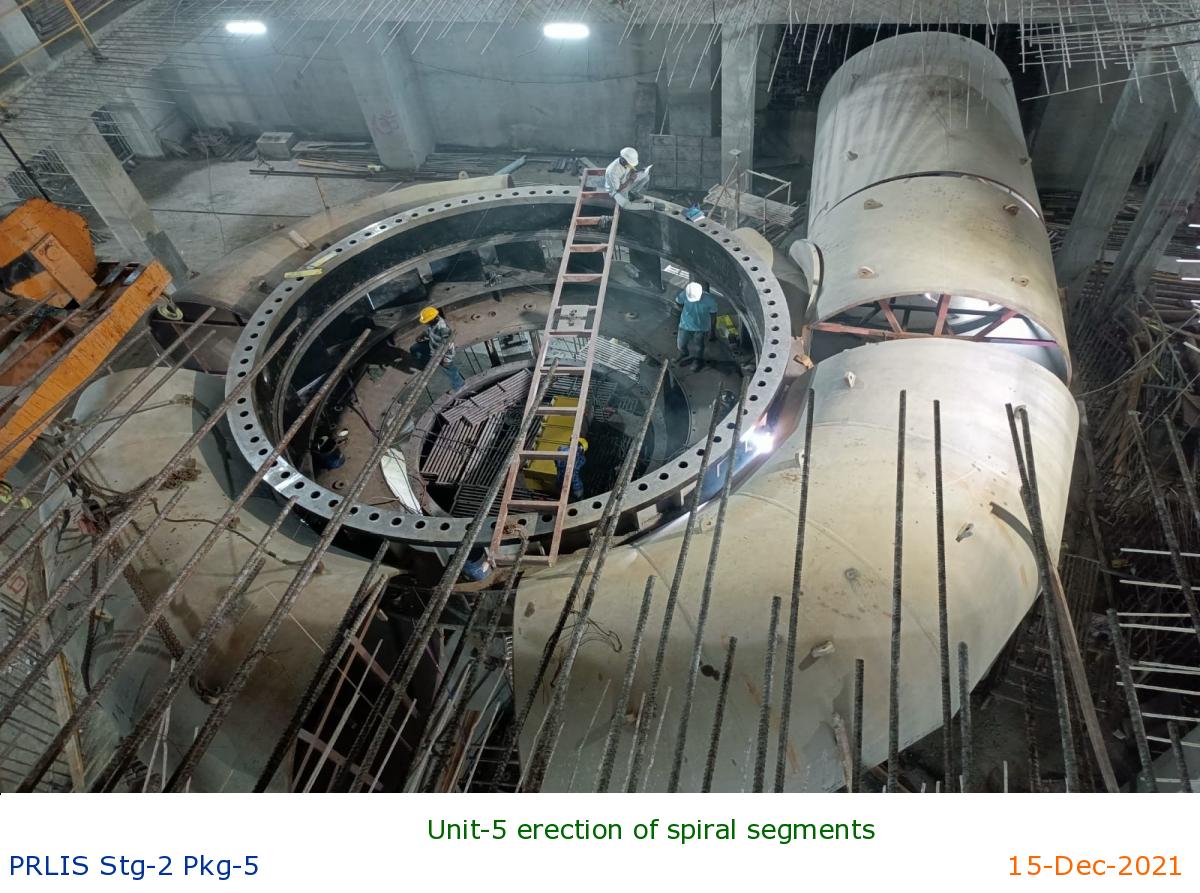

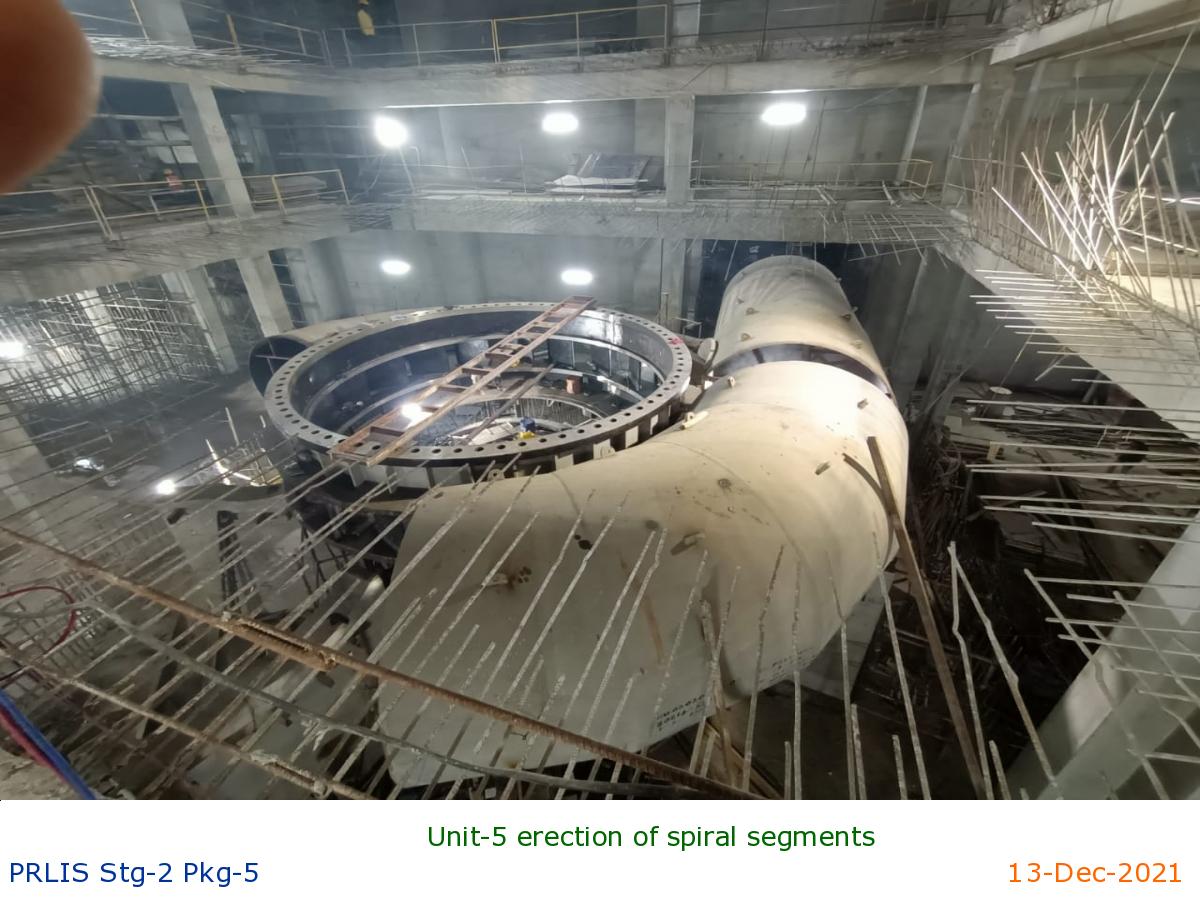

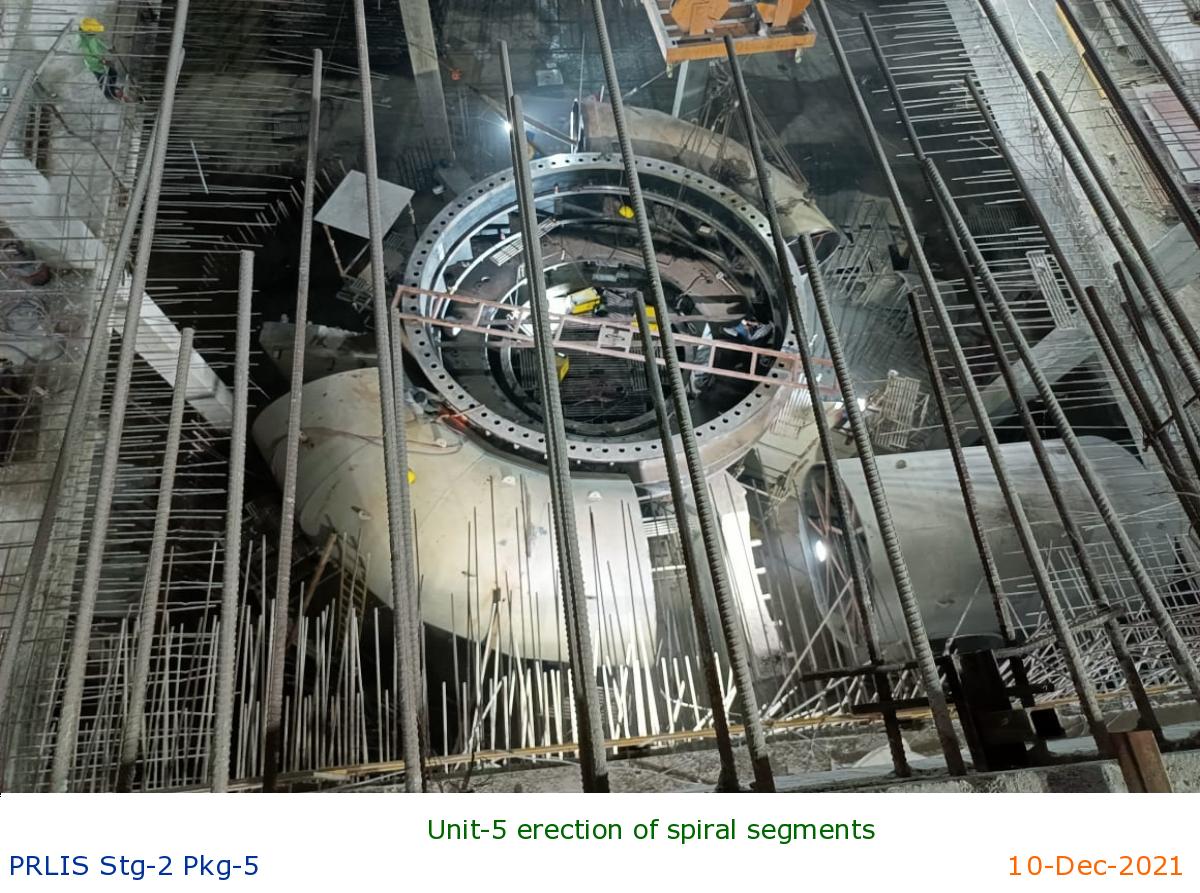

Unit-5 erection of spiral segments

|

Unit-4 concreting of pit liner in progress

|

Unit-3 LGB sloe plate cut out

|

Unit-2 motor barrel concreting in progress

|

Unit-1 positioning of stator sole plates

|

Unit-1 positioning of stator sole plates

|

Unit-1 Erection bus duct in progress.

|

Unit-5 erection of spiral segments

|

Unit-5 erection of spiral segments

|

Unit-1 rotor rim building in progress

|

Unit-4 concreting of pit liner in progress

|

Unit -3 Laying of barrel reinforcement RODS

|

Unit-2 motor barrel concreting in progress

|

Unit-1 finishing of motor barrel /pump in progress

|

Unit-1 second pressing of rotor rim building

|

Unit-5 erection of spiral segments

|

Unit-4 concreting of spiral casing in progress

|

Unit-2 laying of reinforcement rods in progress

|

Unit-3 motor barrel concreting in progress

|

Unit-1 finishing of motor barrel in progress

|

Unit-1 rotor rim building in progress.

|

Unit-5 alignment of spiral partition plate seg.

|

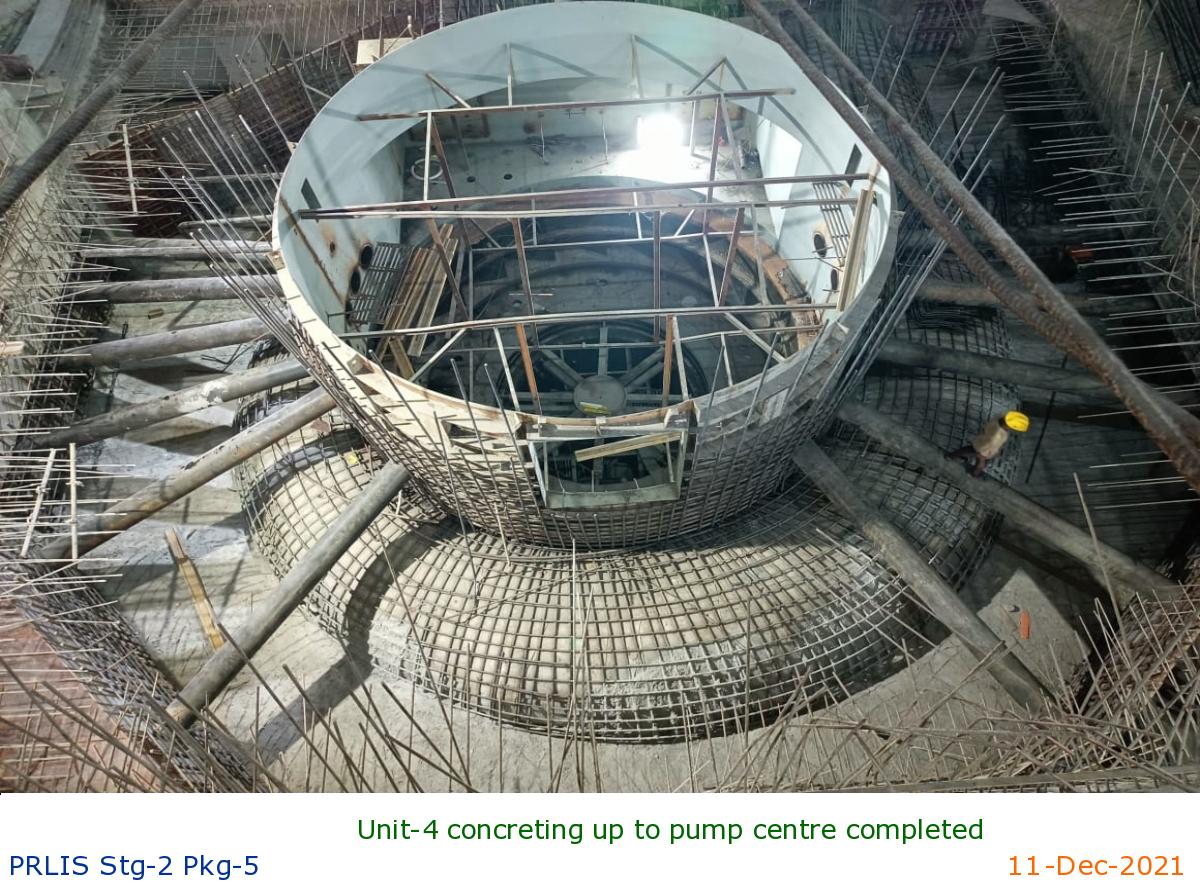

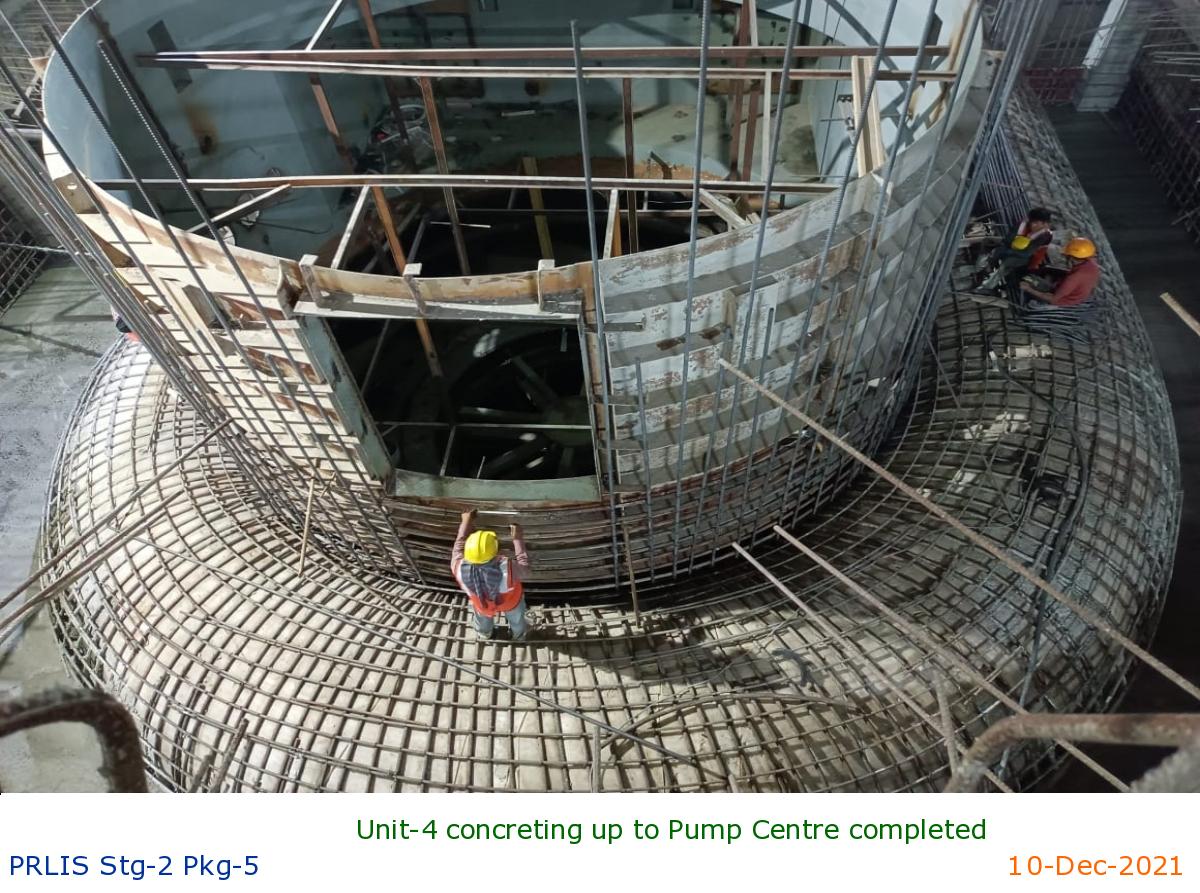

Unit-4 concreting up to pump centre completed

|

Unit-3 LGB sloe plate cut out

|

Unit-2 motor barrel concreting in progress

|

Unit-1 finishing of motor barrel in progress

|

Unit-1 first pressing of rotor rim building

|

Unit-5 erection of spiral segments

|

Unit-4 concreting up to Pump Centre completed

|

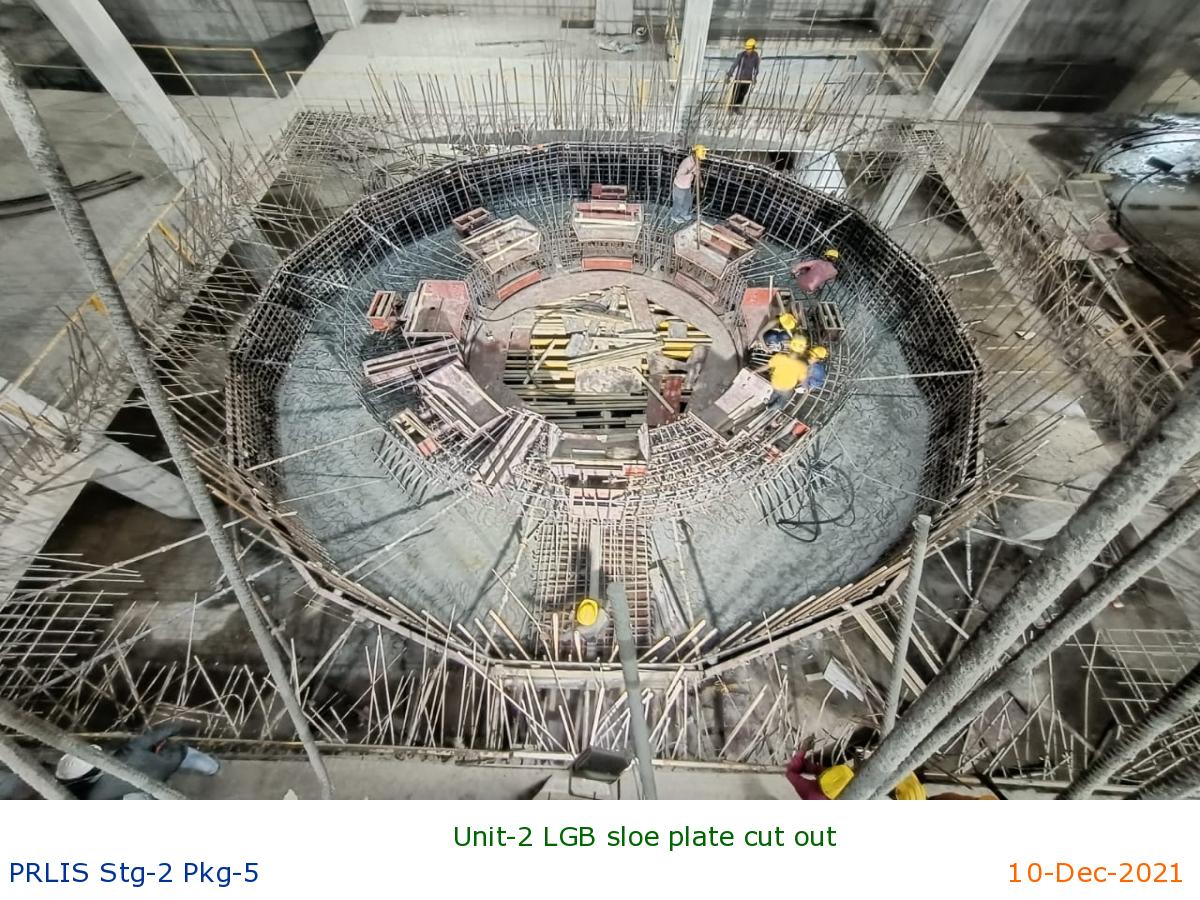

Unit-2 LGB sloe plate cut out

|

Unit-3 Motor barrel concreting in progress

|

Unit-1 motor barrel concreting completed

|

Unit-1 erection bus duct in progress

|

Unit-5 erection of spiral segments

|

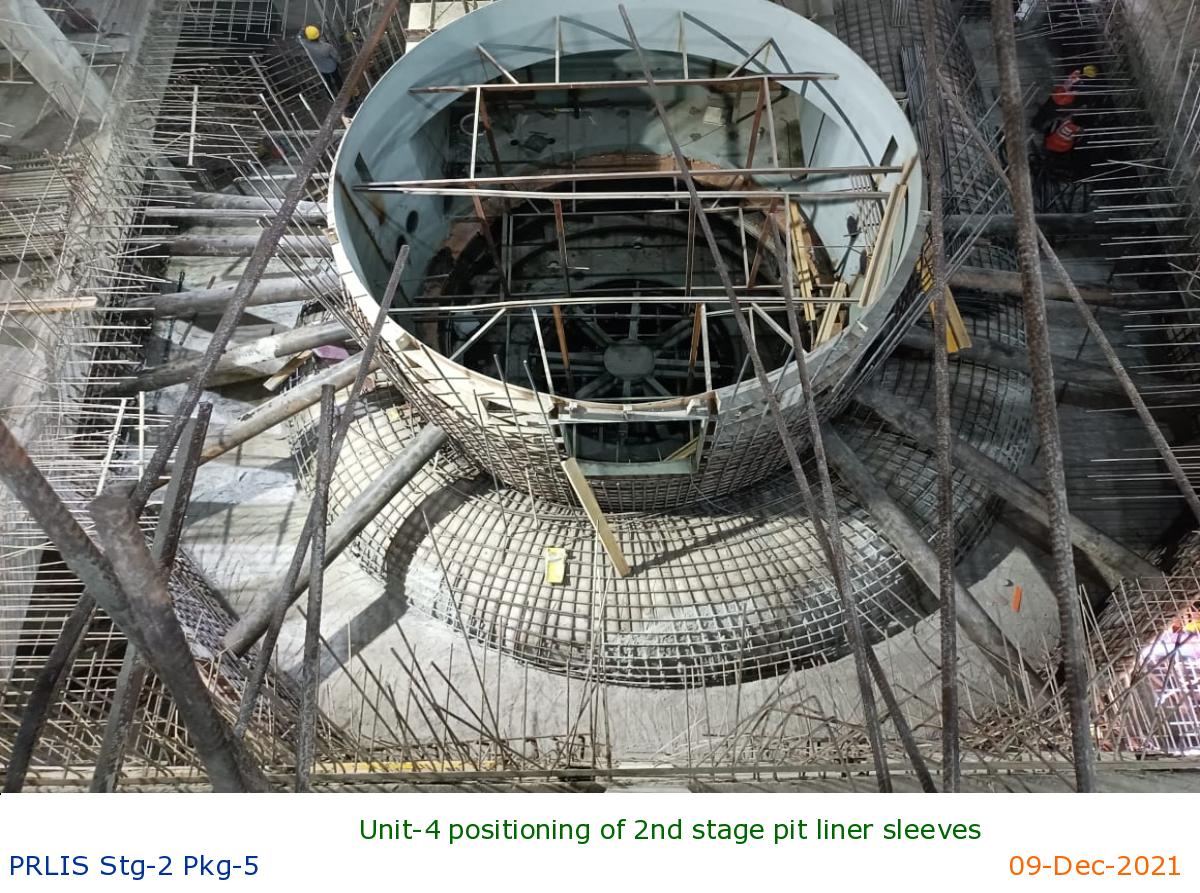

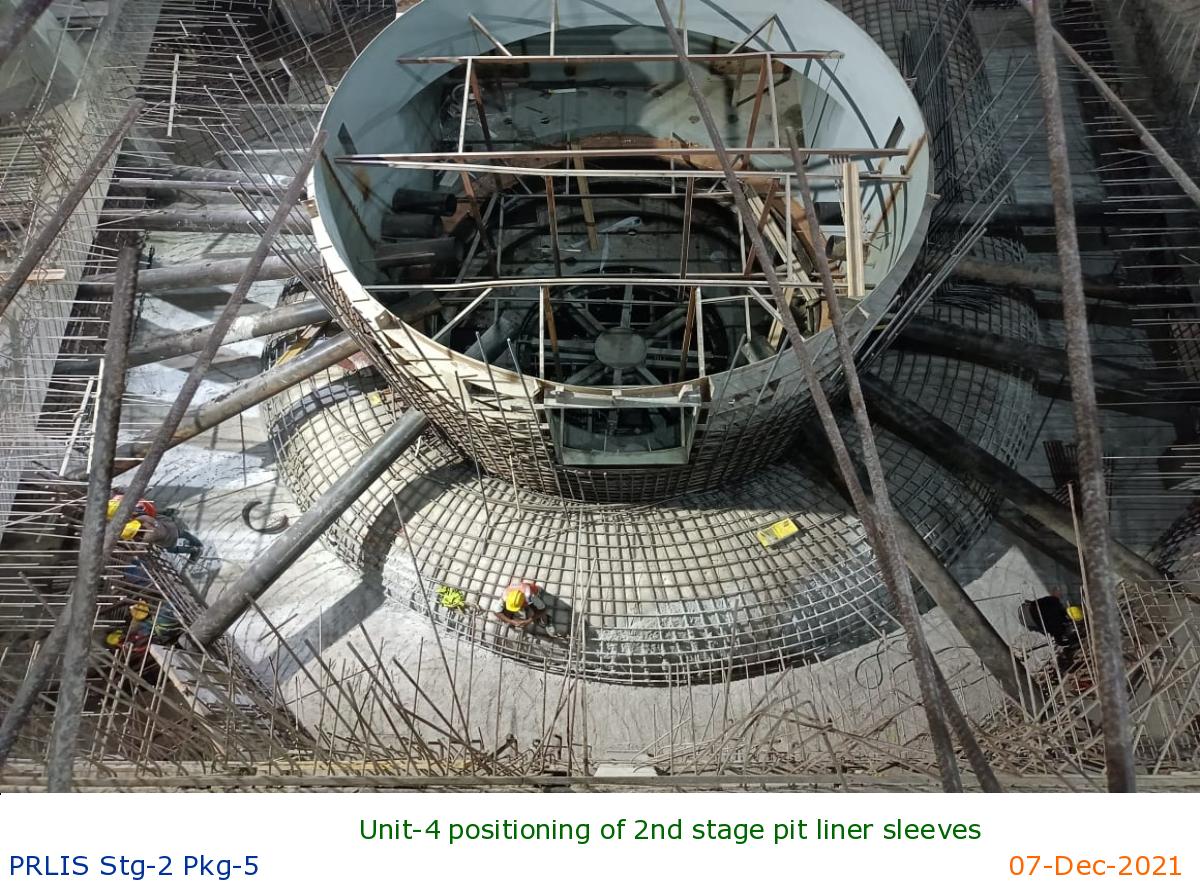

Unit-4 positioning of 2nd stage pit liner sleeves

|

Unit-3 positioning of LGB sole plate cut out frame

|

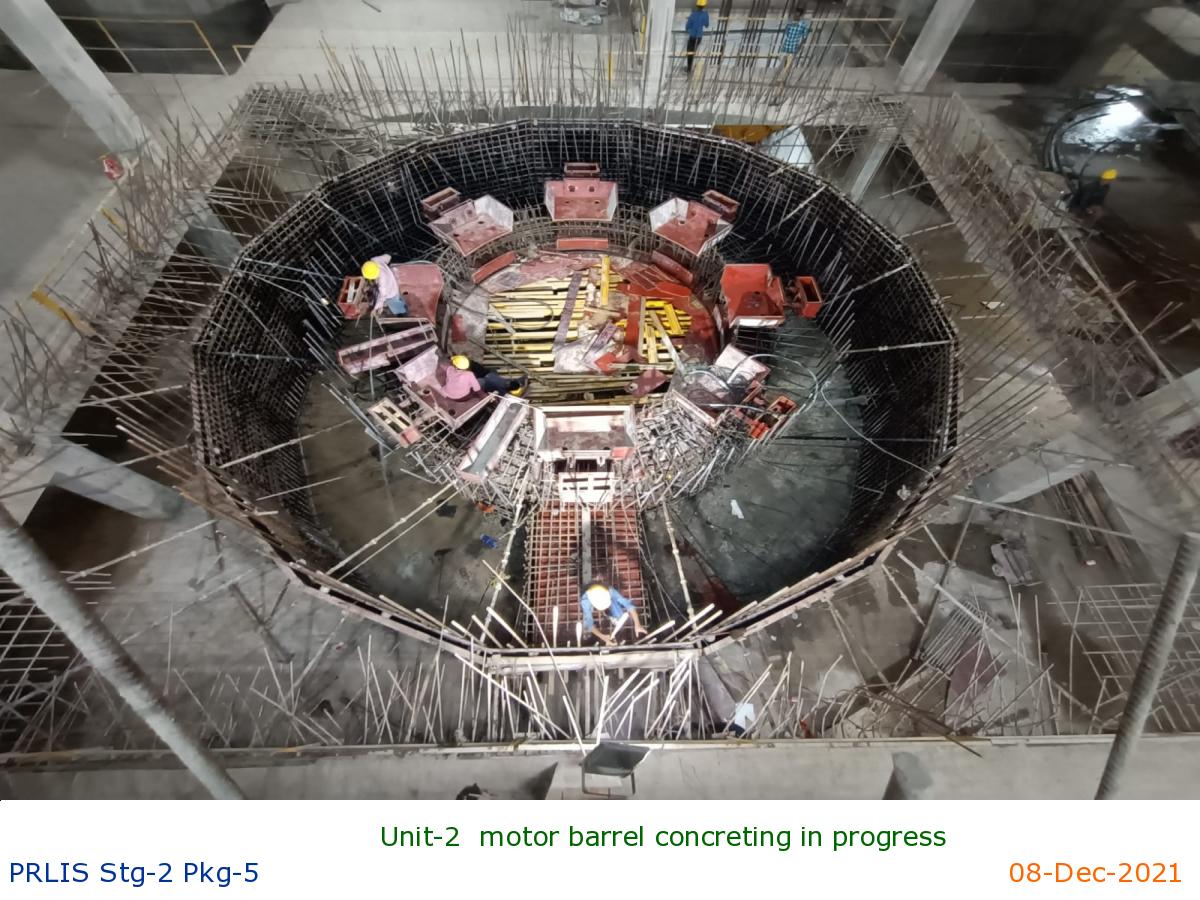

Unit-2 motor barrel concreting in progress

|

Unit-1 concreting of motor barrel completed

|

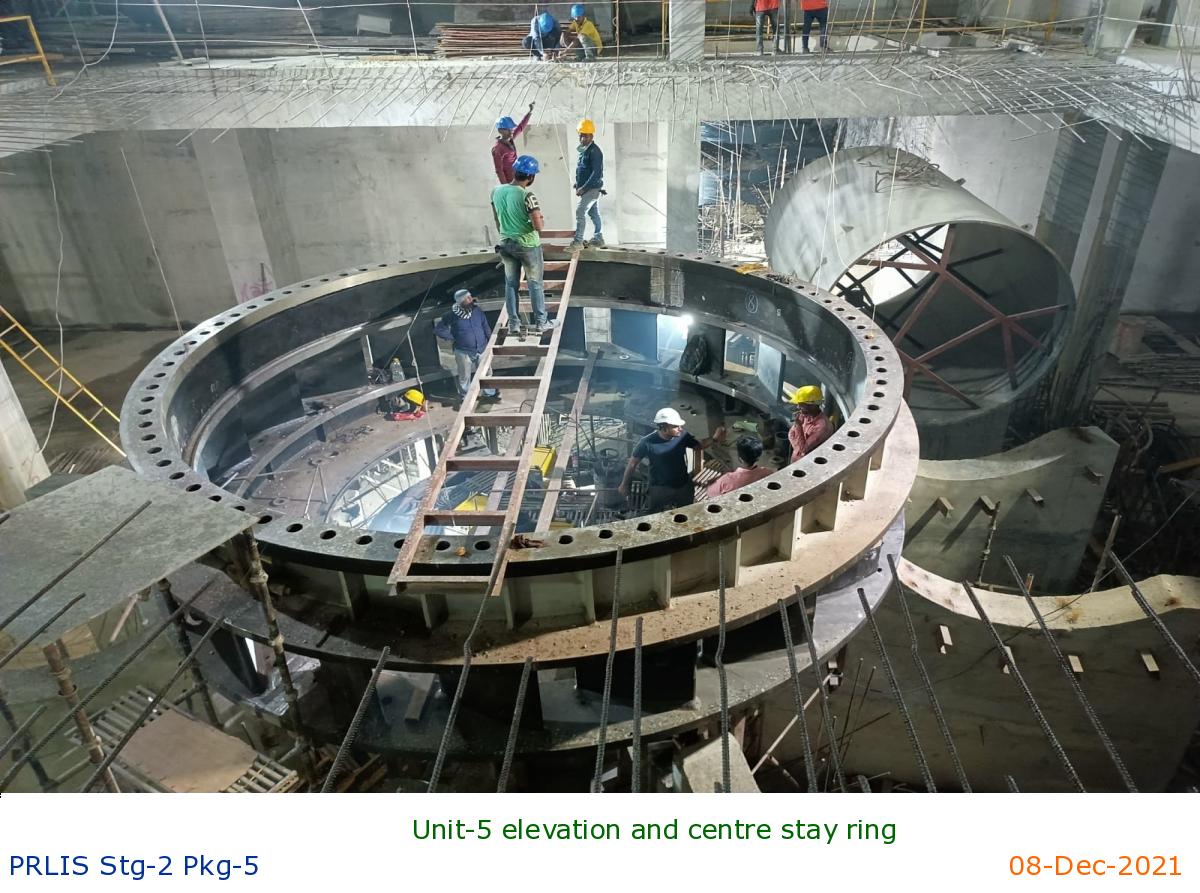

Unit-5 elevation and centre stay ring

|

Unit-4 positioning of 2nd stage pit liner sleeves

|

Unit-3 motor barrel concreting in progress

|

Unit-2 motor barrel concreting in progress

|

Unit-1 concreting of motor barrel completed

|

Unit-5 welding of stay ring joints in progress

|

Unit-4 positioning of 2nd stage pit liner sleeves

|

Unit-3 LGB sloe plate cut out

|

Unit-2 positioning of LGB sole plate sleeves

|

Unit-1 concreting of motor barrel in progress

|

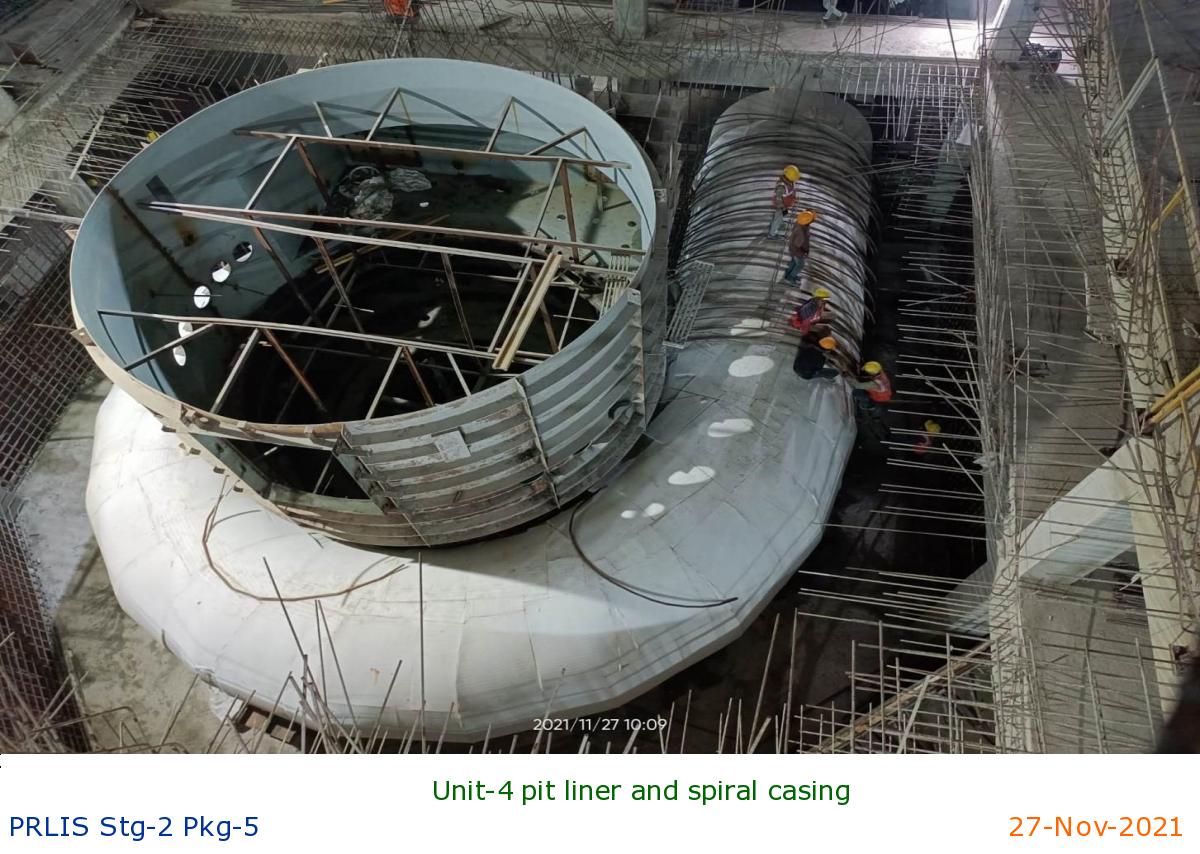

U#4 Pit liner and Spiral Casing

|

U#3 Barrel Concreting in Progress

|

U#2 Barrel Concreting in Progress

|

UNIT-1 ERECTION OF BUS DUCT IN PROGRESS.

|

Unit-5 welding of Stay Ring Joints in progress

|

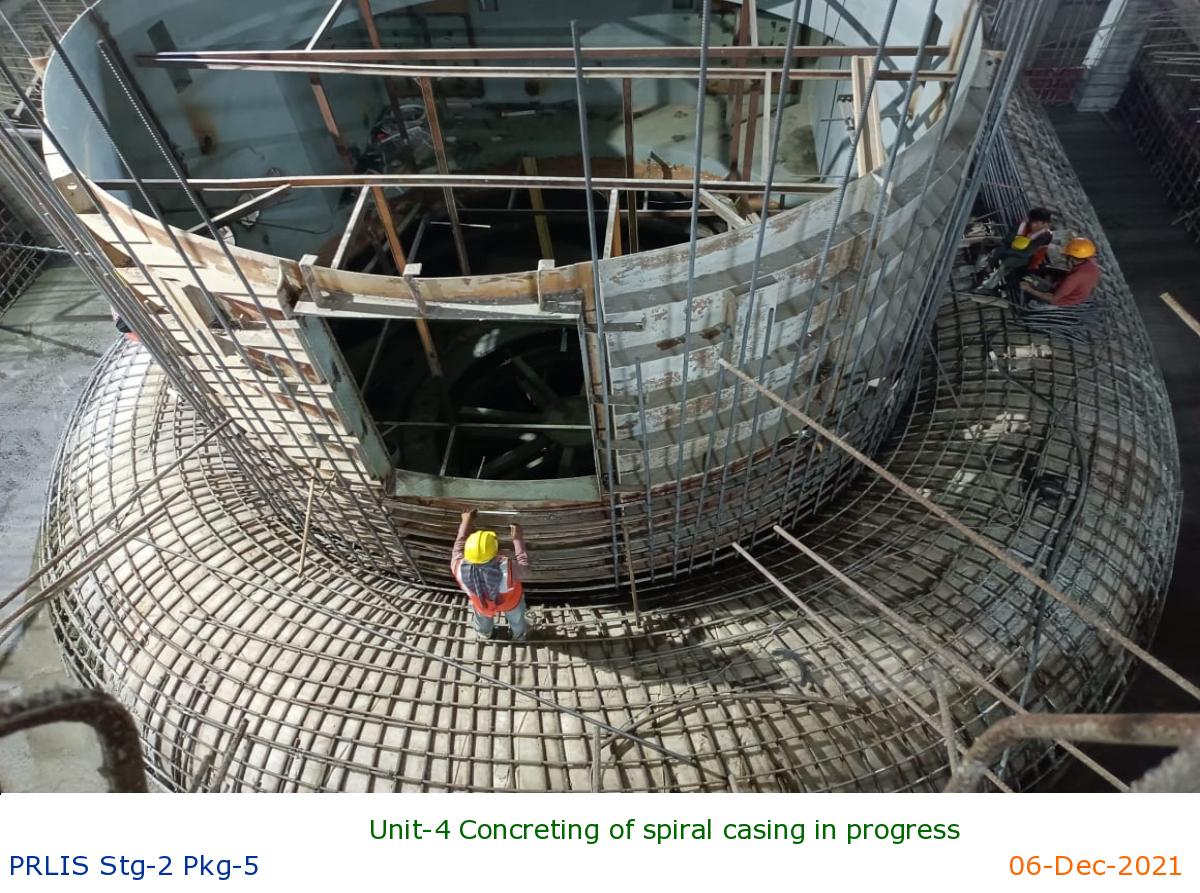

Unit-4 Concreting of spiral casing in progress

|

Unit-3 Pit liner concreting in progress

|

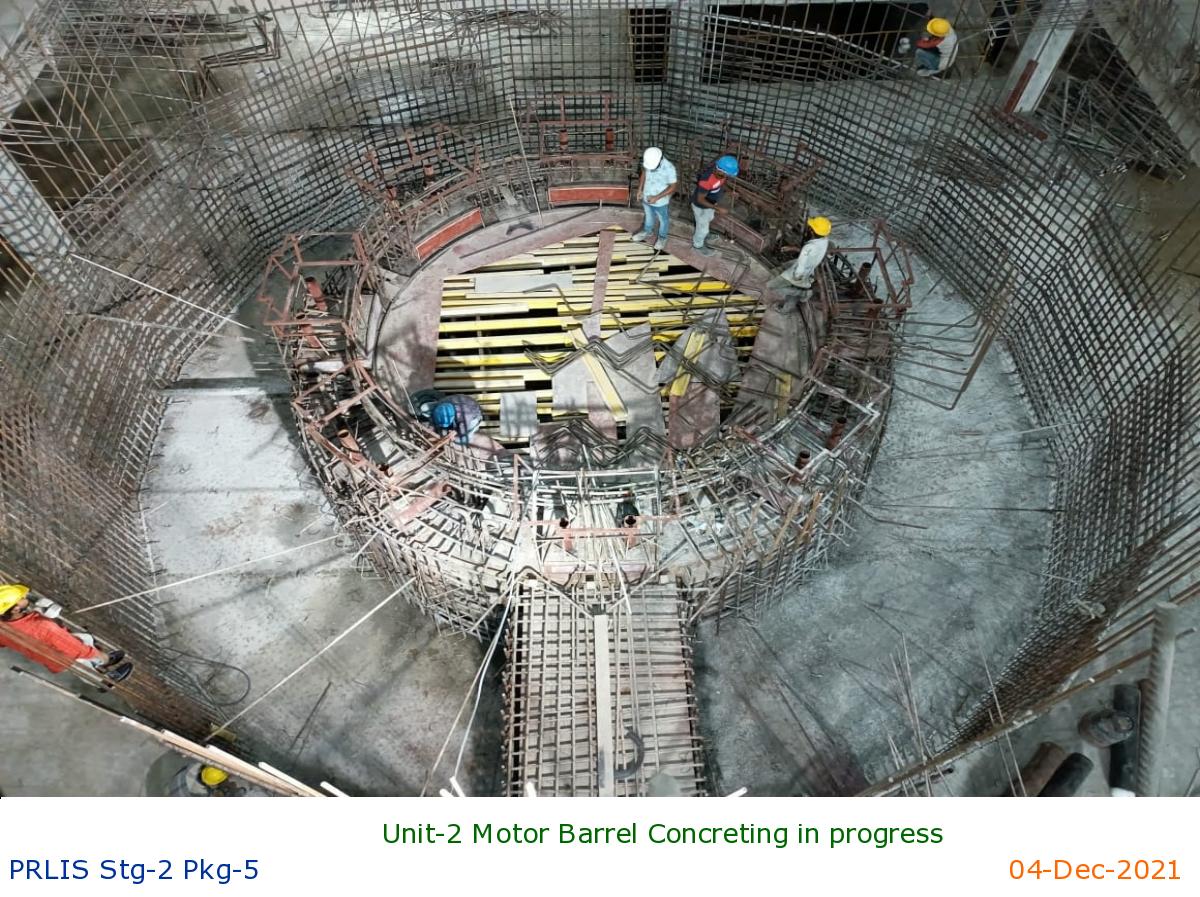

Unit-2 Motor Barrel Concreting in progress

|

Unit-1 Concreating of Motor Barrel in progress

|

U-1 Rotor Rim Building

|

U-1 Generator Barrel

|

U1 Generator Barrel

|

Unit-1 motor stator ready for erection

|

Unit-1 preparation for rotor rim building in progress

|

Unit-5 Full Welding of Stay ring joints in progress

|

Unit-4 concreting up to Pump center completed

|

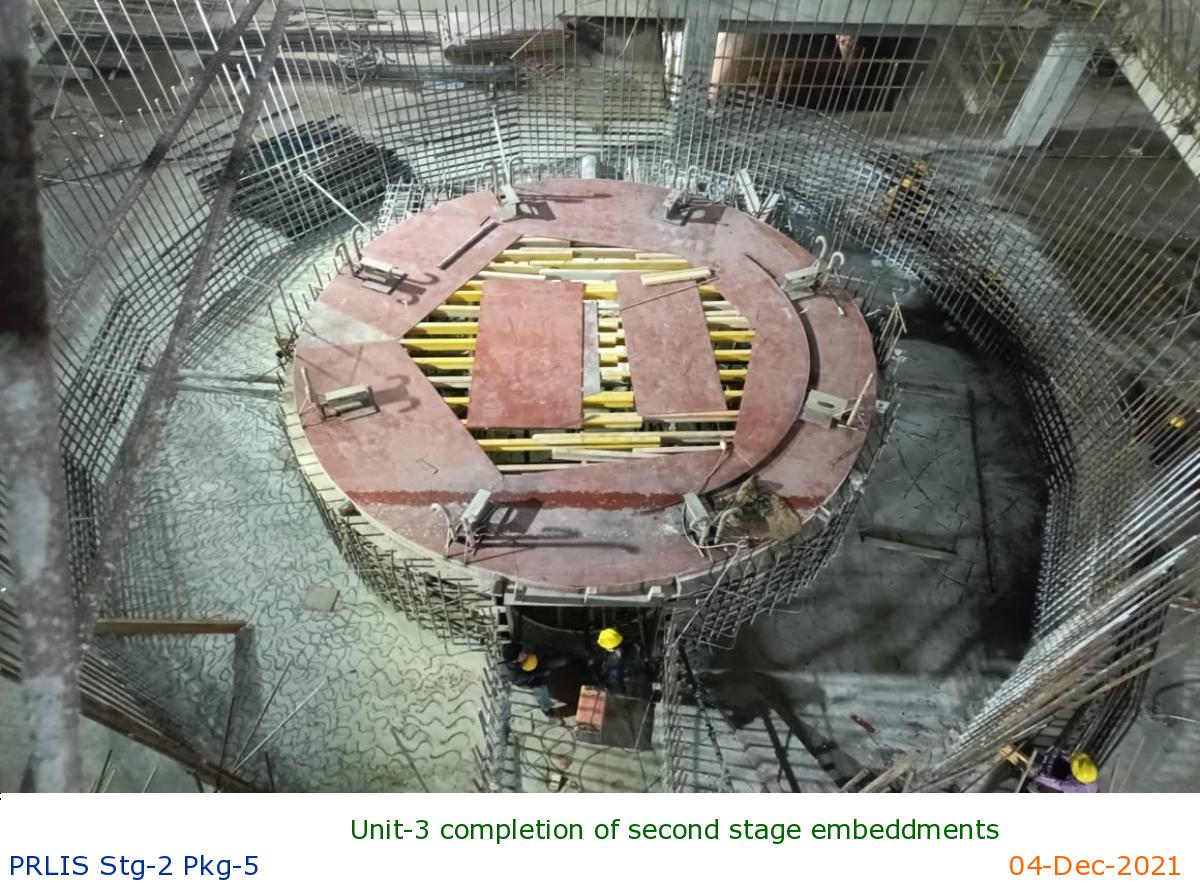

Unit-3 completion of second stage embeddments

|

Unit-2 Motor Barrel Concreting in progress

|

Unit-1 Motor Barrel Concreting in progress

|

Unit-6 to 10- 1st stage embedment erection in prog

|

Unit-5 stay ring leveling & centering in progress

|

Unit-4 pit liner and spiral casing

|

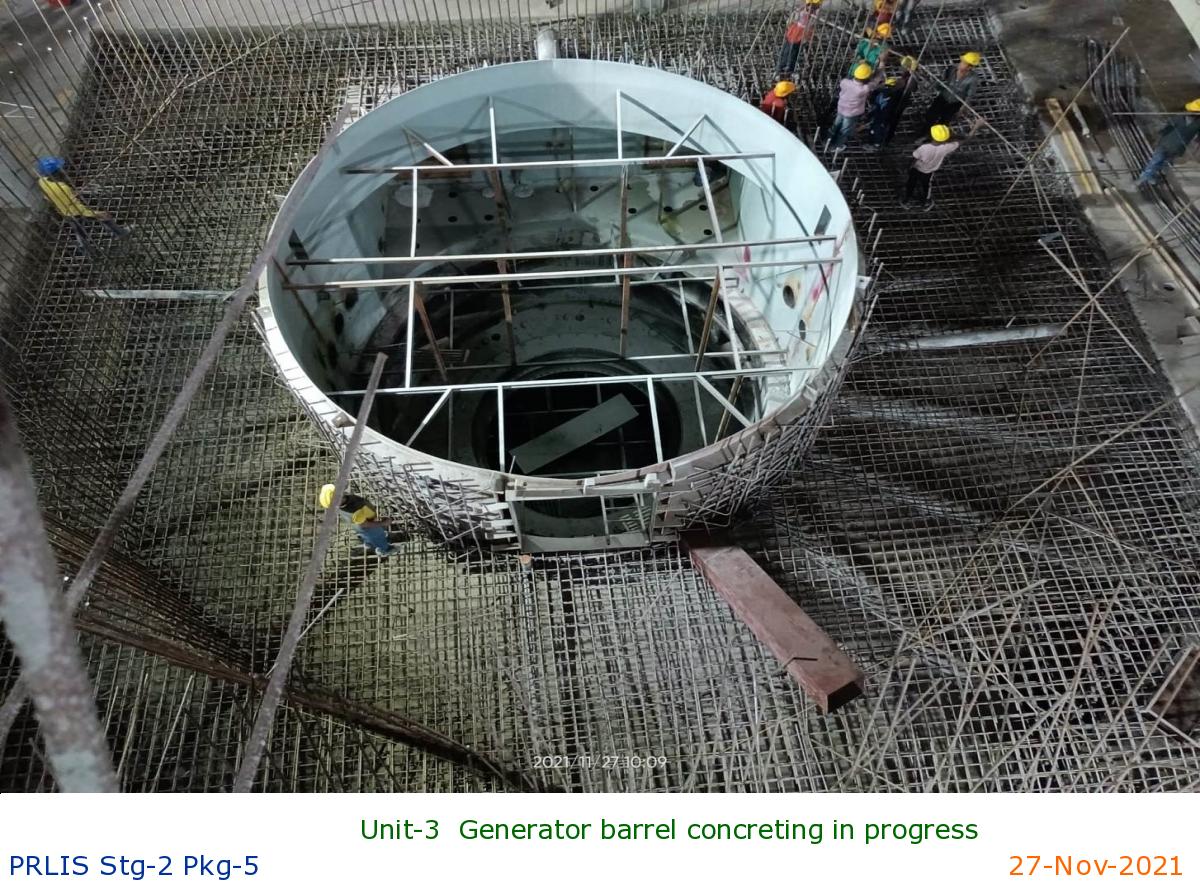

Unit-3 Generator barrel concreting in progress

|

Unit-2 Generator barrel concreting in progress

|

Unit- 6 to 10- Erection of 1st stage embedment in progress

|

Unit-1 Generator barrel concreting in progress

|